Clandestine Drug Laboratory - Attorney

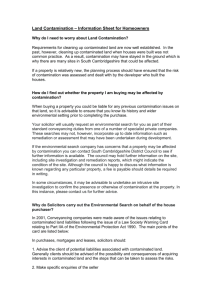

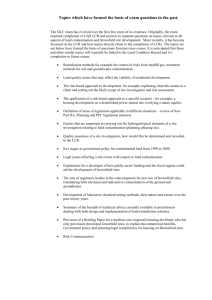

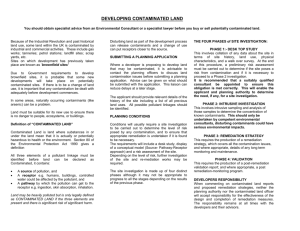

advertisement