requirements for VVBGA Accreditation.

advertisement

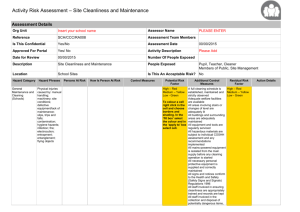

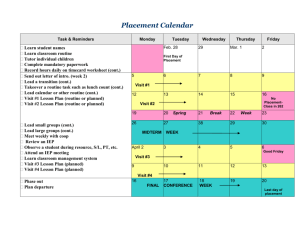

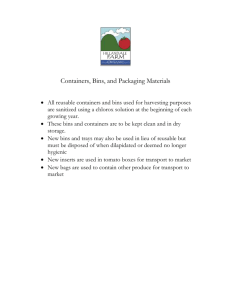

VVBGA Produce Safety Accreditation Requirements To be eligible for VVBGA Accreditation the following items/ practices will be outlined in your Practical Produce Safety Plan and implemented/ practiced on your farm. Item/ Practice* # 1 Soil Fertilization (manure and compost) 2 Potable wash water test Short Description* Outline how you fertilize your soil/crops. If applicable, records of manure waiting periods and compost production are additionally required Summarize the source and quality of your potable water. Describe when and how you train your employees about produce safety. Multiple Rinse or sanitizer for If applicable, outline your practice for washing raw-eaten leafy raw-eaten leafy greens produce such as salad greens ** Outline your routines for cleaning and storing your harvest, packing, Pack and ship containers clean and shipping containers** Cold storage w/ accurate Briefly Describe your cold storage equipment and cleaning routine.** thermometer Dedicated produce bins for Your bins used for harvesting and storing RACS are dedicated for this raw-eaten Agricultural purpose and not used for things that might contaminate them (e.g. Commodities (RACS) garbage, compost, etc) Label a birds-eye farm map. Outline any land-use history or other PS Farm Map/ plan potential extrinsic risks (e.g. flooding) Risk reduction plan for Describe your source(s) and Outline how you reduce risk of RACs irrigation contamination with irrigation water harvest bins cleaned when Outline your routine for cleaning and storing your harvest bins dirty Packing house cleaning Outline your routine for cleaning your pack house. plan/routine Rodent prevention control Briefly describe and qualify your rodent issues and Outline your plan plan/ routine for controlling them. Briefly describe toilet facility location/ access on your farm. Easy Easy Access to toilet facility access= within ¼ mile walk or 5 minute drive at all times. In practice, employees should have a positive and regular practice of Effective-hand washing effective hand-washing . This should be stated in your plan, but more practice and policy importantly be happening daily on your farm! Outline your sick policy, including preventing contagious employees Sick Policy from handling RACs Describe location (s) of stocked “kit (s)” and policy for promptly Easy access to first-aid Kit(s) treating and covering bleeding injuries. Describe the type and contents of labels used for wholesale shipping. Wholesale shipping unit label 3 Employee Training 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Describe how you manage your cooler, including inventory turning and any regular cleaning routines. Describe methods used to cool or keep cool, perishable product from Plan to Maintain Transport 19 harvest to sale, including harvest timing, hydro cooling, 35-45 degree Cold Chain refrigeration, etc. *More complete descriptions and links to resources can be found in the PSA Learn and Write Modules **More detailed photo(s) and SOP (Standard Operating Procedure) is additionally required for this practice. 18 Plan/ routine for cooler cleaning VVBGA Produce Safety Accreditation Requirements The following Items/ Practices are encouraged but not required for Accreditation Item/ Practice # 1 2 Irrigation Testing Non-porous harvest bins Wash water test and/or Sanitizer 3 efficacy for RACs in dunk tanks. 4 Well-drained floor 5 Non-porous wash line 6 Hose management 7 Wholesale Invoice traceability 8 Cold storage temp documentation 9 Transport cleaning routine Short Description* Get to know the quality of your irrigation water! Describe any testing of irrigation water source(s) and present results. Describe the bins you use. Non-porous bin are recommended because they are washable, stackable and relatively inexpensive. If Applicable, describe how you monitor the efficacy of your sanitizer in dunk tanks , and present any E.coli test results of used dunk tank water Describe your pack house floor. Ideally it is a material (porous or non-porous) that drains well and does not puddle. Describe the surface and condition of you wash line. Ideally all contact surfaces are in good repair, non-porous and washable. Describe how you manage water-flow/ hoses in your pack house. Ideally, hoses stay off the ground using a “hose pulley/trolley” or equivalent system. Invoices are most likely required by your buyers or your farms. Ideally, this invoice will connect any product sale to its date and field of harvest (one step forward one step back” Recording cooler temperature and humidity helps many farmers better manage storage and compressor equipment. Ideally, you will post these records if you take them. Ideally vehicles and transport boxes are kept as tidy as practical and regularly cleaned. Describe this routine if applicable. *More complete descriptions and links to resources can be found in the PSA Learn and Write Modules **More detailed photo(s) and SOP (Standard Operating Procedure) is additionally required for this practice.