G Phillips Dissertation MSc REP

advertisement

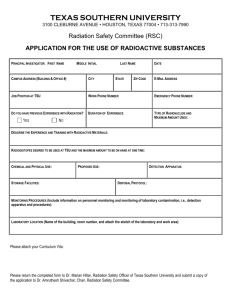

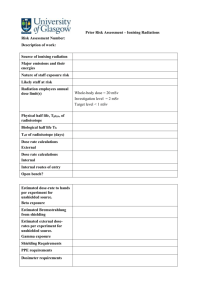

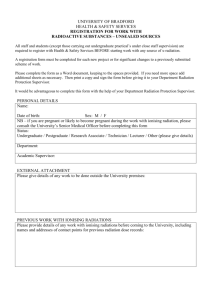

The Identification and Management of Radioactively Luminised Aircraft Components by Georgette Emma Phillips URN: 6045466 A dissertation submitted to the Department of Physics, University of Surrey, in partial fulfilment of the degree of Master of Science in Radiation and Environmental Protection Department of Physics Faculty of Electronics & Physical sciences University of Surrey September 2009 © Georgette Emma Phillips 2009 2 Table of Contents: 1. Abstract 2. Introduction 3. Theory 4. Experimental Method for Detection 5. Results 6. Discussion 7. Conclusions and Summary 8. Acknowledgements and References Annex A: Prior Risk Assessment for Radium Luminised Components Annex B: Prior Risk Assessment for Tritium Luminised Components Annex C: Local Rules for Aircraft Components Containing Radioactive Materials 1. Abstract Industry operating with radioactive materials is legally obliged to manage the company’s sources under the Radioactive Substance Act 1993(1), and is to ensure staff safety by adhering to the conditions of the Ionising Radiation Regulations 1999(2). In order for a company to fully ensure compliance and fulfil their staff safety obligations, a company must be able to account for their holdings and manage them appropriately. Only when the holdings are accounted for and their location confirmed, can a company manage the staff interaction with those radioactive materials. This Dissertation investigates the issues associated with the identification of radioactively luminised aircraft components, and the isotopes investigated are tritium (H3) and radium by comparing the performance of a Mini900 with an EP15 probe, 3 which is of Geiger Muller design, and a Mini900 with a 44b probe, which is a scintillation probe. This report will show that for H3, via Bremsstrahlung and in the right conditions, an EP15 Geiger-Muller tube, which is designed to identify the presence of particulate radiations, will out perform the 44b scintillation probe, which is specifically designed to identify the presence of x-rays (the by product of Bremsstrahlung). This report will also show that both probes could be utilised to identify the presence of radium. 2. Introduction Aircraft instrumentation has been luminised since the 1920’s so that Aircrew could fully understand the situation of their, now unsophisticated aircraft, in low lighting conditions. Instruments were originally luminised by the use of radium being mixed with a phosphorescent paint and then applied by hand, to the face of each dial. Little was known about the biological effects of radiation at the time, which meant that few resources were allocated to radiation safety. After symptoms such as bone growths, soft tissue growths and tooth loss were identified within in the workforce, an investigation ensued, confirming that direct interaction with the radium luminised paint caused ill health to workers. In the early 1970’s western aircraft instrument manufacturers moved towards the use of tritium in place of radium, as the process could be automated which greatly reduced the biological hazards of working with radioactive materials thereby decreasing an individuals’ radiation dose levels. 4 In more modern aircraft, some instrumentation still requires independent illumination so that, in the event of an emergency, the pilot and aircrew do not have to solely rely on the aircraft power to illuminate certain dials and the emergency exits. With this in mind, instrument manufacturers have now moved on to utilising non radioactive illumination methods, but companies involved in the use of aging aircraft for test and evaluation will inevitably come across radium and tritium luminised components and instrumentation, either in flying the aircraft, aircraft servicing or in the logistical management of the fleet components. This report investigates the issues associated with identifying legacy instruments containing radium and gaseous tritium, by the use of ‘in-situ’ monitoring, and will be looking into the management systems that would be appropriate for adherence to the Radioactive Substances Act 1993(1) (RSA93), and the Ionising Radiation Regulations 1999(2) (IRR99). Radium luminised dials are effectively sealed sources whilst the bezel (glass front) remains in place and undamaged, however, the radium paint is aging and thereby ‘flaking’, meaning that contamination issues can arise, if the instrument is opened up for servicing (thereby making the dial an open source). Radium 226 is an alpha/gamma emitter, decaying to the daughter product of the gaseous Radon 222. The alpha from the radium is shielded by the bezel for a complete instrument, but dose assessment should be undertaken for the gamma. The tritium utilised in aircraft instrumentation is in a gaseous form enveloped within a glass capsule. Tritium emits a low energy beta that interacts with a phosphorescent 5 paint. The phosphor in the paint is energised by the beta bombardment, thereby making the instrument detail visible in low lighting levels. Unlike the radium, if an H3 luminised instrument is broken, the area can be ventilated and the workforce evacuated to return after the radioactive gas has dissipated (usually one hour). In the event of a radium luminised instrument breaking, then a Radiation Protection Supervisor should be on hand, and fully trained, in decontamination and disposal procedures. A radiation employer cannot manage any of the above, if they do not understand where the radioactive holdings are, and which staff interact with them, so a radiation employer must have a way of identifying which items contain radioactive materials, and indeed, what radioactive materials are involved. The experiment within this report may at first glance seem very basic, however, it investigates a ‘real world’ problem, as the monitoring must be undertaken on aircraft or in workshops, meaning space is limited and the equipment is be hand held. Also airworthiness requirements must be considered before moving, altering or placing signage on any aircraft instrumentation. This experiment utilises two common ‘insitu’ hand held contamination monitors, a Mini900 with an EP15 GM probe and a Mini900 with a 44b scintillation probe, to attempt to identify if radioactive materials are present, and if so, which isotopes they may be. For radium, one would expect a distinctly positive result due to the gamma emission, however, tritium is much more difficult to identify, as the beta is shielded within the glass envelope, this means that monitoring must be undertaken in such a way so as to identify the presence of Bremsstrahlung. 6 3. Theory Management of Radio Nuclides There are two main pieces of legislation that must be considered before a company allows radioactive materials on to its non nuclear site. The Radioactive Substances Act 1993 (RSA93)(1) and the Ionising Radiation Regulations 1999(2) (IRR99). The RSA93 considers the use, management and disposal of radio nuclides whilst the IRR99 considers staff interaction and environmental conditions when working with radioactive materials, and is a regulation under the Health and Safety at Work Act 1974. Radioactive Substances Act 1993 Under the RSA93(1) most radio nuclides require a Registration from the Environment Agency (EA) to allow the company to hold and manage those radio nuclides identified within the Registration application, however, there are some exemptions under the RSA93 and tritium in a Gaseous Tritium Light Device (GTLD) can be held under the Statutory Instrument 1985 No.1047 The Radioactive Substances (Gaseous Tritium Light Devices) Exemption Order 1985(3) – as long as the Exemption Orders’ conditions are met. Ionising Radiation Regulations 1999 Under the IRR99 Approved Code of Practice (ACOP)(2), Radiation Employers are required to consider provision of a Radiation Protection Advisor, provision of Radiation Protection Supervisors, engineering controls, written procedures, area designation, monitoring requirements, staff engagement and awareness, training and Personal Protective Equipment (PPE) – all of which is geared towards keeping the potential dose to a worker As Low As Reasonably Practicable (ALARP) (2). 7 Radium 226 Radium 226 has a half life of 1600 years and has an interesting daughter series (considering to Polonium 210) (4). The example decay series is as follows: Ra226 – α → Rn222 - α → Po218 - α → Pb214 – β → Bi 214 – β → Po214 – α → Pb210 – β → Bi210 – β → Po210. Where: Ra: Radium, Rn: Radon, Po: Polonium, Pb: Lead and Bi: Bismuth. α is the nucleus ejecting 2 p and 2 n; where p = proton n = neutron, thereby reducing the atomic number by two and the atomic mass by four – hence Ra226 becomes Rn222. β is the action n = p + β- + v; where n = neutron, p = proton, β- = beta and v = neutrino. Meaning that the atomic number reduces by one, but the atomic mass remains the same i.e. Pb210 becomes Bi210. Usually the travel distance of α at STP is a few centimetres and β- particles a few meters, however, α has a radiation quality factor of 20 and although can be shielded by a layer of dead skin, can have a relatively significant biological effect if inhaled, ingested or injected into soft tissue, so the short travel distance should not distract from careful decontamination considerations. 8 Tritium Tritium, or H3, is an isotone of hydrogen as it has one proton and two neutrons. The decay mode is via: n = p + β- + v Where n = neutron, p = proton, β- = beta and v = neutrino. H3 has a half life of approximately 12.33 years and emits 100% β- at and energy of 0.019 MeV. As the energy emission is low, it is not unusual for tritiated instruments to contain Mega Bequerels (MBq) of radioactivity (where one Bq is one atomic decay per second). Usually the travel distance of a β- particle can be meters, however, as the gaseous H3 is contained within a glass capsule and the β- energy is low, the glass capsule tends to shield the β- emission. β- has a radiation quality factor of 1 due to its low linear energy transfer and tritium does not have any radioactive daughter products. Exposure and Biological Hazards Radium As stated earlier, radium is an alpha/gamma emitter. Alpha has a short travel distance at STP but has the largest radiation quality factor. This quality factor is due to the alphas’ energy being in the MeV range and its’ energy curve looking something like Diagram 1. 9 Diagram 1: Example Alpha Energy Curve α track Energy MeV Travel It can be seen from Diagram 1 that the alpha particle is either travelling with energy in the MeV range, or it is coming to a sudden stop due to the rapid loss of energy. Exposure to alpha radiation carries the most risk when the particle interacts with soft tissue. This may be caused by inhalation directly into the lung tissue, ingestion into the digestive system, injection, or by absorption through the skin. The Health Protection Agency has undertaken a number of studies on animals, so as to ascertain the biological effects of acute and chronic exposure to varying radiations, and along with cohort studies, have managed to confirm that alpha radiation can cause single or double strand breakages within the cells deoxyribonucleic acid (DNA) structure, which is contained within the nucleus of the cell. DNA is a ladder like structure of sugar phosphate backbone held together by hydrogen bonds – the ‘rung’ of the ladder if you like. At each end of one of these bonds is either (T)hymine, (A)denine, (C)ytosine or (G)uanine – arranged in base pairs so as to compliment each other. The complimentary base pairing arrangements confirm the purpose of the cell i.e. whether the cell is a hair cell or liver cell etc. 10 When the complimentary base pairing has been disrupted, the cell can either remain unaffected, be affected but attempt to recover, or die – depending on whether the alpha particle has caused a single or double strand breakage within the cells DNA. Illustration 1: Example of DNA Strand Breakage For the purposes of this example, alpha would be considered a heavy ion, and it is therefore the heavy ion track that should be of note in illustration 1. It can be seen that direct interaction between the alpha and the sugarphosphate backbone has caused a double strand breakage, meaning that when the DNA unwinds itself for replication, information will be lost regarding complimentary base pairing – therefore the DNA may attempt to replicate, but where information is lost, it will assume pairings. 11 Illustration 2: Example of Healthy DNA Replication It can be seen from Illustration 2 that the complimentary base pairing in the healthy replication process keeps continuity through the daughter strands: T–A, G–C, C-G, AT etc. Where an interaction between alpha and the DNA may have caused a single or double strand breakage, the cell may choose to pair T with C, G with A and so on, potentially causing the cell to die or causing the cell to mutate – thereby causing biological affects in either the individual exposed, or their future offspring. Tritum Generally there are few hazards associated with gaseous H3 whilst it is encapsulated within the glass, however, the following considerations should be made: Undamaged capsule: under Regulation 27 of the IRR99(2) wipe tests are not usually considered appropriate where the source contains solely gaseous radioactive 12 materials, however leaching of H3 through the glass can occur and the H3 can ‘plate out’ onto nearby surfaces. Therefore, it is deemed best practice to wipe test areas associated with the storage of tritiated components. Bremsstrahlung (discussed later in this section) does occur but is considered to have a very low risk of significant dose. Damaged capsule: the gaseous H3 will escape and there are three potential opportunities for biological exposure. Inhalation: Direct inhalation of the gaseous tritium leaking from the broken instrument, affecting both ground and air crew dependant on where and when the breakage occurs. Absorption: Aircraft cockpits and flight decks are confined areas and there is often a degree of condensation in the air, from the breath of aircrew and via the changes of temperature within the airframe due to altitude. This condensation increases the potential for the gaseous H3 to join any available water molecules in the air, thereby introducing H3 in liquid form which can be absorbed by the body. Ingestion: As the tritiated condensation settles on the aircraft surfaces and evaporates, the H3 can become an ingestion issue as there will be a residual contaminated ‘dust’. This contaminated dust presents a biological hazard to both ground and air crew via handling the aircraft and then not washing their hands. 13 Beta has a radiation quality factor of 1 and can penetrate skin up to 50 microns, however, if interacting with soft tissue, via ingestion, inhalation or absorption, then as can be seen in Illustration 1 (via the x-ray track, which also has a radiation quality factor of 1), the hydrogen bonds between the complimentary base pairings can be affected. Again causing the cell to either be unaffected, die, or affected but attempting recovery. Bremsstrahlung: Bremsstrahlung was discovered by a German scientist called Nikola Tesla in the late 1800’s. The German word Bremsstrahlung literally means ‘braking radiation’ and can be explained as the energy transfer from a β- particle slowing rapidly within an atoms electron cloud, where the energy of the deceleration converts into an x-ray photon emission. These x-rays are a secondary radiation whose x-ray energies are limited to those energies associated with the originating β- radiation and the relative size of the electron cloud it interacts with. An example of this can be seen in generic β- shielding choices within industry, for instance: One would expect to see aluminium or Perspex utilised as the shielding material, due to the low atomic mass, and therefore relatively small electron clouds for the beta to interact with, however, if a higher atomic mass materials were used, such as lead, then one would expect to a greater Bremsstrahlung effect, meaning that the radiation employer may be simply exchanging the beta hazard for an x-ray hazard. 14 Gaseous tritium is a pure β- emitter and, as stated earlier, is enveloped within a glass capsule. The β- is shielded by the glass but Bremsstrahlung does occur. This means that when attempting to identify whether H3 is present in an instrument, the surveyor should consider attempting to identify the presence of x-rays rather than β-. Diagram 2: Example of Bremsstrahlung Originating β- Particle X-ray emission through Bremsstrahlung Nucleus Electron Cloud Slowed β- Assessing Dose It is important to understand potential dose in varying scenarios, so as to ascertain which engineering and administrative controls would be required to undertake the activity, whilst keeping doses as low as reasonable practicable (ALARP), as required under the Ionising Radiation Regulations 1999(2). Biological exposure, i.e. dose, is dependant on the activity of the source, the length of time an individual is exposed, organs exposed, radiation weighting factor and the amount of radionuclide ingested, injected, inhaled or absorbed. 15 Exposure can be assessed as follows: Dose = dose rate x time. Equivalent Dose: The measure of biological effects in seiverts (Sv), where; Equivalent Dose (Sv) = *absorbed dose x radiation quality factor *Absorbed dose is the energy deposited in a medium, measured in Gray (Gy). 1Gy is equal to 1Joule of energy per kilogram of medium. Effective Dose: The effects of radiation on each tissue within the body, where; Effective Dose (Sv) = absorbed dose x radiation quality factor x tissue weighting factor The tissue weighting factor is an important consideration as differing body tissues have different sensitivities to radiation. i.e skin is less sensitive to β- than the lungs, therefore this equation should be undertaken for each organ and the totals collated for the total effective dose. When specifically considering internal dose to H3, one should refer to Annex III of Directive 96/29/Euratom for the radionuclide specific 50year total committed dose figures. General dose limits are set by the Health and Safety Executive (HSE), derived from information provided by the International Commission of Radiological Protection (Publication 103), Euratom and the Health Protection Agency. The HSE have deemed that 20mSv per annum or 100mSv averaged over 5 years, are limits that should not be exceeded. The effects of an exposure can be deterministic – whereby there is a threshold at which effects will be realised, or stochastic, whereby risk increases with dose. See Diagram 3: Dose/Risk Graph for Deterministic and Stochastic Effects. 16 Diagram 3: Dose/Risk Graph for Deterministic and Stochastic Effects Dose Dose Risk Risk Deterministic Effects Stochastic Effects Monitors For the purpose of this experiment, an EP15 GM Probe and 42a and 44b Scintillation Probes will be utilised and compared in their potential to identify the presence of tritium. A brief description of how they operate is as follows; Diagram 4: The Geiger Muller Tube (EP15 Probe) +Ion -Ion X,α β Pulse sent to Mini 900 Monitor for CPS readout Gas filed tube Anode + Mica window Cathode - 17 It can be seen from Diagram 4 that the ionising radiation primarily enters the GM Tube through the Mica window, although photon radiations can also enter through the metal walls of the probe. Once inside the Tube the incident particles, along with the applied voltage, ionise the gas giving rise to further ionisation via a Townsend Avalanche. As only one ionisation within the gas can set off an avalanche, a quenching agent, such as argon, is added to avoid internal related avalanches. The ions move towards the anode and cathode – with the positive ions moving to the cathode (negative charge) and the smaller negative ions moving more swiftly towards the anode (positively charged). The negative ions collect on the positively charged anode and the two opposing charges cancel each other out – creating a ‘pulse’. It is the number of ‘pulses’ detected that creates the Counts per Second (CPS) reading on the monitor. It is worth noting that the negative ions move more rapidly than the positive ions, therefore the slow moving positive ions act to attract negative ions at the anode, effectively making the positive charge around the anode greater than the original anode itself. Another consideration for the GM tube is dead-time. This is the time that the counter is not counting pulses whilst the anode recharges itself, after a pulse. 18 The Scintillation detector operates as follows; Diagram 5: The Scintillation Detector (44b) Reflector Dynode (+) Output Sensor Xγ Photo Cathode (-) Beryllium Shield Amplified Signal Photo Multiplier tube Scintillant It can be seen from Diagram 5 that the incident radiation (in this case x ray or gamma, as alpha and beta are shielded by the beryllium shield) penetrates the light shield and reacts with the scintillant, giving off small ‘sparkles’ of light into the reflector. The reflector reflects the light towards the photo cathode which interacts with the light to produce e-. The e- move up the photo multiplier tube, gaining in multiplication as the e- interact with each dynode, eventually reaching the output sensor, which then sends the signal strength to the monitor for the cps readout. Due to the design, the scintillation probe does not suffer any dead time. 19 4. Experimental Method – For Detection There was no eating, drinking or smoking in the work area and gloves were worn, where dexterity was not impaired. Each monitoring instruments calibration was confirmed by its certification and by the pre-use calibration check, using a Sr90 check source, then five known radioactively luminised aircraft components were selected for monitoring. The radium luminised items selected for monitoring were oxygen gauge and emergency light switch and the tritium luminised items selected for monitoring were a compass, fuel gauge and emergency exit handle. A background reading was taken from each probe and then each aircraft instrument was placed individually on a workbench and was monitored firstly with the EP15 GM probe at contact to the bezel, and then with the 44b scintillation probe at contact to the bezel. The results can be seen in Section 5 – Results. 5. Results The results from the monitoring experiment are shown in Table 1: Results from Monitoring Experiment. Table 1: Results from Monitoring Experiment. Nuclide Mini 900 with EP15 Probe (error: +/-30%) Mini 900 with 44b Probe (error: +/-30%) n/a 2cps 20cps Radium226 1500cps 1600cps Compass H3 8cps 20cps Fuel Gauge Emergency Light Switch Emergency Exit Handle H3 6cps 22cps Radium226 450cps 500cps H3 7cps 20cps Background Oxygen Gauge 20 6. Discussion Experimental Method The experiment itself was very basic, however, the issue is a realistic one and the experiment was designed to reflect the issues genuinely faced by radiation employers working with older aircraft components. Identification of radioactively luminised instruments is important because if the radiation employer does not understand that it is holding radioactive materials then they are not in a position to manage the items or the staff safety, appropriately. Monitoring usually takes place in-situ and is undertaken with hand held instruments in a non-laboratory environment, therefore the monitoring equipment available is limited. Both monitors are available from Thermo Fischer and are used widely within industry. The age of the components tested was unknown, as was the age of the luminising material, and therefore the number of half lives undergone by the H3 could be as many as three – meaning that the activities could have dropped from MBq to KBq. This drop in activity would mean less opportunity for Bremsstrahlung to occur, making the presence of H3 more difficult to detect due to the Bremsstrahlung photon emission falling close to background. In other situations a radiation employer may wish to put shielding in place, to reduce the output of the radium luminised instruments, however, due to airworthiness 21 constraints, additional shielding is not appropriate, therefore staff interaction must be assessed for dose rate (Sv/hr). Results Alpha and beta radiations cannot penetrate the beryllium window of the 44b, therefore it is a photon monitor, detecting radiation through scintillation. It can be seen from Table 1: Results from Monitoring Experiment, that the 44b cps did not rise significantly when the probe was used to monitor the known tritiated components. The probe may not have detected the low energy x-rays of Bremsstrahlung due to either: The low energy x-rays were ‘hidden’ in the probes background detection due to the probes ‘current’ being detected in place of radiation, thereby raising the probes apparent background detection; The 44b may not have registered the Bremsstrahlung x-rays due to its calibration being set to identify photons at higher energies. The EP15 probe does register a slight rise in cps when used to monitor for H3. This could be due to an extremely low background reading and therefore any change in the environment might be registered. Even though the EP15 probe is designed to be sensitive to particulate radiations, it has proven to be sensitive to a large photon energy range and therefore may be capable of registering the low energy photons given by Bremsstrahlung. 22 The radium luminised aircraft instruments gave very positive findings for both monitors, with the 44b being slightly more sensitive than the EP15. The positive readings may be from the higher gamma output from the nucleus, emitted as the alpha particles are ejected and the nucleus then rearranges itself. From experience, the EP15 is known to ‘over read’ gamma so I would have expected the EP15 to have higher counts per second, however, being a GM probe it does suffer from a dead time of approximately 1/10th of a second. With the dead time factored in, the corrected readings would be greater than that of the 44b probe. The 44b probe may have responded so positively to the radium due to the gamma being in an energy range of low MeV, which is closer to its calibrated range of high keV for the original design of x-ray monitoring. Errors: It is worth considering that the monitor calibration has the potential to be +/- 30% due to the instrument calibration service having to calibrate within 10% range (on an annual basis), and daily checks being acceptable if the instrument operates within 20% of the calibration information. This means that there is a potential 60% latitude in monitor performance. An explanation for this allowable latitude could be due to the random nature of ionising radiation – as the radioactive decay is not a true constant. 23 The +/- 30% on calibrated performance is in addition to the dead time experienced by the GM Probe whilst the anode recharges after the negative ions negate the positive charge. Dead time can be in the order of 1/10th of a second, every second. Bremsstrahlung This event could be easier to find if the H3 has not been through many half lives as there would be more beta activity to interact with the atomic structure of the glass capsule. Particular attention should be paid to Bremsstrahlung when considering shielding materials for other radio nuclides emitting beta radiation, either directly, or via the daughter products. Therefore, when considering shielding materials for beta particles, one should select a material with a low atomic mass – such as Perspex or Aluminium. Management of Radionuclides A company must first decide if the use of radio nuclides is justified or if an alternative is available. In this case the instruments, for airworthiness reasons, are specific to the aging aircraft and must be managed under the Radioactive Substances Act 1993(1). Exemption No.1047 Gaseous Tritium Light Devices(3), states that articles falling within the ‘Class C Article’ (articles which are installed, awaiting installation in (i) a vessel or aircraft; or (ii) a vehicle or equipment used or intended solely for use by the armed forces of the Crown) can be held by a company provided that the following conditions are met. Some of the conditions are as follows: 24 No Class C article awaiting installation is stored on the premises for more than one month. Class C articles are marked with the word ‘radioactive’, have the trefoil symbol, state the activity when received, state the manner in which the article will be disposed of. Records of movements are kept for 6 years. All reasonable practicable steps are taken to prevent loss, damage or theft. As a result of damage, tritium gas is dispersed by means of ventilation. Articles are disposed of under Section 4 of the Order. The above means that companies must put in place management systems and a supervisor to ensure the Exemption Order conditions are adhered to. Some of these management systems might be: Stock rotation and secure storage. A supervisor being formally delegated to ensure correct signage, and that muster logs contain the relevant amount of information and are retained for the correct period. Awareness is raised regarding the procedure for damage to the article, in order for staff to ensure sufficient ventilation of the affected area. Management of radium must be undertaken by specific registration with the Environment Agency (EA). If the application for registration is accepted, then the EA will issue a bespoke registration, which is a legal contract between the radiation 25 employer and the EA, outlining the accounting requirements, record keeping and use of the equipment. Disposal or radium luminised aircraft equipment can only be undertaken when the EA has issued an authorisation for the user to accumulate and dispose of radioactive waste. Interesting contradictions can arise regarding following the law and ethical behaviour towards the environment when considering the disposal of radium luminised aircraft components. The specific activity (activity to weight - Bq/kg) of the item for disposal must be declared to the radiation waste management company employed for the disposal, and the company disposing of radioactive materials is ethically obliged to keep the volume of radioactive waste to a minimum, due to land constraints. A radium luminised dial is made of many components meaning that the specific activity for the entire item can be relatively low, however, it is generally only the dial face, needle and bezel that are affected by the radionuclide, so an argument (if deemed safe via a Prior Risk Assessment) can be made to reduce the volume of the item for disposal by removing the unaffected components. This action would increase the specific activity due to the overall weight of the item being less, with the activity remaining the same. Therefore, a balance must be struck between the specific activity requirements of the EA authorisation and the volume of the item for disposal. 26 Ionising Radiation Regulations 1999 Under the IRR99 Approved Code of Practice (ACOP)(2), Radiation Employers are required to consider provision of a Radiation Protection Advisor (RPA), provision of Radiation Protection Supervisors (RPS), engineering controls, written procedures, area designation, monitoring requirements, staff engagement and awareness, training and Personal Protective Equipment (PPE) – all of which are geared towards keeping the potential dose to a worker As Low As Reasonably Practicable (ALARP). Radiation Protection Advisor (RPA) – IRR99 Regulation 13(2): A competent individual possessing the specific knowledge and experience to advise a radiation employer on the observance of the IRR99. This includes PRA content, Local Rule content, engineering controls, designation of areas, competency of RPS, monitoring and surveys, record keeping, signage, storage conditions, justification, optimisation and ALARP dose to staff. *It should be noted that an RPA advises on the IRR99 only and it is the company’s responsibility to ensure adherence to the RSA93 or any Exemptions there under. Radiation Protection Supervisor (RPS) – IRR99 Regulation 17(2): A company shall designate a number of RPS’s to undertake the safe management of articles containing radioactive materials, and these RPS’s shall be identified in the Local Rules. An RPS is to be in a suitable position within the company to influence staff behaviour and to liaise with senior management. 27 The role of an RPS is to manage and undertake the following: Correct designation of areas. Local Rules are up to date, relevant and communicated to the staff. Dosimetry is available to Classified Workers, via the Approved Dosimetry Service (ADS), and any dose received is communicated. Monitors are appropriate and calibrated. Surveys and wipe tests are undertaken of work and storage areas. Area designation is appropriate. Articles are accounted for. Correct and appropriate signage for both the articles and the working areas. Know what to do in the event of breakage, loss or theft. Liaise closely with the RPA, staff and senior management. Know and understand the work activities at hand. Be able to provide evidence of competency. When an RPS is delegated to manage radium and tritium luminised components or instruments, their main considerations may be: Engineering controls: IRR99 Regulations 8&10(2): Engineering controls are the first tier of radiation safety. Controls must be utilised where reasonably practicable i.e. cost verses risk reduction. If it is deemed that the cost can be absorbed by the company, and reduces the risk sufficiently, then engineering controls should be utilised to reduce the potential risk of 28 dose to workers. These controls may take the form of additional ventilation, fire management systems, secure storage, or an equipment upgrade. When working with gaseous H3, the most important engineering controls are ventilation in secure storage and fire management systems in work areas and although most of the instruments containing H3 are over 12.33 years old, and have therefore expended at least one half life but these instruments can start with MBq of activity, so consideration must still be given to their content. When considering the management of radium, the RPS must be confident of any dose assessments so as to monitor staff interaction time, and must be confident that no leakage is occurring, by the initiation of wipe tests on the bezel, and must also be confident of what actions to take in the event of a breakage. Administrative controls: General administration controls are in place when a PRA is written, Local Rules are made available and communicated, signage is on both the item and the store, monitoring is undertaken and findings logged, muster log kept up to date and available for the period outlined within the Exemption Order or EA registration, proof of competency, decontamination procedure and disposal procedures. Written procedures: A procedure known as the Prior Risk Assessment must be written before any radionuclide is brought into the workplace. Once the risks are identified in the PRA and mitigated to an ALARP dose through engineering controls or via 29 administration and training, then the company must ensure Local Rules are available to all staff working with ionising radiation. Content for a PRA – IRR99 Regulation 7(2): A PRA is designed to outline the potential worst case scenario of dose and to identify the daily usual occupational dose – if all of the engineering controls and administrative controls are in place. The object is then to go through the thought process of reducing risk by identifying potential solutions to the scenarios raised. A PRA should consider the following(2): Nature of Ionising Radiation Estimated Radiation Dose Rates Likelihood of Contamination Results of Previous Dose Assessment and Survey Advice from Manufacturer/Supplier Engineering Control Measures and Design Features in Place and Planned Planned Systems of Work Estimated Levels of Airborne/Surface Contamination Effectiveness and Suitability of PPE Extent of Unrestricted Access to Working Areas Possible Accident Scenarios Consequences of Possible Failure of Control Measures Preventative Action Measures and Consequence Limitation The PRA can be a lengthy document as the radiation employer and RPA must consider the impact and risk mitigation for every potential risk scenario identified. 30 A full PRA for radium is included in Annex A and a full PRA for Tritium is included in Annex B, but the main points to note when assessing the risks associated with articles containing Tritium are: Areas where a breakage may occur, such as on the aircraft, in transit and in the store, staff who may be affected, potential maximum dose and controls that may be put in place to avoid the maximum potential dose. Content for Local Rules – IRR99 Regulation 17(2): Local Rules are designed to be a short, working document that all staff must read before undertaking work with ionising radiation. Local Rules content should consider each of these points – as a minimum: Dose investigation level Contingency arrangements Name of the RPS Identification and description of the work area and its classification Appropriate work instructions Example Local Rules for working with radium and tritium can be found in Annex C. 31 Monitoring requirements – IRR99 Regulation 19(2): Wipe tests – radium luminised avionics equipment must be wipe tested every 2 years and a record kept. More consideration must be taken with tritium as due to the gaseous nature of the H3 in the H3 luminised aircraft equipment, the IRR99 ACOP paragraph 487 states that wipe tests are not required. That said H3 is one of the smallest atomic elements and can ‘leach’ out through the glass capsule containing it and ‘plate out’ on the storage surface areas, with this in mind, wipe tests of storage areas should be undertaken at least annually and the storage areas should be well ventilated. Instruments Surveys and Dosimetry (ADS) Radiation employers are legally obliged to keep radiological doses to As Low As Reasonably Practicable (ALARP). With this in mind a Radiation Protection Supervisor is delegated to undertake Monitoring so as to indicate whether the levels of radiation and contamination are safe for work with ionising radiation to be undertaken or continue. All activities are to be undertaken with guidance from the Radiation Protection Advisor in accordance with the Ionising Radiations Regulations 1999(2). Should a suspected gaseous H3 exposure occur in the work environment then the staff member is required to provide a urine sample after 24, 48 and 72 hours. These samples should then be sent to an Approved Dosimetry Service (ADS) for radio assay. 32 The uptake period for tritium is 48 hours and after this period, if found positive for exposure, one would expect to see the daily dose figures reduce, due to the radionuclide leaving the body via urination and defecation. Best practice is for the staff member to drink as much liquid as possible, so as to ‘flush’ H3 from the body. Even though the H3 in the samples will reduce over time, tritium can remain in the body for several months, therefore, samples should continue to be taken at regular intervals, until the H3 content reaches background. It is worth noting that gaseous H3 has no associated taste or odour and that the dose assessments are retrospective. Staff Awareness: Accounting – the RPS must be in a position to understand the movement of equipment from the aircraft to the stores. Any breakdown in communication could lead to the item being unaccounted for and ergo legally mismanaged, therefore the RPS must work closely with the engineers to understand the daily logistics of the item. The RPS must inform the staff they are working with radionuclides and of what to do in the event of breakage, loss or theft, and the actions to be taken in the event of a perceived exposure. This is generally undertaken via the Local Rules. If the RPS fails to do this, then the staff member will not know which items are radioactive (as the trefoil is placed on back of aircraft instruments and cannot be seen on the facia when the instrument is fitted to the aircraft) – this means that potentially 33 no action would be taken in the event of a breakage, and the company could breach their responsibilities under the RSA93(1) and the IRR99(2). Pre-Legislation Illustration 3: Example of Radiation Work before Legislation and Controls: I raise the pre-legislation photograph shown in Illustration 3, take to bring home the message that if the radiation employer doesn’t manage its radioactive materials correctly, then the staff cannot behave appropriately – as they won’t know of the hazards present. It is unknown where the picture shown in Illustration 3 was taken, however for the purpose of this discussion, it is assumed that the image was taken in the United Kingdom, in the 1950’s. The ladies shown in the illustration are radium dial painters, employed to administer the radioactive paint to aircraft dial faces and needles, by hand. 34 Radium was added to the phosphorescent paint and administered by brush, making the exact quantities on each dial, unquantifiable, due to the amount of paint applied onto the brush being unknown and individualistic, as well as the amount of paint applied to each line of the dial being dependent on the painters technique. It can be seen that there are no engineering controls in place and that there is no apparent signage. As the inherent dangers of working with radiation were unknown at the time, it can be assumed that there was little or no staff training or radiation safety awareness programs. With this in mind, the ladies suffered many biological effects due to their ‘tipping’ the paintbrush in their mouths, in order to retain a point on the brush, to paint the fine detail required on the needles and dials. Dial manufacturers have moved away from using radioactive materials to luminise aircraft dials, but, if there were a requirement for dials to be radium luminised today, then it would be reasonable to assume that the Prior Risk Assessment would prove that the process should be automated, so as to remove any biological interaction with the isotope. An automated process would also make radium usage quantifiable, so as to manage and ascertain the specific activity of the radium paint and the amount of paint administered to each dial. The benefits of such a process might be to ensure dose is kept ALARP(2) to the staff and that the radiation employer would be in a position to fully understand their 35 holdings, in order to adhere to any Environment Agency requirements of the Exemption Order or Registration. This information could also be fully utilised if and when the end user of the radium luminised equipment decides to dispose of the dial, in order to apply and comply with the terms and conditions of the EA Authorisation to accumulate and dispose of radioactive materials. If the radiation employer could realistically argue that the cost of full automation would not be practicable, then other engineering controls could be employed. These may include the use of tong boxes, the placement of additional shielding and moving the work stations further apart. The work stations should be well ventilated (with airflow moving away from the worker) and easily decontaminated by being made of non absorbent, smooth surfaces. With either of the solutions mentioned above, it would be reasonable for the radiation employer to put in place administrative controls, which will include: Prior Risk Assessment, Local Rules, staff training and awareness, signage, nomination of a competent Radiation Protection Advisor and Radiation Protection Supervisor, sampling procedures for air and surface, dosimetry for the workers, area classification, monitoring and controlling entry into supervised and controlled areas, bioassay arrangements for incident scenarios, ensuring maintenance, calibration and daily checks of contamination monitors. All of which is clearly missing from the workplace shown in Illustration 3 – because they didn’t understand what they were working with. 36 In addition to the potential engineering and administrative control solutions mentioned in the previous paragraphs, it should also be noted that PPE and RPE must be available to the radiation workers as and when required. It can be clearly seen from Illustration 1, that neither are present. However the employer should be commended for providing a foot box to the lady in the left of the photograph – perhaps she had a back problem. 7. Conclusion and Summary The use of radioactively luminised aircraft components is a legacy issue that must be managed by all companies associated with the use, maintenance, calibration and airworthiness of these aircraft components. These companies cannot rely on historical records as they are not always available, therefore a cost effective, practical and robust alternative means of identification should be available. This investigation has shown that both the EP15 probe and the 44b probe can be utilised to identify the presence of radium, and that the presence of radium can be assumed by the significant counts per second compared to that of the tritium findings. The surveyor attempting to identify the presence of gaseous H3 in aircraft instrumentation should be aware that they are monitoring for low energy x-rays (due to Bremsstrahlung) rather than beta particles. With this in mind, it can be seen from the results in Section 5, that the EP15 probe has proven the most appropriate probe for attempting to identify the presence of H3, in a low background environment. 37 Once identified, the correct management of known radioactively luminised components entails the radiation employer adhering to the Radioactive Substances Act 1993(1), the GTLD Exemption Order(3), and in complying with the Ionising Radiation Regulations 1999(2). The consequences of not identifying these instruments can include; unforeseen staff exposure to the isotope, corporate negligence under the RSA93(1), legal action on the company, by the Environment Agency. 8. Acknowledgements and References Acknowledgements: I would like to thank QinetiQ for their continued professional support and the Department of Physics, University of Surrey, for the opportunity to investigate and discuss the results within this report. References: (1) Her Majesty’s Government: The Radioactive Substances Act 1993, Chapter 12, London, The Stationary Office Limited, 1993 reprinted 1999. (2) Health and Safety Commission: Working with Ionising Radiation, Ionising Radiation Regulations 1999 – Approved Code of Practice, London, The Stationary Office Limited, 2008. 38 (3) Her Majesty’s Government: Statutory Instrument 1985 No.1047; The Radioactive Substances (Gaseous Tritium Light Devices) Exemption Order 1985, London, The Stationary Office Limited, 1987. (4) D Delacroix, JP Guerre, P Leblanc, C Hickman: Radiation Protection Dosimetry, Radionuclide and Radiation Protection Data Handbook 2002, Vol.98 No. 1 2002, Nuclear Technology Publishing, 2002. 39