Gabion Houses

advertisement

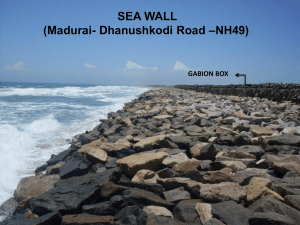

The rubble house project. Background and technical information taken from the Haven/Oxfam America document: Rubble house is considered permanent; it offers an environmentally friendly way to dispose of earthquake rubble, offering a strong safe house as well as possible livelihood opportunities to beneficiaries and communities. Apart from sand and aggregates, the vast majority of housing building materials are imported into Haiti at considerable cost. Using the rubble in the reconstruction effort makes good sense and this project offers a huge opportunity to fine tune methodologies and demonstrate to the international community and donor bodies that using rubble for housing reconstruction is a viable and sustainable opportunity. A gabion is a wire cage that can be stacked vertically in a wall and then packed with various materials. Normally they are used as retaining walls, but in the case of the Gabion House their design has been modified to allow them to be stacked to form a load-bearing, masonry wall. To enable the gabions to effectively perform as a load bearing wall they must: Be laid in stretcher bond; Be wired together, both vertically and horizontally; The lids removed so that the courses ‘mesh’ and transfer load; The masonry material packed tightly to avoid subsidence; Be protected from the weather…in this case by plaster, made with sand from crushed rubble; Be restrained at the top. This is achieved by spacing 12mm threaded rod at intervals of approximately 2 metres around the perimeter wall. The gabion cages provide a matrix of wire mesh throughout the body of the wall. It is this confinement of the masonry, both horizontally and Vertically, plus the tension provided by the tie down rods, that provides the restrained flexibility responsible for earthquake resistance. It is the mass of the walls, plus the foundation to top plate tie down provided by threaded rod, that gives these buildings good hurricane resistance. It is also the mass of the walls and the concrete floor that provide a thermal buffer to external temperature variations, by providing a tempering heat/cool bank. The internal temperature is also controlled by venting the gable ends. Many of the construction processes are semi-skilled so this will enable the employment of the most vulnerable in the community. A pilot gabion house has already been constructed in nearby Croix de Bouquets, this pilot design has been expanded upon to include elements that are appropriate to Haitian architecture. The new building typology allows a shaded veranda for the entrance at the front and a second shaded veranda at the back. These areas of transition between exterior and interior, typical in tropical climate architecture, ensure cooler spaces; these becomes the areas where inhabitants usually spend most of their time at home. The Gabion structure is conceived as a Core house with the two side windows easily adjusted to allow new doors and circulation routes. A two story building has been considered to allow “apartments” solution for areas where land is limited. Five more gabion rows up to railing height will be needed on the second floor. Low tech panels will be used as walls. The second floor will also benefit from an entrance front veranda and a back veranda. The house foundations are designed as a continuous strip. In stable soil conditions the trench is dug twice the width(w) of the wall (2w) and (2w – 150mm) deep. In this instance the gabion wall is 300mm wide so the foundation trench is 600wide and 450 deep. The trench is filled with rubble which has been broken down using a sledge hammer to a maximum size of 100mm pieces of block or concrete. The rubble is then compacted by hand using a tamping rod and levelled using 20mm aggregate from crushed rubble. Once the foundation has been compacted and levelled a 150mm thick reinforced bond beam is poured in situ on top of the rubble foundation. The concrete is mixed using one part ordinary Portland cement, 2 parts sand crushed from concrete block rubble and 4 parts aggregate using 20 mm crushed concrete rubble. ( 1:2:4). In order to ensure that the top of the wall can resist the shear force generated by an earthquake, threaded steel rods are fixed in place using 100 x 200mmsquare steel plates, 6mm thick, under the bond beam. The steel bars are spaced at two metre intervals and are 900mm long. As the wall is constructed the steel rods are extended in three lengths using steel couplers. The gabion baskets are made using (A52) steel reinforcing mesh lined with chicken wire. The gabions are 600mm long x 300mm wide x 300mm high. They are cut into the appropriate shape using bolt cutters. The mesh is then lined with chicken wire and the sides and ends are bent into shape and fastened together with tie wire. The first course of gabion baskets are placed on the bond beam and fastened together using tie wire. They are then filled by hand ensuring the voids are kept to a minimum and that only rubble with one flat side is used on the two exposed faces of the gabion basket; this is important as it minimises the amount of sand/cement render used and ensures that there are a minimum of voids next to the sides of the baskets. The second course is then laid in ‘Stretcher’ bond. The second course is tied to the first with tie wire, both vertically and horizontally. Half gabions are placed wherever necessary to maintain the stretcher bond. A fixing block is placed in every 2nd course adjacent to the joinery frames and secured in place by 2 screws. Work continues in this manner until 4 courses have been laid. After the 4th course, a bed of levelling mortar is placed and the next course of gabions is embedded in this while still moist. The next three courses are placed as before until the seventh course has been laid. We are now at the top of the windows and need to place 2 x 1.5m lengths of 100x100x6mm angle iron on top of the window surround and spanning 300mm on to the adjoining gabions. The supporting gabions and the supported gabions are tied to the angle iron with tie wire. When the eighth and final course is in place the top of the gabions are covered with a lid made from the gabion mesh and a levelling bed of mortar is placed on top of the final course. A 200mm x 50mm timber wall-plate is then bedded in the mortar so that the threaded steel rods protrude through the wallplate and through a 100mm x100mm steel plate which is secured on top of the wallplate and the entire fixed in place with a 12mm hex nut & washer – tightened to the engineer’s specification. The door and window openings are framed with 18mm plywood and 100mm x 50mm timber is fixed to the plywood as window & door frames. The doors are traditional sheeted timber and bracing fixed with heavy T hinges to the frames, to resist strong winds. The windows are traditional shutters made from planks with bracing and also fixed with strong hinges to the frame. A minimum of two coats of sand/cement render are applied to the exposed wall surfaces both inside and outside, the final coat being floated to give a nap finish. The plaster is a 4:1 sand/cement mix; the sand is produced on site from crushed concrete block rubble using a hand-operated crusher. Through the implementation of this programme the following outputs will be achieved: Objective 1: Provision of safe shelter for earthquake displaced families. 4 households will be selected to receive rubble house, based on standard haven vulnerability criteria 4 households will have agreement with Haven outlining the own the land and granting permission to build 4 households will be provided with a permanent house, providing them with a secure and healthy living environment offering privacy and dignity Rubble Shelter design will be in compliance with Sphere standards in terms of space provision 4 families will be involved in an innovative approach to the provision of permanent housing through the use of Gabion rubble construction Objective 2: Develop rubble housing techniques, document the process and provide a platform for rubble housing to be accepted as a viable construction technique which provides housing in accordance with best practice and contributes to solving the rubble disposal problem. Construction techniques will be developed and documented Local labour will be trained in basket making – 4 women rubble crushing – 4 men rubble placing- 4men and general construction techniques – 4 men Income will be generated as workers will be paid on a ‘per unit produced’ basis on not on a daily rate. EG the women will receive 15 Gourde per basket and the men 15 Gourde per bucket of crushed rubble Approx 160m3 of rubble will be utilised and disposed of in productive manner. A video of the process will be produced (IFRC) which will act as an educational resource for further development of the techniques and attract donors. 12.0 Programme Activities Construction of three single storey and one two storey rubble gabion houses Liaison with beneficiaries, relevant government bodies and landowners to collect all relevant agreements / permissions Preparation of detailed construction drawings and details (IFRC). Consult with beneficiaries about their labour contribution during the construction stage Provide basic construction training and tools to beneficiaries to enable them to assist with construction Procurement of all materials Construction of houses (Groundwork and earthwork, fabrication of baskets, rubble selection, sorting, crushing and placing, erection of baskets, installation of rainwater harvesting system and handover) To ensure quality of construction through monitoring and site supervision Haven will appoint a qualified member of the team to over-see the start-up process and on behalf of Oxfam America will employ a consultant rubble expert, recommended by Oxfam America, to work on the project for 25 days in Jan till 31 Jan 2010 Liaise with Oxfam as regards the donation of timber, arrange for delivery of timber to site. Prepare partnership agreements with IFRC who will assist with design, preparation of drawings, provision of expert supervision and management, documentation and recording of the process including production of a DVD. The project is situated in Lilavois 29, in a ‘Lakou’ where mothering in particular, but all activities, are shared among the 9 families of the Lakou. All the buildings in the lakou were badly damaged in the earthquake and needed to be demolished. It is the material from these damaged houses that is being used for the new ones. Positioning of the houses, demolition of existing structures and layout were discussed and agreed with the members of the Lakou before agreeing on this setting. In addition, through its team of local Community Development Workers, Haven will ensure effective and efficient coordination with beneficiaries. This will be conducted through regular meetings, reports and discussions with beneficiaries. The family living in the lakou is made up of three sisters and their children, and the children of two - now dead – brothers. Another brother lives nearby. One of the sisters, Ti Soeur, will have the first house. ‘They came to the camp where I was living and asked who had legal papers to show that they owned land. We did because my father left the property to us. ‘My children are all with my husband’s mother in Leogane and will come back here to live with me when the house is ready. ‘I’m very happy because my house was destroyed, and here I am getting a new one’. So far, Ti Soeur’s house had been demolished, the ground cleared, the new house marked out and the foundations dug and filled ready for building. On the opposite side of the courtyard, another house is being demolished. Here we find Corky and Elizé with a manual stone-crushing machine. They are accompanied by Jean-Claude Hilaire, who wields a large sledge-hammer breaking up pieces of rubble into bits that will fit in the crusher. Broken concrete blocks, they crush into very fine pieces. This is used instead of sand in the concrete mixed for the foundations, floor and for rendering the walls. The reinforced concrete is crushed into larger pieces, which are used as aggregate in new concrete. The men are paid 15 gourdes per bucket, and can grind enough material to fill about 30 buckets a day. The buckets are emptied into sacks; they have filled 20 bags in the last 2 ½ days (4 buckets a bag). They built the prototype house in Meyer 5. The house will be handed over to the community to use as a community centre. Meyer 5 is where we find Iléne and Mirlande. They are busy fixing chicken wire to the flat forms that will be folded to make the ‘gabion’ baskets. Iléne: ‘I am putting chicken wire onto the metal frames and then they close them up and fill them with rubble, and that’s what they use to build these houses. ‘I think these rubble houses are great, and they are much more solid than the ones made of blocks. If another earthquake comes, these houses should be safe. We used to be paid 5$ US a day, but now they pay us 15 gourdes per basket; I can make about 24 baskets a day. Sometimes, like today, my sons and their friends come and help. ‘Before I found this work, I’d find fruit to sell. But it wasn’t real work. Now I can get by because I can buy food for my family. ‘I have no hope because I have no one in the US. As for the country, maybe there is hope, maybe it could change, but it will take a long time as there’s no togetherness.’ Mirlande ‘These will be baskets once they are made up, and I’m fixing the chicken wire onto the frames. It’s hard sometimes because we get scratched by the wires. ‘I do it because they are building homes with them. They pay me 15 gourdes a basket, and I can make about 20 a day and the money helps even though it’s not much. But sometimes my husband finds work. ‘The houses are good because they are very solid.’