008-0763 - Pomsmeetings.org

advertisement

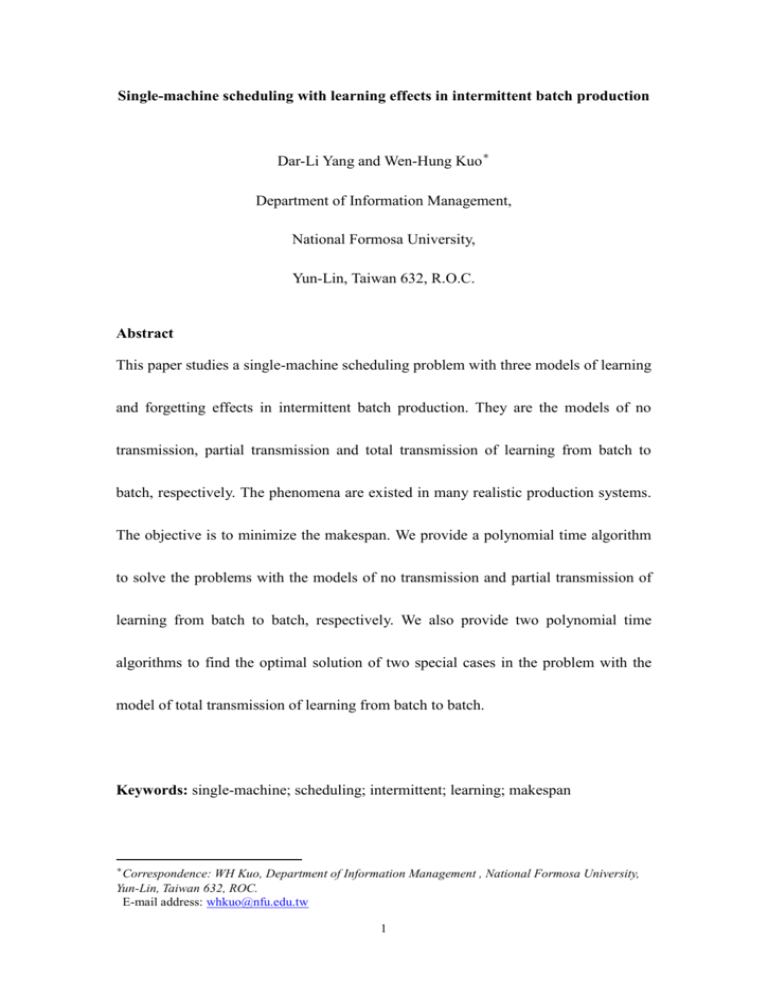

Single-machine scheduling with learning effects in intermittent batch production

Dar-Li Yang and Wen-Hung Kuo*

Department of Information Management,

National Formosa University,

Yun-Lin, Taiwan 632, R.O.C.

Abstract

This paper studies a single-machine scheduling problem with three models of learning

and forgetting effects in intermittent batch production. They are the models of no

transmission, partial transmission and total transmission of learning from batch to

batch, respectively. The phenomena are existed in many realistic production systems.

The objective is to minimize the makespan. We provide a polynomial time algorithm

to solve the problems with the models of no transmission and partial transmission of

learning from batch to batch, respectively. We also provide two polynomial time

algorithms to find the optimal solution of two special cases in the problem with the

model of total transmission of learning from batch to batch.

Keywords: single-machine; scheduling; intermittent; learning; makespan

*

Correspondence: WH Kuo, Department of Information Management , National Formosa University,

Yun-Lin, Taiwan 632, ROC.

E-mail address: whkuo@nfu.edu.tw

1

1. Introduction

In classical scheduling problems, processing times of jobs are assumed to be

constant. However, in many realistic situations, because the firms and employees

perform the same task repeatedly, they learn how to perform more efficiently.

Therefore, the actual processing time of a job is shorter when it is scheduled later,

rather than earlier in the sequence. This phenomenon is known as the “learning effect”

in the literature.

Biskup [1] first proposed a learning effect model in which the processing time of a

job is a function of the job position in a sequence. He showed that single-machine

scheduling problems with a learning effect still remain polynomially solvable if the

objective is to minimize the deviation from a common due date or to minimize the

sum of flow times. Mosheiov [2] provided a polynomial time solution for the

single-machine makespan minimization problem and solved two multi-criteria

problems which can be formulated as assignment problems. He also showed that the

SPT (the shortest processing time first) rule does not remain optimal for the minimum

flow-time problem on parallel identical machines. Mosheiov [3] further showed that

the flow-time minimization problem with the learning effect on parallel identical

machines has a solution which is polynomial in the number of jobs. Mosheiov and

Sidney [4] extended learning effect to be job-dependent, that is, learning rates are

2

different from job to job. They showed that the problems of makespan and total

flow-time minimization on a single machine, a due-date assignment problem and total

flow-time minimization on unrelated parallel machines remain polynomially solvable.

The above learning effect models tell us that, as cumulative jobs increase, the

processing time of the following job decreases in a continuous production system. It

gives the implication of continuous rather than intermittent batch production.

However, the pattern of many realistic production systems is intermittent. There is a

setup between two production runs. In such intermittent production, it is reasonable to

assume that if a large amount of time has elapsed between production runs, the

learning effect would not continue to follow what it was left when production resumes,

but that the processing time of the following job would revert to a higher level. This

suggests a phenomenon of forgetting between production runs. That is, there may be

only partial or even no transmission of learning from one production run to another

one. Hence, it is clear that this problem of learning and forgetting is an interesting

topic for intermittent production.

2. Notations and assumptions

As mentioned above, we consider a single-machine scheduling problem with

learning and forgetting effects in intermittent batch production. The problem is

3

developed using the following notations. Additional notations will be introduced

when needed throughout the paper.

m

: the number of batches. ( m 2 )

Bi : the ith batch, i=1, 2, …, m.

ni

: the number of jobs in batch Bi , i=1, 2, …, m.

n

: the total number of jobs. (i.e. n1 n2 ... nm n )

J ij : the jth job in batch Bi ,

j=1, 2, …, ni .

si

: the batch setup time of batch Bi

ai

: the learning factor of jobs within batch Bi . ( ai 0 )

bi

: the learning factor of batch Bi . ( bi 0 )

pij : the normal processing time of J ij in the original sequence.

pijr : the actual processing time of J ij which is scheduled in the r th position

in a sequence in batch Bi .

p i[k ] : the normal processing time of J i[k ] which is scheduled in the k th position

in a sequence in batch Bi .

pik[ k ] : the actual processing time of J i[k ] which is scheduled in the k th position

in a sequence in batch Bi .

C ij

: the completion time of J ij

C i[k ] : the completion time of J i[k ] which is scheduled in the k th position

in a sequence in batch Bi .

C m a x : the makespan of all jobs.

4

There are n jobs grouped into m batches and processed on a single machine. All

jobs are available at time zero. Assume that there is no setup time between two

consecutive jobs in the same batch. However, a setup time is required to process a

batch and it is sequence-independent. Moreover, the normal processing time of a job

is incurred if the job is scheduled first in the first production batch. The actual

processing times of the following jobs are smaller than their normal processing times

because of the learning effect. Assume that the actual processing time of a job is a

decreasing function of its position in a sequence. Usually, the learning effect can be

accumulated through completing jobs. However, if a large amount of setup time has

elapsed between production runs, it may incur a forgetting effect. That is, there may

be partial or even no transmission of learning from batch to batch. Therefore, three

models of learning and forgetting effects are considered in the following.

3. Model I: No transmission of learning from batch to batch

In the first model, we consider that there is no transmission of learning from batch

to batch. The objective of the single-machine scheduling problem is to minimize the

makespan of all jobs. As mentioned in Biskup [1], we assume that the actual

processing time of job J ij when scheduled in position r in batch Bi , is given by

pijr pij r ai

5

Hence, the makespan of all jobs is as follows:

ni

m

m

i 1

i 1 j 1

C max si pi[ j ] j ai .

For convenience, let LE denote the learning effect and S denote the existence of a

sequence-independent batch setup time. In addition, let B denote that the problem is

an intermittent batch production problem and Tno denote that there is no

transmission of learning from batch to batch. Therefore, following the three-field

notation

of

Graham

et

al.

[5],

the

proposed

problem

is

denoted

by

1 / B, S , LE , Tno / C max .

Theorem 1. For the problem of 1 / B, S , LE , Tno / C max , there exists an optimal

schedule that satisfies the following conditions: (a) the jobs within a batch are

sequenced in non-decreasing order of their normal processing time. (b) the batches

can be sequenced in any order.

Proof. The problem to arrange the job sequence within a batch is the same as the

problem of 1 / LE / Cmax . Mosheiov [2] proved that the optimal schedule is to

sequence the jobs in non-decreasing order of their normal processing time. Therefore,

the theorem follows because there is no transmission of learning from batch to batch

and the batch setup is sequence-independent.

6

□

Based on Theorem 1, a simple algorithm to determine the optimal schedule for the

problem of 1 / B, S , LE , Tno / C max is developed as follow.

Algorithm 1.

Step 1: Arrange jobs within each batch in non-decreasing order of their normal

processing times.

Step 2: Batches are scheduled in any order.

The optimal job sequence within a certain batch Bi can be obtained by a

sorting algorithm and thus taking O(ni log ni ) time.

Hence, the total running time

m

to sequence jobs of all batches is

O(n

i 1

i

log ni ) . On the other hand, the running time

to sequence the batches in any order is O(1) . Therefore, the overall complexity of the

problem of 1 / B, S , LE , Tno / C max is O(n log n) (see Kuo and Yang [8]).

4. Model II: Partial transmission of learning from batch to batch

In the second model, we consider partial transmission of learning from batch to

batch in the single-machine scheduling problem. Therefore, there exists some learning

effect between batches besides the learning effect within a batch. We assume that the

learning effect of jobs within a batch is the same as that in the first model. In addition,

7

the actual processing time of batch Bi when scheduled in the rth batch is defined as

follows.

Pir Pi r bi

where Pi is the total processing time of jobs within batch Bi if there is no

ni

transmission of learning from batch to batch. That is, Pi pi[ k ] k ai .

k 1

Then, the makespan of all jobs is calculated as follows:

m

m

C m a x si pi[1]1ai pi[ 2 ] 2 ai ... pi[ ni ] niai i bi si Pi i bi

(1)

i 1

i 1

Let T part denote that there is only partial transmission of learning from batch to

batch. Then the proposed problem is denoted by 1 / B, S , LE , T part / C max . As in Biskup

[1], let xir be a 0/1 variable such that xir = 1 if batch Bi is the rth batch to be

processed and xir = 0 otherwise. Then the problem of 1 / B, S , LE , T part / C max can be

formulated as the following assignment problem.

m

min

m

i

i 1

m

s.t.

m

s P r

x

i 1

r 1

bi

xir

ir

1,

r =1, 2, …, m,

ir

1,

i =1, 2, …, m,

m

x

i 1 r 1

i

xir 0 or 1,

i, r =1, 2, …, m.

(2)

Since Pi of batch Bi is not affected by the batch sequence, from Theorem 1,

Pi can be minimized by sequencing the corresponding jobs in non-decreasing order

of their normal processing time. Based on the above analysis, a simple algorithm to

8

determine the optimal schedule for the problem of 1 / B, S , LE , T part / C max

is

developed as follow.

Algorithm 2.

Step 1: Arrange jobs within each batch in non-decreasing order of their normal

processing times.

Step 2: Formulate the corresponding assignment problem as Eq.(2) and determine the

batch sequence according to the solution of the corresponding problem.

From the analysis in Section 3, the complexity of Step 1 is O(n log n) . On the

other hand, Step 2 is to solve an assignment problem and thus the complexity of Step

2 is O(m 3 ) . Thus, the overall complexity of Algorithm 2 is O(n log n m 3 ) .

Corollary 1. If the learning factors of all batches are equal, i.e. bi b , then for the

problem of 1 / B, S , LE , T part / C max , there exists an optimal schedule that satisfies the

following conditions: (a) the jobs within a batch are sequenced in non-decreasing

order of their normal processing time. (b) the batches are sequenced in non-decreasing

order of Pi .

Proof. As stated in Theorem 1, the problem to arrange the job sequence within a batch

9

is the same as the problem of 1 / LE / Cmax . Mosheiov [2] proved that the optimal

schedule is to sequence the jobs in non-decreasing order of their normal processing

m

s

time. In addition, the term of

i 1

i

in Eq.(1) is constant. Therefore, to minimize the

m

makespan of all jobs is equal to minimizing the term of

Pi

i 1

bi b , to minimize

i

bi

in Eq.(1). Because

m

Pi

i

i 1

b

is equivalent to minimizing the makespan of the

problem of 1 / LE / Cmax if batches are taken as jobs. Then, the result in part (b) of

Corollary 1 follows.

□

From Corollary 1, if bi b , the complexity of the problem of 1 / B, S , LE , T part / C max

is reduced to O(n log n) .

5. Model III: Total transmission of learning from batch to batch

In the third model, we consider total transmission of learning from batch to batch

in the single-machine scheduling problem. Without loss of generality, assume that

batch Bi is sequenced in the ith batch. Then, the actual processing time of job J ij

when scheduled in position r in batch Bi is as follows.

ai

i 1

p pij r nk .

k 1

r

ij

Hence, the makespan of all jobs is calculated as follows.

10

C max

ai

i 1

si pi[ r ] r nk .

i 1

i 1 r 1

k 1

m

m

ni

Let Ttotal denote total transmission of learning from batch to batch. Then the

proposed problem is denoted by 1 / B, S , LE , Ttotal / C max .

Theorem 2. For any batch sequence of the 1 / B, S , LE , Ttotal / C max problem, the total

processing time of jobs within the batch is minimized by sequencing jobs in

non-decreasing order of their normal processing time.

Proof. The theorem can be easily proved by using simple job interchanging technique.

□

Corollary 2. For the problem of 1 / B, S , LE , Ttotal / C max , there exists an optimal

schedule by sequencing jobs within each batch in non-decreasing order of their

normal processing time.

□

Proof. The result follows directly from Theorem 2.

In the following, two special cases of the problem of 1 / B, S , LE , Ttotal / C max are

discussed in Theorem 3 and Algorithm 3, respectively.

Definition

1.

Bi

is

dominated

by

11

Bj ,

or

Bj

dominates

Bi

iff

max{ pik | k 1,2,..., ni } min{ p jk | k 1,2,..., n j } . The symbol Bi B j denotes that

Bi is dominated by B j .

Definition 2. The batches form an increasing sequence of dominating batches iff

B1 B2 ... Bm .

Theorem 3. If B1 B2 ... Bm and a1 a2 ... am , then for the problem of

1 / B, S , LE , Ttotal / C max , there exists an optimal schedule satisfies the following

conditions.

(a) the jobs within a batch are sequenced in non-decreasing order of their normal

processing time.

(b) the batches are arranged as an increasing sequence of dominating batches.

Proof. The theorem can be easily proved by using simple job interchanging technique.

□

Next, if the job numbers of all batches are equal (i.e. n1 n2 ... nm n

m

n ),

then the proposed problem can be formulated as an assignment problem. Again, let

xir be a 0/1 variable such that xir = 1 if batch Bi is the rth batch to be processed

and xir = 0 otherwise. Then, the problem to minimize the makespan of all jobs is

12

formulated as follows.

m

min

m

i

i 1

m

s.t.

m

n

s p (r 1)n j

x

i 1

r 1

i 1 r 1 j 1

ir

1,

r =1, 2, …, m,

ir

1,

i =1, 2, …, m,

m

x

ai

i[ j ]

xir 0 or 1,

xir

i, r =1, 2, …, m.

(3)

Based on Theorem 2 and the above analysis, to determine the optimal schedule for

the problem of 1 / B, S , LE , Ttotal / C max , a similar algorithm as Algorithm 2 is

developed as follow.

Algorithm 3.

Step 1: Arrange jobs within each batch in non-decreasing order of their normal

processing times.

Step 2: Formulate the corresponding assignment problem as Eq.(3) and determine the

batch sequence according to the solution of the corresponding problem.

Note that Step 1 can be obtained by a sorting algorithm and thus it takes

O ( n log n ) time while Step 2 is to solve an assignment problem and thus it takes

O(m 3 ) time. Thus, the overall time complexity of Algorithm 3 is O(n log n m 3 ) .

13

6. Conclusions

This paper studies a single-machine scheduling problem with three models of

learning and forgetting effects in intermittent batch production. They are the models

of no transmission, partial transmission and total transmission of learning from batch

to batch, respectively. The objective is to minimize the makespan. We provide a

polynomial time algorithm to solve the problems with the models of no transmission

and partial transmission of learning from batch to batch, respectively. We also provide

two polynomial time algorithms to find the optimal solutions of two special cases in

the problem with the model of total transmission of learning from batch to batch.

However, the complexity of the problem with the model of total transmission of

learning from batch to batch is an open question. Therefore, it is an interesting topic

for the future research. Besides, in this study, the learning effect of a job depends on

its position in a schedule. There are other learning effect models studied in the

literature [6,7]. Thus, it is also worthwhile to consider another learning effect model

in intermittent batch production, for example, a time-dependent learning effect model

proposed by Kuo and Yang [8,9].

14

Acknowledgements

This research is supported in part by the National Science Council of Taiwan,

Republic of China, under grant number NSC-94-2213-E-150-016.

References

1. Biskup D (1999). Single-machine scheduling with learning considerations. Eur J

Opl Res 115: 173-178.

2. Mosheiov G (2001a). Scheduling problems with learning effect. Eur J Opl Res 132:

687-693.

3. Mosheiov G (2001b). Parallel machine scheduling with learning effect. J Opl Res

Soc 52: 1-5.

4. Mosheiov G and Sidney JB (2003). Scheduling with general job-dependent

learning curves. Eur J Opl Res 147: 665-670.

5. Graham RL, Lawler EL, Lenstra JK, Rinnooy Kan AHG. (1979). Optimization and

approximation in deterministic sequencing and scheduling: A survey. Annals

Discrete Mathematics 5: 287-326.

6. Alidaee B, Womer NK (1990). Scheduling with time dependent processing times:

Review and extensions. J Opl Res Soc 50: 711-729.

7. Cheng TCE, Ding Q, Lin BMT (2004). A concise survey of scheduling with

15

time-dependent processing times. Eur J Opl Res 152: 1-13.

8. Kuo WH, Yang DL (2006). Single-machine group scheduling with a

time-dependent learning effect. Comput Opns Res 33(8): 2099-2112.

9. Kuo WH, Yang DL (2006). Minimizing the total completion time in a single

machine scheduling problem with a time-dependent learning effect. Eur J Opl Res

174(2): 1184-1190.

16