effects of storage & packaging materials (tin cans & glass bottles)

advertisement

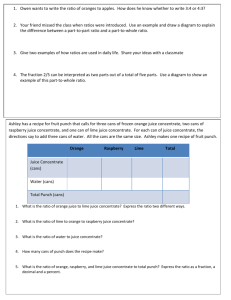

Dept. of Science Laboratory, Rufus Giwa Polytechnic, P.M.B. 1019, Owo, Ondo State, Nigeria. 8th February, 2010 The Executive Editor PJSIR, Scientific Information Centre, PCSIR Lab. Campus, Pakistan. Dear Sir, LETTER OF UNDERTAKING I would like to submit the attached manuscripts for possible evaluation and publication in your Journal. Title: Effects of Storage and Packaging Material on Some Physico-Chemical Properties, Sensory and Microbiogical Qualities of Pineapple Juice (Anana comosus). Name and Address of Corresponding Author: Arawande Jacob Olalekan. Department of Science Laboratory Technology Rufus Giwa Polytechnic, P.M.B. 1019 Owo, Ondo State, Nigeria E-Mail:joawande1@yahoo.com; Mobile Phone Number: 234-8034391608 I affirm that the manuscript has been prepared in accordance with the given instruction for authors and that the content of this manuscript has not been published and not under consideration elsewhere. I also wish the editor should send the manuscript to any potential referees of their choice. Thanks Yours faithfully Signed, Arawande, J.O. EFFECTS OF STORAGE AND PACKAGING MATERIALS ON SOME PHYSICO-CHEMICAL PROPERTIES, SENSORY & MICROBIOLOGICAL QUALITIES OF PINEAPPLE JUICE (Ananas comosus) 1SHAKPO, ITUNNU OLUBUNMI Department of Food Science and Technology Rufus Giwa Polytechnic, P.M.B. 1019, Owo, Ondo State, Nigeria. E-mail: isskpo4ever@yahoo.com Mobile Number: +2348036267170 1 2*ARAWANDE, JACOB OLALEKAN Department of Science Laboratory Technology, Rufus Giwa Polytechnic, P.M.B. 1019, Owo Ondo State, Nigeria. * Corresponding Author: E-mail:joawande1@yahoo.com Mobile Number: +2348034391608 2* ABSTRACT Concentrated pineapple juice was prepared in the laboratory and stored in Tin Cans and Glass bottles of equal capacity at ambient temperature and observed over a period of ten weeks. The stored juice was analyzed at a regular interval of two weeks for pH, Brix, Total solid, Titratable acidity, Vitamin C, Specific gravity, microbiological and sensory qualities (Taste, Colour and Aroma). There was a slight increase in the pH values from 4.2 to 4.7 and 4.8 in canned and bottled pineapple juice respectively. The titratable acidity decreased from 8.1 to 5.1 and 4.6 in canned and bottled pineapple concentrates respectively. The total solids (g/100ml Citric acid) of pineapple concentrates decreased from 76.23 to 65.47 and 60.38 for canned and bottled pineapple concentrates respectively. The Vitamin C contents of the concentrates decreased appreciably, over 90% loss of Vitamin C was observed. The bottled samples retained more Vitamin C than the canned samples. The microbial contents of pineapple concentrate ranged from 2.0 x 103 to 2.4 x 104 sfu/ml and 0 x103 to 6 x 103 cfu/ml for fungi and total mesophilic bacteria respectively. Sensory analysis revealed that the freshly prepared single strength juices from pineapple were more preferred in terms of taste and colour. While the reconstituted juice from the bottled concentrate competed favourably well with the fresh sample in terms of colour. The canned samples lost their colours within the 10 weeks of storage. The glass bottled samples has characteristic desirable aroma. It was established that concentrated juice in glass bottles stored at room temperature enhanced the keeping quality of the juice and competed more favourably with the fresh juice than the canned concentrated juice. 2 INTRODUCTION Fruits are developed from matured ovary and are common food materials which contribute micronutrients (Vitamins and Minerals) and natural soluble sugars for energy to support human nutrition (Ihekoronye and Ngoddy, 1985). Juice is obtained from fruits among which are orange, pineapples, cashew etc. Juice concentrates can be obtained by partial evaporation of moisture from the fruit juice and this is likely to have a longer shelf life than the juice due to lower moisture content (Takahashi, et al., 2000) Pineapples (Ananas comosus) are one of the most common non-citrus tropical and sub-tropical fruits. They have attractive flavour, reducing sugar, a very rich source of Vitamin C and organic acids. Pineapples contain high level of sugars and other carbohydrates and are therefore major sources of dietary fibre and enzymes which can serve as digestion aid (Takahashi, et al., 2000). Pineapple is a non-citrus fruit. It is a member of the Bromiliaceae family, Ananas genus and Sativa species (Garcia and Medina, 2005).Pineapple is the second harvest of importance after bananas, contributing to over 20% of the World production of tropical fruits (Coveca, 2002). Nearly 70% of the pineapple is consumed as fresh fruit in producing countries. Its origin has been traced to Brazil and Paraguay in the Amazonic basin where the fruit was domesticated (Garcia and Medina, 2005).Thailand, Philippines, Brazil and China are the main pineapple producers in the World supplying 50% of the total output (FAO, 2004). Other important producers include India, Nigeria, Kenya, Indonesia, Mexico and Costa Rica and these countries provide most of the remaining fruit available (50%). Pineapple as a plant serves a number of uses. The leaves can be used in three forms; fresh dried and in silage (Geo coppens, 2001). One of the best known properties is as a diuretic. This helps to eliminated toxins through the urine, helping patients with ailments of kidneys bladder and prostate. Due to the fibre content of the pulp, pineapple prevents constipation and regularizes the intestinal flora (FAO, 2004). Furthermore, there is evidence of appetite reducer, heat protection and aid for fever, sore throat and mouth aches and inflammation (Gastron0mia, 2004). Lightly boiled ground pineapple can be used to clean 3 infected wounds because it eliminates dead tissues, not affecting live tissue, acts as disinfectant and accelerates cicatrisation (Mundogar, 2004). Unfortunately, this fruit is seasonal, highly perishable and prone to high post-harvest losses. Extracting and concentrating the juice will reduce the losses by enhancing the keeping qualities thereby making it available all the year round. Post-harvest losses occur in fruits during transportation, storage and while waiting to be processed. Pineapples, after harvesting are still physiologically active. Deterioration of fruit can result from physical factors such as bruises, action of their own enzymes (proteolytic enzyme), microbial action, or combination of these agents (Adetuyi, 2007). Losses in pineapple during air transport are minimal if careful handling is employed. Mechanical damage include bruising or puncturing caused by poor handling, dropping or abrasion which results in localized area of softening and development of secondary microbial infection (Food market exchange, 2004). Pineapple handlers can minimize fruit damage by taking protective measure throughout all handling stages. Other agents of spoilage are yeast, bacteria and fungi. Microorganisms isolated from pineapple juices include Bacillus species, Lactobacillus species, Pseudomonas species and Mucor species, (Aderibigbe et al., 2001). Canning is a method of food preservation which involves subjection of the food materials in cans to an elevated temperature for the purpose of eliminating both pathogenic and spoilage organisms and hermetically sealing the cans to avoid external influence from the environment. Bottling is also a method of preservation which employs the use of sterile glass bottles with lids in food packaging. The chemical and microbial compositions of a food are the most important parameters in determining the overall quality of that food. The changes in these parameters which occur during its preparation and storage after preparation are indices of the suitability or otherwise of the product for consumption and its suitability. Although, food preservation is necessary, the maintenance of the nutrients in the food is also of utmost importance. Pineapples have been known as 4 the best source of vitamin C, greater amount of which was lost during storage at room temperature (Aderibigbe et al., 2001). Previous works on pineapple showed that it contains 81.2 to 86.2% moisture and 13-19% total solids of which sucrose, glucose and fructose are the main components. Carbohydrates are up to 85% of the total solids whereas fibre makes up to 2-3%. Of the organic acid, citric acid is the most abundant. The pulp has very low ash content, nitrogen compounds and lipid (0.1%). From 25-30% of nitrogenous compound are true proteins. Out of this proportion 80% has proteolytic activity due to a protease known as Bromelin (Dull, 1971). Utilization of by-products from pineapple culture, canning and juice extraction has been encouraged for feed production (Geo coppens, 2001). There is limited information on the effect of juice concentration, canning and bottling on pineapples. Therefore the objectives of this research work are to extract, concentrate pineapple juice in form of thick slurry in tin cans and glass bottles and to examine the effects of storage containers on the physico-chemical properties, sensory and microbiological qualities of the juice stored over a period of ten weeks. MATERIALS AND METHOD Pineapple fruits used for this research work were purchased from a renowned market called “Oja Koko” in Owo Local Government area, Ondo State, Nigeria. The fruits were extracted for juice following the procedure described by Ihekoronye and Ngoddy (1985) (Figure 1). The juice was concentrated to 71% brix using water bath. The concentrate was divided into two; one part was canned in tin cans while the other was bottled in glass bottles of equal capacity. The physico-chemical properties, sensory qualities and microbial content of pineapple juice and concentrate were fort-nightly determined for a period of ten weeks. 5 RAW MATERIALS (PINEAPPLE FRUITS) SORTING AND WASHING WEIGHING PEELING CUTTING/CORING CRUSHING/EXTRACTION FILTRATION EVAPORATION/CONCENTRATION STERILIZATION OF CANS & BOTTLES FILLING BOTTLING LIDDING/CLINCHING EXHAUSTING/VACUUMING SEALING COOLING JUICE CONCENTRATES FIG. 1: FLOW CHART FOR THE PRODUCTION OF PINEAPPLE JUICE CONCENTRATE 6 Determination of the Physico-chemical Properties of Pineapple Juice The physico-chemical properties determined were pH, brix, total solids, specific gravity, total titratable acidity, and vitamin C. The pH of fresh pineapple juice as well as the concentrated juice was determined using pH meter. While the brix levels were determined using Abbe refractometer. The total solids, specific gravity, total titratable acidity and vitamin C were determined using standard methods (AOAC, 2005). Sensory Evaluation of Pineapple Juice Concentrate Sensory evaluation based on Taste, Colour and Aroma was carried out as described by Larmoud (1982) using a team of 10 taste panelists for each set of samples. Each panelist’s score was reflected on a nine point Hedonic scale ranging from nine (9) (like extremely) to one (1) (dislike extremely). The result obtained was subjected to Statistical analysis of variance and means were calculated using Duncan’s Post Hoc. Test. Microbiological Analyses of Pineapple Juice Concentrate The media used in carrying out the microbial count of the samples were MacConkey agar (MA) and Potato Dextrose Agar (PDA) for total mesophilic bacteria and fungi tests respectively. The media were prepared according to the method described by Franzetti and Galli (1999). RESULTS AND DISCUSSION From the result of the various analyses after the ten weeks of storage, several data trends were observed. The results tabulated below are a combination of trends seen in the experiments (on canned and bottled pineapple concentrates). The means and standard deviation are based on triplicate analysis from both fresh and concentrated juice container per condition. Table 1 shows some physico-chemical properties of pineapple juice and concentrate stored in tin cans and glass bottle for a period of ten weeks. The fresh pineapple juice contains pH 3.70 ± 0.10, Brix 12.20±0.427%, and Total titratable acidity of 1.38 ± 0.03g/100ml citric acid, Vitamin C 153.3±0.4mg/100ml, Total solid 10.11±0.11% and Specific gravity of 1.21±0.033. This is consistent with the 7 findings of Kristin (2005) who obtained 12.8% Brix, and 0.724g/100ml total acidity. The concentrated juice has pH 4.20 ± 0.10, Brix 71.01±0.115%, Total titratable acidity of 8.17 ± 0.148g/100ml citric acid, Vitamin C 781.94±0.051mg/100ml Total solid 76.23±0.252% and Specific gravity 1.25±0.104. It was observed that these parameters except pH decreased as the storage period increased in both the canned and bottled concentrates. The pH, Brix and Vitamin C of bottled concentrate were relatively higher than that of the bottled concentrate while the reverse trend was noticed for titratable acidity and total solid over the ten weeks storage period. However, the parameters of the fresh juice were much lower than that of the concentrated juice (Canned and Bottled concentrates). This can be traced to the fact that the concentrated juice contains reduced moisture content (Fagbemi and Adigun, 1998). Over the period of storage, the range values of pH, Brix, Total titratable acidity, Vitamin C and Total solid of canned concentrate were 4.20 – 4.70, 71.30 – 62.50, 8.17 – 5.11, 780.91 – 7.02 and 76.23 – 65.47 respectively while that of bottled concentrate were 4.20 – 4.80, 70.92 – 66.33, 8.17 – 4.61, 781.94 – 13.02 and 76.23 – 60.38 accordingly. 8 TABLE1: SOME PYSICO-CHEMICAL PROPERTIES OF PINEAPPLE JUICE AND CONCENTRATE STORED IN TIN CANS AND GLASS BOTTLES FOR A PEROD OF TEN WEEKS TIME (WEEKS) 0 2 4 6 8 10 *PINEAPPLE JUICE SAMPLES *pH *BRIX (%) *TITRATABLE ACIDITY (g/100ml citric acid) *VITAMIN C (mg/100ml) *TOTAL SOLID (%) *SPECIFIC GRAVITY 1.38 ± 0.03 153.3 ± 0.40 10.11 ± 0.11 1.21 ± 0.033 Fresh Juice 3.70 ± 0.10 12.20 ± 0.427 Concentrated Juice 4.20 ± 0.10 71.01 ± 0.115 8.17 ±0.148 781.94 ± 0.051 76.23 ± 0.252 1.25 ± 0.104 Canned concentrate 4.20 ± 0.09 71.30 ± 0.609 8.17 ± 0.020 780.91 ± 0.415 76.23 ± 0.330 1.31 ± 0.01 Bottled concentrate 4.20 ± 0.07 70.92 ± 0.382 8.17 ± 0.023 781.94 ± 0.05 76.23 ± 0.436 1.31 ± 0.01 Canned concentrate 4.40 ± 0.10 63.42 ± 0.289 7.64 ± 0.04 141.03 ± 0.147 74.42 ± 0.42 1.34 ± 0.142 Bottled concentrate 4.50 ± 0.10 66.30 ± 0.482 7.62 ± 0.02 177.66 ± 0.602 70.37 ± 0.07 1.33 ± 0.033 Canned concentrate 4.53 ± 0.153 63.29 ± 0.189 7.04 ± 0.02 72.99 ± 0.431 71.41 ± 0.01 1.32 ± 0.01 Bottled concentrate 4.60 ± 0.10 67.33 ± 0.147 6.94 ± 0.055 80.29 ± 0.101 66.39 ± 0.09 1.33 ± 0.01 Canned concentrate 4.57 ± 0.06 62.92 ± 0.520 6.90 ± 0.02 34.16 ± 0.183 68.39 ± 0.09 1.30 ± 0.052 Bottled concentrate 4.60 ± 0.20 66.87 ± 0.108 6.58 ± 0.026 41.13 ± 0.539 63.44 ± 0.481 1.30 ± 0.038 Canned concentrate 4.63 ± 0.06 63.07 ± 0.066 6.37 ± 0.03 12.06 ± 0.053 66.14 ± 0.087 1.31 ± 0.043 Bottled concentrate 4.70 ± 0.48 66.25 ± 0.250 6.22 ± 0.026 16.03 ± 0.095 61.82 ± 0.261 1.28 ± 0.018 Canned concentrate 4.70 ± 0.10 62.5 ± 0.33 5.11 ± 0.11 7.02 ± 0.046 65.47 ± 0.07 1.31 ± 0.01 Bottled concentrate 4.80 ± 0.06 66.33 ± 0.144 4.61 ± 0.03 13.02 ± 0.03 60.38 ± 0.07 1.29 ± 0.09 *MEAN VALUE ± STANDARD DEVIATION OF TRIPLICATE DETERMINATIONS 9 There was a sharp decrease in the brix content of pineapple juice between the week of production (week 0) and the second week of storage (week 2) while it was relatively steady for the rest week of storage with slight difference. Slight increase in pH with the corresponding slight decrease in the titratable acidity of pineapple juice in both the storage container was observed with the storage period and this is in agreement with the findings of Fagbemi and Agun (1998). Total solid and Vitamin C were also observed to decrease with time. Vitamin C was remarkably decreased to the tune of more than 90% loss, while the Total solid was slightly decreased over the storage period. Specific gravity which is a measure of purity was observed to be stable throughout the period of storage with negligible difference. The colour of the juice concentrate reduced with storage period. The juice concentrates being acidic reacted with the cans and resulted to darkening of the colour. Despite the transparency of the glass bottles, the sample in bottle container competes favourably with the fresh samples in terms of colour. This may be due to the fact that the samples were not exposed to light.It was also observed that the bottled sample retained more Vitamin C which is the major nutrient in juices than the canned samples. Table 2 depicts the mean score of the sensory quality; it was observed that there were significant differences in terms of taste, colour and aroma among the samples examined. However, the fresh juices were mostly preferred to the reconstituted juices followed by the bottled concentrate, while the canned concentrates were ranked least in terms of colour. Table 3 reveals the microbial contents of Pineapple fresh juice and concentrate. The total mesophilic count, yeast and mould counts were reduced with concentration process. However they increased with storage up to fourth and sixth week and later start diminishing. The predominant members were mould and yeast and this is due to the fact that the juice concentrate are acidic (Ihekoronye and Ngoddy, 1985). Bacteria contamination may be due to poor handling during processing. In the canned sample, the microbial load was lesser than that of the bottled samples due to the anaerobic condition in the cans. In any case, the reconstituted juices from the concentrates are microbiologically fit for consumption since the microbial loads were within tolerable limit for human consumption. 10 TABLE 2: SENSORY QUALITY OF PINEAPPLE JUICE AND CONCENTRATE SAMPLES Time (Weeks) Attributes TASTE 5.8b 5.5b 5.3b 0 COLOUR 7.4a 5.8b 6.9ab AROMA 6.3b 5.5b 5.5b 2 4 6 8 10 Fresh juice C PC BPC TASTE 6.2a 4.2b 4.7b COLOUR 6.2a 5.9a 5.7a AROMA 7.5a 6.5a 5.8a TASTE 7.8a 6.1b 6.1b COLOUR 7.0b 6.8b 8.2a AROMA 7.1b 6.4b 6.2b TASTE 6.7a 5.1b 4.8b COLOUR 6.6a 7.1a 6.8a AROMA 7.9a 6.2b 5.8b TASTE 8.0a 5.8b 5.5b COLOUR 7.9a 6.4b 6.7b AROMA 7.2a 5.6b 6.2b TASTE 5.3b 4.3b 4.1b COLOUR 7.8a 6.4b 6.4b AROMA 4.9b 6.0ab 6.2ab Means of sensory scores Means with different subscript in a row for each week are significantly different (P=0.05) CPC: Canned Pineapple Concentrate, BPC: Bottled Pineapple Concentrate 11 TABLE 3: MICROBIAL CONTENTS OF PINEAPPLE JUICE AND CONCENTRATE Time (Week) Pineapple Sample 0 2 4 6 8 10 Fungi (sfu/ml) Total Mesophilic bacteria (cfu/ml) Fresh Juice 2.4 x 104 5 x 103 Concentrated Juice 2.0 x 103 1 x 103 Canned concentrate 2.0 x 103 1 x 103 Bottled concentrate 2.0 x 103 1 x 103 Canned concentrate 6.0 x 103 2.0 x 103 Bottled concentrate 8.0 x 103 4.0 x 103 Canned concentrate 1.2 x 104 3.0 x 103 Bottled concentrate 2.0 x 104 6.0 x 103 Canned concentrate 8.0 x 103 2.0 x 103 Bottled concentrate 2.0 x 104 6.0 x 103 Canned concentrate 6.0 x 103 NP Bottled concentrate 4 1.4 x 10 2.0 x 103 Canned concentrate 4.0 x 103 NP Bottled concentrate 1.0 x 104 2.0 x 103 NP – Not Present CONCLUSION It was shown that the juice concentrates that are stored in glass bottles had better physico-chemical and sensory qualities due to glass inertness; therefore it prevented certain reactions from occurring. However, concentrated fruit juices in cans contained lesser microbial load but with unacceptable colour. Conclusively, Pineapple juice and concentrate stored in glass bottle retained more nutrient and is preferred to the juice stored in cans in terms of colour, taste and Vitamin C retention. 12 REFERENCES Aderibigbe, E. Y., Ogungbola, F. F. and Alayerogun, T. B. 2001.Microbiological and Biochemical Studies of Fruits (Pineapple and Orange) Purchased in Ado-Ekiti, Nigeria. Journal of Technoscience 5: 43 – 48 Adetuyi, F. O. 2007. Spoilage associated with fruits and vegetables during Transportation. Journal of Food Science. 39: 200 – 205 AOAC. 2005. Official Methods of Analysis, 17th ed., Association of Official Analytical Chemist. Washington d. c. Coveca. 2002. Comision veracruzana de comercializacion agropecuaria. Gobierno del Estado de Veracruz, Mexico Dull, G. G.; T 1971. The pineapple: General. In: A. C. Hulme (Ed) The Biochemistry of fruits and their products. Academic Press, New York.2: 303 – 324. Garcia, H.S. & Medina J. De La Cruz 2005. Pineapple Post-Harvest Operation. Instituto Technologico de Veracruz (http://www.itver.edu.mx) Fagbemi, T. N.; Agun, B. J. 1998. The effect of Storage and Film Packaging on the Nutritional Qualities of Processed juices (Orange, Pineapple Mango). Journal of Technoscience. 2(1): 26 – 29. FAO. 2004. http://www.fao.org/livestock/agap/frg/afris/espanol Food Market Exchange 2004. Food market exchange.com.2004 http://www.foodmarketexchange.com/datacenter/product/fruit/pineapple Franzetti, J.; Galli P. 1999. Microbial Quality Indicators in Minimally Processed Carrot. Gibson America Gastronomia 2004. http://www.peru.com/gastronomia/docs2/ Geo coppens 2001 http://www.ciat.cgiar.org/ipgri/fruits_from_americas/ frutalesgeoCoppensd’eEeckenbrugge and Dimary Libreros Ferla Handwerk, R. L.; coleman, R. L. (1988) Approaches to the citrus Browning Problem: A review. Journal of Agric Food Chem. 36: 23-236 Ihekoronye, A. I. and Ngoddy, P. O. 1985. Integrated Food science and Technology for the Tropics .1st Edition. Macmillan Publishers Ltd., London Kristin, A. N. 2005. Photochemically induced flavour changes in Orange juice exposed to light in glass and Polyethylene Terephthalate at 4oC. A Thesis presented to theGraduate School of the University of Florida p. 4-9 Larmoud, E. 1982. Laboratory methods for sensory Evaluation of food. Department of Agricultural, Canada Publication 1637 Mundogar, 2004. htpp:/www.mundogar.com Takahashi, H.; Inada, Y.; Mori, D.; Tatsuka, k. 2000. Changes in Volatile constituents of Satsuma mandarin oranges during canning and storage of the products. Kenkyu Hokokusho-Tyo shokuhim kogyo Tanki Daigaku, Toyo shokulim kenkyusho 23: 54-64 13