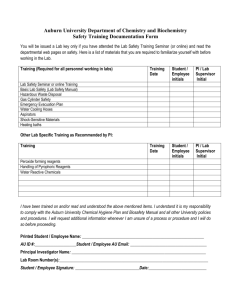

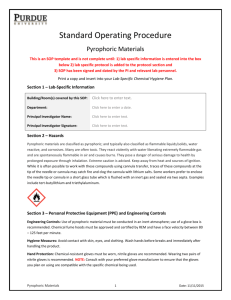

Pyrophorics Manual

advertisement

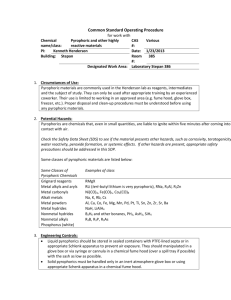

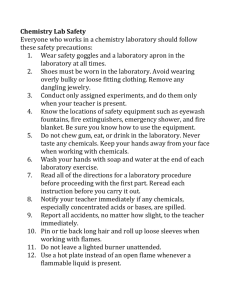

School of Chemistry SAFETY MANUAL FOR THE USE OF PYROPHORIC AND AIR-SENSITIVE REAGENTS No researcher should use pyrophoric and air-sensitive reagents unless they have read and understood these notes (including Gill, G. B; Whiting, D. A. Aldrichimica Acta 1986, 19, 31–41 and Aldrich Technical Bulletin AL-134), and agree to abide by the general recommendations, protocols and prohibitions contained therein. Your research supervisor must be aware that you are using pyrophoric and air-sensitive reagents. The protocols outlined in this manual constitute a COSHH assessment. 2013 Pyrophoric and Air-Sensitive Reagents 1. Hazards Pyrophoric materials ignite spontaneously on contact with air. Most pyrophoric materials are also highly reactive with water and can ignite when coming into contact with water or under humid conditions. When using pyrophoric reagents, the primary hazard is fire. This problem can arise in several ways: Accidental discharge of pyrophoric material into the atmosphere. Accidental discharge of pyrophoric material into a cooling bath containing a flammable organic solvent. Loss of inert atmosphere containment in the stock bottle of reagent or in the reaction vessel/apparatus. Inadvertent contact of the pyrophoric material with an oxidant. It is extremely important that pyrophoric and air-sensitive compounds are handled away from combustible materials and organic solvents as far as this is possible. Pyrophoric and air-sensitive compounds may have additional associated hazards (e.g. corrosive, toxic, irritant, etc.). Although COSHH assessments have to take account of all of these hazards on a reaction-by-reaction basis, the in-house methods for handling pyrophoric and air-sensitive materials (i.e. good chemical laboratory practice + fume hood + “pyrophorics protocol”) are designed to minimise the risk of accidental exposure to skin, eyes and respiratory tract. Hence, the general protocols outlined here must be adopted by all researchers who handle such materials; these protocols constitute a COSHH assessment. 2. General Considerations Most of the detailed practical information is contained in Gill, G. B; Whiting, D. A. Aldrichimica Acta 1986, 19, 31–41 and the Aldrich Technical Bulletin AL-134 and so this part of the manual merely highlights the main aspects of the protocol to be adopted. Ordering An inventory of the pyrophoric and air-sensitive materials currently in stock must be recorded within each research group. These materials should be regarded as communal within each group. 1 Ideally, pyrophoric materials should also be regarded as freely available within the Department of Chemistry in order to achieve rapid turn over. This will ensure rapid turnover and help minimise storage space, waste and costs of disposal. Do not re-order a pyrophoric or air-sensitive reagent unless stock levels are very low or the present stock material has deteriorated to the point where it is no longer of use. Research groups must adopt a policy of regular disposal of decomposed pyrophoric materials before ordering new batches. Documentation New items must be documented as follows: Write on the label (pencil or permanent felt tip) your supervisor's initials, the month and year of purchase (e.g. JSC/10/08) and the date the bottle was first opened. Enter the pyrophoric or air-sensitive chemical (including solvent and concentration) into your research group inventory at the time of ordering. Delete ownership of pyrophoric or air-sensitive reagents that have been used up or have been destroyed. Storage Non-pyrophoric items (e.g. low concentrations of n-BuLi) can sometimes be stored at room temperature in the laboratory. Many, but not all, pyrophoric items should be refrigerated and the “store at” instructions on the bottle or provider by the supplier should be followed. Do not place pyrophoric solutions in the freezer, the freezer compartment of the refrigerator, or in a cooling bath below 5 C. Store all pyrophoric substances away from flammable solvents and other readily-combustible materials. Note: It is not usually financially advantageous to buy large (>250 mL) quantities of a pyrophoric reagent that is used occasionally unless it is intended to split it up into smaller containers for storage. Once the septum has been pierced, gradual deterioration of the reagent is inevitable unless the septum is replaced regularly. It is more efficient to have a rapid turnover (and complete consumption) of a given reagent. Details on how to rebottle pyrophoric reagents are given in Gill, G. B; Whiting, D. A. Aldrichimica Acta 1986, 19, 31–41. 2 Transportation If the storage area for the item is some distance from the work area (e.g. in another laboratory), then a suitable/approved bottle carrier must be used to transport pyrophoric material. 3. Handling Pyrophoric Materials If you are in any doubt about the hazards and safety protocol for your experiment you must consult your supervisor. The attached article (Gill, G.B; Whiting, D. A. Aldrichimica Acta 1981, 19, 31–41) covers general points only and may not be specific enough for your intended experiment. Key points: Before you start Never work alone in the laboratory and do not handle pyrophoric reagents outside core working hours (8 am to 5 pm). Always wear a laboratory coat (non-synthetic) on top of non-synthetic clothing that covers the body fully. Wear safety glasses plus a face shield when transferring highly pyrophoric reagents. Make sure that you know exactly where fire blankets, extinguishers and safety showers are located in your laboratory before starting the experiment. Make sure that your fume cupboard does not contain significant quantities of flammable solvents (especially in open containers) when transferring pyrophoric reagents. In general, pyrophoric and air-sensitive materials should be handled as solutions in an appropriate (‘inert’) solvent. Examine the septum of the reagent bottle before using the reagent. If the pre-existing puncture hole is enlarged or the septum has multiple punctures, the quality of the reagent should be assessed and the septum should be replaced (see: Gill, G.B; Whiting, D. A. Aldrichimica Acta 1981, 19, 31–41). For extremely pyrophoric material (e.g. diethylzinc, trimethylaluminium etc.), place the reagent bottle (firmly clamped) in a bucket of sand whilst transferring the reagent and have a dry-powder fire extinguisher to hand just in case. The solution of pyrophoric reagent should normally be at room temperature before transfer commences in order to avoid problems (expansion etc.) that may be experienced as the solution warms up. 3 Transfer of the pyrophoric reagent Syringes are commonly used to transfer a pyrophoric and air-sensitive reagent from the stock bottle to the reaction flask. Use only syringes in which the needle and the syringe barrel are securely locked together (i.e. a Luer-lock syringe). Use a wide-bore needle – narrow-bore needles are prone to block and should be avoided. When transferring a pyrophoric reagent, never use forced pressure of N2 or Ar but instead use a balloon or a through-flow of inert gas with a bubbler to equalise the pressure. Never fill the syringe more than half full (i.e. do not risk over-extending the plunger). It is also worth asking a colleague to stand ready with a powder fire extinguisher and a sand bucket while you transfer a pyrophoric reagent into the reaction flask. Material should be withdrawn under an inert gas atmosphere into a dry syringe equipped with a dry needle that is bent into a U-shape. Try to ensure that the needle passes through an existing hole in the septum as multi-punctured septa tend to leak badly. The syringe is used in the upside-down configuration as this helps to prevent accidental discharge of material during manipulations. The syringe plunger and barrel must form an air-tight seal, otherwise reaction of the compound with air will lead to the deposition of solid material which may cause the syringe to jam. With glass syringes, it is best to seal the plunger–barrel gap first by drawing-in and discharging dry inert solvent. There is greater risk of jamming of the syringe or blockage of the needle if the same syringe is used for multiple consecutive transfers of a pyrophoric or air-sensitive reagent. It is best to use a syringe of sufficient capacity so that it needs to be filled only once. For the transfer of an appreciable quantity of material (>20 mL) it usually better to use a cannula connecting the reagent bottle and an addition funnel (also under inert atmosphere) attached to the reaction apparatus (see: Gill, G.B; Whiting, D. A. Aldrichimica Acta 1981, 19, 31–41). The required volume should be marked on the addition funnel prior to transfer. If your syringe should jam with a significant amount of material in it, place a septum on the end of the needle and seek advice from the Organic or Departmental Safety Officer. In this event, the most sensible course of action will often be simply to break the syringe under safe, controlled conditions. You should seek expert advice before doing this. After transfer of a pyrophoric reagent Make sure that syringes, needles or cannulae are cleaned thoroughly immediately after use and take particular care when decomposing residual material in syringes. Check that stock bottle of pyrophoric reagent is properly sealed and returned to the correct storage location. 4 4. Disposal of Pyrophoric Materials If an item in store is judged to have decomposed to such a degree that it is no longer of use, arrange for its safe disposal through the Organic or Departmental Safety Officer. In cases where the amount of material is very small (i.e. dregs left in an otherwise empty bottle), the following protocol should be adopted: Puncture the septum of the container to produce a small, permanent, non-sealing hole using a short needle. Leave the reagent bottle at the back of the fume hood for a period on not less than two weeks so that the moist air has the opportunity to effect the necessary decomposition of the very small amount of residual material. Do not assume that all the material has been decomposed when undertaking the next step. Add one drop of a suitable reactant (e.g. n-butanol for n-BuLi) and assess whether the reagent is no longer highly reactive. If this is the case, add further reactant cautiously until the decomposition is complete, otherwise leave the reagent bottle undisturbed for a further period of a few days. Dispose of the residues in the appropriate way (e.g. high dilution with water) and then rinse out and dry the reagent bottle prior to disposal. 5