Table of Contents

advertisement

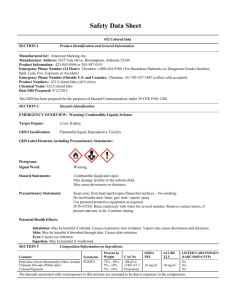

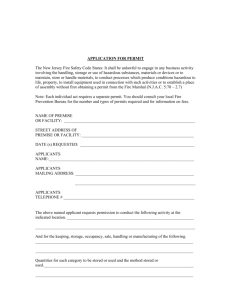

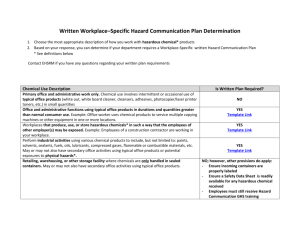

CITY AND COUNTY OF DENVER Department of Safety Fire Department Fire Prevention and Investigation Division 745 West Colfax Avenue Denver, Colorado 80204 (720) 913-3474 HAZARDOUS MATERIALS INVENTORY STATEMENT (HMIS) Table of Contents Scope ......................................................................................................... 3 Annual Permit Requirements .................................................................... 3 Submittal Information ............................................................................... 3 Instructions for Completing the HMIS .................................................... 4 General Information Form ........................................................................ 4 Chemical Inventory Spreadsheet .............................................................. 4 Hazardous Materials Management Plan (HMMP .................................... 4 Facility Graphics Maps ............................................................................. 5 Permit Level Amounts .............................................................................. 8 NFPA 704 Ratings/Hazard System........................................................... 11 NFPA 704 Placarding .............................................................................. 15 Definitions ................................................................................................. 15 Frequently Asked Questions ..................................................................... 20 -2- I. SCOPE If your business uses, stores or handles hazardous materials in quantities exceeding the Permit Level Amounts (page 10) as stated in the International Fire Code (IFC) with Denver Amendments (IFC Section 2701.5.2), you are required to fill out a Hazardous Materials Inventory Statement (HMIS) and to obtain a Hazardous Materials Permit. The permit constitutes permission to maintain, store, use or handle materials, or to conduct processes that produce conditions hazardous to life or property, or to install equipment used in connection with such activities. II. ANNUAL PERMIT REQUIREMENTS The Denver Fire Department, Fire Prevention & Investigation Division will issue the annual Hazardous Materials Permit. For new and existing facilities that store or use hazardous materials, an HMIS is required by the fire department to evaluate applicant’s storage layout, methods of storage and use and commodities being stored for compliance with all International Fire Code, International Building Code, and NFPA requirements. The HMIS shall be completed by a qualified individual who is familiar with the requirements of the International Fire Code, International Building Code, and applicable provisions of the National Fire Protection Association publications. The fire code official is authorized to require HMIS submittals to be prepared by an authorized individual or firm. These are the Four Required HMIS Forms: (1) General Information Form – Sign the last page - Scanned copy allowed (2) Chemical Inventory Report (the ACTUAL DFD Excel spreadsheet: Submit Annually) (3) Hazardous Materials Management Plan (HMMP) - Scanned copy allowed (4) Facility Graphic Maps - Scanned copies allowed A permit may be suspended or revoked when it is determined that the permit was issued in error or in violation of an ordinance, regulation or code. False statements or misrepresentations of information provided in the HMIS submittal may result in a criminal complaint being issued for violation of Section 109.2.2.1 of the IFC Denver Amendments. III. SUBMITTAL INFORMATION NEW HMIS SUBMITTALS FOR TENANT FINISH, NEW CONSTRUCTION, OR RELOCATION When applying for building permits, submit to Development Services the construction drawings and a CD with the Four Required HMIS Forms for review by the Denver Fire Department Fire Protection Engineers. Upon approval of the construction drawings by Development Services, email the Four Required HMIS Forms to DFDHMIS@denvergov.org OR mail a CD to the address provided below. FOR RENEWAL OF HAZARDOUS MATERIALS PERMIT ONLY DO NOT MAIL PRINTED MATERIALS 60 Days prior to expiration of your current permit, e-mail the Chemical Inventory Report as well as any updates of the other Required HMIS Forms to DFDHMIS@denvergov.org OR mail a CD containing the Chemical Inventory Report as well as any updates of the other Required HMIS Forms to: Denver Fire Department - Hazardous Materials Unit 745 W. Colfax Avenue Denver, CO 80204 Phone (720) 913-3458, Fax (720) 913-3596 -3- IV. INSTRUCTIONS for COMPLETING the HMIS (1) GENERAL INFORMATION FORM Complete the General Information Form. Save file as: ‘your street address, date’ (i.e. 123 Main Street, 012010) in Microsoft Word. Provide an electronic signature or scan a signed copy. (2) CHEMICAL INVENTORY SPREADSHEET The information needed to complete the Chemical Inventory Spreadsheet can be found on the Material Safety Data Sheets (MSDS) and/or the product label for each product. Fill in the following fields: The product’s name, CAS number, location code, both use and total amounts of each product, all NFPA 704 Ratings of the product, and all corresponding IFC Hazard Categories that apply. Follow all instructions provided in the comment boxes, red flagged on spreadsheet. Save file as: ‘your street address, date’ (i.e. 123 Main Street, 01-2010). CHEMICAL INVENTORY REPORTING GUIDELINES: Mixtures shall be classified in accordance with hazards of the mixture as a whole. For mixtures which have more than one single CAS number, list all CAS numbers. Any product or chemical which meets or exceeds the permitable amounts in any IFC classification shall be reported. Report the Maximum Quantity of products you would have on site at any given time. If the products or chemicals to be bulked are stored or used in different control areas in your facility, each location will require a separate entry on the chemical inventory report. Products or chemicals that are in temporary locations (awaiting transport on shipping dock, etc.) shall be reported from their primary or permanent location. Report separate entries for ‘Use’ and ‘Storage’. All products or chemicals will require an individual entry on the chemical inventory report spreadsheet. Exceptions: If products are: 1) stored or used in the same location, 2) have the same NFPA 704 hazard rating, 3) and are in containers not greater than 1 gallon or 10 pounds. These may be reported as aggregates. For example: Paints having the same base, but different colors and containers sizes up to 1 gallon may be bulked as one entry on the spreadsheet. (3) HAZARDOUS MATERIALS MANAGEMENT PLAN (HMMP) Any facility with a permit for hazardous materials shall develop a Facility Contingency Plan and provide a narrative description of the operations and processes taking place at the facility. Inspectors will confirm that a copy is on site. Save file as: ‘your street address, date’ (i.e. 123 Main Street, 01-2010) in Microsoft Word. The Plan shall include the following: General Facility Information: General information, including business name and address, emergency contacts, business activity, business owner or operator, SIC code, number of employees and hours, Dunn and Bradstreet number, and signature of owner, operator or designated representative. Hazardous Materials Handling: Information showing that all activities involving the handling of hazardous materials between the storage areas and manufacturing processes on-site are conducted in a manner to prevent the accidental release of such materials. Provide details of how this is accomplished. Chemical Compatibility and Separation: Information showing procedures, controls, signs or other methods used to ensure separation and protection of stored materials from factors which may cause accidental ignition or reaction of ignitable or reactive materials. -4- Monitoring Program: Information including, but not limited to the location, type, manufacturers’ specifications, if applicable, and suitability of monitoring methods for each storage facility when required. Inspection and Record Keeping: Schedules and procedures for inspecting all monitoring equipment, safety and emergency equipment. The permittee shall develop and follow a written inspection procedure acceptable to the chief for inspecting the facility for malfunctions and deterioration, operating errors, poor housekeeping practices and discharges which may cause, or may lead to unauthorized discharges of hazardous materials. These inspections must be at a frequency appropriate to detect problems prior to a discharge. An inspection check sheet shall be developed and used in conjunction with routine inspections. This check sheet shall provide for the date, time and location of each inspection, noting any problems and any corrective actions taken, name of inspector and the countersignature of the safety manager for the facility. (These inspection reports shall be made available to the Denver Fire Department during any site inspection.) Fire detection, alarm and extinguishing systems shall be maintained in an operative condition at all times, and shall be replaced or repaired where defective. Non-required fire protection systems and equipment shall be inspected, tested and maintained or removed. International Fire Code: 901.6 Records of all system inspections, tests, and maintenance required by the referenced standards shall be maintained on the premises for a minimum of 3 years and made available to the fire code official upon request. International Fire Code: 901.6.2 Employee Training: A training program appropriate to the categories and quantities of hazardous materials stored or used shall be conducted to prepare employees to safely handle hazardous materials on a daily basis and during emergencies. The training program shall include: * Instruction in safe storage and handling of hazardous materials, including maintenance of monitoring records. * Instruction in emergency procedures for leaks, spills, fires or explosions, including shutdown of operations and evacuation procedures. * Recordkeeping procedures for documenting training given to individual employees. Emergency Response: A description of emergency procedures is to be provided. (4) FACILITY GRAPHIC MAPS A minimum of four (4) representative graphics are required for each site. On each map, specifically identify where hazardous materials are stored and used at your facility. These graphics are crucial to the emergency planning for both the facility and the local emergency response authority. Photocopy the “Plan of the Facility” page and use that for all three graphics maps. These graphics will not be directly available to the general public (see FAQ #6). Save each required graphic separately as a windows bitmap. Graphic A – 500-foot Map This map shall include the area extending 500 feet from any point from the property line. This graphic shall include: 1. All streets, alleys, access roads, storm drains and fire hydrants. 2. Buildings within the area a. Label each with company name, address and type of business b. Label each building with the number of stories above grade 3. Location of wells, flood plains, ditches, surface water bodies and general land uses 4. Indicate all educational and institutional occupancies (i.e., schools, hospitals, nursing homes, day care centers, etc.) -5- Graphic B – Facility Plan This drawing is an overview of your entire facility. Include all buildings, sheds, exterior storage areas, tanks, permanent access ways, parking lots, internal roads, chemical loading area, equipment cleaning areas, emergency and safety equipment. Label all areas so we can identify storage and use areas as listed on the inventory sheets. Graphic C – Building Floor Plans These graphics represent each building at your facility. Include all rooms, doorways, corridors and exits. Label all rooms and indicate all hazardous material storage areas by type of hazard present in those areas. This plan shall be to scale and show all dimensions for above locations. Graphic D - Storage Layout This plan shall show dimension between racks, bin boxes, shelves, and pile, along with dimension between walls, openings and exits. Height of stored items shall be identified and the item being stored (i.e., combustibles, flammables, IB, etc.) shall be identified. SYMBOL KEY FOR GRAPHICS MAP IS ON THE NEXT PAGE -6- -7- V. PERMIT LEVEL AMOUNTS Aggregate quantities at or above these levels will require a hazardous materials permit. Aerosols – Type 48 Levels 1, 2 and 3 300 lbs. = 1 unit Battery Systems (Stored Power Supply Systems) – Type 64 Gallons of Electrolytes 10 - 50 gallons 51 – 100 gallons 101 – 200 gallons 201 – 500 gallons 501 + gallons $225.00 $275.00 $350.00 $475.00 $650.00 Combustible Fibers – Type 8 Loose Baled 100 cubic feet = 1 unit 1000 cubic feet = 1 unit Compressed Gases-Code 10 Flammable (except cryogenic fluids and liquefied petroleum gases) Oxidizing (including oxygen) Corrosive, Irritant, Sensitizer Other Health Hazards Toxic and Highly Toxic Any amount requires a permit Pyrophoric Any amount requires a permit Radioactive Any amount requires a permit Unstable/Reactive Any amount requires a permit Inert and/or Simple Asphyxiant Compressed Natural Gas – Type 10 200 cubic feet = 1 unit 504 cubic feet = 1 unit 200 cubic feet = 1 unit 650 cubic feet = 1 unit 10 cubic feet = 1 unit 10 cubic feet = 1 unit See Code 39 below 10 cubic feet = 1 unit 6000 cubic feet = 1 unit Refer to Compressed Gases - Flammable Cryogenics – Type 11 Flammable Oxidizer (includes oxygen) Physical or Health Hazard Not Indicated (Any amount requires a permit) Inert / Nonflammable Inside 1 gallon = 1 unit 10 gallons = 1 unit 1 gallon = 1 unit Outside 60 gallons = 1 unit 50 gallons = 1 unit 1 gallon = 1 unit 60 gallons = 1 unit 500 gallons = 1 unit Explosives/Blasting Agents – Type 13 Any amount requires a permit Explosive/Potentially Explosive/Blasting Agents 1 lb. = 1 unit -8- Flammable/Combustible Liquids – Type 15 Class I-A, I-B, I-C Class II, III-A Class III-B Inside 30 gallons = 1 unit 60 gallons = 1 unit 1000 gallons = 1 unit Outside 60 gallons = 1 unit 120 gallons = 1 unit 1000 gallons = 1 unit Hazardous Materials – Type 26 Biohazards Any amount requires a permit / 1 gallon or 10 lbs. = 1 unit Carcinogens - Liquids/Solids 1 gallon or 10 lbs. = 1 unit Corrosives - Liquids/Solids 55 gallons / 550 lbs. = 1 unit Flammable solids Inside 100 lbs. = 1 unit Highly Toxic – Liquids and Solids Any amount requires a permit/1 gallon or 10 lbs. = 1 unit Irritant - Liquids/Solid 55 gallons or 550 lbs. = 1 unit Organic Peroxides - Liquids/Solids Unclassified, Detonable Class I & II Class III Class IV Class V Any amount requires a permit / 1 gallon or 10 lbs. = 1 unit Any amount requires a permit / 1 gallon or 10 lbs. = 1 unit 1 gallon or 10 lbs. = 1 unit 2 gallons or 20 lbs. = 1 unit No permit required Other Health Hazards - Liquids/Solids 55 gallons or 550 lbs. = 1 unit Oxidizing - Liquids / Solids Class IV Class III Class II Class I Any amount requires a permit/1 gallon or 10 lbs. = 1 unit 1 gallon or 10 lbs. = 1 unit 10 gallons or 100 lbs. = 1 unit 55 gallons or 500 lbs. = 1 unit Pyrophoric – Liquids / Solids Any amount requires a permit/1 gallon or 10 lbs. = 1 unit Radioactive Materials Not Sealed Sealed Over 1 microcurie requires permit – 1 microcurie = 1 unit Over 1 millicurie requires permit – 1 millicurie = 1 unit Sensitizer Liquids/Solids 55 gallons / 550 lbs. = 1 unit Toxic Liquids/Solids Any amount requires a permit/1 gallon or 10 lbs. = 1 unit -9- Outside 100 lbs. = 1 unit Hazardous Materials – Type 26 (continued) Unstable (reactive) Liquids and Solids Class 4, Class 3 Class 2 Class 1 Any amount requires a permit 1 gallon or 10 lbs. = 1 unit 1 gallon or 10 lbs. = 1 unit 10 gallons or 100 lbs. = 1 unit Water Reactive Liquids and Solids Class 3 Class 2 Class 1 Any amount requires a permit 1 gallon or 10 lbs. = 1 unit 5 gallons or 50 lbs. = 1 unit 10 gallons or 100 lbs. = 1 unit Liquefied Petroleum Gas – Code 31 Any amount requires a permit LP gas – storage, use and handling inside or outside of buildings Gallons of Propane 01 to 24 gallons 25 to 71 gallons 72 to 118 gallons 119 to 237 gallons 238 to 355 gallons 356 gallons and above **Mushroom Heater Pounds of Propane 01 to 100 lbs. 101 to 300 lbs. 301 to 500 lbs. 501 to 1000 lbs. 1001 to 1500 lbs. 1501 lbs. and above Hazardous Materials Permit Fee Calculation Tables Number of Units 01 to 10 units 11 to 50 units 51 to 100 units 101 to 200 units 201 to 500 units 501 and more units Permit Fee $175.00 $225.00 $275.00 $350.00 $475.00 $650.00 - 10 - Permit Fee $125.00 $200.00 $250.00 $300.00 $475.00 $650.00 $75 each / $200 annual VI. NFPA 704 RATING SYSTEM HEALTH: Read the HEALTH HAZARD INFORMATION section of the MSDS and determine the rating (0-4) which best meets the product. Report the NFPA 704 RATING and all corresponding HAZARD CATEGORIES that apply on the CHEMICAL INVENTORY REPORT spreadsheet. RATING 4 3 DESCRIPTION Materials, including those that are too dangerous to be approached without specialized protective equipment, which on very short exposure could cause death or major residual injury, even if prompt medical attention is received. Materials, including those requiring protection from all bodily contact, which after short exposure could cause serious temporary or residual injury, even after prompt medical care is received. 2 Materials, including those requiring the use of respiratory protective equipment with an independent air supply which after either intense or short exposure could cause temporary incapacitation or possible residual injury unless prompt care is obtained. 1 Materials, including those requiring airpurifying respirators, which on short exposure could cause irritation but only minor residual injury if no care, is obtained. Materials that on short exposure under fire conditions would offer no hazard beyond that of ordinary combustible materials. 0 - 11 - HAZARD CATEGORY Carcinogen Highly Toxic Radioactive Carcinogen Corrosive Cryogenic Flammable Cryogenic Oxidizing Other Health Hazards Toxic Carcinogen Irritant Other Health Hazards Carcinogen Sensitizer Other Health Hazards NFPA 704 RATING SYSTEM FLAMMABILITY: Read the FIRE AND EXPLOSION HAZARD DATA section of the MSDS and determine the rating (0-4) which best meets the product. Report the NFPA 704 RATING and all corresponding HAZARD CATEGORIES that apply on the CHEMICAL INVENTORY REPORT spreadsheet. RATING DESCRIPTION HAZARD CATEGORY Combustible Dust Cryogenic Flammable Flammable Gas (gaseous or liquefied) Flammable Liquid I-A Organic Peroxide I Pyrophoric Gas 4 Materials having flash points below 73 F and a boiling point less than 100 F. This would include materials that ignite spontaneously when exposed to air; also included are flammable gases and flammable cryogenic materials and Class I-A flammable liquids. 3 Materials having flash points below 73 F and having a boiling point at or above 100 F and those liquids having a flash point at or above 73 F and below 100 F. This would include Class I-B and Class I-C flammable liquids. Combustible Fiber Flammable Liquid I-B Flammable Liquid I-C Organic Peroxide II Pyrophoric Solid or Liquid 2 Materials having flash points between 100 F and 200 F. This would include Class II and III-A combustible liquids. 1 Materials having flash points above 200 F. This includes Class III-B combustible liquids. Combustible Liquid II Combustible Liquid IIIA Flammable Solid Organic Peroxide III Combustible Liquid III-B Organic Peroxide IV 0 Materials that will not burn. - 12 - NFPA 704 RATING SYSTEM REACTIVITY: Read the REACTIVITY DATA section of the MSDS and determine the rating (0-4) which best meets the product. . Report the NFPA 704 RATING and all corresponding HAZARD CATEGORIES that apply on the CHEMICAL INVENTORY REPORT spreadsheet. RATING DESCRIPTION 4 Materials that are readily able to detonate, or are of explosive decomposition or reactive at normal temperatures and pressures. 3 Materials capable of detonation or explosive decomposition or explosive reaction but require a strong initiating source or that must be heated under confinement. Materials that readily undergo violent chemical change at elevated temperatures or pressures; this includes materials that may react violently with water or form potentially explosive mixtures with water. Materials that in themselves are normally stable but can become unstable at elevated temperatures and pressures; this includes materials that change or decompose on exposure to air, light, or moisture. Materials that in themselves are normally stable even under fire conditions; this includes materials that do not react with water. 2 1 0 - 13 - HAZARD CATEGORY Explosives Organic Peroxide Unclassified, detonable Unstable Reactive Class 4 Unstable Reactive Class 3D Organic Peroxide I Organic Peroxide II Unstable Reactive Class 3N Water Reactive Class 3 Organic Peroxide III Unstable Reactive Class 2 Water Reactive Class 2 Organic Peroxide IV Unstable Reactive Class 1 Water Reactive Class 1 NFPA 704 RATING SYSTEM SPECIAL HAZARD: Read the HEALTH HAZARD INFORMATION section, the FIRE AND EXPLOSION HAZARD DATA section, and the REACTIVITY DATA section of the MSDS and determine the rating which best meets the product. Report the NFPA 704 RATING and all corresponding HAZARD CATEGORIES that apply on the CHEMICAL INVENTORY REPORT spreadsheet. RATING W OX RAD COR UD 4D 3D 3N DESCRIPTION Water Reactive. Materials that react with water. HAZARD CATEGORY Water Reactive Class 3, 2, or 1 Oxidizer. Materials with oxidizing properties. Cryogenic Oxidizing Compressed Gas Oxidizing Liquefied Gas Oxidizing Oxidizer Class 4, 3, 2, or 1 Radioactive Radioactive. Materials or combinations of materials that spontaneously emit ionizing radiation. Corrosive. Materials that cause visible destruction of, or irreversible alterations in, living tissue by chemical action at the site of contact. Unclassified Detonable. Materials that present an extremely high explosion hazard through rapid explosive decomposition and are regulated as explosive materials. Class 4 Detonable. Materials which in themselves are readily capable of detonation or of explosive decomposition or explosive reaction at normal temperatures and pressures. Class 3 Detonable. Materials that, in themselves, are capable of detonation or of explosive decomposition or explosive reaction but which require a strong initiating source or which must be heated under confinement before initiation. Class 3 Non-Detonable. Materials which explode or decompose explosively, but that do not detonate. - 14 - Corrosive Unclassified Detonable Class 4 Detonable Class 3 Detonable Class 3 Non-Detonable VII. NFPA 704 Placarding In all occupancies where hazardous materials are stored, dispensed, used or handled in quantities requiring a permit the IFC requires visible hazard identification signs, as specified in NFPA 704. This standard provides a simple system of readily recognizable and easily understood markings, which will give at a glance a general idea of the inherent hazards of any material and the order of severity of these hazards as they relate to fire prevention, exposure and control. This standard requires all buildings with chemical amounts exceeding the permit quantities to be placarded. The placard for each building or area shall represent the collective extreme hazard rating for all products in that building or area. The Denver Fire Department requires a minimum of two external placards mounted in separate locations: One placard must be mounted on the front of the building in a permanent and stationary location, with no visual barrier to the street. The second placard must be fixed near the secondary means of egress. If your facility is fenced, this second placard may be placed on the vehicle entrance gate. Fences surrounding exterior storage areas and detached storage buildings must also be placarded. Internal placards are also required Position placards above doorways to rooms where hazardous materials are stored or used. In open, inside locations where hazardous materials are stored or used, mount the placards on the wall above and behind the product; rack storage requires that placards be placed at both ends of the aisle. All signage must comply with NFPA 704. All signs must have contrasting numbers and symbols. Exterior signs shall be a minimum of 15" by 15"; interior signs shall be a minimum of 10” by 10”. In situations where a wide variety of materials having varying degrees of hazards are stored, the identifying numerical values and symbols shall indicate the most severe degree of hazard in each category. These placards are available from companies listed in the phone book under “Fire Protection”. If you have any questions or concerns, please feel free to contact the Fire Prevention Bureau, Hazardous Materials Division, during normal business hours at 720-913-8288. VIII. Definitions AEROSOL. A product that is dispensed from an aerosol container by a propellant. Level 1 aerosol products. Those with a total chemical heat of combustion that is less than or equal to 8,600 British thermal units per pound (Btu/lb) (20 kJ/g). Level 2 aerosol products. Those with a total chemical heat of combustion that is greater than 8,600 Btu/lb (20 kJ/g), but less than or equal to 13,000 Btu/lb (30 kJ/g). Level 3 aerosol products. Those with a total chemical heat of combustion that is greater than 13,000 Btu/lb (30 kJ/g). CARCINOGEN. Any substance that causes the development of cancerous growths in living tissue. A chemical is considered to be a carcinogen if it: 1. Has been evaluated by the International Agency for Research on Cancer (IARC) and found to be a carcinogen or potential carcinogen, or 2. Is listed as a carcinogen or potential carcinogen in the latest edition of the Annual Report on Carcinogens published by the National Toxicology Program (NTP), or 3. Is regulated by OSHA as a carcinogen. - 15 - Chemical mixtures (generally zero-prefixed CAS numbered items) will be indicated as being carcinogenic if the mixture contains a carcinogen in a concentration of 0.1% or more as indicated on the MSDS. COMBUSTIBLE FIBERS. Readily ignitable and free-burning fibers, such as cocoa fiber, cloth, cotton, excelsior, hay, hemp, henequen, istle, jute, kapok, oakum, rags, sisal, Spanish moss, straw, tow, wastepaper, certain synthetic fibers or other like materials. COMPRESSED GAS. A material, or mixture of materials, which: 1. Is a gas at 68 F (20ºC) or less at 14.7 psia (101 kPa) of pressure; and 2. Has a boiling point of 68 F (20ºC) or less at 14.7 psia (101 kPa) which is either liquefied, non-liquefied or in solution, except those gases which have no other health- or physical-hazard properties and are not considered to be compressed until the pressure in the packaging exceeds 41 psia (28 kPa) at 68 F (20ºC). CONTROL AREA. Spaces within a building which are enclosed and bounded by exterior walls, fire walls, fire barriers and roofs, or a combinations thereof, where quantities of hazardous materials not exceeding the maximum allowable quantities per control area are stored, dispensed, used or handled. CORROSIVE. A chemical that causes visible destruction of or irreversible alterations in, living tissue by chemical action at the point of contact. A chemical shall be considered corrosive if, when tested on the intact skin of albino rabbits by the method described in DOT 49 CFR 173.137, such chemical destroys or changes irreversibly the structure of the tissue at the point of contact following an exposure period of 4 hours. This term does not refer to action on inanimate surfaces. CRYOGENIC FLUIDS. A fluid having a boiling point lower than -130F. (-89.9C.) at 14.7 pounds per square inch atmosphere (psia) (and absolute pressure of 101.3 kPa). EXPLOSIVE/BLASTING AGENT. Explosive. A chemical compound, mixture or device, the primary or common purpose of which is to function by explosion. The term includes, but is not limited to, dynamite, black powder, pellet powder, initiating explosives, detonators, safety fuses, squibs, detonating cord, igniter cord, igniters and display fireworks, 1.3G (Class B, Special). The term “explosive” includes any material determined to be within the scope of USC Title 18: Chapter 40 and also includes any material classified as an explosive other than consumer fireworks, 1.4G (Class C, Common) by the hazardous materials regulations of DOTn 49 CFR. Blasting Agent. A material or mixture consisting of a fuel and oxidizer, intended for blasting provided that the finished product, as mixed for use or shipment, cannot be detonated by means of a No. 8 test detonator when unconfined. Blasting agents are labeled and placarded as Class 1.5 material by US DOTn. FLAMMABLE GAS. A material which is a gas at 68F (20ºC) or less at 14.7 pounds per square inch atmosphere (psia) (101 kPa) of pressure [a material that has a boiling point of 68F (20ºC) or less at 14.7 psia (101kPa)] which: 1. Is ignitable at 14.7 psia (101kPa) when in a mixture of 13 percent or less by volume with air; or 2. Has a flammable range at 14.7 psia (101 kPa) with air of at least 12 percent, regardless of the lower limit. The limits specified shall be determined at 14.7 psi (101 kPa) of pressure and a temperature of 68F (20ºC) in accordance with ASTM E 681. - 16 - FLAMMABLE LIQUEFIED GAS. A liquefied compressed gas which, under a charged pressure, is partially liquid at a temperature of 68F (20ºC) and which is flammable. FLAMMABLE/COMBUSTIBLE LIQUIDS. FLAMMABLE LIQUID. A liquid having a closed cup flash point below 100F (38C). Flammable liquids are further categorized into a group known as Class I liquids. The Class I category is subdivided as follows: Class IA. Liquids having a flash point below 73F (23C) and having a boiling point below 100F (38C). Class IB. Liquids having a flash point below 73F (23C) and having a boiling point at or above100F (38C). Class IC. Liquids having a flash point at or above 73F (23C) and below 100F (38C). The category of flammable liquids does not include compressed gases or cryogenic fluids. COMBUSTIBLE LIQUID. A liquid having a closed cup flash point at or above 100F (38C). Combustible liquids shall be subdivided as follows: Class II. Liquids having a closed cup flash point at or above liquids are those having flash points at or above 100F (38C) and below 140F (60C). Class IIIA. Liquids having a closed cup flash point at or above 140F (60C) and below 200F (93C). Class IIIB. Liquids having closed cup flash points at or above 200F (93C). The category of combustible liquids does not include compressed gases or cryogenic fluids. FLAMMABLE SOLID. A solid, other than a blasting agent or explosive, that is capable of causing fire through friction, absorption or moisture, spontaneous chemical change, or retained heat from manufacturing or processing, or which has an ignition temperature below 212F (100ºC) or which burns so vigorously and persistently when ignited as to create a serious hazard. A chemical shall be considered a flammable solid as determined in accordance with the test method of CPSC 16 CFR; Part 1500.44, if it ignites and burns with a self-sustained flame at a rate greater than 0.1 inch (2.5mm) per second along its major axis. HIGHLY TOXIC MATERIAL. A material which produces a lethal dose or lethal concentration which falls within any of the following categories: 1. A chemical that has a median lethal dose (LD50) of more than 50 milligrams or less per kilogram of body weight when administered orally to albino rats weighing between 200 or 300 grams each. 2. A chemical that has a median lethal dose (LD50) of 200 milligrams or less per kilogram of body weight when administered by continuous contact for 24 hours (or less if death occurs within 24 hours) with the bare skin of albino rabbits weighing between 2 and 3 kilograms each. 3. A chemical that has a median lethal concentration (LC50) in air of 200 parts per million by volume or less of gas or vapor, or 2 milligrams per liter or less of mist, fume or dust, when administered by continuous inhalation for one hour (or less if death occurs within one hour) to albino rats weighing between 200 and 300 grams each. - 17 - Mixtures of these materials with ordinary materials, such as water, might not warrant classification as highly toxic. While this system is basically simple in application, any hazard evaluation that is required for the precise categorization of this type of material shall be performed by experienced, technically competent persons. IRRITANT. A chemical which is not corrosive, but which causes a reversible inflammatory effect on living tissue by chemical action at the site of contact. A chemical is a skin irritant if, when tested on the intact skin of albino rabbits by the methods of 16 CFR 1500.41 for four hours' exposure or by other appropriate techniques, it results in an empirical score of 5 or more. A chemical is an eye irritant if so determined under the procedure listed in 16 CFR 1500.42 or other appropriate techniques. LIQUEFIED PETROLEUM GAS (LP-gas). A material which is composed predominantly of the following hydrocarbons or mixtures of them: propane, propylene, butane (normal butane or isobutane) and butylenes. ORGANIC PEROXIDE. An organic compound that contains the bivalent -0-0- structure and which may be considered to be a structural derivative of hydrogen peroxide where one or both of the hydrogen atoms have been replaced by an organic radical. Organic peroxides can present an explosion hazard (detonation or deflagration) or they can be shock sensitive. They can also decompose into various unstable compounds over an extended period of time. Class I. Describes those formulations that are capable of deflagration but not detonation. Class II. Describes those formulations that burn very rapidly and that pose a moderate reactivity hazard. Class III. Describes those formulations that burn rapidly and that pose a moderate reactivity hazard. Class IV. Describes those formulations that burn in the same manner as ordinary combustibles and that pose a minimal reactivity hazard. Class V. Describes those formulations that burn with less intensity than ordinary combustibles or do not sustain combustion and that pose no reactivity hazard. Unclassified detonable. Organic peroxides that are capable of detonation. These peroxides pose an extremely high-explosion hazard through rapid explosive decomposition. OTHER HEALTH HAZARDS. Target organ toxins - substances which cause damage to particular organs or systems. Including: hepatoxins, nephrotoxins, neurotoxins, blood or hematopopoistic system toxins, pulmonary damaging agents, reproductive toxins, cutaneous and eye hazards not classified as irritant or corrosive. OTHER HEALTH HAZARD MATERIAL is a hazardous material which affects target organs of the body, including, but not limited to, those materials which produce liver damage, kidney damage, damage to the nervous system, act on the blood to decrease hemoglobin function, deprive the body tissue of oxygen, or affect reproductive capabilities, including mutations (chromosomal damage) or teratogens (affect on fetuses). OXIDIZER. A material that readily yields oxygen or other oxidizing gas, or that readily reacts to promote or initiate combustion of combustible materials. Examples of other oxidizing gases include bromine, chlorine and fluorine. Class 4. An oxidizer that can undergo an explosive reaction due to contamination or exposure to thermal or physical shock. In addition, the oxidizer will enhance the burning rate and can cause spontaneous ignition of combustibles. Class 3. An oxidizer that will cause a severe increase in the burning rate of combustible materials with which it comes in contact or that will undergo vigorous self-sustained decomposition caused by contamination or exposure to heat. - 18 - Class 2. An oxidizer that will cause a moderate increase in the burning rate or that causes spontaneous ignition of combustible materials with which it comes in contact. Class 1. An oxidizer whose primary hazard is that it slightly increases the burning rate but which does not cause spontaneous ignition when it comes in contact with combustible materials. PYROPHORIC. A chemical with an autoignition temperature in air, at or below a temperature of 130F (54C). RADIOACTIVE MATERIAL. radiation. A material or combination of materials that spontaneously emits ionizing SENSITIZER. A chemical that causes a substantial proportion of exposed people or animals to develop an allergic reaction in normal tissue after repeated exposure to the chemical. TOXIC MATERIAL. A chemical falling within any of the following categories: 1. A chemical that has a median lethal dose (LD50) of more than 50 milligrams per kilogram, but not more than 500 milligrams per kilogram of body weight when administered orally to albino rats weighing between 200 or 300 grams each. 2. A chemical that has a median lethal dose (LD50) of more than 200 milligrams per kilogram but not more than 1,000 milligrams per kilogram of body weight when administered by continuous contact for 24 hours (or less if death occurs within 24 hours) with the bare skin of albino rabbits weighing between 2 and 3 kilograms each. 3. A chemical that has a median lethal concentration (LC50) in air of more than 200 parts per million but not more than 2,000 parts per million by volume of gas or vapor, or more than 2 milligrams per liter but not more than 20 milligrams per liter of mist, fume or dust, when administered by continuous inhalation for 1 hour (or less if death occurs within 1 hour) to albino rats weighing between 200 and 300 grams each. UNSTABLE (REACTIVE) MATERIAL. A material, other than an explosive, which in the pure state or as commercially produced, will vigorously polymerize, decompose, condense or become self-reactive and undergo other violent chemical changes, including explosion, when exposed to heat, friction or shock, or in the absence of an inhibitor, or in the presence of contaminants, or in contact with incompatible materials. Unstable (reactive) materials are subdivided as follows: Class 4. Materials that in themselves are readily capable of detonation or of explosive decomposition or explosive reaction at normal temperatures and pressures. This class includes materials that are sensitive to mechanical or localized thermal shock at normal temperatures and pressures. Class 3. Materials that in themselves are capable of detonation or of explosive decomposition or explosive reaction but which require a strong initiating source or which must be heated under confinement before initiation. This class includes materials that are sensitive to thermal or mechanical shock at elevated temperatures and pressures. Class 2. Materials that in themselves are normally unstable and readily undergo violent chemical change but do not detonate. This class includes materials which can undergo chemical change with rapid release of energy at normal temperatures and pressures, and that can undergo violent chemical change at elevated temperatures and pressures. Class 1. Materials that in themselves are normally stable but which can become unstable at elevated temperatures and pressure. - 19 - WATER REACTIVE. A material that explodes; violently reacts; produces flammable, toxic or other hazardous gases; or evolves enough heat to cause self-ignition or ignition of nearby combustibles upon exposure to water or moisture. Water-reactive materials are subdivided as follows: Class 3. Materials that react explosively with water without requiring heat or confinement. Class 2. Materials that may form potentially explosive mixtures with water. Class 1. Materials that may react with water with some release of energy, but not violently. IX. Frequently Asked Questions 1. Why must I complete this Hazardous Materials Inventory Statement? Completion of the Hazardous Materials Inventory Statement is a requirement of the International Fire Code, Section 2701.5.2. 2. How will this information be used? It will be used by the Fire Department to evaluate the hazardous materials used at your facility and to issue your hazardous materials permit. 3. Is it necessary for me to report each chemical in the facility? Yes. The only exception is to NOT report small amounts of consumer size and strength supplies such as: a container of furniture polish, window cleaner, etc. used for housekeeping or maintenance at your facility. 4. Do I have to use the forms provided? Yes. This format is required by the Denver Fire Department. 5. How often must I complete a Hazardous Materials Inventory Statement? Annually; an HMIS is required every year in order to renew your hazardous materials permit. Also, an amended HMIS shall be provided within 30 days of the storage of any hazardous materials which changes or adds a hazard class or which is sufficient in quantity to cause an increase in the quantity which exceeds 5 percent for any hazard class. 6. Is the information I submit available to the public? Yes. By written request only. 7. Is it important that I keep copies of the Hazardous Materials Inventory Statement? Yes. This will assist you in preparing the forms the following year. 8. Do I need to submit the Materials Safety Data Sheet (MSDS) with this form? No. Those are for your information and records. Only as requested for supplemental information. 9. Does the completion of this form meet the requirements for SARA Title III reporting? While completion of this form meets the requirements of the International Fire Code, you may also need to file a SARA Title III report (or EPCRA) with the State Emergency Response Commission (SERC) and the Local Emergency Planning Committee (LEPC). Your business may also meet the requirements to report on the Clean Air Act 112r. You must contact the Environmental Protection Agency (EPA) to find out if your business is required to report. For SARA Title III and 112r information call the EPA at (303) 312-6312. - 20 -