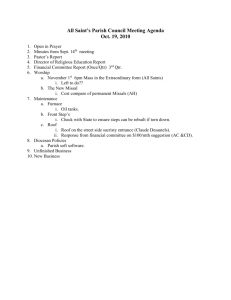

25277 Demonstrate knowledge of metal roof and wall cladding

25277 version 1

Page 1 of 7

Demonstrate knowledge of metal roof and wall cladding systems

Level 2

Credits 8

Purpose People credited with this unit standard are able to demonstrate knowledge of: specifications used for metal roof and wall cladding; the work procedures used for installing metal roof and wall cladding; underlays used in metal roof and wall cladding; insulation used in metal roof and wall cladding; fastenings used in metal roof and wall cladding; and the use of soldering for joining metals. They are also able to identify: common residential metal roof parts and types; common industrial metal roof and wall cladding types; common support framing for metal roof and wall cladding; metals, profiles, and coatings used for profiled metal roof and wall cladding; and the purpose and use of sealants.

Subfield Plumbing, Gasfitting and Drainlaying

Domain

Status

Status date

Date version published

Roofing

Registered

23 January 2009

23 January 2009

Planned review date

Entry information

31 December 2013

Open.

Accreditation Evaluation of documentation by NZQA.

Standard setting body (SSB) The Skills Organisation

Accreditation and Moderation Action Plan (AMAP) reference 0227

This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do.

Special notes

1 Legislation relevant to this unit standard includes but is not limited to

– Health and

Safety in Employment Act 1992, Building Act 2004.

2 Reference

The NZ Metal Roof and Wall Cladding Code of Practice , 2008 is available from the

New Zealand Metal Roofing Manufacturers Inc – http://www.metalroofing.org.nz.

New Zealand Qualifications Authority 2020

25277 version 1

Page 2 of 7

3 The following applicable document is available for download on the Department of

Building and Housing website: http://www.dbh.govt.nz/

– Building Code compliance document Clause E2, containing Acceptable Solution

E2/AS1 for External Moisture.

4 The New Zealand Building Code (NZBC) is a schedule to the Building Regulations

1992. It provides requirements for compliance with the Building Act when constructing a new building or altering an existing one. The Building Code sets out performance standards that building work must meet and covers aspects such as structural stability, fire safety, access, moisture control, durability, and services and facilities.

5 Definitions

Company requirements

– include the policies, procedures, and methodologies of the company. They include requirements documented in company and site health and safety plans, quality assurance documents, and contract work programmes.

Industry practice

– sound industry practice that meets legislative requirements.

Site procedures – refer to the procedures which are required to be observed for safe work practices at a particular site.

6 This unit standard may be assessed against off-job.

Elements and performance criteria

Element 1

Demonstrate knowledge of specifications used for metal roof and wall cladding.

Performance criteria

1.1 Use of plans or written specifications and sketches to define the roof or wall cladding is described in accordance with industry practice.

1.2 The use of manufacturer specifications is described in terms of specific installation requirements and instructions.

1.3 Legislation and codes that may affect roof installation specifications are identified in accordance with industry practice.

Range includes but is not limited to

– the New Zealand Metal Roof and

Wall Cladding Code of Practice, the NZBC, New Zealand

Standards, Material Safety Data Sheets.

New Zealand Qualifications Authority 2020

25277 version 1

Page 3 of 7

Element 2

Demonstrate knowledge of the work procedures used for installing metal roof and wall cladding.

Performance criteria

2.1 The purpose of communication and toolbox meetings is described in terms of information sharing and job organisation.

2.2 Procedures for handling and protecting materials are described in accordance with site procedures.

2.3 Procedures for using ladders and walking on roofs are described in accordance with site procedures.

2.4 The roles and responsibilities of project people are described in accordance with company requirements.

Range may be for a simulated scenario; project people may include but are not limited to

– site supervisor, foreperson, architect, installation gangs, owner.

Element 3

Identify common residential metal roof parts and types.

Performance criteria

3.1 Common residential metal roof types are identified using industry terminology.

Range includes but is not limited to – pitch, gable, angled gable, cross gable, dutch gable, hip, four hip, mansard, mono slope, bull nose, verandah, lean-to, parapet, stepped, hipped dormer, dog kennel dormer, dormer gable, crimp curve, drape curve, skillion.

3.2 The parts that form a common residential metal roof are identified using industry terminology.

Range includes but is not limited to – dormer, eaves, fascia board, flashing, collar flashing, penetration, fascia gutter, rainwater head, ridging, ridge cap, flat roof, gable, hip, hip end, ridge, soffit, valley, lean-to, down pipe, chimney penetration, foam filler blocks.

New Zealand Qualifications Authority 2020

25277 version 1

Page 4 of 7

Element 4

Identify common industrial metal roof and wall cladding types.

Performance criteria

4.1 Common industrial metal roof types are identified using industry terminology.

Range includes but is not limited to – pitch, low slope, parapet, saw tooth, draped curve, crimped curve.

4.2 The parts that form common industrial metal roof and wall cladding are identified using industry terminology.

Range includes but is not limited to – internal gutter, parapet capping, internal sump, ridging, fascia gutter, barge flashing, apron flashing, internal corner, ventilator, ridge vent, external gutter, foam filler blocks.

Element 5

Identify common support framing for metal roof and wall cladding.

Performance criteria

5.1 Common structural components used for the roof support framework are identified.

Range purlins, rafters, portal frames, trusses.

5.2

Element 6

Common uses of timber and steel as support frameworks are identified according to building type and size.

Identify metals, profiles, and coatings used for profiled metal roof and wall cladding.

Performance criteria

6.1 Metals used for metal roof and wall cladding are identified in terms of their properties, advantages, and disadvantages.

Range aluminium, galvanised steel, zinc, copper, stainless steel.

6.2 A range of metal roof profiles are identified.

Range asymmetrical trapezoidal, symmetrical trapezoidal, corrugated, self-supporting concealed fixing, fully supported concealed fixing.

New Zealand Qualifications Authority 2020

25277 version 1

Page 5 of 7

6.3 Profiled metal cladding terms are identified.

Range cover width, web, rib width, trough, pan, rib, crest, depth, corrugate, corrugate lap, swage, vertical rib, trapezoidal lap, anticapillary groove.

6.4 Pre-coated profiled steel sheeting is described in terms of advantages and disadvantages.

Element 7

Range client’s requirements, installation economy.

Demonstrate knowledge of underlays used in metal roof and wall cladding.

Performance criteria

7.1 The purpose of underlays is identified in terms of their role in the metal roof or wall cladding system.

7.2 Common underlay types are identified according to their use in metal roof and wall cladding applications.

Range impregnation types, self-supporting, grades.

7.3 Underlay support system types are identified in terms of their advantages and disadvantages.

Element 8

Range wire netting, safety mesh, strapping.

Demonstrate knowledge of insulation used in metal roof and wall cladding.

Performance criteria

8.1 Bulk insulation options are identified in terms of composition.

8.2

8.3

Reflective insulation is identified and compared with bulk insulation.

Installation methods for insulation are identified according to roof type.

Range roof with attic type space, skillion roof type, metal wall cladding.

New Zealand Qualifications Authority 2020

25277 version 1

Page 6 of 7

9.3

9.4

Element 9

Demonstrate knowledge of fastenings used in metal roof and wall cladding.

Performance criteria

9.1 Types of fastenings used are identified in terms of their purpose.

Range primary, secondary, screw, nail, rivet.

9.2 Fastening material options are identified according to fastening type and common use.

Methods of fixing are identified in terms of tools used and technique.

Head types and drivers are identified.

Range head type

– hexagon, countersunk, pan, wafer; drivers – Phillips, pozi drive, square, slotted, external hexagon, multi-head.

9.5 Head stamp information is identified according to manufacturer and fastenting class.

9.6 Screw point types are identified in terms of their use.

Range type 17, self-drilling, self-piercing, self-tapping.

9.7 The purpose of fastening washers is identified.

Element 10

Identify the purpose and use of sealants.

Performance criteria

10.1 The purpose of sealants is identified in terms of use in a roof installation.

10.2 The use of sealants is identified in terms of sealant type, preparation and application options in accordance with industry practice.

Element 11

Demonstrate knowledge of the use of soldering for joining metals.

Performance criteria

11.1 The difference between hard and soft soldering is identified in terms of soldering method and joint strength.

New Zealand Qualifications Authority 2020

25277 version 1

Page 7 of 7

Please note

Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment.

Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards.

Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards.

Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The

AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements.

Comments on this unit standard

Please contact The Skills Organisation info@skills.org.nz if you wish to suggest changes to the content of this unit standard.

New Zealand Qualifications Authority 2020