Spill Prevention

advertisement

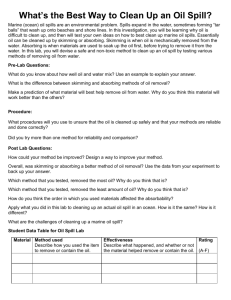

Date: 1/30/2009 Petroleum Management and Spill Clean-up (Suggest instead: Spill Prevention, Preparedness and Clean-Up) Curriculum Primary Author(s): Steve Leppälä Minnesota Pollution Control Agency 218-723-4897 (beginning March 10, 2009: 218-302-6609) steve.leppala@pca.state.mn.us I. Target audience(s) Loggers, maintenance people, mechanics, fuel jobbers, etc. II. Learning Objective(S)/Purpose Impress upon the audience that preventing spills should be their first consideration. Not only will it save time and money required for cleaning up a spill, it also saves money by not losing product and necessary repairs of malfunctioning equipment. Well maintained and regularly inspected equipment is worth the, “ounce of prevention”. No matter how well equipment is maintained, spills will occasionally happen. Being prepared for spills will help to minimize their severity so that cleanup will be less complicated and more effective. Clean-up kits are discussed as helpful preparedness tools. Spill reporting requirements are discussed. Spill cleanup options depending upon the type, volume and site conditions are discussed along with treatment/disposal options for spilled wastes. [Page 90, last bullet, of the FMG book is misleading concerning when you may thin-spread petroleum contaminated soil.] Enforcement for unreported and/or inadequate cleanups are possibilities and may include monetary penalties. Having to remobilize to a site to conduct a cleanup adds to overall costs and land owners may decide to restrict further use of their properties to loggers that leave a mess. III. Presentation Outline A. Prevent spills from occurring. Maintain equipment to prevent failures that could cause spills. Inspect equipment for small drips or spills and worn hoses or parts that may soon fail. Replace worn equipment before failures. Take care when adding or removing products and fuels. B. Be prepared for when spills do occur. Minimize the volume of spills by stopping releases as soon as possible. Capture or contain spills. Catching spills onto drip pans or by using absorbent material will minimize spills to the ground. When a spill is flowing away from a release site, try to contain it with a berm, ditch or absorbent materials. Special care must be taken from petroleum reaching surface waters including streams. When such impacts do occur, floating booms and absorbent pads can be used to contain and collect product and even sheens. Dispersants in surface waters should never be used because they make the petroleum more toxic to the water column. Reporting petroleum spills of 5 gallons or more is required. If the quantity is unknown, there is no problem in reporting estimated volumes. If no assistance is needed, state follow-up is unlikely. Also, the State Duty Officer can connect callers to the MPCA on-call person who can offer cleanup advice and suggestions. C. Cleanup options are discussed. Types of petroleum and their ease of natural degradation is discussed. Gasoline volatilizes quicker than diesel or hydraulic oil. Patches of stained soil can usually be scrapped up and spread on site or even raked and broken up so that natural break down can more quickly occur. Petroleum contaminated soil of 10-cublic yards or less can usually be spread on site. Discussion with the property owner as well site conditions for thin-spreading and ways to maximize the effectiveness of this treatment method is discussed. Absorbent pads and boom that are not completely saturated can usually be let to dry in the sun and reused. Disposal of saturated used absorbent material can usually be handled through the company that receives used oil and other similar wastes. On-site burning of waste from spills is prohibited. D. Enforcement. Spills that were unreported when required or were not adequately cleaned could result in enforcement actions, including penalties, by the Minnesota Pollution Control Agency (MPCA). As part of many enforcement actions, corrective action is often required which would mean returning to the site to conduct an adequate cleanup. Outside of formal MPCA enforcement actions, property owners where messes are left may decide to prohibit further logging contracts on their properties. Also, it is poor public relations to anyone that may come across spills left at logging sites. IV. Discussion Questions Can you afford to waste product from your equipment or containers? What are some ways to prevent spills from occurring in the first place? What are some ways to stop and contain a release? What types of equipment or supplies could you use to minimize the size and extent of a release? What are some ways to cleanup small spills at your site? Who should you call to report a spill or just to ask advice about spill cleanup? Are there any consequences for not conducting a cleanup after a spill? V. Frequently Asked Questions Petroleum comes from the ground in the first place, why worry about spills? In addition to fire hazard and potential human health impacts, spills cause damage to the environment. Petroleum spills could take a very long time to degrade when left in a concentrated form. Spills can impact ground water. Spills that impact surface water can make the water column toxic to biota in the water column. Where can we get rid of waste product that we collect after a spill? Most companies that accept used oil also have that capability to accept used absorbent material. If they don’t, they should know someone who can. VI. Group Activity / Case Studies Let’s say that you have an elevated 55-gallon drum at your site used to store diesel to fuel your equipment. The drum gets knocked over when moving a skidder and the drum starts leaking product down a slope towards a stream. What are some suggestions for preventing this release in the first place? Ways to minimize the amount and extent of the release? What are some suggested for cleanup options? Suggestions may include: better planning regarding where the fuel drum should be located in the first place, i.e. away from traffic areas where it may get hit and away from sensitive or problematic areas (near a slope) if it does tip or fail; make the drum more visible so it is easier to avoid; store spill response equipment near the drum to be better prepared for a release; if flowing down a slope, try to get in front of the flow as soon as possible to contain product with a berm or ditch; if any spill reaches a surface water, try to contain with absorbent or containment boom and collect with absorbent pads. VII. Resources Spill kit, absorbent pads and boom, small containment box, rake, and Duty Officer phone number. VIII. Handouts Cleaning up small petroleum spills http://www.pca.state.mn.us/publications/c-er4-02.pdf Minnesota Duty Officer http://www.pca.state.mn.us/publications/mndutyofficer-poster.pdf Thin-spreading small quantities of petroleum-contaminated soils http://www.pca.state.mn.us/publications/c-er4-04.pdf IX. Facility, field site or other presentation needs Field sites for these presentations should be at the types of areas where fuel storage, product storage and equipment maintenance may typically occur. X. Other