Doc 9 - saisc

advertisement

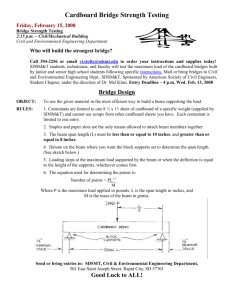

SAFE LOAD TABLES FOR SIMPLE STEEL BEAMS Instructions Look carefully at the two surfaces the ends of the beam will rest on. They must be on the same level (height) and each surface must be level. If there is any doubt about whether the surface might crumble, crack or yield under the load, place something strong like a steel plate or a concrete pad on it. Also make sure that it’s not just the surface that’s strong enough but also the structure underneath it; for example, don’t support a beam on top a wall if there’s a window just below it, or on steel or timber that’s not strong enough. The following organisations can be contacted for advice on the strength of the support structure: Cement and Concrete Institute (http://cnci.org.za) Tel (011) 315 0300 Concrete Manufacturers Association (http://www.cma.org.za) Tel: (011) 805 6742 Measure the distance between the centers of the supports (the ‘span’) in meters. Determine the weight to be supported (including the weight of the chain block) accurately, in kilograms. Use the table to select the beam that can carry the weight for the particular span. The steel beam MUST be made from grade S355JR steel. Obtain a beam that is long enough so that at least 100 mm (10 cm) can lie on the support surface on each side. Place the beam in position. Make a brace from flat steel, a small angle or something similar, and attach it to the top of the beam and to the support surface so that it forms an angle with the vertical (see the sketch). Attach the brace to the support surface and the top of the beam with bolts. (Alternatively, use another approach to ensure that the top of the beam will be prevented from moving sideways, so that the beam will not be able to roll over.) If the weight will hang from the beam as shown in the sketch install the rope or chain by which the weight will be supported. Use the timber block to protect the beam from damage. If the weight is to be placed on top of the beam, provide proper supports to prevent the weight and the top of the beam from moving sideways, or from toppling over. The weight must only be positioned somewhere in the central third of the beam. Apply the weight slowly. If anything looks worrisome, stop and think again. Get advice if you are concerned about anything. Note that heavy weights can be dangerous, especially if they are in a elevated position. You need to be extremely careful, and obey the Occupational Health and Safety Act. This note is not intended to replace the structural engineer. If it is a requirement of the local authority, if there is any complexity, if the load or the span is bigger than in the tables, or if there is any reason for concern – get the services of a qualified structural engineer. BRACE ATTACHED TO TOP OF BEAM AND TO SUPPORT SURFACE TO PREVENT SIDEWAYS MOVEMENT (ROLLING) OF THE TOP OF THE BEAM. HARDWOOD BLOCK TO PROTECT TOP FLANGE. AT LEAST 100 mm OF END OF BEAM TO REST ON HARD, SOLID SURFACE; BOTTOM OF BEAM MUST NOT BE ABLE TO MOVE SIDEWAYS. 2 IPE Sections IPE 100 100 IPE 120 150 IPE 140 250 IPE 160 350 IPE 180 500 IPE 200 650 I-Sections (Parallel Flange) 203x133x25 1 000 254x146x31 1 450 305x102x25 600 305x165x41 2 000 356x171x45 2 000 STRONG ENOUGH ROPE (OR CHAIN) AND HOOK. Maximum Load [kg] Span [m] 3 4 150 200 300 400 650 900 350 1 450 1 550 5 6 400 600 250 400 200 300 950 1 000 650 700 500 550 150 250