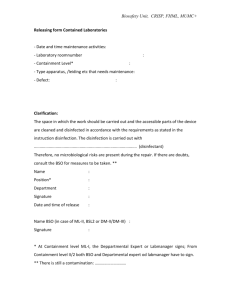

Secondary Containment Post Consultation draft 2011.06.23

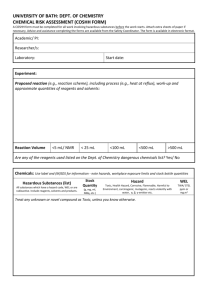

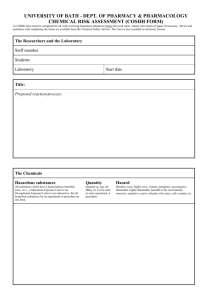

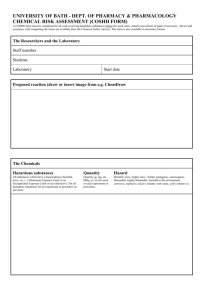

advertisement