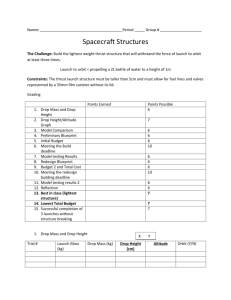

A.8.1.1.3.1 Thrust Misalignment

advertisement

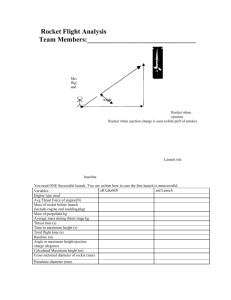

A.8.1.1.3.1 Thrust Misalignment 1 A.8.1.1.3.1 Thrust Misalignment Thrust misalignment occurs due to a difference in the direction of forces as compared to the axis of our launch vehicle. Misalignment causes moments about the launch vehicle due to a radial component of thrust and a decrease in axial thrust. If moments are not taken into account due to the misalignment, the structural integrity of the launch vehicle is compromised. Also, the decrease in axial force causes the need for additional propellant for the launch vehicle to meet its objective. Below is a figure to illustrate the thrust offset that may occur. Fig. A8.1.1.3.1: Illustration of difference between actual thrust and axial thrust. (Nicole Wilcox) In the above figure, the force, F, is the desired force and would occur in an ideal situation of which no misalignment occurs during design, manufacturing, or flight. The force, Fm, is the force that occurs due to physical misalignment of the nozzle or engine. The force, Fo, is the actual force that occurs due to all thrust offsets that may occur. The total thrust offset angle is described by α. During spin stabilization, it is important to account for the thrust angle offset so that the velocity pointing error may be minimized.1 During manufacturing and assembly of the nozzle, bumps, scratches, and dents inside the nozzle can cause unexpected shocks which may alter the overall performance of the Author: Nicole Wilcox A.8.1.1.3.1 Thrust Misalignment 2 nozzle.2 During assembly specifically, the nozzle may be misaligned itself by a few hundredths of a degree. The actual misalignment of the nozzle is what is typically thought of as creating the thrust misalignment, however, many more causes may be to blame. During flight, nozzle erosion, mass flow misalignment (swirl torque), and chamber pressure changes may cause nozzle distortions.2 The Vanguard rocket had much larger thrust misalignments due to chamber pressure changes causing distortion of the chamber near the throat. During burning, the chamber would increase in volume due to the pressure changes causing distortions or misalignments of up to 0.38 degrees.3 Industry standard for thrust misalignments today are less than 0.25 degrees and most are near 0.15 degrees for solid rocket motors.1,2 For solid rockets, the unsymmetrical burning of ablative cooling materials may allow additional heat transfer to one side of the chamber causing bubbling or melting.4 The above factors usually occur in slow increments throughout flight, but some misalignments may occur rapidly. Rapid misalignments occur as a result of unsymmetrical burning of solid or hybrid fuels or ablative materials.2 If the chamber walls become excessively hot, even momentarily, the walls may deform. In an unsymmetrical case, this would cause misalignment toward the opposite radial direction of the rapidly heated portion of chamber. Other rapid causes could include denting or scratching of internal nozzle structure due to solid propellant or ablative materials ejecting without burning.2 Low tolerances for thrust misalignment are important. As little as one degree may create a radial force that is 1.75 % thrust produced. For any vehicle this causes a need for: additional control capabilities added structural integrity additional propellant additional battery capabilities for control systems Author: Nicole Wilcox A.8.1.1.3.1 Thrust Misalignment 3 All of the above necessities require that the launch vehicle mass increases. We are trying to minimize cost which is a strong function of the mass of the vehicle. Therefore, thrust misalignment must be accounted for, but minimized. When designing an engine nozzle, tolerances are set on the physical misalignment of the nozzle assembly. However, average misalignment and standard deviation data is found through testing engines or computational fluid dynamic models. Due to the nature of this class, neither was possible and average offsets and standard deviations from historical data were used. Below is a table showing the averages and standard deviations used: Table A.8.1.1.3.1.1 Thrust Misalignment Rocket Motor Hybrid Solid Average (deg) 0.3171 0.25 Standard Deviation (deg) 0.09 1,2 0.04 2 When scaling the thrust offsets, I used a linear method as shown in the Eqs. (A.8.1.1.3.1.1) & (A.8.1.1.3.1.2). S design Tdesign Thistorical (Eqn. A.8.1.1.3.1.1) S historical where α is the angle offset and T is the tolerance. design Tdesign Thistorical historical (Eqn. A.8.1.1.3.1.2) where α is the angle offset and T is the tolerance. Due to the difficulty in finding historical data for hybrid rocket motors, we used an average between liquid and solid rocket motors. Liquid rocket motor data was taken from the Vanguard report due to the higher tolerances offered in the report. Using the average seems a reasonable assumption due to added possibility of a liquid injector offset that would further increase the overall thrust offset angle. Author: Nicole Wilcox A.8.1.1.3.1 Thrust Misalignment 4 This analysis was a significant iteration through the Monte Carlo analysis that ultimately decided the success of our launch vehicle. We can ensure that our launch vehicle is successful with the numbers chosen because they were the maximum numbers found from historical data. Greater thrust misalignments would entail an over designed launch vehicle. Over designing the vehicle is not feasible due to the additional costs associated. References 1 Javorsek, D., and Longuski, J.M., “Velocity Pointing Errors Associated with Spinning Thrusting Spacecraft,” Journal of Spacecraft and Rockets, Vol. 37, No. 3, 2000, pp. 359-360. 2 Knauber, R.N., “Thrust Misalignments of Fixed-Nozzle Solid Rocket Motors,” Journal of Spacecraft and Rockets, Vol. 33, No. 6, 1996, pp. 794-799. 3 Klaurans, B. “The Vanguard Satellite Launching Vehicle,” The Martin Company. No. 11022, April 1964. 4 Humble, R. W., Henry, G. N., Larson, W. J., Space Propulsion Analysis and Design, McGraw-Hill, New York, NY, 1995. Author: Nicole Wilcox