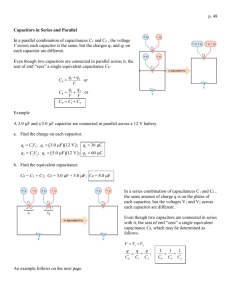

Figure 8. Equivalent diagram of a capacitance sensor when all the

advertisement

Capacitance transducers – Basic principles By Erling A Hammer Introduction The principle of a capacitance transducer is very simple, but in practice there are many factors that influence the measurements in such a way that the results can easily be miss-interpreted if the basic principles are not thoroughly understood. Capacitance sensors can be used to predict the concentration ratios in two-phase or twocomponent flow if the two components or the two phases have different electrical permittivity (dielectric constant). The principle is based on the fact that the difference in permittivity of the different components or phases flowing between two capacitance plates (electrodes) makes the capacitance between these two plates dependent on the ratio of concentration of the components or the phases in the flow. The connection, however, between the concentration ratio and the permittivity of the mixture, and hence, the sensor capacitance, is not simple and depends on the distribution of the components or the phases in the mixture (the flow regime). Even if the capacitance technique is flow regime dependent it can still be used for concentration measurements if the components are homogeneously mixed . The sensor The simplest capacitance sensor consists of two parallel metal plates separated a distance d from each other (figure 1). Sensing electrode Cs 0 r Guard electrodes d Exitation electrode Figure 1. Basic capacitance sensor If the guard electrodes are kept at the same potential as the sensing electrode but electrically insulated from it, so that the influence of the fringe field or edge effect of the electrodes is eliminated, the measured capacitance will be: Cs r 0 A d (1) where A is the area of the sensing electrode (m2) d is the distance between the electrodes (m) r is relative permittivity of the material between the electrode plates is permittivity of free space (8.85410-12 F/m) If now the material between the electrodes consists of components 1 and 2 and these components have different permittivity the volumes of these two components can be found if we know how the permittivity depends on the component fraction. 1 A more practical sensor is shown in Figure 2. detector electronics detector electronics Guard ectrodes Bare inner electrodes Surface plate electrodes D D D Electrical insulating material Steel pipe (Screen) Electrical insulating material Liner a Steel pipe (Screen) Figure 2. Surface plate electrodes Liner b Figure 2b. Innside naked electrodes The electric field between the electrode plates will, for this type of sensors, not be homogeneous and it will be more sensitive to concentration variations in the surroundings of the gaps between the plates. However, the guard arrangement shown in Figure 2a will eliminate the influence of the strongest inhomogeneous field at the edges of the electrodes and thus make the sensor less sensitive for inhomogeneities in the flowing medium. In Figure 2b the electrode plates are placed inside the liner. They are exposed direct to the mixture and have therefore a very high electrode capacitance Ce that will increase the sensitivity. Another used capacitance sensor is the coaxial electrode sensor. This sensor consists of an inner electrode supported in the centre of the pipe as shown in Figure 3. Inner electrode Outher electrode Pipe Inner electrode d r D Figure 3. The principle of the coaxial electrode sensor The electric field from this sensor is strongly inhomogeneous but symmetric around the pipe axis. The sensitivity to variation in concentration of the liquid will be highest close to the inner electrode. The capacitance pr unit length of this sensor is 2m 0 Cs (2) ln Dd where m is the relative permittivity of the mixture flowing through the sensor head. 2 Guarding and screening of the capacitance electrodes In order to perform as accurate measurements as possible it is necessary to both guard and screen the capacitance sensor. In real sensor the electrodes are arranged as shown in Figure 2. To make it easier to display the different spread capacitances a parallel capacitance sensor is sketched as shown in Figure 4. From this figure we see that the equivalent diagram of a capacitance sensor will be as shown in Figure 5. A Guard Screen CA CG CAG CX CBG CB B Figure 4. Capacitance sensor with guard electrode and screen. Electrode A is the detector electrode and electrode B is the exitation electrode Cs CX A CA B CB CAG CBG S CG G Figure 5. Equivalent diagram of capacitance sensor head equipped with guard electrode and screen For all practical sizes of sensors the parasite capacitances CA and CB are considerable, thus resulting in an unwanted shunting of CX. It is also a disadvantage that both CA and CB will change when the permittivity of the mixture in the pipe changes due to displacement of the field lines between the electrodes and the screen. However, the influence of all the parasite capacitances shown in Figure 4 and 5 can be diminished if a proper guard-driver detector is used. The basic capacitance detector system - There is in principle only one method used to eliminate the influence of the various parasite capacitances in the sensor head. This principle is based on the virtual ground circuit. 3 Figure 6. shows the basic principle of this circuit. Neither CA, CB nor CAG, CBG nor CG will influence on the output voltage Uout, if the operational amplifier has a high open loop gain AOL, so that the differential input voltage e 0 . ZF CX B A e CA CB Uosc AOL CAG CBG Uout S CG G Figure 6. Capacitance transducer with grounded guard and screen and guarded electrode (A) connected to a virtual ground circuit It can easily be seen that if AOL is large, the differential input voltage e 0 and the output signal of the circuit given in Figure 6 is: (3) uout uosc zF jcX and if the feedback impedance ZF is a capacitor C0 (ZF = 1/jC0) equation (3) can be written: uout uosc Cx C0 (4) Other used detector circuits are the oscillator circuit and the charge/discharge circuit. They are both based on the virtual ground principle. Interpreting the capacitance signals To utilise the information gained by using capacitance transducers it is of great importance to know the basic theory that underlies this technique. This is not as simple as many believe. It is not difficult to foresee that the capacitance sensors will be dependent on the distribution of the different components in a mixture. It is therefore quite obvious that reliable measurements can be made only if the flow regime is constant and the most stable regime is the homogeneous flow where the two components are well mixed. Maxwell (1873) [1], Bruggeman (1935) and many others have developed formulae for the permittivity and conductivity of homogeneous mixtures of two different materials. On the basis of a model developed by van Beek (1967), Ramu and Rao (1973) have derived formulae, which are also valid, if one of the components in the mixture has a high conductivity. If 1 2 and 1<<2 Ramu and Raos equations for the expression of the mixture permittivity and conductivity [4] can be written as: 4 m 1 1 2 1 m 1 (5) 1 2 1 (6) which is valid for component 1 as the continuous phase and 2 (7) m' 2 3 2 (8) m' 2 3 for component 2 as the continuous phase in the mixture. Here m is the relative permittivity of the mixture when component 1 makes the continuous phase 'm is the relative permittivity of the mixture when component 2 makes the continuous phase m is the conductivity of the mixture when component 1 makes the continuous phase m is the conductivity of the mixture when component 2 makes the continuous phase 1 is the relative permittivity of component 1 2 is the relative permittivity of component 2 1 is the conductivity of component 1 2 is the conductivity of component 2 is the volume fraction of the component 2 Let us assume that the conductivity of component 1 is zero and makes the continuous phase when 0.5 and that component 2 is conductive (2 0) and is the continuous phase when 0.5 . The relative mixture permittivity will then be as shown in Figure 7. m m 2 Mixture conductivity Mixture permittivity 2 m m 0.42 0.42 m 41 m 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 Figure 7 Mixture permittivity and conductivity versus the volume fraction of component 2 of a homogeneous mixture of component 1 and 2. Only component 2 is conductive To understand how a capacitance sensor reacts to changes in the permittivity of the mixture it is useful to work out an equivalent diagram for the sensor. Such a diagram is shown in Figure 8. 5 Ce1 Rm Cm Z Ce2 Figure 8. Equivalent diagram of a capacitance sensor when all the spread capacitances are eliminated In Figure 8, C m and Rm are the capacitance and the resistance between imaginary electrodes, placed at the mixture/liner interface, and with the same area as the sensor electrodes. C e 1 and C e 2 are resultant capacitances between the sensor electrodes and the mixture with the electrode insulating material as dielectric. If component 1 is non-conducting and makes the continuous phase in the flow, Rm , and the measured capacitance will be: CeCm Cs (9) Ce Cm where Ce = 1/2C1=1/2C2 If component 2 is conducting and makes the continuous phase then the current through Cm will be by-passed by Rm. It can be shown that the current through Cm is equal to the current through Rm if: 2 fe (10) 20 2 An example of this can be the measured capacitance for a capacitance sensor used for measuring the water content in a mixture of crude oil/saline water (w). This is shown in Figure 9. The transition point is here chosen to be c= 0.7 Cs Ce Sensor capacitance f<<w/20w fw Coil 0 Water cut 0.7 1 Figure 9. Measured capacitance of a capacitance sensor as function of the water fraction of a homogeneous mixture of oil and water. Excitation frequency f water / 20 water The dotted line indicates the characteristic if f water / 20 water 6 Conclusions As we have seen, the water content in oil can only be determined accurately, when the distribution of the water is exactly known. In practice this means that usually only homogeneous mixtures of oil and water can reliably be determined. The continuous component in a process oil/water mixture changes from oil to water at around 20 to 40% water concentration. The transition point in a mixture of crude oil and water will occur somewhere between 60% and 80% water fraction, depending on the type of crude, temperature and content of emulsion breaker etc. Whether the water concentration is detectable or not above the transition point is dependent on the water conductivity and sensor excitation frequency. The sensor capacitance will increase with increasing water fraction, even above the transition point (>C), if the sensor excitation frequency 1 w f fe (11) 2 0 w In North Sea oil the conductivity of the water component in the crude will approximately be 5 S/m and the relative permittivity approximately 70 giving a critical excitation frequency of f e 1.3 10 9 Hz. However, higher excitation frequencies than 1.3.109 Hz cannot be used because the capacitance detector will not eliminate the influence of the parasitic capacitances at frequencies higher than approximately 1 MHz. The water content of North Sea crude can therefore not be measured with these types of capacitance sensors if the mixture is water continuous (>C). Some capacitance sensors on the marked to day are bare (naked) electrodes inside an insulating liner as shown in Figure 10. These sensors have large interface capacitances Ce1 and Ce2 (Approximately 1-5 F/cm2 ) resulting in high sensitivity for Cm and Rm . Still the sensor cannot be used for capacitance measurements in water continuous phases but the electrodes can be used for conductivity measurements and thus the water content can be determined in water continuous phases. Figure 10. Bare (naked) inside capacitance electrodes (Roxar Flow Measurement AS) 7 References [1] Hammer, E.A., Chapter 14.1.1 Capacitance transducers – Basic Principles. Multiphase Flow Handbook, 2003. Crowe, C (editor), Multiphase Flow Handbook, (Taylor and Francis Group) ISBN 0-8493-1280-9. [2] Maxwell, J.C., A Treatise on Electricity & Magnetism, The Clarendon Press, Oxford, Vol. 1, 1st edition 1873. [3] Bruggeman, D.A.G., Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen, Annalen der Physik, 5. Folge, Band 24, 1935 [4] Van Beek, L., Dielectric Behaviour of Heterogeneous Systems. Progress in Dielectrics, Vol 7, 1967 [5] Ramu, T.S. and Narayana Rao, Y., On the Evaluation of Conductivity of Mixtures of Liquid Dielectrics, IEEE Transactions on Electrical Insulation. Vol. E1-8, No. 2, June 1973. [6] Hammer, E.A., Three-Component Flow Measurement in Oil/Gas/Water Mixtures using Capacitance Transducers, Ph.D. thesis, University of Manchester,. CMI-No. 831251-2, 1983 [7] Hammer, E.A., Multi modality tomography systems - State of the art and possible future applications. 5th International Symposium on Process Tomography in Poland, Zakopane, 25–26.08.2008 8