The Hazard Communication Standard (regulated by OSHA)

advertisement

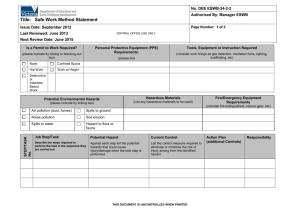

The Hazard Communication Standard (regulated by OSHA) The Hazard Communication Standard (29 CFR 1910-1200), also known as the “Right to Know Law,” provides to staff members the right to know about chemical hazards in their workplace. As part of this standard, new staff members from affected departments receive training immediately upon hire. Training includes information on: Staff members’rights under the standard; Physical and health hazards of the materials and methods of detection; Where to locate and how to read the Material Safety Data Sheet (MSDS) covering toxic or hazardous substances used, handled, or stored in their workplace; Applicable protective equipment, clothing for personal protection; and Labeling of substances that are hazardous. Affected departments include Administrative Staff, Facilities & Services, Faculty and research staff, and students. Each staff member is given a copy of the written Hazard Communication Program upon hire. All staff have the right to access any MSDS during their normal work shift. MSDS can also be obtained by from the Physical Plant Office, the Environmental Health & Safety Manager or by going on-line. Many manufacturers have complete listings of MSDSs available on their websites. WHAT DO I NEED TO KNOW ABOUT CHEMICALS? A chemical is considered hazardous if that chemical is likely to cause harm. There are two types of hazards associated with chemicals: Physical Hazards: the way a chemical interacts with other substances or the environment Examples: explosion, ignition (fire), reacting violently with other substances Health Hazards: the way that a chemical interacts with your body Examples: short-term (dizzy, headaches, nausea); long-term (cancer, damage to internal organs) Not all chemicals can be detected by odor. There are other ways to detect a release or presence of chemicals. Other ways to detect are by appearance, odor, or immediate effects. 1 of 7 WHAT WILL THE LABELS LOOK LIKE? Various manufacturers have different labeling systems. Many companies use the universal hazard symbols on the labels, as shown below. (Highly) Toxic Very hazardous to health when breathed, swallowed, or in contact with the skin and may even lead to death Avoid contact with the body and immediately consult a doctor if exposure occurs. (Highly) Flammable Spontaneously flammable substances, avoid contact with the air. Highly flammable gases, avoid formation of flammable gas-air mixtures and keep away from sources of ignition Substances sensitive to moisture, which become readily flammable on contact with water – avoid contact with moisture or water Flammable liquids with flash points below 21°C, keep away from open fires, sources of heat and sparks. Corrosive Tissue as well as equipment are destroyed on contact Do not breathe vapors and avoid contact with skin, eyes and clothing Explosive Substance may explode under definite conditions Avoid shock, friction, sparks and heat. Harmful to the Environment (do not dispose of these materials into the drain) Harmful (Xn) or Irritant (Xi) May also have an “Xn” or “i” written above the X Xn: When taken in by the body, can cause slight damage Avoid contact with the body, including inhalation of vapors. Xi: May have irritating effect on skin, eyes, and respiratory organs Do not breathe vapors and avoid contact with skins and eyes. Oxidizer Can ignite combustible material or worsen existing fires and thus make fire-fighting more difficult Keep away from combustible material Carcinogen (cancer hazard) Chronic exposure may lead to the development of cancer Do not breathe vapors and avoid contact with skin and eyes. WHAT OTHER HAZARD SYMBOLS MIGHT I ENCOUNTER? The symbols below may be found on doors in CAMP, Rowley, and the Science Center and are there to warn you of the potential hazards inside the room. Lasers (Class 3b and 4) Can cause harm to skin and eyes if not properly protected Consult with Faculty prior to entering the area. Biohazardous Material Materials may be blood, body fluids, or tissue from humans or human-like primate Avoid exposure to skin and mucous membranes (skin, eyes, nose, or mouth) Caution: Radiation Area Radiation device or with exposure at or exceeding 5 mR/hr (millirem per hour) Consult with Faculty or Radiation Safety Officer prior to entering. Caution: Radioactive Materials Room contains low-level radioactive materials. Must be locked and secured when not in use. All equipment will be posted with this symbol. 2 of 7 CLARKSON UNIVERSITY HAZARD SIGNS The sign to the right is posted on every laboratory door. Hazards present in the laboratory will be indicated on the door. Chemical hazards will be indicated in the “Health”, “Flammability”, and “Physical Hazard” section. Details on understanding the information on this sign can be found on page 7 of this guide. OTHER LABELING INFORMATION Some labels may have the following National Fire Protection Association (NFPA) labeling system present. Fire Hazard (Red) 0- Will not burn 1- Ignites after preheating 2- Ignites if moderately Heated 3- Can be ignited under almost all normal temperature conditions 4- Very flammable gases or very volatile flammable liquids Health Hazard (Blue) 0- No unusual hazard 1- Can cause irritation 2- May be harmful if inhaled or absorbed. 3- Corrosive or toxic. Avoid skin contact or inhalation. 4- Can cause death or major injury on short exposure. 4 (RED) 2 3 (BLUE) (YELLOW) W (WHITE) Reactivity (Yellow) 0- Normally stable. Not reactive with water. 1- Normally stable. Unstable at high temperatures and pressure. May react with water. 2- Normally unstable but will not detonate. 3- Can detonate or explode but requires strong initiating force or heating under confinement. 4- Readily detonates or explodes. Specific Hazard (White) POL- Polymerizes under normal conditions OXY- Oxidizing agent COR- Strong Corrosive W- Water Reactive EXP- Explosive-heat or shock sensitive 3 of 7 USER'S GUIDE TO MATERIAL SAFETY DATA SHEETS Material Safety Data Sheets (abbreviated MSDS) are prepared by manufacturers to summarize the health and safety information about their products. TO OBTAIN AN MSDS Search for MSDS documents on the chemical manufacturer website. Search the MSDS files in the Physical Plant. Call the Environmental Health & Safety (EH&S) Manager (x 6640). Call the manufacturer. COMPONENTS OF AN MSDS SECTION ONE: IDENTITY Trade name used on the label and inventory list Manufacturer's name, address, and emergency telephone number Preparation and revision dates SECTION TWO: HAZARDOUS INGREDIENTS Chemical and Common Names of all the hazardous components Exposure Limits ACGIH TLV: 8-hour time-weighted average OSHA PEL: 8-hour time-weighted average These are not necessarily proven safe levels of exposure. If the exposure limit is not listed, don't assume that a chemical is safe. Contact the EH&S Manager for further information. Percentage of the Mixture (optional). The percentages do not usually add up to 100% since only the hazardous ingredients have to be listed. SECTION THREE: PHYSICAL/CHEMICAL CHARACTERISTICS Vapor Pressure--a measure of a liquid's tendency to evaporate. Vapor Density--reflects whether a vapor or gas is lighter or heavier than air Appearance and Odor--These are warning properties that allow you to detect when you are being exposed to a material. SECTION FOUR: FIRE AND EXPLOSION HAZARD DATA Flash Point--the lowest temperature at which a liquid gives off enough vapors, which when mixed with air, can be easily ignited by a spark. The lower the flash point, the greater the risk of fire or explosion. Remember, it's the vapors that burn, not the liquid. SECTION FIVE: REACTIVITY DATA Reactivity, in this context, is the tendency for a material to chemically change or breakdown and to become more dangerous. Precautions include: Conditions to Avoid--such as light or heat Materials to Avoid--for example: sodium and water will react vigorously to generate hydrogen, creating a fire hazard. 4 of 7 SECTION SIX: HEALTH HAZARD DATA Routes of entry-- How a hazardous material can enter your body: Inhalation, Skin Absorption, and Ingestion. Short-Term Health Effects (ACUTE)-- symptoms which may be felt immediately after the first brief contact, like: burns, watery eyes, sore throat Long-Term Health Effects (CHRONIC)-- symptoms which may be felt after repeated contact with the same hazardous material over a long period of time. References that list a chemical as a carcinogen or potential carcinogen. Signs and Symptoms of Exposure Medical Conditions Generally Aggravated by Exposure Emergency and First-Aid Procedures If you need health hazard information that is not listed on the MSDS, contact the EH&S Manager (x 6640). SECTION SEVEN: PRECAUTIONS FOR SAFE HANDLING AND USE Spill and Leak Procedures—The EH&S Manager or Institute Safety Officer can advise you on specific procedures and provide protective equipment. The person or laboratory who creates a spill is responsible for assisting in the clean-up if he/she is not injured. Waste Disposal—Contact Phil Dennicort in the Chemical Stock Room (x 2338) or the EH&S Manager (x 6640) for further information. SECTION EIGHT: CONTROL MEASURES The EH&S Manager can answer specific questions regarding ventilation and personal protective equipment for normal working conditions and emergencies. Suitable control measures are based on how a material is used. 5 of 7 PROTECTIVE MEASURES There are many ways to protect yourself against exposure to hazardous materials. Below are some examples of ways to reduce your risk of exposure. For further information, contact the Environmental Health & Safety Manager. SUBSTITUTION Substitution is used when alternative materials are available. A less hazardous material should be substituted for the more hazardous material being used. Factors that should be taken into consideration include cost effectiveness of the substitute and potential hazards of the new substance. ENGINEERING CONTROLS Using other means to control or reduce exposure is another way to protect workers. The use of ventilation is one example of an engineering control. By installing additional ventilation, inhalation hazards can be reduced. Another engineering control would be the installation of a barrier, such as a glove box or screens. The use of a barrier places additional protection between the worker and the hazard. SAFE WORK PRACTICES The implementation of proper procedures and other policies can inform staff on what protective measures should be taken when handling the material. Staff who know and follow the procedures will reduce their risk of exposure. PERSONAL PROTECTIVE EQUIPMENT Clarkson University is responsible for selecting and providing appropriate personal protective equipment for their employees and for providing training. Personal Protective Equipment (PPE) are not equally effective for every hazardous material. Therefore, selection is to be based on the specific material to be handled. Your supervisor or the EH&S Office can provide information on the appropriate PPE used in your work area. Respirators: If worn improperly or under the wrong conditions, respirators can be more hazardous than protective. If you think there is a need for respirator use in your area, please contact the EH&S Manager prior to wearing the respirator. The EH&S Manager will determine whether engineering controls can be put into place or if a respirator is required. Staff must be medically cleared and fit-tested before wearing any respirator. Please contact the EH&S Manager at x 6640 with questions regarding respirator use at Clarkson University. 6 of 7 Hazard Door Sign Guide Health Definitions 4 Severe 3 Serious Death or major injury Extreme danger 2 Moderate Hazardous Slight Minimum Chronic Slightly hazardous No unusual hazard Effects may be seen after long-term exposure 1 0 * Flammability Definitions 4 Severe Burns readily 3 Serious Will ignite at most ambient conditions 2 Moderate Will ignite if moderately heated 1 Slight Will ignite if preheated 0 Minimum Will not Burn Physical Hazards 4 Severe 3 Serious Biohazard Contact Hazard Cryogenic Safety Glasses Gloves Goggles Lab Coat Physical Hazard Definitions May emit ionizing radiation May cause damage to health or environment Level 1 No harm to humans, minimal hazard potential Level 2 Moderate Slight Minimum Personal Protection Equipment (PPE) Physical Hazard Definitions Radioactive Materials 2 1 0 Human biological material or pathogens; Concern with direct contact; no inhalation hazard Dangerous when exposed to skin, eyes, mucous membranes Water Reactive W High energy light May cause eye injury or sun burn Ultraviolet Light Laser Material with severely low temperatures Asphyxiation, frostbite, pressure build up and explosion hazards Unusual reactivity with water Compressed gas under pressure Gas Cylinder Intense beam of light; hazard to eyes and skin Exempt Lasers Class 1 Class 2 Low Power Visible Lasers Class 3 Medium Power Lasers and Laser Systems Class 4 High Power Lasers and Laser Systems Explosive or extremely rapid release of gas and heat Can increase the rate of combustion or fire Oxidizer Explosive or reactive May form explosive mixtures or react with source Materials unstable and may undergo violent chemical change Normally stable, but can become unstable Normally stable; will not react Explosive 7 of 7