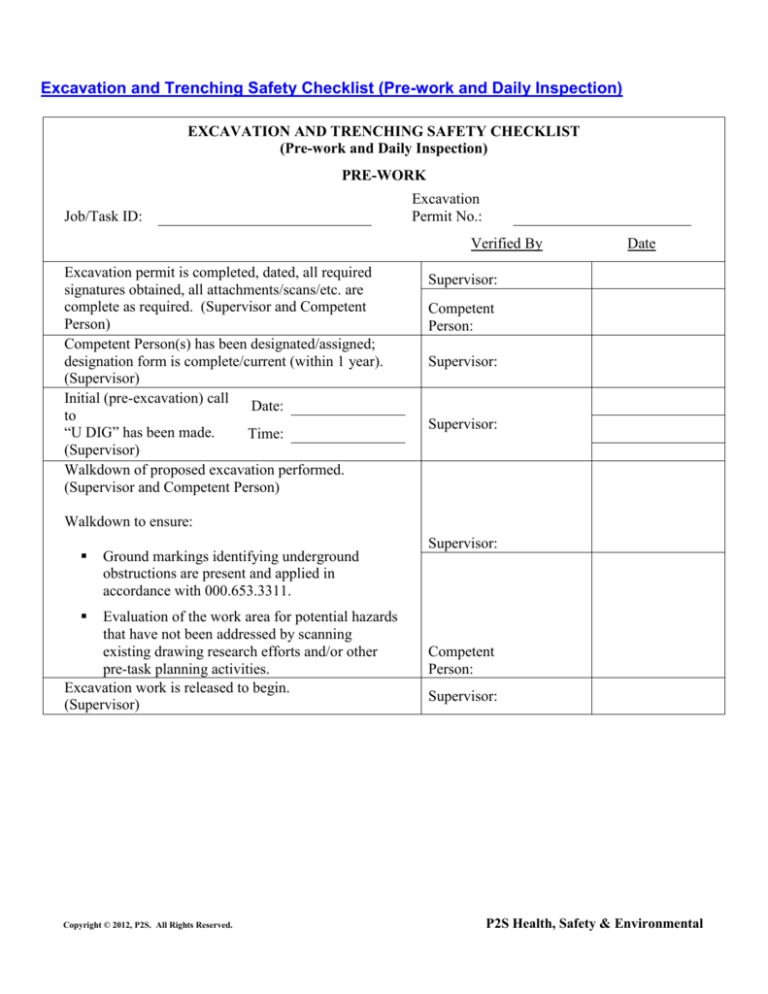

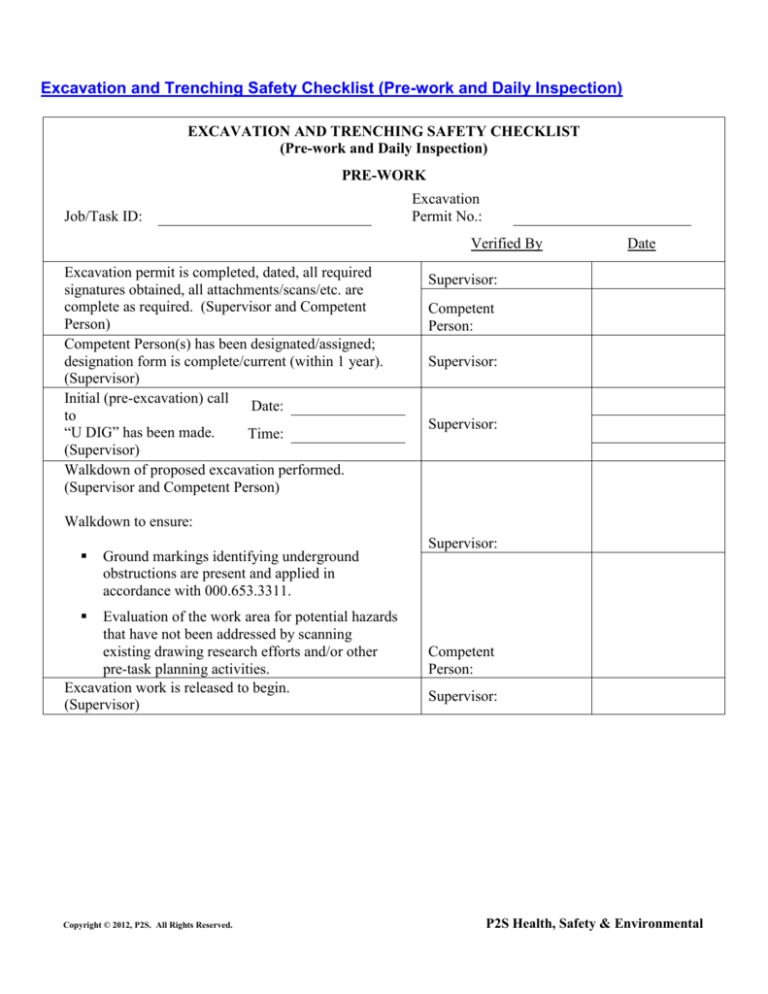

Excavation and Trenching Safety Checklist (Pre-work and Daily Inspection)

EXCAVATION AND TRENCHING SAFETY CHECKLIST

(Pre-work and Daily Inspection)

PRE-WORK

Job/Task ID:

Excavation

Permit No.:

Verified By

Excavation permit is completed, dated, all required

signatures obtained, all attachments/scans/etc. are

complete as required. (Supervisor and Competent

Person)

Competent Person(s) has been designated/assigned;

designation form is complete/current (within 1 year).

(Supervisor)

Initial (pre-excavation) call

Date:

to

“U DIG” has been made.

Time:

(Supervisor)

Walkdown of proposed excavation performed.

(Supervisor and Competent Person)

Date

Supervisor:

Competent

Person:

Supervisor:

Supervisor:

Walkdown to ensure:

Ground markings identifying underground

obstructions are present and applied in

accordance with 000.653.3311.

Supervisor:

Evaluation of the work area for potential hazards

that have not been addressed by scanning

existing drawing research efforts and/or other

pre-task planning activities.

Excavation work is released to begin.

(Supervisor)

Copyright © 2012, P2S. All Rights Reserved.

Competent

Person:

Supervisor:

P2S Health, Safety & Environmental

Excavation and Trenching Permit

Project Name

Project Location

Project No. /Contract No.

Date

Time

Expiration Date

Job Description and Location (be specific)

Before Trenching and Excavation

Soil Classification:

Stable Rock

Check for previously disturbed ground

Type A

Type B

Type C

Adequacy and availability of all equipment, including personal protective

Requirements have been met and required data

recommended

gear, shoring material, signs, barricades, and machinery

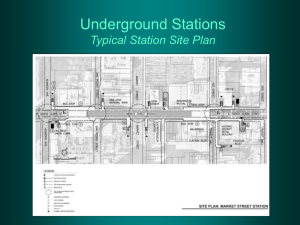

Proximity to utilities, buildings, footings or pilings,

and sources of vibration

Allowable slope

Other known obstructions (such as footing concrete encasements)

Owners of utilities, service, or transmission piping, (electrical,

telephone, water, sewer)

Site of Excavation:

Depth ________ Width ________ Length ________

Changing ground conditions, particularly after rain

fall

Monitor for possible oxygen deficiency or gaseous

conditions

Adequacy of shoring and/or sloping as work progresses

Entrance and Exit Facilities:

Stairway

Ladders

Ramp

Change in vehicular and machinery operation

patterns

Water removal equipment and operation

Adequacy of portable trench boxes or trench

Overhead obstructions reviewed

Protective systems depth of a trench or excavation of 5 feet (1.5 meters) or

more – check the applicable boxes below:

Sloping and benching

Timber shoring for trenches

Aluminum hydraulic shoring for trenching

Alternative to timber shoring

Selection of protective systems

Designed shoring (data must be filed on site)

Note: Sloping or benching for excavations greater than 20 feet

(6.1 meters) deep must be designed by a registered professional

engineer.

Atmospheric testing required

Oxygen

LEL (%)

Yes

Toxics

No

shields

Comments

Approver

Approval Signatures

Date

Competent Person

Electrical

Equipment Operator

Supervisor

Mechanical Engineer

Civil Superintendent

Other Approval if Required by Civil Engineer or

Registered Professional Engineer

Note: All items must be evaluated before start of work.

Copyright © 2012, P2S. All Rights Reserved.

P2S Health, Safety & Environmental