PERSONAL DATA: - curriculum juan carlos carbonell

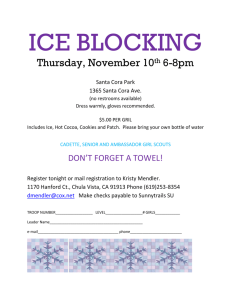

advertisement

Curriculum vitae PERSONAL DATA: Name: Juan Carlos Carbonell Date of Birth: April 8, 1944 Birthplace: Hughes (Pcia de Santa Fe) Nationality: Argentina ID: 6135096 Marital Status: Married E-mail jc@carbonell.com.ar STUDIES: Primary school: 6th grade School Attorney No. 504 Hughes. (Province of Santa Fe) Secondary Title: Mechanic Technician Industrial 40 Rosario. (Province of Santa Fe) COURSES AND SEMINARS: 1 - Conducting staff Training Center Supervisors 13 to 17 August 1977. 2 - Treatment of effluents Centro Argentino de Production Executives May 7, 1978 3 - Mobile Cranes and lifting items Setec 17 to 21 August 1980. 4 - Industrial water treatment Drew Chemical S.A. 1 October 8, 1984. 5 - Steam generation Steam generation Argentine Institute of Industrial Automation 1 to April 5, 1984. 6 - Maintenance of Hydraulic Systems and Pneumatic Argentine Institute of Industrial Automation 15 to July 20, 1984. 7 - Manufacturing and roller coating technology BTR Paper Group 1-2 July 1985. 8 - Training courses in industrial safety years 1972 / 74 Argentina Cement Company Years 1982 / 84 / 85 Alto Parana SA 1995 Defensive Driving Techniques Petrolera San Jorge 1996 Electrical safety Petrolera San Jorge 1998 Safety Course STOP Petrolera Perez Companc 9 - Training course on communication and leadership. 1999. CN SAPAG S.A. 10 - Training Course on Motivation, delegation, teamwork. 1999. CN SAPAG S.A. 11 - Training in maintenance of Caterpillar engines. 1999. MACROSA S.A. 12 - Maintenance of modern machines SEMTEC. November 18, 1996 13 - Course Worcester valves of S. Argentina A. June 18, 1996 14 - Course SKF Industrial Maintenance April 19, 1995 15 - the Embassy of Algeria and Argentina to the participation and technical support in the assembly and operation of the Nuclear Reactor NUR years 1987-88. 16 - Awarded for Petrolera San Jorge by the input mechanical seals where technology allowed lower maintenance costs at the site The Trapial 17 - Look at our leadership. May 16 2005 UPSA Private University of Santa Cruz de la Sierra Bolivia. 18 - Origin and petroleum exploration. May 30 2005 UPSA Universidad Privada de Santa Cruz Bolivia. 19 - Certification of lifting equipment and road machinery. Qualification of 2 operators for oil industry. September 19, 2005 UPSA Universidad Privada de Santa Cruz de Sierra Bolivia. 20 - First aid and CPR r. c. p. October 6, 2005 Servimed Schayman Santa Cruz de la Sierra, Bolivia 21 - Workers in high yield. Leadership and Motivation 5 - May 6, 2006 M. Eng INFOCORP M. Balcazar Santa Cruz de la Sierra, Bolivia 22 - Management of safety, health and environment 15-16 - May 17 2006 Petrolera Chaco SA UPSA Private University Santa Cruz de la Sierra, Bolivia 23 - Operation and design of compressors 6 - June 7, 2006 Hoerbiger Santa Cruz de la Sierra, Bolivia 24 - Skanska Peru in the Cross Training Program 2007 First edition from 15 to 19 October 2007 in Lima, Peru. 25 - Mobil Industrial Lubricants productivity seminar held on 14 to November 16, 2007 in Ciudad de Campana, Argentina. 26 - Peru's Skanska training program Great Boss as Change Advisors. 23.24 and 25 June 2008. Lima Peru. TEACHING: 1 - Training courses for Foguistas and boards Company: Argentina Cement Company Years: 1973-74. 2 - Training courses for supervisors Maintenance Mechanic Company: Alto Paraná S. A. Year: 1986. 3 - Training course for supervisors and mechanics Ammonia and Freon cooling Company: INVAP S.E Years: 1989-90. 4 - Training courses for mechanics Cryogenic Equipment Liquid nitrogen generators Company: INVAP S.E Years: 1989-90. JOB PERFORMANCE: SKANSKA SA of Peru Service Leader From April 2007 to present Service and maintenance of gas compression Petrobras Energía Peru Lot X El Alto - Talara – Peru 3 SKANSKA Bolivia ISSA OIL & GAS Service Leader From June 2003 until March 2007 Gas compression and rotating equipment maintenance deposits Repsol North Zone and Boomerang Block Mamoré HP Total-operated 70,000. SIMA Engineering Neuquén SA Petroleum Services Chief Threshold Yacimiento Ramos Mexia area Neuquén Since 01 April 2001 until May 2003 Operation maintenance and monitoring of new drilling equipment contract with the Geologist of the company. Preliminary work on the drilling teams did their own construction of the locations and placement of guides and their shirts cementation. After drilling all the monitoring and installation of pumps with the assistance of PCP provider Weatherford. The subsequent normal site was made with equipment and staff. The treatment plant design and assembly of our own company and was under my supervision. SIMA Engineering Neuquén SA Petroleum Services Technical Representative Maintenance service in Chevron San Jorge SA Yacimiento The Trapial From January 01 to May 30, 2001 SADE Engineering & Construction Head of Maintenance (contract) Patagonian Marine Terminals SA TERMAP launching services operation and maintenance of terminals in the shipment of oil tankers by monoboya system at sea, Caleta Córdova Chubut, Santa Cruz and Caleta Olivia. Preparation of plans predictive and preventive maintenance of the two terminals. From July 27 2000 to August 27, 2000. Coordinator works delegation NQN Rincon de los Sauces from August 28 until December 28 2000 end of the contract. Weatherford GLOBAL Head of plant compression Yacimientos REPSOL YPF area Rincón de los Sauces. . Lomitas, Desfiladero Bayo, Puesto Molina, Barda Paso, El Volcán, Cerro Bayo and the hammock. 4 Since February 1st 2000 until May 30 2000 Operation and maintenance of alternative engine compressors high pressure gas and electric screw compressors low pressure. Gas treatment plants dehydrated. (TEG.) SAN JORGE PETROLERA S.A. (CHEVRON) Inspector assemblies (contractor). Since April 1 1999 to January 30, 2000. Inspection of motor mounts, dehydrator plant and gas purification plant fuel (Grace Membranes). Montajes general lines, gas and oil pipelines. SIMA Engineering S.A. Neuquén Petroleum Services Head of Maintenance Since: December 1993 to March 1999 Responsible for maintenance services in deposits (San Jorge SA and Trapial confluence), Perez Companc SA (Entre Lomas), San Jorge S.A (Black River North) Maintenance workshops of the firm, light vehicles, roads and cranes. Experience in motor, engine powered by gas explosion. Plant Glicolera moisture separator gas. (TEG.) Treatment plant fuel gas membrane grace. Water treatment plant by reverse osmosis. Sara Marie Foundation Furman (Teleferico Cerro Otto) San Carlos de Bariloche, Rio Black. Middle elevation Chief Technician Since: May 1992 to June 30, 1993 Responsible for the operation, maintenance, mechanical, electrical and electronic equipment. Here we work with several teams of different powers electric motors, speed reducers of various sizes and types. Control system of wind speed (anemometers) with computerized records Individual security cabins through an FM transmission system. Safety measures underway for an emergency system with engine explosion. Other systems very own half lifting of continuous operation. Química Integral S.A. Neuquén (Quinsa) Multipurpose plant chemistry Director assembly From: October 1991-January 1992 Responsible for the mechanical, electrical and instruments. Payre assembly contractor with a total of 90 operators. Working with various elements of a plant of this type. Pipes and containers-316 stainless steel, titanium, steel glass, steel Teflon, 5 FRP, PVC, carbon steel. The various rotating equipment with special seals and materials like pipes and containers. Paintings Epoxi structures and equipment with special treatments at the request of the production areas. Maintenance and services division head From: February 1992 to April 1992 Responsible for the organization and implementation of service areas: steam generation, compressed air, demineralised water, cooling water system with closed circuit cooling tower induced draft, instrument air dryers, nitrogen gas generator by molecular sieve system, fire protection system, systems of primary and secondary thermal fluids, water by aqueduct 10 KM., power transformer, distribution and M.CC., emergency power generation with diesel engine control PLC. Arre maintenance: machine shop and boiler Electrical Workshop and tools (pneumatic and electronic) Maintenance of production and service areas. INVAP S.E. San Carlos de Bariloche, Rio Black. Applied Research Uranium enrichment plant Chief Since: July 1987 to September 1991 Responsible for the operation and maintenance of service areas, Usina diesel generation and distribution transformer of 123 KV power from hydroelectric Alicurá. Industrial refrigeration equipment with freon and ammonia at temperatures from - 40 to - 70 ° c System for process cooling water in closed circuit cooling tower induced draft. Generation system for liquid nitrogen cryogenic distillation separation, saturated steam boilers for process water treatment plant effluents and river. Workshop on maintenance of vehicles and road machinery. Of special machines and laundry contaminated. Attention of the pipeline and internal distribution of the plants that compose the factory compound. In 1988 and 1989 I was sent to oversee the work of assembling a nuclear reactor research sold to the Democratic Socialist Republic of Algeria. As the company sold services to other, I had the responsibility of the maintenance plan for the Complex Teleferico Cerro Otto (Medium Lift) and its regular monitoring of implementation. Alto Parana SA (APSA) Puerto Esperanza, Misiones. Cellulose pulp 2nd Chief of Thermoelectric Power Plant From: April 1980 to October 1983 6 During the play worked as an inspector of the assembly of high pressure boilers Gotaverken, BBC turbine of 40 MW. Hs After the play I took my position and started operations with the launch of the plant and its auxiliaries. Division Chief (Maintenance of mechanical plant) Since: November 1983 to October 1984 By provision of the management was transferred to the maintenance area of the Central Termoelectrica. Responsible for mechanical maintenance plans predicative, preventive and corrective. Coordination and maintenance of electric instruments. Planning of import and domestic parts. Division Chief (Maintenance mechanic production areas) Since: November 1984 to June 1987 By provision of the management was transferred to the maintenance area of the production areas and workshops for heavy machinery, light vehicles, cranes. Responsible for the maintenance of mechanical and hydraulic: digestion, washing, laundry machine, drying and baling (daily production pasta TN 840) Coordinator of the electrical and instrument maintenance. Planning of import and domestic parts. When the import was closed by the government, began the nationalization of the means of engineering developments with national companies, which was affected. Papel Prensa SA San Pedro, Buenos Aires. Paper mill for newspapers Head of support services From: December 1978 to March 1980 During assembly of the plant was responsible for monitoring areas of my responsibility. Staff selection, coaching, training and launching areas: generation of steam and compressed air, water treatment for boilers and process, treatment of industrial effluents and sewage them. Argentina Cement Company (CACP) Olavarria, Buenos Aires. Manufacture of Portland Cement Thermoelectric Power Plant Foreman shift From: February 1970 to March 1971 Responsible for the operation of the plant and shift their auxiliaries Assistant Chief Plant Since: March 1971 to December 1978 Responsible for operation and maintenance of mechanical plant and its auxiliaries, plus the management of all staff. Coordinator of the electrical and instrument maintenance. The plant consisted of five General Electric turbogenerators ten Mellor Goovrin 7 boilers, cooling towers, two water condensers and closed circuit for all the auxiliaries. A sub. Power station in DEBA from 50 Hz to 33 KV power converter Asea rotational frequency of 8 MW. Hs, 4.16 KV, 60 Hz Transformers 5 MVA and 10 Own generation of 21 Mw. Hs Petroquímica Argentina S.A. (PASA) Rosario, Santa Fe Petrochemical industry Petroleum Fellow in a training course of processes of hydrocarbons. From: April 1965 to September 1965 Studies of Inorganic and Organic Chemistry and Hydrocarbons processes. Operator "A" (boards) Since: November 1966 to December 1968 Responsible for taking the time to process the plant section desh Butadiene hydrogenation with commanders on the field operators. Sub - shift supervisor From: January 1969 to January 1970 Responsible for the shift operating section deshidrogenización Butadiene plant. Experience in high-capacity centrifugal compressor driven turbines. Operation and maintenance of gas turbines Westhingouse. Busetti and Fontana Rosario, Santa Fe Manufacture of auto parts Tornero Matricero From: January 1960 to December 1964 Responsible for work of precision and automatic lathes prepared. 8