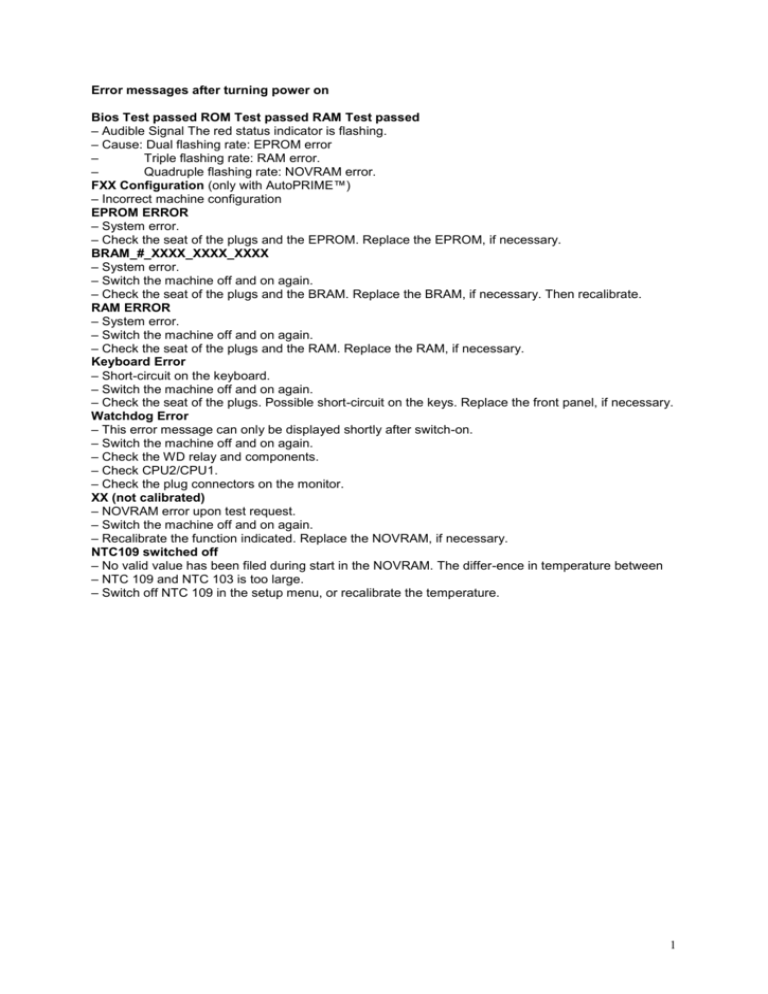

Error description:

advertisement