World Journal of Engineering Introduction Carbon nanotube (CNT

advertisement

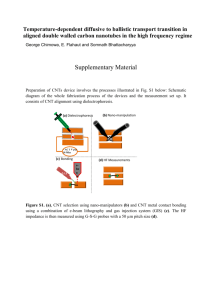

World Journal of Engineering FACILE PREPARATION AND H2 SEPARATION OF MULTIWALLED CARBON NANOTUBE BUCKYPAPER MEMBRANES WITH TUNABLE PORE SIZES Xiaoshuang Yang, Lixiang Yuan, Andrew I. Minett, and Andrew T. Harris School of Chemical and Biomolecular Engineering, University of Sydney, Sydney, Australia (Millipore), washed with deionized water and dried at 110 ºC. Three different sonication durations (5, 10, 15 min) were undertaken to prepare buckypapers with 50 mg CNTs dispersed in 300 ml ethanol. The suspensions were then filter through 0.45 μm PTFE membranes. Buckypapers were peeled off from the PTFE membranes and dried at 110 ºC. Introduction Carbon nanotube (CNT) based membranes have attracted more and more attention and exhibited great potential to a wide range of applications, such as water and gas separation, field emission, and fuel cells [1]. Buckypapers, as the simplest type of CNT membranes, are self-supporting mats of tangled carbon nanotubes held together by van der Waals interactions, and present inherent flexibility within a mechanically stable structure. Buckypapers are usually prepared by filtration of carbon nanotube dispersions in polymer or surfactant solutions. Chemical functionalization, crosslinking and surfactant addition are usually used to assist the CNT dispersion and buckypaper fabrication [2]. In this study, a facile, sufactant-free assembling process was used to prepare multi-walled CNT (MWNT) buckypaper membranes without the aid of cross-linking or functionization. The pore structures and gas permeance of the as-prepared buckypaper membranes were examined. Characterization The as-synthesized and purified CNTs (20.5-97.8%) were examined using thermogravimetric analysis (TGA, TA SDT Q600) and fourier transform infrared spectroscopy (Bruker IFS66V FTIR Spectrometer). The thickness and the fine surface structures of buckypapers were observed by field emission scanning electron microscopy (SEM, Zeiss Ultra plus). 300 pores were selected for each buckypaper sample from the SEM images to calculate the apparent pore sizes using ImageJ software. The pore structures of the as-prepared buckypapers were analyzed by N2 adsorption/desorption measurements obtained at 77K (Quantachrome Autosorb). Experimental Results and Discussion Preparation of multi-walled carbon nanotube buckypapers MWNTs were produced by chemical vapour deposition in a fluidized-bed, under the conditions of 600 ºC, 25% ethylene concentration and 60 min deposition time [3]. The as-produced CNTs were purified using a microwave technique described previously[4]. In a typical purification process, 200 mg of as-synthesized CNTs were added to 20 ml of 5 mol/L sulfuric acid in a sealed, PTFE-lined, microwave transparent pressure vessel. The sample was heated for 20 minutes to 220 ºC (at a rate of 10 ºC/min) in a microwave workstation (MDS-10, Sineo Microwave Technology). The purified products were then filtered through 0.45 μm PTFE membranes A highly efficient purification process was employed to purify the as-produced CNTs, achieving a high purity of 97.8%. FTIR results (not shown here) show that no functional groups were introduced to the CNTs after the microwave-assisted purification process. In order to examine the properties of pure CNT buckypapers and simplify the fabrication process, we avoided introducing any other functional groups or agents to the CNTs. In the fabrication process, sonication time is one of the factors that influence the structure of buckypapers. In current study, Figure 1 shows the CNT dispersion during 5 min sonication time. CNTs did not form buckypaper when they were weakly dispersed in ethanol below 5 min. When the sonication duration was 1265 World Journal of Engineering increased to 10 and 15 min, the CNTs were more dispersed in the solvent and the pore size of the resulting buckypapers increased from 35.3 ± 9.7, to 40.5 ± 9.1, 43.3 ± 11.9 nm, respectively. The porosity also increased from 59.4% to 70.2% and 71.8%. Fig 2. Gas (H2, Ar, C2H4, CO2) fluxes through the as-prepared buckypaper membrane at different pressure difference. Fig 1. CNT dispersions in ethanol after (a) 1min, (b) 3min, (c) 5 min sonication; (d) the as-prepared CNT buckypapers; side (e) and top (f) view and of the as-prepared CNT buckypaper Conclusion Tunable pore-size MWNT Buckypapers were prepared by a facile process of purification, sonication and filtration, without the assistance of surfactants, crosslinking or functionalization. This method enables us to examine the properties of the resultant buckypapers with pure CNTs. The pore structures of the as-prepared buckypaper varied with the sonication duration to disperse CNTs. H2 selectivities over other gases show that the buckypaper membranes can be used as H2 purification membranes. The H2 permeance of the buckypaper membranes prepared by 10 min sonication was obtained by measuring the gas flux through them under different pressure difference at 30 °C. Three other common laboratory gases (Ar, C2H4, CO2) were also tested. For all the gases (H2, Ar, C2H4, CO2), the as-prepared buckypaper exhibited a linear relationship between the flux and the pressure difference, indicating a pressureindependent diffusion in the buckypaper membrane. Based on the pore size of the buckypaper, the gas permeance behavior can be predicted by Knudsen diffusion. However, the gas permeance of the asprepared buckypaper membrane was 2.63 – 3.34 times of that predicted by Knudsen diffusion, suggesting an enhancing effect due to the existence of the CNTs. Several studies have reported that the gas fluxes through the CNT inner channels were 1 – 2 orders of magnitude higher than those predicted by Knudsen diffusion due to the smoothness of the CNT surface. It is likely to suggest that the outside wall of the CNT is capable in providing a smooth surface for fast gas transport similar to the inner wall does. The ideal selectivities of H2 over other gases (SH2/Ar = 4.19, SH2/C2H4 = 3.34, SH2/CO2 = 4.27) were calculated based on the single gas permeance and were found to be similar to those predicted by Knudsen diffusion. Reference 1. Wu Q, Zhu W, Zhang C, Liang Z, Wang B. Study of fire retardant behavior of carbon nanotube membranes and carbon nanofiber paper in carbon fiber reinforced epoxy composites. Carbon, 48 (2010) 1799-1806. 2. Whitby RLD, Fukuda T, Maekawa T, James SL, Mikhalovsky SV. Geometric control and tuneable pore size distribution of buckypaper and buckydiscs. Carbon, 46(2008) 949-956. 3. See CH, MacKenzie KJ, Dunens OM, Harris AT. Multi-parameter optimisation of carbon nanotube synthesis in fluidised-beds. Chem Eng Sci., 64(2009) 3614-2621. 4. Liu J, Dunens OM, Mackenzie KJ, See CH, Harris AT. Postsynthesis microwave treatment to give high-purity multiwalled carbon nanotubes. AlChE J., 54(2008) 3303-3307. 1266