Fracture of natural biomaterials - Rutgers University School of

advertisement

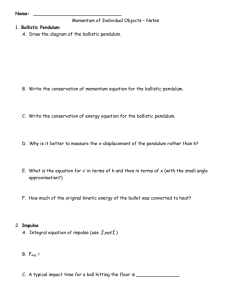

Fracture of natural biomaterials TA Charlie Florek In basement of fiber optics building Department of Biomedical Engineering Rutgers, The State University of New Jersey Safety: 1. Safety glasses must be worn during the impact fracture tests. 2. Use gloves when working with the impact apparatus. 3. Stand well clear of the impact apparatus during operation 4. NEVER stand in front or behind the machine during testing (the front is the direction in which the pendulum swings). [1] Purpose There are two goals to this lab: 1. to understand how materials fracture and how this is related to their microstructure. 2. to relate the concepts of materials fracture to the properties and structure of natural biomaterials. You will examine the surfaces of materials which have undergone brittle and ductile fracture to see the typical morphological features of the fracture surface. You will perform impact fracture tests on a ceramic, wood (across the grain and with the grain) and bone. After completing the experiments you should be able to: Explain how natural biomaterials have evolved to reduce the risk of fracture. Explain why pure ceramics are poor synthetic biomaterials. Estimate the fracture surface energy for a brittle material. [2] Introduction Natural biomaterials such as bone, teeth and wood have evolved to have a complex microstructure which enables them to withstand large mechanical stresses and impacts without fracturing. They are also relatively light and have a high strength to mass ratio. Synthetic biomaterials based on pure polymers, ceramics or metals cannot match the natural materials they replace in terms of strength, fracture resistance and mass. However, composite artificial biomaterials which contain more than one material and have a carefully engineered microstructure can have similar properties to the natural biomaterials they replace. This lab will use a series of impact fracture tests to examine the relative fracture resistance of natural and synthetic materials. The test is loosely based on the standard Charpy impact test for examining brittle and ductile fracture in bulk samples. [3] Apparatus The apparatus is a purpose built impact tester based upon a swinging pendulum (see Fig. 1). The pendulum impacts the test sample at the bottom of its downward swing. The impact breaks the sample and the pendulum continues on its upward swing. Some of the pendulum’s kinetic energy is lost in fracturing the sample and this reduces the height of the pendulum’s upward swing. The length of the upwards swing is found by examining the maximum angle of the pendulum during its upswing. By evaluating the lost energy it is possible to estimate the energy needed to create the fracture surface. pendulum sample Fig. 1: The impact testing apparatus. [4] Experiments: Part A – Fracture Surfaces You have been provided with several samples that have already been fractured. These are: (a) glass microscope slide (b) wood broken across the grain (c) wood broken with the grain (d) ceramic tile (e) rib bone (cooked) You have also been given a short piece of copper tubing which you can fracture by bending it (you may need to bend it several times before it breaks in two). For each of the samples visually examine the fracture surface, then describe and sketch it on pages 1 & 2 of the results sheet (at the end of this document). [5] Experiments: Part B – Impact Tests You have been provided with 8 samples for fracture testing. These are: (a) 3 pieces of ceramic tile (b) 2 pieces of wood across the grain (c) 2 pieces of wood with the grain (d) 1 bone Before you begin you must calibrate the impact tester. This requires you to find the maximum angle of the pendulum on its upward swing when it does not strike a sample. To find this, one of you must lift the pendulum until it is vertical (Fig. 2a). The pendulum is then released and swings downwards and then upwards (Fig. 2b). One of you should be position at the side of the pendulum to visually see how high the pendulum swings. (a) (b) Fig. 2: (a) pendulum at the top of its swing and (b) pendulum at the end of its swing. You should repeat this procedure several times until you are confident that you can assess the correct angle for the end of the pendulum’s swing. Now you can being testing the samples. Test the ceramic tile first, then the wood samples and lastly the bone. It is important that you test the bone last as you only have one sample and you need to be certain that you test it correctly. For each sample place it in the vise with the scratch or groove just above the vise’s jaws and parallel with them. DO NOT over-tighten the jaws as this may fracture the ceramic or bone samples. The correct mounting is shown in Fig. 3. Fig. 3: Correct sample mounting. Now repeat the procedure you used for calibrating the impact testing apparatus. This time the sample will break when the pendulum impacts it. The upward swing of the pendulum should be reduced. Record the angle of the upward swing on page 3 of the results sheet and then complete the other sections of the sheet. The energy lost in fracturing the sample is the maximum potential energy for the upward swing from the calibration minus the maximum potential energy for the upward swing from the sample. [6] After the Experiments Collect all the broken fracture samples and place them in the box provided by the TA. Leave the area tidy for the next group. Make sure you have completed all 3 pages of the results sheets. [7] References Fracture of Brittle Solids (2nd edition) B.R.Lawn (Cambridge University Press) http://www2.umist.ac.uk/material/research/intmic/features/charpy/notes.htm PART A: Results - For each sample sketch and describe the fracture surface. Glass Description:____________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ Wood (across grain) Description:____________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ Wood (with grain) Description:____________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ Ceramic Description:____________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ Bone Description:____________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ Copper Description:____________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ PART B: Results - For each sample enter the maximum angle of the pendulum’s upward swing. Sample Maximum angle (°) Example 156° Maximum Height Energy Lost 0 Calibration 1 0 Calibration 2 0 Calibration 3 0 Calibration 4 0 Calibration 5 0 Example 144° Ceramic 1 Ceramic 2 Ceramic 3 Example 154° Wood with grain 1 Wood with grain 2 Example 138° Wood across grain 1 Wood across grain 2 Example 140° Bone 1 To calculate the maximum height you need the pendulum’s length (76cm). To calculate the energy lost in the impact you need the pendulum’s mass (1 kg) and then you should use the standard method to find gravitational potential energy (PE=mgh). Note that there is slight offset in the pendulum arm of -2 at the bottom of the swing. Example: Maximum angle = 156; Angle at bottom of swing = -2; Total swing length = 158; Maximum height (h) = 0.76[1+sin(158-90)]=1.465 meters; P.E. = 1 x 9.8 x 1.465 = 14.357 joules