Respiratory Protection Program - LSU Fire and Emergency Training

advertisement

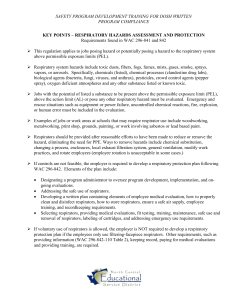

KING COUNTY FIRE DISTRICT 16 SAFETY MANUAL POLICY: 2405-01 Subject: Respiratory Protection Program Reference: WAC 296-305 and WAC 296-62 Part E Effective Date: Pages: 7 5/1/99 X-Ref. Policies/Procedures: 4100P-3 Attachments: Approved By: RESPIRATORY PROTECTION PROGRAM WAC 296-305, the State Fire Fighter Safety Standard, section 04001 (4) and WAC 296-62 Part E, the State Respiratory Protection Standard require that a written respiratory protection program, with specific procedures and elements for required respirator use, be established by an employer. There are additional requirements in WAC 296-62, Part I-I Asbestos, Tremolite, Anthophyllite and Actinolite and in Part J. WAC 296-305-01513 requires that "Every employer shall provide and require the use of appropriate safety devices and safeguards. All fire fighting methods and operations shall be so designed as to promote the safety and health of its employees. The employer shall do everything reasonably necessary to protect the safety and health of employees." Thus it is mandatory to have a respiratory protection program in place that is designed to reduce or prevent fire fighters exposure in IDLH, potentially IDLH, unknown atmospheres, and confined spaces. WAC 296-62 Part E Respiratory Protection requires the employer to develop and implement a written respiratory protection program in any workplace where respirators are necessary to protect the health of the employee, with required work site-specific procedures and elements for required respirator use. The program must be administered by a suitably trained program administrator. The written respiratory protection program shall be updated as necessary to reflect those changes in workplace conditions that affect respirator use. The employer shall include in the respiratory protection program all of the following provisions: Procedures for selecting respirators for use in the workplace. Medical evaluations of employees required to use respirators. Fit testing procedures for tight-fitting respirators. Procedures for proper use of respirators in routine and emergency situations. Procedures and schedules for cleaning, disinfecting, storing, inspecting, repairing, discarding, and otherwise maintaining respirators. Procedures to ensure adequate air quality, quantity, and flow of breathing air for atmosphere-supplying respirators. Training of employees in the respiratory hazards to which they are potentially exposed during emergency situations. Training of employees in the proper use of respirators, including putting on and removing them, any limitations on their use, and their maintenance. Procedures for regularly evaluating the effectiveness of the program. PROGRAM ADMINISTRATION The program administrator designated by the employer must be qualified by appropriate training or experience that is commensurate with the complexity of the program to administer or oversee the respiratory protection program and conduct the required evaluations of program effectiveness. This individual will have the authority to act on any and all matters relating to the operation and administration of the respiratory protection program. All employee/members must cooperate to the fullest extent with the Respiratory Protection Program Administrator. The person in this position will have the responsibility for monitoring or conducting an exposure assessment of the respiratory hazard, developing standard operating procedures for this program, maintaining records, and conducting program evaluations. The employer must provide respirators, training, and medical evaluations at no cost to the employee. General Requirements. The employer must provide an appropriate respirator based on the respiratory hazard(s) to which the worker is exposed. Because the fire service cannot identify or reasonably estimate the employee exposure in an emergency response, the atmosphere is considered to be IDLH. In IDLH atmospheres only a full facepiece pressure demand SCBA certified by NIOSH for a minimum service life of thirty minutes, or a combination full facepiece pressure demand supplied-air respirator (SAR) with auxiliary self-contained air supply is acceptable. All oxygen-deficient atmospheres also shall be considered IDLH. The employer must select a NIOSH-certified respirator. Respirators provided only for escape from IDLH atmospheres shall be NIOSH-certified for escape from the atmosphere in which they will be used. Each respirator must be used in compliance with the conditions of its certification. Management / Supervisory Responsibilities. The fire department may identify by way of policy, individuals or assignments that are responsible for insuring that personnel under their control are knowledgeable of the department's respiratory protection requirements and comply with the respiratory protection program, including respirator inspection and maintenance. Procedures including re-training and discipline should be administered for employees who do not comply with respirator requirements. An effective respirator program has these components: A written statement of policy Written standard operating guidelines Administration which includes: * Implementation * Periodic evaluation * Modification as needed * Documentation Employees / members. It is the responsibility the department to develop an awareness of the respiratory protection requirements as explained by policy and this manual. Employees are also responsible for wearing the provided respiratory protective equipment according to proper instructions and for maintaining the equipment in a clean and operable condition. They must also report to the responsible person any change in his/her medical status that may impact their ability to wear a respirator safely. MEDICAL EVALUATION Using a respirator may place a physiological burden on employees and the medical status of the employee. Accordingly, WAC 296-62 Part E specifies the minimum requirements for medical evaluation that employers must implement to determine the employee's ability to use a respirator. Every employee who is being considered for inclusion in the Respiratory Protection Program must participate in a medical evaluation. A determination is made initially upon employment, or change into a job classification requiring respiratory protection, and every twelve months thereafter. If the physician denies approval, the employee will not be able to participate in the Respiratory Protection Program. Copies of the medical evaluation and questionnaire must be kept in the employee's personnel file in accordance with policy. There are additional (optional) supplements to the questionnaire including a Request for Medical Clearance for Respirator users in the Medical Section of the Program Supplement. The program administrator will ensure the minimum information required for the medical questionnaire is completed and provided to the physician. A fire department should provide and require the structured participation of all members in a program to develop and maintain appropriate levels of physical fitness. The maintenance of a fitness level should be based on fitness standards determined by the department and physician that reflects the individuals assigned functions and activities, and that are intended to reduce the probability and severity of occupational injuries and illnesses. Limitations. The employer must provide a medical evaluation to determine the employee's ability to use a respirator before the employee is fit tested or required to use the respirator in fire department operations. The employer may discontinue an employee's medical evaluations when the employee is no longer required to use a respirator and cannot be assigned tasks requiring the use of SCBA. USE OF RESPIRATORS, SELECTING RESPIRATORY PROTECTION Only positive pressure SCBA with a rated 30 minutes or greater service life, or positive pressure air line respirators with auxiliary SCBA will be allowed in IDLH, potentially IDLH and unknown atmospheres. Negative and positive pressure respirators shall not be used with beards or other facial hair that prevents direct contact between the face and the edge of the respirator. The emergency response community usually goes straight to the positive pressure SCBA, which provides the best available respiratory protection. However, some response teams may be able to work using air purifying filter respirators for some of their work, so they and others who may use a variety of types of respirators will need to work from an established selection process for when and where each respirator may be used. The selection process must be contained in the respiratory protection program which will establish when and where each respirator may be used. The type of air purifying respirators referred to include: Singe use or quarter mask Half mask Full facepiece It is important to remember that downgrading the level of respiratory protection below that of positive pressure SCBA only may be done when the incident commander determines through the use of air monitoring and/or in the case of air borne pathogens, that the decreased level of respiratory protection will not result in hazardous exposures to personnel. Single Use or Disposable Respirators A respirator must be provided to a member who transports an individual with suspected or confirmed infectious TB in an enclosed vehicle (e.g. ambulance, helicopter) or who transports an individual with suspected or confirmed infectious TB within a facility when that individual is not masked. Single use or disposable respirators are used for protection against M Tuberculosis (TB). These HEPA or N-HEPA filters are highly efficient, they remove the airborne TB virus or droplets by physically trapping them as air is inhaled though the filter material. Individually issued respirators may be re-used and only discarded when excessive resistance, physical damage, or any other conditions renders the respirator unsuitable for use. Mechanical Filter Respirators Mechanical filter respirators do not provide protection against gases, vapors, or oxygen deficiency. These filters consist essentially of a soft resilient facepiece of either half mask or full face design to which is directly attached one of several types of mechanical filters. Other than the difference between a half-mask and a full facepiece, which is used when the particulate exposure is harmful irritating to the eyes, as well as the respiratory tract, the filter is the most essential component. Mechanical filter respirators are approved for one or any combination of the following particulate hazards: nuisance, fibrosis-producing and/or toxic dusts; mists and fumes; radon daughters and radionuclides. Chemical Cartridge Respirators Chemical Cartridge Respirators are non-emergency respiratory protection devices and should never be used in immediately dangerous atmospheres (IDLH) They afford protection against light concentrations of certain acid and alkaline gases, organic vapors and mercury vapors by utilizing various chemical filters to purify the inhaled air. They differ from mechanical filter respirators only in that they use cartridges containing chemicals to remove harmful gases and vapors. RESPIRATOR TRAINING Employee training must be performance orientated. Members will be tested on their knowledge of their responsibilities in the respiratory protection program. They will also be instructed in the hazards, need, use, limitations, and care of their respirator using materials from the Training Appendix. Retraining must be given at least every quarter and annually after the initial training for each individual. FIT TESTING Before an employee may be required to use any respirator with a negative or positive pressure tight-fitting facepiece, the employee must be fit tested with the same make, model, style, and size of respirator that will be used. The department's Respiratory Protection Policy will specify the kinds of fit tests allowed, and the policies' medical appendix will describe the procedures for conducting them, and how the results of the fit tests must be used. When fit test problems occur with specific challenge agents, there are choices of challenge agents and related protocols described in the Supplement to the Respiratory Program. Positive pressure tight fitting respirators are fit tested in the negative pressure mode. Individual fit testing records are kept on each individual completing the Qualitative or Quantitative Fit Test. Record forms are found in the Policy Fit Test Appendix. Fit testing of employees with any facial hair growth such as stubble beard growth, beard or long sideburns that extend under the face seal or interfere with the facial seal is prohibited. SCBA INSPECTION, MAINTENANCE CARE AND STORAGE The respiratory protection program must indicate the means by which respirators will be maintained to retain their original effectiveness by way of periodic inspection, repair, cleaning and proper storage. This respiratory protection standard requires the employer to provide for the cleaning, disinfecting, storage, inspection, and repair of respirators used by employees. Storage. The employer shall ensure that respirators are stored to protect them from damage, contamination, dust, sunlight, extreme temperatures, excessive moisture, and damaging chemicals. They shall be packed or stored to prevent deformation of the facepiece and exhalation valve. Whenever feasible, individual facepieces should be issued with individual members responsible for cleaning, inspection and storage. Cleaning and disinfecting. The employer must provide each member with a respirator that is clean, and sanitary. The employer shall ensure that respirators are cleaned and disinfected using the procedures in the Respiratory Protection Policy appendix, or procedures recommended by the respirator manufacturer, provided that such procedures are of equivalent effectiveness. Respirators shall be cleaned and disinfected at the following intervals: Respirators issued for the exclusive use of an employee shall be cleaned and disinfected as often as necessary to be maintained in a sanitary condition. Respirators issued to more than one employee shall be cleaned and disinfected before being worn by different individuals. Respirators used in fit testing and training shall be cleaned and disinfected after each use. Inspection. The employer must ensure that respirators are inspected before each use and during cleaning. Respirator inspections include the following: A check of respirator function, tightness of connections, and the condition of the various parts including, but not limited to, the facepiece, head straps, valves, connecting tube, and cartridges, canisters or filters. A check of elastomeric parts for pliability and signs of deterioration. Self-contained breathing apparatus shall be inspected monthly. Air cylinders shall be maintained in a fully charged state and shall be recharged when the pressure falls to 90% of the manufacturer's recommended pressure level. The employer shall determine that the regulator and warning devices function properly. Company officers should periodically spot check respirators for fit, usage and condition. Detailed inspection procedures are located in the Respiratory Program Policy Appendix. Repairs. The employer shall ensure that respirators that fail an inspection or are otherwise found to be defective are to be removed from service immediately and replaced, discarded, repaired or adjusted in accordance with the following procedures: - - Repairs or adjustments to respirators are to be made only by persons appropriately trained to perform such operations and shall use only the respirator manufacturer's NIOSH-approved parts designed for the respirator. No attempt shall be made to replace components or make adjustments, modifications or repairs beyond the manufacturer's recommendation. Repairs shall be made according to the manufacturer's recommendations and specifications for the type and extent of repairs to be performed. Reducing and admission valves, regulators, and alarms shall be adjusted or repaired only by the manufacturer or a technician trained by the manufacturer. Fire fighters must in no way adjust the interior parts of a regulator unless he/she is a certified technician trained by the manufacturer or a recognized agent of the manufacturer. BREATHING AIR QUALITY AND USE The employer must provide employees using atmosphere-supplying respirators (supplied-air and SCBA) with breathing gases of high purity and ensure that compressed air, compressed liquid air, for respiration accords with the minimum requirements for Grade D Air established by the Compressed Gas Association as stated in Commodity Specification for Air (ANSI/CGA G-7. 1), 1989 as well as meeting a water vapor level of 24 ppm or less. Air must be tested at least quarterly, see Breathing Air Quality Appendix. Testing. SCBA bottles, and Cascade System DOT bottles must be tested at a frequency specified by the manufacturer. RESPIRATOR USE Use of Respirators. Members must use a properly fitting respirator at all times while performing an operation defined as hazardous or potentially hazardous. Operations in the following situations are considered hazardous: Smoke Overhaul Oxygen Deficient Airborne Pathogens Toxic, Poisonous Members must use only positive pressure SCBA in IDLH situations, unknown atmospheres or concentrations and oxygen deficient atmospheres. Negative pressure respiratory protection may only be used for fumes, mists and airborne pathogens where the substance and its concentration is known. Emergency Procedures. Training must cover emergency procedures for each model of SCBA utilized by the department. Team Requirements. Members must not work in a hazardous atmosphere on an individual basis. Fire Fighters must always work in teams of two with additional members suitably equipped with a similar breathing apparatus in contact with the entry team and available to render assistance if necessary. PROGRAM EVALUATION In addition to periodic monitoring, the Respiratory Protection Program must be reviewed and evaluated every twelve months. The program evaluation must determine that SCBA's are used, fitted and maintained in a safe manner. The program is audited by using the procedures in the Program Evaluation Appendix and immediate action must taken to correct all defects found in the evaluation. A written report should be made of the evaluation, summarizing the findings and recommended target dates for implementation of corrective plans. Copies of the summary reports would be filed with the Department's Safety Officer. Program evaluation records shall be maintained for a five (5) year period. Requirements. The requirements contained in the Respiratory Protection Program are not optional for members. The Department must consider their policy mandatory and a condition of employment for each member.