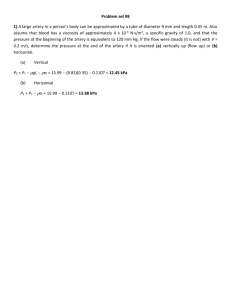

IntroTHT_2e_SM_Chap13

advertisement