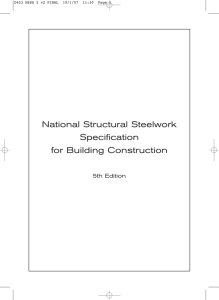

Item 5 - Design Guide - Protection of Steelwork against Corrosion

advertisement

Roads in Hertfordshire: Highway Design Guide 3rd Edition Volume 5 – The Specification for Highway Work Chapter 13 – Protection of Steelwork Against Corrosion (Series 1900) Roads in Hertfordshire: Highway Design Guide 3rd Edition Volume 5 – The Specification for Highway Work Chapter 9 – Kerbs, Footways and Paved Areas (Series 1100) 13. Protection of Steelwork Against Corrosion (Series 1900) 13.1. Appendix 19/5: General Requirements, Protection against Corrosion .............. 2 13.1.1. Road Lighting / Traffic Signs ............................................................................ 2 13.1.2. Traffic Signals and Intelligent Transport Systems ........................................... 2 13.1.3. Highway Structures / Bridges.......................................................................... 3 13.1.4. Surface preparation and protection ............................................................... 3 13.1.5. Quality Assurance ........................................................................................... 3 13.1.6. Required Durability ......................................................................................... 3 13.1.7. Colour .............................................................................................................. 3 1 Roads in Hertfordshire: Highway Design Guide 3rd Edition Volume 5 – The Specification for Highway Work Chapter 9 – Kerbs, Footways and Paved Areas (Series 1100) 13.1. Appendix 19/5: General Requirements, Protection against Corrosion The scheme promoter or designer may propose other protective finishes for approval by HCC. Alternatives will only be considered if sufficient evidence is supplied about the protection and lasting properties of the finish. 13.1.1. Road Lighting / Traffic Signs The contractor should either: Pre-treat galvanised external surface with “T” Wash application to be fully in accordance with Technical Data Sheet (shop applied). Followed by a one coat application of thermoplastic cross-linked copolymer using an in line electrostatic spray to the external surface of the column providing a uniform thickness of not less than 600m with colour to BS4800, 12D45 and 18B29 for conservation areas. Other specific areas may require the final colour and finish to be determined on an individual basis; or Pre-treat galvanised external surface of the column and the internal root to 250mm above ground level with “T” Wash application to be fully in accordance with Technical Data Sheet (shop applied). Followed by the application of: o one coat of two pack micaceous iron oxide Item 121 to the external surface of the column and the internal root to 250mm above ground level minimum dry film thickness 100m (shop applied); o one coat of two pack glass flake epoxy to the external and internal root to 250mm above ground level minimum dry film thickness 200m colour black (shop applied); and o one coat two pack high solid polyurethane finish item 168 to the external surface of the column from ground level minimum dry thickness 50m colour with colour to BS4800, 12D45 and 18B29 for conservation areas. Other specific areas may require the final colour and finish to be determined on an individual basis. All lighting columns shall be packed at contact points for transport and storage to protect the finish. All post top columns shall have a 76.1mm diameter 100mm Plain Spigot unless otherwise specified by the engineer. Strimmer guards to be provided in grass verges when requested by the scheme promoter or designer. 13.1.2. Traffic Signals and Intelligent Transport Systems Steel poles, brackets and all exposed ferrous metal work for traffic signals & ITS works shall be protected against corrosion before leaving the factory by: Hot dipped galvanized (minimum thickness 100 microns) prior to the application of plastic coating; 2 Roads in Hertfordshire: Highway Design Guide 3rd Edition Volume 5 – The Specification for Highway Work Chapter 9 – Kerbs, Footways and Paved Areas (Series 1100) Equipment shall not be supplied with pre-drilled holes for push button units. Once drilled on site, holes shall be de-burred and treated with a suitable zinc rich paint or suitable rust-inhibiting paint as agreed by HCC. 13.1.3. Highway Structures / Bridges Finishes for exposed ferrous metal work on bridges and other highways structures will be agreed during the technical approval procedure. For more information please see Section 2, Chapter 11 Structures and Section 4, Chapter 5 Structures - Detail. 13.1.4. Surface preparation and protection Finishes for bridge steelwork shall be carried out in accordance with: Manual of Contract Documents for Highways Works, Specification for Highway Works, Series 1900. 13.1.5. Quality Assurance All paints to be used on structural steelwork should have a current BBA HAPAS Road and Bridges Certificate or equivalent. 13.1.6. Required Durability The durability requirements will be determined by the exposure condition and accessibility of the steelwork on an individual basis. The minimum durability requirement of applied paint systems will be; maintenance free for 12 years, only minor maintenance required from 12 years and major maintenance after 20 years. 13.1.7. Colour Colours will be agreed from available colours specified in BS4800. The final colour and finish will be determined on an individual basis and will be suitable for the type of structure and location. 3