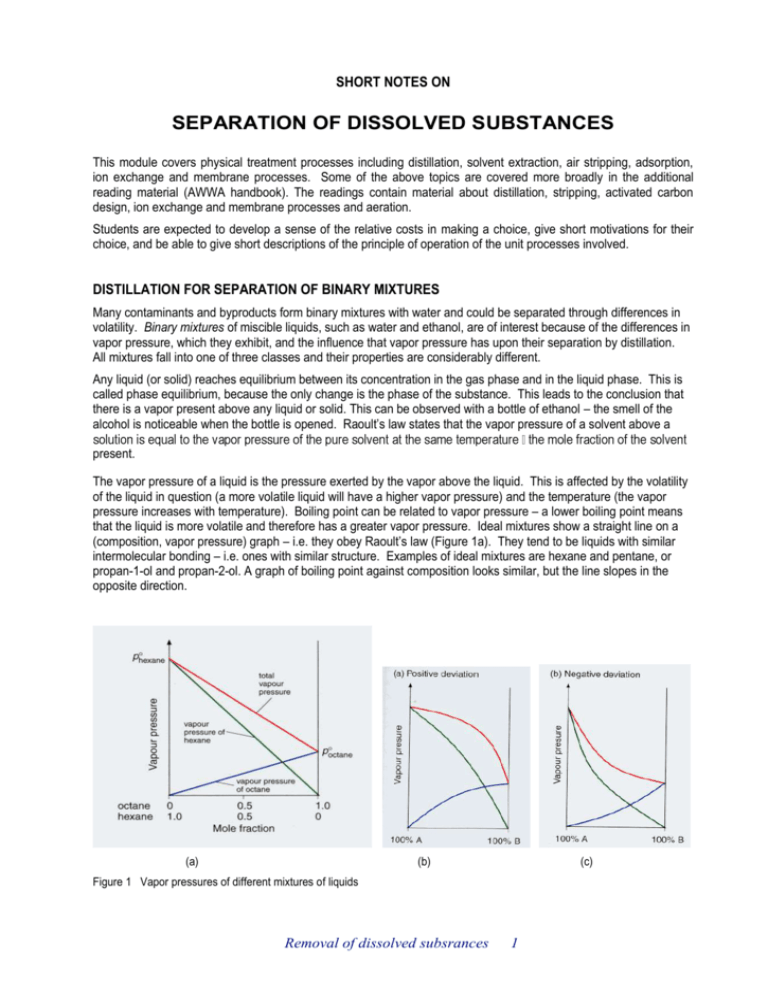

Separation of dissolved substances

advertisement