Biological Use Authorization - Environmental Health & Safety

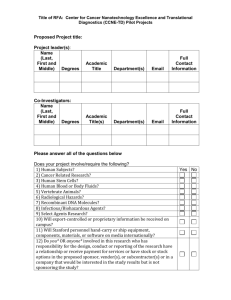

advertisement

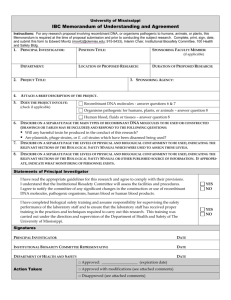

2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION SECTION 1. Principal Investigator and Laboratory Information This project involves: Application type: New BUA # Renew BUA # Terminate BUA # Recombinant DNA (Sec 3) Infectious Agents (Human, animal, or plant) (Sec 4) Major change amendment, BUA # Bloodborne pathogens, human & nonhuman primate materials (Sec 5) Storage only, BUA # Storage only (Sec 6) Principal investigator Dept Phone Date received: IBC Reviewer: BSL/RG: NIH Classification: Exempt under NIH Guidelines section: IIIF: IBC review dates App. C: First review: Action: Second review: Action: Third review: Action: Third review: Approval date: Action: Expiration date: Title Building E-mail address Room Phone Title: CoShared space investigator/Co-PI A “Shared space owner” is the director, manager, or owner of research space or special equipment not assigned to the Principal Investigator. A “coinvestigator” is a UA faculty or staff member with a significant collaborative role in the research. Use additional sheets if necessary. Department: Building: Room: Phone: Phone: E-mail address: Check here if you have listed additional shared space owners or co-investigators on a separate sheet Title: Lab contact if not PI Department: Building: Room: Phone: Phone: E-mail address: General conditions for Biological Use Authorization approval The Principal investigator agrees to the following (please check boxes on the left): Ensure that personnel listed in this application have received or will receive appropriate documented training in basic biosafety and if applicable bloodborne pathogens via the SkillSoft Academy before any work begins on this project and at least annually thereafter. Contact EHS to arrange training Ensure that personnel listed in this application have received or will receive appropriate documented training in safe laboratory practices and procedures for this protocol before any work begins on this project and at least annually thereafter Ensure that personnel listed in this application are aware of the PPE requirements for working with chemicals or biological materials and will enforce the PPE requirements in their area Follow the health surveillance practices as approved for this protocol and inform those working on the protocol about appropriate emergency assistance information for their location(s). Inform Biosafety Officer, Biosafety Manager and/or EHS of any research-related accident or illness as soon as possible after its occurrence. Comply with the UA Biosafety Manual, with UA and UA system-wide biosafety policy and procedure, with the NIH Guidelines for Research Involving Recombinant DNA Molecules, with Biosafety in Microbiological and Biomedical Laboratories, 5 th edition, and with all other applicable laws and regulations. 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION Submit in writing (via a BUA) a request for pre-approval from the Institutional Biological Committee for any significant deviations from the biohazard containment or personnel protection provisions of the approved BUA , or any modifications to the study or additions or deletions of personnel, facilities, recombinant or infectious agents, procedures or locations. By signing below, I certify that I have reviewed the above conditions and agree that all project personnel will abide by those requirements and adhere to all University of Alabama policies and procedures governing the use of recombinant DNA and infectious agents. Principal investigator: Date: Shared space or co-investigator (if applicable): Date: Department chair (required): IBC chair: Biological Safety Officer/Manager: Date: Date: Date: 2013-2014 Section 2: Project Title: THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION Facilities and Practices Project Abstract: In layman’s terms, please supply a brief description of your research that specifies the agents or recombinant constructs to be used, the animal or plant species (if applicable) to be used, and the types of potentially hazardous manipulations involved (aerosol generating, use of sharps, medical waste generation). Funding Agency: Award #: Start/End dates: Work and equipment locations (use additional sheets if necessary) Lab biosafety level Specific use Laboratory location (eform will need to allow additions) Housed vertebrate animals (eform will need to allow additions) Autoclave for non-medical waste Medical waste accumulation site or approved autoclave Storage: RT 4º -20º -80 º LN2 Biological Safety Cabinet: Yes No BSL 1 2 3 ABSL 1 2 3 ABSL 1 2 3 No Locked? Yes (if yes certification date Institutional approvals for this project (applicable to this BUA) IACUC (Vertebrate animals) IRB (Human Subjects) Agency permits* Building Room No. Shared space ) Protocol No. Protocol status (submitted, pending, approved) Approval date Exempt Permit type Permit No. Date issued Expiration date USDA-APHIS http://www.aphis.usda.gov/permits/ CDFA Other Other *Attach a copy of the permit (note in “List of Attachments” below) or mail a copy to Biosafety Office, EHS Disposal Practices (check applicable boxes) Terminal inactivation and waste disposal. Indicate your methods for terminal inactivation of the biological agent or transgenic material (microorganisms, animals, plants, plant transformation agents, tissues, etc). If generating multiple types of waste please clarify what waste is being disposed of in the text field after each checkbox (i.e. rDNA, infectious, transgenic material, etc.). If an autoclave will be used to inactivate waste (liquid or solid), the autoclave must be tested according to ADEM Admin. Code r. 335-13-7-08 as referenced in the UA Biosafety Manual. If you will be using a method that is not already described below, please use the “Other“ field at the bottom and clarify why you are using that method. Liquid Waste: 0.5% hypochlorite (final concentration of hypochlorite ion) with 30 minutes of contact time, then drain disposal. Autoclave liquids (121oC, 15 psi, 30 minutes), then drain dispose. Not generating liquid waste. Solid Waste: Autoclave (121oC, 15 psi, 30 minutes) in approved autoclave bags with an indicator (autoclave tape or steam indicator strip). Medical waste stream. In red medical waste bag contained within a leak-proof, lidded, and labeled secondary container. 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION Animal caging and bedding is: autoclaved treated with disinfectant: untreated, regular trash other: Not generating solid waste. Sharps: Medical waste sharps – red biohazard plastic sharps container. Sharps containers will be closed when full and transported to the medical waste accumulation site within 7 days of reaching the fill line. Non-medical waste sharps – in clearly labeled sharps containers. Sharps containers will be closed when full and transported to proper disposal by lab personnel. Not generating sharps waste. Animal carcasses and gross tissues: Incineration via medical waste program. Not generating carcass or tissue waste. Other terminal inactivation or waste disposal method not already described will be discussed below: Transport Practices (check applicable boxes) Transport and shipping. Indicate any transport of biohazardous materials (human, animal, and plant pathogens), transgenic materials (cell lines, microbes, plants, etc), and other materials, including origin and destination laboratories or other facilities, frequency of transport, and measures you will employ to prevent accidental release of biohazardous materials. When transporting materials within (or between) facilities, we will use secondary containers that are sturdy, leak-proof, lidded, labeled appropriately (with a biohazard symbol if material is handled at BSL2 or above), with enough absorbent material to absorb any spill. We ship/transport materials daily, weekly, monthly, annually, or . When shipping materials we will comply with relevant campus, IATA (Dangerous Goods Regulations), DOT, and other pertinent Federal regulations regarding packaging, labeling, shipper training, etc. Attach a copy of shipping certifications or please initial if shipping will be provided by EHS: No Shipping No transport between buildings or rooms For other transport or shipping conditions, please describe: Risk Minimization (check applicable boxes) Biohazard containment and risk reduction. Identify measures you will employ to contain biohazardous materials and transgenic animals in such a way as to prevent researcher, community, or environmental exposure to biohazardous agents, recombinant DNA, and contaminated material. Access to the laboratory (or facility) will be restricted while work is in progress. We will provide general laboratory (or facility) safety training to personnel. Sharps Safety: Not Applicable (not using sharps) Please indicate which manipulations will involve sharps. Please indicate what would happen immunologically in the event of auto-inoculation (with the agent or genes of interest). We will train personnel in the safe handling of sharps. Please describe all sharps safety practices in use: Centrifugation Safety: Not Applicable (not using a centrifuge) Please indicate what biohazardous materials will be centrifuged: We will train personnel in the safe use of centrifuges. We are going to use: centrifuge tubes with O-rings sealed buckets. We are going to load and unload our buckets or centrifuge rotor in the BSC. We are going to disinfect tubes coming out of the BSC and only open those tubes in the BSC after centrifugation. For other centrifugation safety practices, please describe: 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION Safety practices to minimize generating aerosols when working with biohazardous materials which present a human hazard: Not Applicable (not performing any activity that might generate aerosols, other than centrifugation) We will pipette materials and will train personnel in the proper pipetting techniques. Please indicate other procedures that involve the potential generation of aerosols. Please indicate how you will contain aerosols (e.g. use of a biological safety cabinet). Safety practices pertaining to animal work: Not Applicable (not working with animals) We will train personnel in the safe handling of animals. We will use cages that prevent animal escape while in their housing or during transport. Identify transgenic animals (vertebrate or invertebrate): Rodent caging: filter-tops on cages individually ventilated caging wire top caging other: Infected animals will be housed in cages labeled with the universal biohazard symbol. For other animal-related safety practices, please describe: Safety practices pertaining to plant work: Not Applicable (not working with plants) We will train personnel in the appropriate handling and disposal of transgenic plants and infectious plant materials. We will ensure that plants are labeled with PI name and identifiable as transgenic or infectious to all staff. We employ a recordkeeping system for tracking transgenic plants from creation until terminal inactivation. We will transport plant materials in a manner that will prevent unintentional release or establishment in the environment. We will train all workers handling or providing care to materials regulated under permits on applicable permit conditions. For other plant-related safety practices, please describe: Personal Protective Equipment (PPE): Please list the appropriate PPE required for each type of work (check “No” if not working with the material). Examples of PPE: lab coat, gown, scrubs, gloves, goggles, face shield, surgical mask, respirator, hair net, shoe covers. (UA minimum PPE requirement is glasses, gloves, and lab coat anywhere chemical or biological materials are used or stored unless otherwise justified by risk assessment and approved by the Biosafety Officer/Manager.) Recombinant DNA Yes No Animals Yes No Infectious Agents Yes No Bloodborne Pathogens Yes No Plants Yes No Biological Safety Cabinet work not already addressed above: Please indicate which other procedures will be performed in a BSC (e.g. tissue culture work, necropsy of animals with infectious agents). Other risk minimization safety practices not already addressed above: Health protection, health surveillance and post-exposure treatment programs to be used in this project If needed, consult medical professionals BEFORE completing the Biological Use Authorization application. All surveillance, vaccination, post-exposure treatment, and PPE clearance and fit-testing services are to be provided at no cost to the employee. 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION Please provide a declaration/description of what you consider to be the element of this research project that constitutes the greatest biohazard: Check all that apply: Health surveillance is not planned for this project Bloodborne pathogens: HBV vaccination (or declination) on file with EHS, post-exposure follow-up and treatment, vaccination record retention by Principal investigator, initial BBP training and annual retraining, and universal precautions, BBP exposure control plan attached HIV post-exposure prophylaxis: Post-exposure treatment with anti-retroviral drugs within two hours, with medical follow-up Orthopoxviruses (vaccinia and others): Medical screening, vaccination and contraindication awareness, and training Prion research: Training and special procedures for exposure reporting, decontamination and records handling Cercopithecine herpesvirus-1 (Herpesvirus simiae, Herpes B): Initial training and post potential exposure follow-up and treatment Health history form: Consult with EHS Respirator clearance and fit-testing: Clearance from medical personnel and fit-testing at EHS Custom health surveillance/immunization program will be adopted: Please describe the plan in the appropriate headings of Section 2C, 2D, or 3. Be sure to obtain medical approval before submitting the plan to the IBC Other: List of attachments to this application References on vector design (for vectors from non-commercial sources) Vector genetic map (for vectors from non-commercial sources) Facility floor plan Agency permits (e.g. USDA/APHIS, CDFA) Bloodborne Pathogen Exposure Control Plan Other documents: 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION Section 3: RECOMBINANT or SYNTHETIC DNA In the context of the NIH Guidelines, recombinant and synthetic nucleic acids are defined as: (i) molecules that a) are constructed by joining nucleic acid molecules and b) that can replicate in a living cell, i.e., recombinant nucleic acids; (ii) nucleic acid molecules that are chemically or by other means synthesized or amplified, including those that are chemically or otherwise modified but can base pair with naturally occurring nucleic acid molecules, i.e., synthetic nucleic acids, or (iii) molecules that result from the replication of those described in (i) or (ii) above. If your project involves recombinant or synthetic DNA molecules, transgenic animals, transgenic plants, check all that apply: NA This project does not involve work with recombinant DNA. Deliberate transfer of drug resistance into microorganisms (III-A-1) Cloning of toxic molecules, LD50<100ng/kg (III-B-1) Experiments that have been previously approved by NIH/OBA as Major Actions under the Guidelines (letter from NIH/OBA Director or RAC should be attached) Experiments Involving the Deliberate Transfer of Recombinant or Synthetic Nucleic Acid Molecules, or DNA or RNA Derived from Recombinant or Synthetic Nucleic Acid Molecules, into One or More Human Research Participants (III-C-1) Experiments with pathogenic agents (Risk Groups 2, 3, 4 or restricted agents) as host vector systems (III-D-1) Cloning DNA from pathogenic agents (Risk Groups 2, 3, 4 or restricted agents) into nonpathogenic prokaryotic or lower eukaryotic host-vector systems (IIID-2) Use of infectious DNA or RNA virus or defective DNA or RNA virus in the presence of a helper virus in tissue culture systems (III-D-3) Experiments involving recombinant DNA and whole animals (vertebrate or invertebrate), including breeding and colony maintenance of transgenic strains. (III-D-4) Experiments involving recombinant DNA in whole plants, including genetically engineering the plants, using such plants for other experimental purposes (e.g., response to stress), the propagation of such plants, using plants together with microorganisms or insects containing recombinant or synthetic nucleic acid molecules (III-D-5) Large-scale (>10L culture) experiment or production of recombinant host or vector (III-D-6) Experiments with influenza viruses (III-D-7) Experiments involving recombinant or synthetic DNA not included in previous sections and generally carried out at BSL-1 containment per NIH Guidelines (III-E). Experiments involving the formation of recombinant or synthetic nucleic acid molecules containing no more than two-thirds of the genome of any eukaryotic virus (III-E-1) Experiments involving whole plants if those experiments involving nucleic acid molecule-modified whole plants, and/or experiments involving recombinant or synthetic nucleic acid molecule-modified organisms associated with whole plants do not fall into a previously identified category. (III-E2) Experiments involving transgenic rodents (III-E-3) Recombinant or synthetic DNA work that is exempt from the Guidelines per III-F or Appendix C. Please give the justification for exemption: The Principal Investigator has taken the training on the “NIH Guidelines for Research Involving Recombinant DNA Molecules” The Co-Investigator has taken the training on the “NIH Guidelines for Research Involving Recombinant DNA Molecules” 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION Section 3A. Recombinant experiment components TABLE 1. Host, vector and gene information. Please provide specific names including strain designations. We will add the information you provide here to the Biological Use Authorization database so please double-check for completeness and spelling. Use additional sheets in the same format if necessary. A host is a recipient for recombinant DNA constructs; any organism that incorporates or replicates a recombinant/synthetic DNA molecule. A vector is the agent which transfers DNA to the recombinant host, the accessory DNA molecules that accomplish the transfection/incorporation/replication. Component Appropriate BSL 1 Name 2 Hosts Vectors Genes and related genetic material to be cloned DNA/RNA organismal source (scientific names) Check here if you have listed additional components on a separate sheet Section 3A, continued. Further information on recombinant components. Check the boxes as appropriate and complete only the indicated Section(s) Host (check all that apply for all hosts listed above in Table 1, and complete the listed Sections) E. coli K-12 (or its derivatives), Saccharomyces cerevisiae, S. uvarum, Bacillus subtilis or B. licheniformis Risk Group 2 or 3 microbial agent (Complete Sections 3D, 3E and 4 if applicable) Plant pathogen (Complete Section 4; include information on genetic modifications to pathogen) All other microbial agents (excluding Agrobacterium used as a plant transformation agent) (Complete Section 3D) Cultured eukaryotic cells (other than plants): Primary Cell line (Complete Sections 3D and 3E if viral vectors are to be used) Plants, plant cells, or plant parts (Compete Section 3C) 3 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION Domestic mouse (Mus musculus or M. domesticus, including first captive generation “wild type” (e.g., M. spretus) (Complete Section 3B for pronuclear injection-generated transgenics appropriately housed at ABSL-1; otherwise complete section 3D) All other animals (vertebrate and invertebrate) (Complete Section 3D) Vector (check all that apply for all vectors listed above in Table 1 and complete the listed sections) Molecular construct (e.g., plasmid) or non-biological delivery system (e.g., nanoparticles, biolistic gene delivery) (Complete the most appropriate Section; if unsure, please check with the Biosafety Officer/Manager) Risk Group 3 agent (Please contact the Biosafety Officer/Manager before submitting this application; this work may not be allowed at UA) (Complete Sections 3D, 3E, and 4) Plant transformation agent is Agrobacterium or other viable plant transformation agent (Complete Section 3C) RNA interference system in animals or animal cells (Complete Section 3D) (and 3E if viral vectors are to be used) Viral vectors in animal host(s) Section 3D, 3E) (includes whole animals and cells) Replication-competent (please list) Readily transmissible Viral vectors in plant host(s) (please list) (Section 3C) Recombinant constructs that contain more than two-thirds of a viral genome (Please list: (Plant viral vectors complete section 3C with description of viral vector system) Replication-defective (please list) Not transmissible (please list) ) (Complete Sections 3D and 3E) Recombinant constructs that contain two-thirds or less of a viral genome (Please list: viral vectors complete section 3C with description of viral vector system) ) (Complete Sections 3D and 3E) (Plant Recombinant constructs that contain less than one-half of a viral genome (Please list: viral vectors complete section 3C with description of viral vector system) ) (Complete Sections 3D and 3E) (Plant Genetic material (check all that apply for all genes and related genetic material listed above in Table 1) Not believed to have biohazardous potential (human, animal, plant, or environmental) (Complete the most appropriate Section; if unsure, please check with the Biosafety Officer/Manager) Encodes directly or encodes a unique component of a pathway that produces: A known, suspected, or potential oncogene (e.g., transcription factor) (Complete Section 3D) – Specify the oncogene(s): A virulence factor or any other gene or gene component capable of conferring or enhancing microbial pathogenicity (Complete Section 3D) – Specify the gene(s): Includes more than two-thirds of the single strand genome of a Risk Group 2 agent (Complete Section 3D) From a Risk Group 3 or 4 agent, Select Agent, or an animal or plant pathogen normally handled at BSL 3 (Complete Section 3D, but please discuss this project with the Biosafety Officer before submitting application; this work may not be allowed at UA) 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION Section 3B. Transgenic mouse development and production (BSL1/ABSL1). ____ Not applicable. (Indicate with an “x” if section is not applicable). If your project involves transgenic laboratory mouse development (by pronuclear injection and implantation) with downstream phenotype evaluation, novel crosses involving transgenic parents in unrelated lines, or congenic production with at least one transgenic parent with no additional biohazardous component, please respond to the following three questions to complete your application. Insert the requested information in the box beneath each question (the box will expand automatically as necessary). Please define all technical acronyms at the first use (universally understood acronyms (e.g. “DNA”) do not require definition) If the transgenic construct is likely to require containment above Biosafety Level 1 (e.g., significant viral genome or known or potential oncogenes) or involves animal species other than the laboratory mouse, skip this section and complete Section 3D. 1. Research project summary. Describe your project objectives and experimental design and describe the known or hypothesized function of the gene(s) of interest. Describe your goals in working with transgenic lines, developing targeted gene knockouts, or breeding to produce congenic lines. Specify the mouse strain(s) to be used for transgenic production, crosses, or congenic development. Identify the facility that will produce the initial transgenic construct if applicable (e.g., Murine Targeted Genomics Laboratory or other similar facility or collaborator, or your own laboratory). 2. Risk assessment. Describe the potential consequences of introducing your transgenic mouse genome into wild populations of house mice and related species (e.g., Mus spretus) potentially already established at UA, or inadvertently into established laboratory mouse colonies. Identify lethal combinations (if known) that can result from your breeding plan. Cite existing data or published references to support your assessment. Section 3C. Recombinant plant development and characterization. ____ Not applicable. (Indicate with an “x” if section is not applicable). If your project involves recombinant plant development or downstream phenotype evaluation, please respond to the following questions to complete your application. Insert the requested information in the box beneath each question (the box will expand automatically as necessary). Please define all technical acronyms at the first use (universally understood acronyms such as “DNA” do not require definition) If exotic plant pests, noxious weeds, infectious viral plant transformation strategies, RNAi constructs, or other hazardous gene constructs that require elevated containment and practices (BSL2-P or higher) will be used complete question 6 describing nature of elevated risk and specific practices to address the hazard. 1. Research project summary. Describe your project objectives and experimental design; specify method of plant transformation. Specify if your work involves gene discovery and how the genetic material will be obtained. Specify whether seed or progeny from transgenic plants will be produced or evaluated. Specify the types of facilities where transgenic plants will be produced, maintained and tested (greenhouse, laboratory, growth chamber, field planting). Provide an overview of how all the components will be used (i.e. what gene will be inserted into which vector to be propagated in which host) 2. Sources of components. Specify the sources of all hosts, vectors, and DNA species named in Table 1 (above, section 3A). Include commercial sources or names and addresses of collaborators supplying biohazardous materials or recombinant components, and transgenic plant production facilities as appropriate. Include any pertinent information on required federal or state permits. 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION 3. Vector and gene information. Describe any plasmid vectors used and composition of the inserted DNA construct, including genes of interest, promoters or other control elements. If expression of a known protein is an objective of your work, describe the function of the protein, how it will be expressed in the plant or plant cells. Specify whether gene inserts or expression products could increase the known hazards of the biological transformation agent or plasmid vectors used. 4. Risk assessment. Describe the potential for release of your recombinant plant material into the local campus environment or into agricultural or wild plant populations and any adverse effect that would result. In your response, please consider the following properties of the untransformed plant host and resulting recombinant plant material: mode of reproduction, mode of pollen dissemination, potential for release of pollen or seed in work area, allergenic or irritant properties of plant exudates and pollen (i.e.. hazard to workers), invasive or weedy tendencies of the plant and the genetically modified traits being evaluated. Cite existing data or published references to support your assessment. 5. Special risks and containment measures for quarantined materials, exotic plant pests, readily transmissible viral vectors and potentially hazardous gene constructs. If exotic plant pests, noxious weeds, infectious viral plant transformation strategies, RNAi constructs, or other hazardous gene constructs that require elevated containment and practices (BSL2-P or higher) will be used, describe the nature of the increased risk introduced by the specified experimental materials and the corresponding measures that will be employed to contain materials and reduce risk of release to the environment. Write “N/A” if this question is not applicable. 6. Field trials and environmental release. Briefly describe the nature of the field trials explaining the need for environmental release or field study and citing applicable permit conditions for containment and disposal. Attach existing permits to this BUA application for review and notify the Biological Safety Office of new permit applications or amendments. Write “N/A” if this question is not applicable. Section 3D. All other projects that involve the production or use of recombinant constructs. ____ Not applicable. (Indicate with an “x” if section is not applicable). Please respond to the following questions regarding your proposed research. Insert the requested information in the box beneath each question (the box will expand automatically as necessary). This information will allow IBC members to evaluate the project and formulate a risk assessment. Important: The information you provide in this section should address procedures to generate and the biohazards resulting from the recombinant construct. Please define all technical acronyms at the first use (universally understood acronyms (e.g. “DNA”) do not require definition) Please double-check thoroughness and clarity—the Biosafety Office will not submit a BUA application to the IBC for review until such errors are corrected 1. Research project summary. Specify your project objectives and experimental design. Briefly discuss the involvement of the genes of interest in the project objectives. Specify if your work involves gene discovery. Justify in detail any large-scale work (>10L culture). Specify any agency permits (e.g., USDA) that have been issued to cover your work. Provide an overview of how all the components will be used (i.e. what gene will be inserted into which vector to be propagated in which host). 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION 2. Sources of components. Specify the sources of all hosts, vectors, and DNA species named in Table 1 (above, Section 3A). Include commercial sources, names and addresses of collaborators supplying biohazardous materials or recombinant components, and transgenic animal production facilities as appropriate. Include any pertinent information on required federal or state permits. 3. Inserted sequence and gene information. Specify the nature and functions of the genetic material being inserted into the host (DNA or RNA, promoter, gene, locus, etc.) If expression of a foreign protein in a host is an objective of this research discuss the protein and identify any anticipated phenotypic changes to the host. 4. Vector information (For work with viral vectors disregard this question and complete Section 3E). Provide technical information regarding the transformed and untransformed vector, including composition and size of insert, nature and specificity of promoters and other elements, types of species targeted (E. coli, mammalian, etc), and types of tissues targeted. If your vector did not originate from a commercial source, cite the original reference for its development and include a genetic map of the vector that identifies all relevant elements. If possible, provide an electronic copy of the reference. 5. Transformation methods. Describe your methods for transforming the vector and host. A detailed step-by-step protocol is not necessary, but please provide sufficient information on your procedures so that the committee can identify the steps that involve the greatest likelihood of worker or environmental exposure to biohazardous materials. Indicate the steps that will be conducted in a biological safety cabinet (including reagent and construct preparation). 6. Risk assessment. List the known or suspected biohazards of your research materials, including hazards of your gene(s) of interest, vector, and transformed host to healthy adult or immunocompromised people, or to pregnant women and to other animal species and to plants (where applicable). Describe any significant potential environmental impacts if the host escapes containment and becomes established in agricultural or natural ecosystems, whether by hybridization or by direct colonization. Section 3E. Additional information on viral vectors. ____ Not applicable. (Indicate with an “x” if section is not applicable). If your research involves the use of viral vectors, please respond to the following questions in addition to the questions in the preceding Section (3D). Note that you are not required to complete Section 4 of this application unless you are also working with infectious agents other than genetically modified viral vectors 1. Viral vector identification and source. Identify the viral vectors to be used in your research. Specify the types of vector (as checked off in Section 3A) and the strains or other identifying designations. 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION 2. Viral genes remaining in vector. Specify the native viral genes that are known to remain in the vector. 3. Replication competence status. Specify whether the vector is replication competent or defective, and specify the viral generation. If the vector is replication competent or is replication defective and used in conjunction with a helper virus, please justify its use in your experiments. If the vector is a replication defective construct from a non-commercial source, describe your methods and protocol for verifying replication incompetence at receipt and periodically thereafter. Discuss helper virus, packaging cell systems and gene complementation systems (that would yield an infectious virus) involved with your experiments. 4. Specify the viral envelope and identify the species and cell types known to be targeted by this vector. 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION Section 4: INFECTIOUS AGENTS AND TOXINS (Viral vector used in recombinant experiments requires completion of Sections 3C (plants) or 3D and 3E (other viral vector systems), but does not require completion of this section) I am working with Human Risk Group-2 or -3 infectious, pathogenic, or toxin-producing agents, other than viral vectors Yes No I am working with Human Risk Group 1 biological agents that are infectious or pathogenic to animals Yes No I am working with Human Risk Group 1 biological agents that are infectious or pathogenic to plants This work involves biological toxins including those that are on the Select Agent list but are not Tier 1 agents. List Yes No agents: If you checked Yes to any of the above, please complete the rest of Section 4. Yes No Table 2. Infectious agents and/or arthropod vector information. Please provide scientific or technical names, including strain names. Be sure to include the intended host for your infectious agent, if applicable, and check all applicable boxes for each agent. Use additional sheets as necessary. The information provided here will be entered into the BUA database. Agent / Host / Agent / Host Agent / Host Agent / Host Agent / Host / / / / Appropriate BSL 1 1 1 1 1 2 2 2 2 2 BBP1 Lab Safety Other2 3 3 3 3 3 Arthropod vector Arthropod vector 1 Bloodborne Pathogen: Human Immunodeficiency Virus (HIV), Hepatitis B and C viruses (HBV, HCV), other human pathogens that could be present in human blood, tissues, cell lines, and body fluids and could be transmitted by percutaneous exposure 2 Contact EHS to schedule other training Check here if additional agents are listed on a separate sheet Please respond to the following questions regarding your proposed research. Insert the requested information in the box beneath each question (the box will expand automatically as necessary) This information will allow IBC members to evaluate the research project and formulate a risk assessment. Important: Do not enter “N/A” in any text box (except Question 4, if it is not applicable)—all requested information must be provided. Please define all technical acronyms at the first use (universally understood acronyms (e.g. “DNA”) do not require definition) If the project involves genetic modification of any of the listed pathogens, describe the details of the recombinant DNA work in section 3C (plants) or section 3D (animal or human pathogens). If you are considering the use of any Select Agents or Toxins contact the BSO prior to submitting this application, as this work may not be allowed at UA. Name of Select Agent under consideration: 1. Research project summary. Describe your project objectives and experimental design. 2. Sources of agents. Specify the sources of the individual biohazardous materials obtained from natural sources, from commercial vendors (include vendor names), or from collaborators (names and addresses). Include any pertinent information on required federal or state permits. 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION 3. Technical information regarding infectious agents. Provide technical information regarding the infectious agent strain(s), including any genetic modifications, genetic recombination or drug resistance. For antibiotic drug resistant strains provide strain name, resistance factor, and source. If drug resistance traits that are being added to infectious agents are also known to be acquired naturally, reference at least one supporting publication. If your genetically altered strains did not originate from a commercial source, cite the original references for their development or specify “developed in this laboratory” as appropriate (or specify “wild-type”). Specify if you are using clinical isolates of human or animal pathogens or receiving environmental samples for isolation or identification of pathogens. For plant pathogens, specify the plant hosts, symptoms of host infection, mode of pathogen transmission (water, soil, insect or other), potential insect vectors 4. Arthropod vector and insectary information. Provide technical information regarding the host-vector-agent system you will be using, including the natural history of agent-vector infection and vector-host infection. Discuss vector-host specificity and other natural limits on disease transmission (physical, geographic, and biological). Be sure to state the natural geographic distribution of the vector and natural hosts, and note any agency permits that you have been issued or are pending. Discuss in detail your insectary facilities (provide a floor plan) and arthropod colony husbandry program, with special attention to your containment provisions. 5. Risk assessment. Specify the known and suspected biohazards of your infectious agents, including hazards to healthy adults, pregnant women or immunocompromised individuals, and to other species. If applicable, specify the symptoms of significant exposure or infection in humans. Include a one- or two-sentence review of laboratory acquired infections involving the agents you plan to use (statistics and outcome trends across all laboratories). If you are using an exotic arthropod vector system or any plant pathogen, discuss the possible consequences of a release into local agricultural areas or natural ecosystems. 6. Experimental procedures. Specify the experimental procedures including isolation and culture methods and conditions that involve biohazardous materials that you will use to accomplish your objectives. A detailed step-by-step protocol is not necessary, but please provide sufficient information on your procedures so that the committee can identify the steps that involve the greatest likelihood of worker, community, or environmental exposure to biohazardous materials. Indicate the procedure steps that will be conducted in a biological safety cabinet. Specify which procedures will happen in growth chambers, greenhouses or field plots, if applicable. 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION Section 5. Bloodborne Pathogens including human and non-human primate cell lines, blood, and tissues. Yes Yes No No I am working with human source materials I am working with non-human primate source materials For projects that involve the use of human and non-human primate (NHP) source materials such as unfixed human and NHP tissues, primary cell cultures, established cell lines, blood, blood products, body fluids, or other potentially infectious materials, the Principal Investigator completes this section of the BUA application in addition to any other relevant section. Under the UA Bloodborne Pathogen (BBP) policies, the Principal Investigator is obligated to offer the hepatitis B vaccination series at no cost to all personnel who work with or are otherwise exposed to human materials potentially containing bloodborne pathogens. PIs should contact EHS to arrange training and to coordinate the vaccination series/declination documentation. Although vaccination against hepatitis B is strongly recommended as a very effective health protection measure for individuals whose job duties involve exposure to human source materials, an individual may choose to decline hepatitis B vaccination. Each department is responsible for maintaining records of who is currently subject to the requirements of the BBP Standard, as well as who has received vaccinations or signed declinations. This information should be reviewed and updated with EHS each October. Non-human primate materials: Projects that involve the use of unfixed non-human primate tissues, primary cell cultures, cell lines, blood, blood products, or body fluids must also handle these materials as though they are infectious (BSL2 standards, equipment, and practices are appropriate for most projects) and must manage the disposal of waste through the medical waste program. Offer of hepatitis B vaccination is not required for projects that involve only non-human primate materials. UA requires that the Principal Investigator review and update the Bloodborne Pathogen Exposure Control Plan annually, and that laboratory personnel be retrained annually in bloodborne pathogen exposure control as well as basic lab safety and biosafety. The Principal Investigator must submit the Bloodborne Pathogen Exposure Control Plan with the BUA application, and must be able to provide the current editions of the plans to EHS personnel during laboratory audits. Table 3. Please specify the the human or non-human primate cell lines, primary cell cultures, blood, blood products, blood borne pathogens (e.g., HIV, HBV, HCV), body fluids, and tissues that you use in your research. Use additional sheets if necessary. Materials listed below which are sources for genetic material or hosts for recombinant should also be listed in Section 3A, Table 1. Check here if you have listed additional components on a separate sheet BBP Research project. Describe the experimental procedures (including procedures conducted in a BSC, if any). Indicate the source of the materials (i.e. from study participants, commercial vendors, or from collaborators). 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION Section 6. Storage only. Yes No I have materials that are only being stored and not used or propagated When a project covered under an approved BUA is completed and you have no plans to continue that investigative path you should transfer or destroy and dispose the biohazardous components or products of the work. To transfer biohazardous materials to another user, submit a BUA Amendment form that identifies your transfer destinations and transport methods. Biohazardous materials may only be transferred to on-campus users who have current Biological Use Authorizations that allow the possession of the specific biohazardous materials. They may not be transferred to a co-investigator or an “authorized user” on your BUA without prior IBC approval. Biohazardous materials may be transferred to non-UA locations but you must first obtain a letter from the director of the receiving facility and this may require a Material Transfer Agreement. Contact the Office of Technology Transfer and submit a transfer plan to the IBC. The IBC will review your transfer plan and you may initiate the transfer upon notification of Committee approval. If you choose instead to inactivate and dispose your biohazardous materials, use the BUA amendment form to notify the Committee. If you wish to store viable or usable stocks of biohazardous materials from completed experiments in your own laboratory and you do not anticipate using them for planned work, file an amendment to your existing BUA and indicate “storage only.” Attach a list of all biohazardous materials (including any laboratory identification codes) in storage that were previously approved in your BUA, and indicate the storage conditions and the locations of the stored materials (e.g., freezer shelf number and location on the shelf). To prepare biohazardous materials for storage, label the materials accurately (use general common names such as “lentiviral vector” in addition to laboratory codes), package them securely, identify the Principal Investigator, department, and storage date, and affix the universal biohazard label including genetic material and recombinant constructs if appropriate. When the BUA that originally provided for use of those materials expires, you must renew the BUA, check “storage only” on the front page, and obtain all required signatures. Should you decide to resume work with “storage only” biohazardous materials, you must amend your BUA to detail the new work for IBC review. Use the regular BUA form and check “Major Change Amendment” if the same project covered in an earlier BUA is to be resumed, or check “New” if it is a new project with your stored materials. This system enables the Biosafety Office to track stored biohazardous materials that may otherwise eventually be forgotten. Storage of biohazardous materials. Attach a complete list of biohazardous materials to be held in storage. Use the following format. Alternatively, attach a spreadsheet that provides the required information in a tabular format Recombinant description or infectious agent species and strain Laboratory identification codes (if applicable) Risk Group (consult the Biosafety Officer/Manager if help is needed) BUA for which the biohazardous materials were obtained or produced (if applicable) Storage conditions (Room temperature, 4º, -20 º, -80 º, LN2) Building Room Storage site and unit in laboratory( freezer, refrigerator, dewar, cabinet, etc) Location in storage unit (shelf #, box # and location, etc) Locked? 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION This page is not subject to F.O.I.A.* requests Section 6. Authorized users (use additional sheets if necessary) Note: Complete this page for all personnel involved with your project (including co-PIs). The Biosafety Office and the IBC will keep the information on this page and on the animal care protocol page confidential. CWID1 Name Telephone e-mail address (text will wrap) Biosafety2 BSC3 BBP4 Date hepatitis B vaccine was offered for BBP ECP Principal Investigator Laboratory contact Check here if additional users are listed on a separate sheet If not a UA affiliate, specify “non-UA” but include requested local contact information Biosafety=Formal EHS-provided or approved training in the Principals and practices of biological safety, mandatory before beginning work; approved annual refresher training required. 3BSC=Biological Safety Cabinet training (mandatory for users of Biological Safety Cabinets; can be fulfilled via EHS training) 4BBP=Bloodborne pathogen exposure control training (if applicable, mandatory before beginning work, must be repeated annually) 1 2 5 6 *F.O.I.A.=Freedom of Information Act 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION Appendix A. University of Alabama Policies and Standard Operating Procedures for work with biohazardous agents Note: Your signature on Page 1 of the BUA Application affirms that you have reviewed the material in this appendix and agree to abide by all of its provisions. 1. Training. Only those persons who are adequately trained may work with biohazardous materials (human, animal, plant, environment) at UA or its satellite laboratories. This standard includes all students, staff, and faculty involved with the project including the Principal investigator, and includes visiting scholars and volunteers. In addition, very short-term visitors to the laboratory (<1 day) who might be inadvertently exposed to biohazardous materials must receive PI-supplied information regarding the nature of the hazards, measures required for avoiding exposure, procedure for post-exposure treatment and follow-up, and the PI’s contact information. Basic biosafety, bloodborne pathogen control, medical waste management, as well as the “NIH Guidelines for Research Involving Recombinant or Synthetic DNA” training are available from UA Environmental Health and Safety. Training in these topics must be renewed annually. More specialized training may be available). The Principal investigator is responsible for all lab- and project-specific training, including experimental methods and techniques, specific hazards associated with the project components, methods employed to reduce the risks to an acceptable level, available project-specific medical surveillance and treatment, and training to use lab equipment. The training record should include a list of topics covered and materials used (such as the approved BUA), and the trainer and trainee should both sign the training record sheet. All training, including short-term visitor orientation, must be documented. A written quiz or some other method of evaluating trainee comprehension should also be included in the training and training documentation. 2. Shipping and Receiving. All shipments (domestic and international) of biological materials must follow university policy and all applicable federal and international regulations and permitting requirements. Biohazardous materials may not be personally transported to or from campus unless specifically authorized by the IBC in your approved BUA and packaged to comply with current DOT, IATA, and public health agency guidelines, standards and regulations. Biohazardous materials may not be transported in private vehicles unless authorized by the IBC. Export of etiologic agents or recombinant DNA constructs may require federal agency permits (USDA, US Department of Commerce). Biohazard shipments of materials that have not been approved for use by the IBC should be shipped to EHS until IBC review is complete and approval for use is granted. 3. Local Transport of Infectious Materials. Intracampus transport of infectious materials must be specifically authorized by the IBC as part of your approved BUA protocol. Biohazardous materials transported between laboratories or to other on-campus facilities must be packaged in absorbent material (enough to absorb the entire liquid volume of the biohazardous material) in a primary leak-proof container with a sealed lid or top, which is enclosed in a secondary leak-proof, non-breakable container (e.g., a Coleman cooler) appropriately labeled with the biohazard symbol (for human biohazards). 4. Personal Protective Equipment (PPE). Wear appropriate PPE such as gloves, safety glasses and a laboratory coat whenever you work with biohazardous materials. Specific PPE requirements are determined by the risk assessment for the research. 5. Footwear. No open-toed or open-heeled shoes or sandals are allowed in the laboratory. A good practice is to keep a set of lab-dedicated closedtoed, closed-heeled shoes at the laboratory work site. Change into them when you arrive at the lab, and change back to street shoes when you are ready to leave the building. 6. Hand washing. After working with biohazardous materials remove your gloves immediately and wash your hands with soap and water. If soap and water are not available (such as in field work locations), use disinfectant hand wipes. 7. Use of sharps. Minimize the use of sharps with biohazardous materials. Never recap, bend or shear needles—use only hard-walled sharps containers and do not overfill. Wherever possible, replace glassware with plasticware. Keep sharps containers readily available in all locations where sharps waste may be generated. Any programmatic use of sharps in a biological safety cabinet should be documented by a risk assessment that shows that no other alternative is acceptable and that details additional training to safeguard the users. 8. Plastic sharps. The Biological Safety Office recommends strongly that plastic pipettes and pipette tips contaminated with agents biohazardous to humans be disposed in a hard walled red sharps container. Medical waste bags used for pipette tip disposal must conform to current regulatory agency bag color and strength standards. Medical waste must be disposed in the approved medical waste stream. 2013-2014 9. THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION Food and Beverage. Eating, drinking, storing food and drink for human consumption, smoking, applying cosmetics or lip balm and handling contact lenses in the laboratory are prohibited in all UA laboratories. 10. Aerosol Generation. Procedures that could generate biohazardous aerosols must be performed in a certified biological safety cabinet or equivalent approved containment device. Experimental systems at BSL1 containment (no demonstrable biohazard to humans, plants, or animals) are exempted from this requirement unless specified in permit conditions for the organism 11. Safe use of biological safety cabinets. Specific training in the safe use of biological safety cabinets is required for all users of these protective devices. EH&S offers a class that satisfies this training requirement. Biological safety cabinets should be sited as far from doorways and common use walkways as possible. All biological safety cabinets must be certified under the NSF49 standard before first use, annually thereafter, and after the cabinet has been relocated or repaired and certification records must be on file with EHS. Biological safety cabinets used for containment of Risk Group 2 microbiological agents use must be decontaminated by an approved method before being relocated or decommissioned. EHS must approve and coordinate vendors for decontamination. Only one person at a time may use a biological safety cabinet. Open flames are prohibited in biological safety cabinets.. Never work in a biological safety cabinet when the UV light is energized, and never operate the UV light with the sash open. Best practice: use the UV light only when the laboratory is unoccupied. Best practice of all: do not use the UV light—it is a mediocre to ineffective method of decontaminating biological safety cabinets and presents significant hazards to the laboratory occupants. 12. Proper Labeling. EHS will place universal biohazard label and hazard signage adjacent to the doorway of a lab where biohazardous materials that are infectious to humans are used. Also lab personnel should label work areas, containment cabinets, and equipment including freezers, refrigerators, incubators, centrifuges, shakers, etc. with the biohazard label. Permitting agencies may also require door and equipment labeling for microbial agents not normally biohazardous to humans. Transgenic plants and animals must be labeled in a way to distinguish them from wildtype (unaltered) plants or animals. 13. Decontamination Procedures, General Use a spray bottle of 10% solution of household bleach in water (made fresh daily) to decontaminate equipment and work surfaces. Where bleach could cause corrosion (stainless steel surfaces), use an iodophor such as Wescodyne., or wipe away the sprayed bleach and spray 70% ethanol on the surface. Decontaminate liquids by adding bleach to a final concentration of 10%, with a 30 minute contact time. Quaternary ammonium disinfectant may be used to disinfect greenhouse benches and materials exposed to plant pathogens. Follow manufacturer label instructions to disinfect solid non-porous surfaces and materials. 14. Spills. Any spill involving infectious agents or recombinant DNA must be reported immediately to the Biological Safety Officer, Biological Safety Manager, and/or EHS. a. b. Risk Group 2 agent spill outside of a biological safety cabinet: Let the spill “settle” for at least 30 minutes—evacuate the laboratory and post signs on the doors to prevent re-entry before it is safe. Wear lab coat or Tyvek gown, gloves, goggles, and at least a surgical mask to clean biohazardous spills outside of a biological safety cabinet. Wear a properly fit-tested respirator (at least N95) to clean Risk Group 2 agent spills if aerosol infection is possible (including plasmids with oncogenes). Distribute paper towels around the periphery of the spill, then towards the center. When the spill is fully contained, spray 10% bleach or other approved disinfectant on the paper towels, allow 30 minutes contact time, and clean up the paper towels with large forceps. Change gloves, and spray 10% bleach or other approved disinfectant on the surface residue. Wipe up the residue with paper towels and repeat at least once. Dispose all of the paper towel waste in a medical waste bag. Risk Group 2 agent spill inside of a biological safety cabinet: Always ensure that the bottom drain is closed before working at a biological safety cabinet. Use the same techniques described above regarding paper towel placement and disinfectant use, but a 30 minute wait for the initial spill to settle is usually not necessary unless some of the spill occurred outside of the biological safety cabinet. If 10% bleach is used to decontaminate the spill on a stainless steel surface, follow with sprayed water or 70% ethanol and wipe dry with paper towels. 15. Mouth Pipetting. Mouth pipetting may lead to accidental ingestion of biohazardous material and is strictly prohibited. 16. Storage. Store all biohazardous materials in containers clearly labeled with the universal biohazard symbol. Permanently label stored biohazardous material with common names wherever possible, in addition to lab-specific codes. 17. Waste. If your work results in the production of medical waste (materials in contact with human and non-human primate tissue, other waste known or suspected to harbor human infectious agents or potentially harbor such agents naturally), you conform to the UA Medical Waste Management Plan. Medical waste must be autoclaved in a unit certified to handle medical waste or must be transported to a medical waste 2013-2014 THE UNIVERSITY OF ALABAMA INSTITUTIONAL BIOLOGICAL SAFETY COMMITTEE BIOLOGICAL USE AUTHORIZATION accumulation site for disposal in the medical waste stream. Research lab dry waste known or suspected to harbor other types of infectious agents (animal and plant) must also be accumulated in sturdy (non-red) bags and autoclaved (autoclave maintained at the medical waste standard is recommended) before disposing to the landfill. Deface all biohazard symbols before disposing autoclaved biohazardous waste to the landfill. “Biotechnology waste” (with NIH-exempted cloning hosts such as E. coli K-12 or Saccharomyces cerevisiae but free of all infectious agents) can be accumulated in clear autoclave bags (deface any imprinted biohazard symbols) and must be autoclaved before disposal to the landfill. As discussed above, liquid waste of any kind that is contaminated or potentially contaminated with any viable agent (infectious or noninfectious) must be decontaminated by 30 minutes exposure to 10% (final concentration) household bleach before it is disposed in the sanitary sewer. 18. Autoclaves and autoclave safety. The standard autoclave sterilization process is 30 minutes exposure at 121ºC (250º F). This measure is intended to reflect the temperature and pressure conditions at the center and throughout the load, not the outside edges. Large volumes of material can require longer exposure times. Always use a sterilization indicator such as autoclave tape. Prion inactivation requires longer exposure at higher temperature, usually preceded by exposure to strong alkali. Always wear heat-resistant gloves, goggles or safety glasses, and a laboratory coat when opening an autoclave. Be sure to allow the superheated steam to dissipate before attempting to remove the autoclave contents. All autoclave usage and maintenance should be per ADEM Admin. Code r. 335-13-7-08. 19. Incidents, Injuries, and health emergencies. Report all injuries and accidental autoinoculation, ingestion or inhalation of infectious agents to the lab director or supervisor, and the Biological Safety Officer. Follow the UA policies for medical evaluation and possible treatment. Dial 911 (or 348-5454) immediately for any medical emergency. After normal business hours and on weekends DCH handles UA employee health emergencies. Any spill, needle stick, or other exposure or release involving infectious agents or recombinant DNA must be reported immediately to the Biological Safety Officer/Manager! 20. Emergencies. During natural disasters, fires, power failures, bomb threats, major biohazardous spills, or other emergencies, take the following precautions and evacuate the lab by posted or ordered evacuation routes a. Secure infectious materials as quickly as possible. If a biological safety cabinet is being used, close all containers and if possible close the sash. b. Call 911 (or 348-5454) and request emergency response. c. When the incident is resolved, if the building is safe to enter (at the direction of the incident commander), proceed to the lab, don appropriate PPE, and assess the lab for the disaster-related release of infectious material. Use the above spill control procedures to contain released material. d. Report any spills involving infectious agents or recombinant DNA to the Biological Safety Officer/Manager immediately!