Success Story of Sangli Raisin Making Cluster - Reg

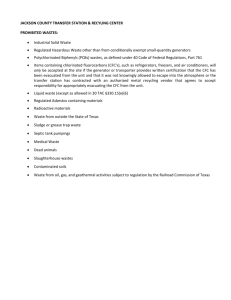

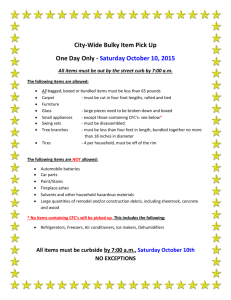

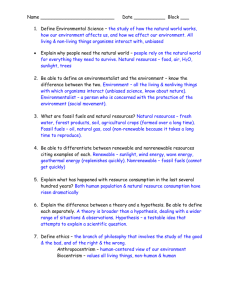

advertisement

Success stories of Raisin Cluster, Sangli in State of Maharastra Worldwide Micro, Small and Medium Enterprises play the most crucial role for its national economic growth and socio-economic transformation. In India, this sector contributes about 8 per cent of the country’s GDP, 45 per cent of the manufactured output and 40 per cent of the total exports. This is a key driver of our country’s industrial growth as it comprises about 36 million enterprises that generate over 6,000 products and employ over 80 million persons. The MSME sector is characterized by its heterogeneity. It is diverse in terms of size, technology level, location and product range that spans from grass-root village industries to sophisticated units producing auto components, micro-processors, electronic components and electro-medical devices. MSME faces new challenges continuously for its competitiveness and self sustainable growth in the globalized market scenario. MSME units have a high degree of geographic dispersion, their development assumes great significance for an equitable and inclusive growth which is the ultimate objective of our economy. Ministry of MSME of the Govt. plays a key role to function as engine of growth of our nation and implements various schemes with the objective of enhancing the competitiveness, productivity as well as bringing sustainable growth to this sector. The Government has adopted the cluster approach as a key strategy and Micro and Small Enterprises – Cluster Development Programme (MSE-CDP) is one of the flag-ship schemes of the Ministry. A cluster is a group of enterprises located within an identifiable and as far as practicable, contiguous area and producing same/similar products/services. The essential characteristics of enterprises in a cluster are (a) Similarity or complementarily in the methods of production, quality control and testing, energy consumption, pollution control, etc (b) Similar level of technology and marketing strategies/practices (c) Channels for communication among the members of the cluster (d) Common challenges and opportunities. The cluster approach has proved as the most effective and successful tool for up gradation of industry all over the country in a cost effective manner and reliance on industrial clusters has been found prudent in many countries. By providing shared access to amenities like testing centres, utilities, roads, security, effluent treatment, training of workers, and marketing, clusters can provide substantial benefits in terms of technology absorption, efficiency enhancement and growth of units. The cluster development initiatives in various clusters have delivered remarkable results. 796 interventions such as diagnostic study, soft interventions and Visit of Hon’ble- Minister Shri. R.R. Patil, Home Minister Maharashtra state setting up of CFCs have been taken in various clusters spread all over the country. Raisin Cluster, Sangli in State of Maharastra is one of the total 2443 Clusters in India , where MSE-CDE intervention were taken up since 2009. Diagnostic study: MSE-CDP activities the first and foremost activity for any cluster is its Diagnostic Study. The main objective of these Diagnostic Study Reports (DSR) is to map all the business processes of the cluster units to find out the strength, weaknesses, opportunities and threats (SWOT) and problems etc. of the cluster and to suggest a well drawn action plan for enhancing the competitiveness and to ensure their self sustainable growth in terms of turn-over, employment generation, etc. Diagonostic Study for raisin making cluster was approved by 15th Steering Committee of MSE-CDP on 14.1.2008 at the project cost of Rs.2 lakhs and GoI grant of Rs. 1.8 Lakhs.. Maharashtra covers 70% of grape mainly through its districts Sangli, Nasik, Solapur, Ahmadnagar and Pune. Sangli is one of the largest raisin producer district in the country. Raisins are basically dry grapes and they are known as kishmish, Manuka, Bedana or dry fruits. During earlier days, grapes were dried on plants only which was very crude method resulting wastage. The project of converting of grapes to raisin began around 40 to 45 years ago. But last 3 to 5 years the production has been virtually strengthening. There are two types of raisins 1) Golden yellow, 2) Darker sweetened(Black). Raisin Manufacturing : Raisin production is one of the important activity under taken in Sangli district. The farmers (growers cum processors) undertake raisin production activity themselves and marketed raisin in open market. For production of quality raisin, grapes harvested, graded, washed and dipped in solutions containing 1 ltr of ephylolete and 0.20 kg. of potassium carbonate (k2co3) per 100 ltrs. Water (ph9.5 to 11.00) for 2 to 5 minutes. These grapes then brought to drying shed and spread on shed. (Temperature 35 degree to 41 degree) Drying is complete within 15 to 21 days depending upon whether condition. The raisins are collected, sorted and graded before packing. The graded raisin is packed in the boxes of 15 kg and plastic bag 1 kg and 2 kg Soft Intervention : Under this Micro and Small Enterprises – Cluster Development Programme (MSECDP) Soft Intervention programme consist of activities which leads to creation of general awareness, counseling, motivation and trust building, exposure visits, market development including exports, participation in seminars, workshops and training programmes on technology upgradaion etc. Soft Interventions were approved on 29.5.09 with a project cost of Rs.3.3 lakhs and GoI grant of Rs.2.97 lakhs: Capacity Building: This activity led to creation of general awareness, counseling, motivation and trust building. SPV was formed as M/S.Sangli Grape Processing Marketing & Research InDustries Ltd, Subhashnagar, Tq. Miraj Dist .Sangli. Website Launched on29/09/2010 & Broacher Published. Enquiries were received for supply of hygienic raisins from Local & International Market Marketing Development Cluster Units participated in B2 x B meeting on local & national level at 1.Exhibition , W.T.O. Mumbai , one 27, 28,29 Jan. 2011 2.Exhibition at MSME Office on 19,20 Feb 2011 (MSME, Mumbai). They interacteded with National, International level buyers and know the needs of customer Visit of Shri Ajij Khan IAS Principal Secretary for Industries in B2B programme at Mumbai Visit of Shri Sanjay Sethi IAS D. C. (Industries ) Directorate of Industries Mumbai at CFC Site Soft Intervention Program: B2B At Mumbai ( Visit of Shri Sanjay Sethi IAS ) Soft Intervention Program: Participation in Exhibition at MSME Mumbai Technology up gradation & Quality Control Workshop & Seminar conducted on Technology up gradation & Quality aspects at Central food technology Institute Mysore Dr.Satyenaryan A/p-Malgaon Tal-Miraj, Dist-Sangli on 27.11.2009 and at A/p-Junoni, Ta-Sangola, Dist-Solapur. On 09.02.2010. Development & Technical Consultancy National Research Center, Pune 1)Dr. Adsule 2)R.G.Somkumar 3)S.D.Sawant 4)A,K,Upadye, Information /Guidance Received 1)Different varieties of grapes used for raisin making in the world & their yields their parameters followed by codex standards.2) Nutrient & water requirement in grapes/raisin 3) Different types of diseases & their control & weather forecasting Information /Guidance Received 1)Method of Drying of Grapes, 2)Different types of Chemical used for quality raisin. Technology up gradation Management Development Cluster units attended seminar on management practice at VP Institute of Management Sangli on Dt.23/9/2010 and visited to M/s. Balaji on Dt.2/8/2010 to Know the New Technology in Potato wafers making which is similar process of proposed raisin making Know the ISO . Interacted with Bankers at Hotel Season 4, Vishram bag, Sangli on dt.2/2/2010 at 2.00 pm. As a result, Bankers know the needs & scale of finance of cluster & MSME units . Soft Intervention Program Interaction with Bankers and financial institutes Hard Interventions i.e. setting up of Common Facility Centers consist of tangible “assets” as Common Facility Centres (CFCs) like Common Production/Processing Centre (for balancing/correcting/improving production line that cannot be undertaken by individual units), Design Centre, Testing Centre etc. Date of Admn. Approval for CFC was accorded on 16th August, 2010 with the following components : CFC Bhumi Pujan S. No. Component of Cost 1. Land Amount (Rs. in lakh) 18.00 2 Building 96.60 3 Plant & machinery 454.01 4 Furniture & Fixtures 3.00 5 74.51 6 Accessories & Misc. Fixed Assets Total fixed Assets (TFA) 7 Add: - Margin Money for WC 1.78 8 Add:- Preelli & Pre-op. exp & 5% of TFA Add:- Contingencies & 2% of Building Add:- Contingencies & 5% of Plant & Machinery and other F.A. Total cost of the project 32.44 9 10 646.12 1.93 26.58 Visit of Hukum Sing Meena IAS Additional Commissioner MSME New Delhi 708.85 Means of finance S.No. Particulars 1. 2. 3. 4 Total Govt. of India Govt. of Maharashtra SPV Contribution Bank Loan Amount (in Lakhs) 496.18 70.89 % of Project cost 70% 10% 106.33 15% 35.45 708.85 5% CFC Construction in Process Facilities of CFC : a) Common Processing Centre b) Common Testing Centre c) Common Packaging Centre, Expert Technical Agency : a) National Research Centre for Grapes Pune b) C.F.T.R.I. Mysore 1) Raisin sorting machine is useful for colors gradation and size gradation. In short time with the high speed colors gradation and size gradation can be done with the help of this machine. Miraj Dis Sangli (Top View) 2) Raisin processing machine is helpful for washing, drying, destining, metal separation and packing. 3) Testing laboratory which gives colour testing pulpiness and sweetness. Miraj Dis Sangli (Frount View) CFC Processing Unit CFC Processing Unit CFC Packaging Unit CFC Packaging Unit CFC Benefits. S.N. Before CFC 1. Grading and Sorting is manually done by labour, chances of mixing of stones, impurities are more in manually sorting. Opportunities for export of manually sorted raisins are less. 2 No testing and inspection facility are available in cluster area. 3. Packaging facility is not available in cluster area. After setting up of CFC Common processing Sorting and processing is done by atomized machinery, it produces hygienic and export quality raisins. MSME units (Members) are directly and indirectly exported the CFC processed raisins in various countries i.e. Dubai, Kuwait, Russia. Common Testing Laboratory Chemical and biological testing facility for finished good and raw material is available in CFC.Water testing, Colour testing, Moisture testing , Soil and leaf testing, facilities are also available in CFC Common Packaging Centre Packaging facility for Export quality raisins are available in CFC. Also packing facility of raisins in to small Pouches for domestic market are available in CFC. Visit of Shri Ambore Dir. MSME Inspection by Dir. Shri Daptardar MSME Mumbai Tangible Benefits of CFC Increase the efficiency and productivity of the MSME units (Members) Reduced cost of Product Mfg. of the internationally competitive raisins is possible. Improved the quality of raisins. Which fulfill the need of global market. Value addition are increased by 10 to 20 % Quantified Benefits: Total Processed (May 2012 to March 2013) : 2227 MTs. Value addition for Processed raisins : Rs. 433.20 Lakhs. No. of Beneficiaries (Services Given) - 109 Nos. Value addition per Beneficiaries - 3.97 lakhs. No. of MSME Raisin units in Cluster Area on 31/03/2011 : 560 Nos. No. of MSME Raisin units in Cluster Area as on 31/03/2013 : 670 Nos. Production of Raisin in Cluster Area as on 31/03/2011 : 60000 MTS. Production of Raisin in Cluster Area as on 31/03/2013 : 80000 MTS Employment in CFC : 40 Nos. No. of Members : 140 Nos. Quantity Processed (MTs) Market Price of unprocessed raisins(Rs. Per Kg.) Value of Processed raisins in CFC(Rs. Per Kg.) Net Increased (Rs. Per Kg.) Month Green/Yellow B Grade Black C Grade A Grade Black C Grade 110 225 120 120 0 0 0 0 80 84 81 79 60 62 58 65 0 0 0 0 94 98 96 95 80 82 79 87 0 0 0 0 14 14 15 16 20 20 21 22 21 56 41 85 132 77 0 0 0 70 75 90 35 37 35 0 0 0 84 88 106 56 60 64 0 0 0 14 13 16 20 23 29 84 70 88 53 125 0 175 0 120 0 70 100 80 79 84 90 60 0 65 0 65 0 80 130 94 95 98 110 80 87 84 100 0 0 0 30 14 16 14 20 20 22 20 20 A Grade Green/Yellow B Grade Black C Grade 74 47 75 51 A Grade Green/Yellow B Grade Black C Grade Green/Yellow B Grade A Grade May.2012 0 Jun.2012 0 Jul.2012 0 Aug. 0 2012 Sep. 2012 0 Oct.2012 0 Nov. 0 2012 Dec.2012 0 Jan. 2013 0 Feb.2013 0 Mar.2013 208 Increase in Revenue (Rs. in Lakhs) 32.36 51.58 36.45 34.56 19.94 37.64 28.89 36.76 49.7 36.32 87 ***