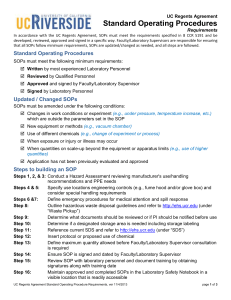

HACCP-Based Standard Operating Procedures (SOPs)

advertisement