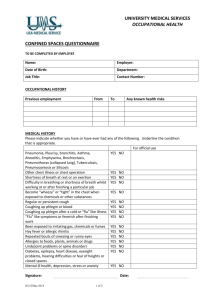

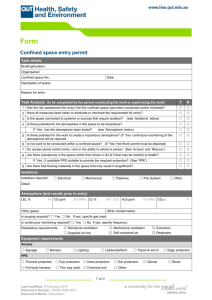

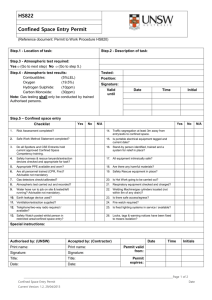

Application of the Permit-Required Confined Spaces Standard

advertisement