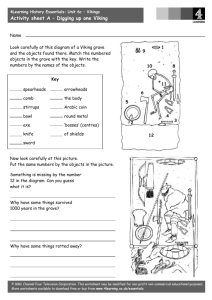

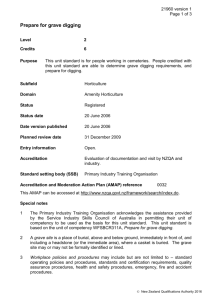

Perform grave digging using machinery

advertisement

21962 version 1 Page 1 of 4 Perform grave digging using machinery Level 3 Credits 8 Purpose This unit standard is for people working in cemeteries. People credited with this unit standard are able to: conduct grave excavation using machinery; minimise risk of grave collapse; and clean up and make safe an open grave site. Subfield Horticulture Domain Amenity Horticulture Status Registered Status date 20 June 2006 Date version published 20 June 2006 Planned review date 31 December 2009 Entry information Recommended: The unit standard(s) covering operation of the machinery used, or demonstrate equivalent knowledge and skills. Accreditation Evaluation of documentation and visit by NZQA, industry and teaching professional in the same field from another provider. Standard setting body (SSB) Primary Industry Training Organisation Accreditation and Moderation Action Plan (AMAP) reference 0032 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 The Primary Industry Training Organisation acknowledges the assistance provided by the Service Industry Skills Council of Australia in permitting their unit of competency to be used as the basis for this unit standard. This unit standard is based on the unit of competency WFSBCR313A, Perform grave digging using machinery. 2 A grave site is a place of burial, above and below ground, immediately in front of, and including a headstone (or the immediate area), where a casket is buried. The grave site may or may not be formally identified or lined. New Zealand Qualifications Authority 2016 21962 version 1 Page 2 of 4 3 Workplace policies and procedures may include but are not limited to – standard operating policies and procedures, standards and certification requirements, quality assurance procedures, health and safety procedures, emergency, fire and accident procedures. 4 Legislation and regulations that must be complied with include but are not limited to the Health and Safety in Employment Act 1992, Burial and Cremation Act 1964, Land Transport Act1998, Traffic Regulations 1976, Land Transport (Driver Licensing) Rule 1999, and bylaws. Operators must have the necessary driver licence and endorsements for the vehicle being operated and the manner in which it is operated. 5 This unit standard does not cover the skill and knowledge needed to drive the machinery used in the context of this unit standard. 6 Tools, equipment and machinery may include but are not limited to – spreaders; boards; hydraulic braces; stabilisers; spade; shovel; pick; crowbar; auger; timber tong; sledge hammer; timber mallet; explosive power tool; power saw; hand saw; timber of correct grade, size and type; ladder; backhoe/front-end loader; skidsteer loader; excavator; tractor; truck. Elements and performance criteria Element 1 Conduct grave excavation using machinery. Performance criteria 1.1 Appropriate grave site is identified and located. 1.2 Personal protective equipment is prepared and used in accordance with health and safety procedures and workplace policies and procedures. Range may include but is not limited to – protective clothing, head protection, foot protection, eye protection, ear protection, sun protection, two-way radio. 1.3 Graves are dug using machinery to suit dimensions of coffins or caskets in accordance with health and safety procedures, workplace policies and procedures, and applicable legislation. 1.4 Displaced earth is placed on vehicle, vacant site, or other appropriate location pending backfilling and/or removal. 1.5 Top and/or sides of the grave are shored if required by workplace policies and procedures or applicable legislation using appropriate shoring method, tools, and equipment. Range shoring methods may include – box set; closed timbering for wet sand and/or refilled ground; solider set or box sets for firm, hard clay; shields where suitable for rock. New Zealand Qualifications Authority 2016 21962 version 1 Page 3 of 4 1.6 Access and egress to and from confined spaces are undertaken by means of an appropriate ladder. 1.7 Tools, equipment, and machinery are used in accordance with supervisor’s instructions and manufacturer’s guidelines. 1.8 Effective communication is carried out with other team members in accordance with workplace policies and procedures. Element 2 Minimise risk of grave collapse. Performance criteria 2.1 Surface loadings are maintained at levels appropriate for the soil type and condition. 2.2 Excavation is monitored for grave collapse warning signs. 2.3 Grave collapse warning signs are identified in accordance with workplace policies and procedures. Range 2.4 Appropriate strategies to prevent the grave collapse are identified and agreed with team members. Range 2.5 may include but is not limited to – fretting from top edge, slump in the surface near an excavation, tension cracks, support timbers bowing or creaking. may include but is not limited to – shoring, reducing soil loadings. Selected strategies are implemented in accordance with health and safety procedures. Element 3 Clean up and make safe an open grave site. Performance criteria 3.1 Surface area from the edge of the excavation is covered appropriately to ensure the integrity and stability of the soil. 3.2 Grave supports and lowering devices are placed in readiness for the coffin or casket. 3.3 Area adjacent to grave is tidied and earth is removed or stockpiled in accordance with workplace policies and procedures. 3.4 Any damage to adjacent graves caused by machinery is assessed and addressed in accordance with workplace policies and procedures. New Zealand Qualifications Authority 2016 21962 version 1 Page 4 of 4 3.5 Protective restraints are placed to limit access to the site when grave is left unattended, in accordance with workplace policies and procedures and applicable legislation. Range may include but is not limited to – sheeting, barricades, temporary fencing, reinforced covers. Please note Providers must be accredited by the Qualifications Authority, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by the Qualifications Authority before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the New Zealand Industry Training Organisation www.primaryito.ac.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016