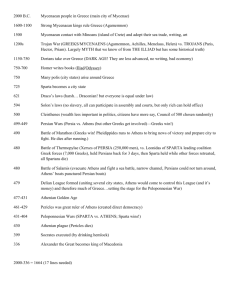

Abstract

advertisement

Friday 28/09/2012 09:15 – 11:30 B.1. Control & Automation Session Chair: C. Alafodimos – D. Dimogianopoulos – D. Kalligeropoulos – S. Vassiliadis B.1.1. Case study: Test-Rig for shape-shifting aircraft control surfaces. Manufacturing process of the Test-Rig Chris Cabouris (1), Nicolas Cabouris (2) (1) Technological Educational Institute of Piraeus, Department of Electronic & Computer Systems, 250 Thivon avenue, Athens, 122-44, Greece, aims_021@yahoo.com, (2) Stakam s.a., Advanced Industrial Manufacturing Systems 55-57 Adigonis str. Athens, 104-42, Greece, stakam@stakam.gr Abstract The scope of the current paper is to illustrate the manufacturing details of a completed construction from the field of aeronautical research. The case study refers to the manufacturing of a Test-Rig which will be used for the assessment of aircraft flaps or ailerons implementing morphing materials. This is a part of a large European Community research project. Shape-shifting or morphing surfaces are of great interest to EC academic institutes as well as the aviation industry since they commonly pursue the incorporation of greener technologies in flights. The flaps undergo a series of stress tests that recreate the loads during a number of full flight cycles; a flight cycle includes take-off, cruise and landing. Stress tests comprise of different combinations of static and dynamic loads, since a key component of a flap assessment is the characterisation of its vibrational behavior. The rig receives all the test loads. It is designed to withstand them, with the minimum interference in the measurement processes. Furthermore, the rig is scheduled to participate in tests in different laboratories across Europe. Two of the key specifications have been the ease of disassembly - transportation (by air or ground vehicles) - assembly, and assuring that assembly accuracy is maintained. Naturally, another key issue has been the cost. 3D CAD and CAE software tools have been extensively used for the design. Informatics helped to speed up the creation and the validation of a test-rig model, indicating that the rig behaves under load according to requirements. And yet, one of the most crucial aspects of the development phase is the “design for manufacturability” issue. Requiring expertise and skills, “designing for manufacturability” still remains an engineer's duty, even though software tools have evolved exponentially. This paper presents the manufacturing process of the test rig highlighting a few of the important points where “manufacturability” is involved. From a systemic point of view, this paper addresses the subject of closing the design loop, from concept to implementation. Keywords : Test-Rig, design for manufacturability, precision alignment. 1 B.1.2. Aeronautics R&D on the ground: CAD & CAE tools facilitate the structural design of an experimentation platform. 3D software assisted modelling and analysis of the load bearing structure Chris Cabouris (1), Nicolas Cabouris (2) (1) Technological Educational Institute of Piraeus, Department of Electronic & Computer Systems, 250 Thivon avenue, Athens, 122-44, Greece, aims_021@yahoo.com, 2 ( ) Stakam s.a., Advanced Industrial Manufacturing Systems 55-57 Adigonis str. Athens, 104-42, Greece, stakam@stakam.gr Abstract Novel architectures for aircraft control surfaces (flaps, ailerons, stabilizers, canards, rudders, etc.) have been a major focal point of the aeronautic research & development community. In our times, prototypes are initially rendered on computer screens where they undergo static and dynamic analysis among other tests. After a series of refinements, a prototype is actually constructed and submitted in a number of tests, since its characteristics and behavior must be assessed and compared against specifications and expectations. The present document reports the main information about a test rig that will be used for measuring and assessing the characteristics of aircraft flap prototypes. Being itself a prototype, the test rig has been developed and studied with the use of CAD systems. The inputs of the design process in the initial phases have been the flap dimensions, expected aerodynamic loads on flap, nature of tests to be conducted and required access space. During the design process, a number of possible implementations has been suggested and studied with the help of CAD and CAE tools. Finally, the candidates have been narrowed to one, which, after thorough examination, has got approved for construction. A brief selection of the final 3D model drawings, manufacturing drawings, of the static analysis & modal analysis results, appear in the paper. Furthermore, the paper offers examples on how CAD software helps detect weak areas and points-out the areas that need improvement. In this sense, CAD platforms act as decision-support tools, long before the implementation phase, i.e. before any single part is constructed. Keywords : Test-Rig, Airplane flaps, Static Analysis, Modal Analysis, 3 Dimensional design platforms. B.1.3. Energy Savings & Power Quality in dc Motor Driving Systems in the Hellenic Territory: Methodology & Early Results G.Ch. Ioannidis1, C.S. Psomopoulos1, S.D. Kaminaris1, G.A.Vokas2, P. Pachos1 and S.Tsiolis1 1 Department of Electrical Engineering, TEI of Piraeus, P. Ralli & Thivon 250, 122 44 Egaleo, Greece, Tel: +30 5381578, Fax: +30 5381578, E-mail: gioan@teipir.gr 2 Department of Electronics Engineering, TEI of Piraeus, P. Ralli & Thivon 250, 122 44 Egaleo, Greece, Tel: +30 5381180, Fax: +30 5381180, E-mail: gvokas@teipir.gr Abstract 2 In this paper a research work and its preliminary results exploring the possibility of energy savings in existing dc drive systems in Greece are presented. The purpose of this research is to develop a new motor drive system and its respective control technique to upgrade existing dc drive systems in order to reduce power consumption and at the same time effectively control their speed and torque characteristics. In addition, the new high-voltage low loss semiconductor switches relying on silicon carbide (SiC) are studied, and compared to the existing silicon (Si) semiconductor switches. Furthermore, the possibility of applying H∞ or/and fuzzy logic theory to optimize the control of the dc drive system and the application of a reduced losses dc converter will be considered. Moreover, the harmonic distortion due to the use of rectifiers will be investigated and the methodology for the measurement of the low order harmonics and related disturbances emitted to the network is presented. B.1.4. Simulation of magnetohydrodynamic stability control with high-frequency electromagnetic waves in nuclear fusion experiments Ioannis Kakogiannos, Department of Automation, Technological Educational Institute of Piraeus250, Petrou Ralli & Thivon str., Egaleo, 122 44 Athens, Greece, E-mail: gkakogiannos@gmail.com Christos Tsironis , School of Electrical & Computer Engineering, National Technical University of Athens 9, Iroon Polytechneiou str., Zografou, 157 80 Athens, Greece, Email: ctsiron@mail.ntua.gr (also at: ctsiron@teipir.gr) Iordanis K. Giannopoulos, Department of Automation, Technological Educational Institute of Piraeus 250, Petrou Ralli & Thivon str., Egaleo, 122 44 Athens, Greece, E-mail: iogian@teipir.gr Dimitrios Kalligeropoulos, Department of Automation, Technological Educational Institute of Piraeus 250, Petrou Ralli & Thivon str., Egaleo, 122 44 Athens, Greece, E-mail: dkal@teipir.gr Abstract Controlled thermonuclear fusion, still in experimental stage, is a prospect for a viable and environment-friendly solution to the energy problem. Necessary for optimizing tokamak device operation is to develop automatic control systems that implement the entire loop from the diagnostic sensors to the actuators, in order to control multiple plasma parameters connected to the magnetic equilibrium, stability and machine safety. The main actuators involved in tokamak control schemes are magnetic coils, electromagnetic waves and gas puffs, where high-power microwave sources are used for handling plasma instabilities and for measuring the plasma state. In present-day experiments the implemented control schemes are rather simple, however in ITER more sophisticated control design will be required, involving realistic closed-loop control simulations, modern control concepts and real-time estimation in terms of computationally feasible plasma models. In this work we present the current status in the development of a block system design for the simulation of magnetohydrodynamic instability control. The control design is developed in Simulink and includes: (a) the open-loop system dynamics, coming from an established physics model for the instability evolution, (b) the model for the wave actuation, which involves the steerable mirror guiding the beam to the plasma, the motor controlling the mirror rotation and the plasma wave propagation, (c) the effect 3 of the diagnostic sensors, based on the physics processes in the measurement of the instability parameters, and (d) controller design based on classical and modern control tools. We identify the characteristics of the control problem regarding the transient response and the steady-state error of the closed-loop system under realistic conditions, as well as the effect of the system parameters and the input on the controller design. Keywords: Controlled thermonuclear fusion, electromagnetic waves, tokamak control simulations. B.1.5. Acceleration of Finite Impulse Response Filter Algorithms with Hardware, to Embedded System in a Programmable Device I.Maltezos1, V. Adrianoupolitou2 1 Computer Systems & Networks Laboratory, 7th School Laboratory Center, Pireaus, Greece Tel: 2109937947, E-mail: johnmaltezos@hotmail.com 2 HELLENIC SCIENTIFIC ASSOCIATION FOR TECHNICAL - VOCATIONAL EDUCATION AND TRAINING, Athens, Greece Tel: 2108053539, E-mail: a_vassia@hotmail.com Abstract The target of the reported study is the design of a Digital System on Programmable Chip, aiming at the optimized output, from side of time, of a digital finite impulse response filter. This is achieved by two ways, with the addition of hardware accelerator that collaborates in the realization of the filter algorithm with the NIOS II processor of ALTERA, and with the addition of special instructions in the processor instruction set. It is done bibliographic examination in the subject of special purpose processors in order the reader to know the design techniques of the system. A special purpose processor is designed for an application or for group of applications with common characteristics. The success of the design lies to the most optimal exploitation of particular characteristics of applications, so the requirements in speed, surface, and consumption of power are satisfied. For this purpose, the effort is focused in the optimization of intensive, computational, calculating tasks that are critical for the total performance of the processor. The system is based on the soft-core processor NIOS II of ALTERA and on hardware IP cores that are provided, thus we are analyze completely the technical characteristics and the utilization method for the above cores. Before the stage of system realization, it was useful to report the fundamental mathematics of digital signal processing, on which we based in order to design the hardware accelerator system and the hardware on what we execute the special instruction of digital finite impulse response filter. For reasons of realistic approach in the design methodology for the software system, was used the Real Time Operating System FreeRTOS, wich runs all realization processes for digital signal processing algorithms, as much as the processes that are used to display the measurements on screen and the operational validation of the system. In the stage of hardware realization, are presented analytically the design process of the accelerator and the way to import the special instruction, as well as the results of optimization that we achieve from the above approaches. 4 The case study objectives which were achieved are: the important acceleration for implementing a digital finite impulse response filter algorithm, about 40 times with use of hardware accelerator, and 100 times with use of special instruction that is embedded in the instruction set of processor NIOS II, the investigation of a way to design software with use of Real Time Operational System for processor NIOS II and the presentation of a methodology for design other corresponding systems that requires acceleration of execution time. In order of the methodology practical appliance, were imported, sound, and numerical data, in order to be evaluated for the output and the validation of the designed system. Key-words: Embedded Systems, Systems on Programmable Chip, HardwareSoftware Co-Design, Real Time Operating Systems, Application Specific Instruction Processors B.1.6. Programming the Solar Station in LabVIEW: A study in the Design and Development of a Complete Measurement System Argyris Konstantinos1, Michalis Loukas2, Panetsos Spyros3 and Vandoulakis Antonios4 1 Lecturer, Department of Electronics Engineering, ASPETE, kargiris@aspete.gr 2 External Labs Staff, ASPETE, lmichali@otenet.gr 3 Associate Professor, Department of Electronics Engineering, ASPETE, s.panetsos@aegean.gr 4 Technical Engineer, Epsilon Metrix, a.vandoulakis@emetrix.gr Abstract Computers have been built and programs have always been written to process data. Numerical and text data would be read from the screen or from files, in the computer’s hard disk and the output of the processing would similarly be written on the screen or in various files, in the computer’s disk. As processors have become both smaller and faster, the computer’s range of applications has become broader. The types of data and the form of processing have grown more complex to include the processing of speech, images, video and the production of motor action. The source of data that used to be constrained to manual input from the keyboard and file I/O operations from the computer’s hard disk, has expanded as sensors and measurement devices get connected to the computer and directly feed data, images and measurements into its processing unit (Figure 1). The processor inside a computer takes the form of a microprocessor or a microcontroller. In that form, it runs the programs and applications in mobile phones and household appliances. It controls various systems, like the ABC system in cars, functions as the executive center of robots and becomes part of measurement systems, reading and processing measurements and producing various actions in response to those measurements, by operating motors and the switches in measurement organs. Microprocessors and microcontrollers serve as the basis to build embedded systems. They are connected to sensors, measurement organs and motors to form DAQ systems. Different processors can be combined across networks to form distributed systems. As the processor is embedded into real time modules, new methods have emerged for programming those more complex systems: the GPIB protocol, FPGA and Graphical programming. 5 In this paper we examine the common component, underlying embedded, measurement systems and robotics. The hardware and the programming environments and methods that we use to develop the extended programs that control those systems, reading data form sensors and measurement organs, processing that data and producing the appropriate motor action. We examine the programming of measurement and embedded systems, by programming the NXT solar station (Figure 2), in LabVIEW. The solar station is built out of the Lego Mindstorms NXT pieces. It consists of a solar panel, sensors tracking and detecting a light source and motors that can rotate the solar panel in the three dimensional space to track the movement of the light source. In the paper / presentation, we will show how we can program in LabVIEW, the solar station to track a moving light source that changes its position, matching the sun’s daily movement. The objective is to build a stable and robust solar tracker that can take into account and compensate for seasonal variations in the sun’s movement. That can track the light’s movement under various conditions, as when a surface temporarily obstructs the light, corresponding to clouds hiding the sun, gradually building a real world system, made of sensors and motors that could control and guide the movement of an actual solar panel. 6 B.1.7. Increasing the efficiency through optimize production parts enrollment Böhm Gabriella, Doble Liliana, Pop Mirela Abstract This paper aims to show how the work of MD Best Nest program in achieving the fastest and best classification of a product templates. MD Best Nest is a program designed to optimize framing textiles, realizing fully automatic framing, improving their time granted by the user (maximum 2 minutes). Also it is possible to achieve and framing manually, or automatically combining the manual framing with that. [X] [Y]. Placement efficiency achieved automatically by MD Best Nest exceeds the efficiency obtained mostly through manual classification in conditions of impeccable quality and placement of related parts to reduce the time allocated to achieve them. Framing is the operation by which all parts of a product template which is placed on corresponding material, taking account by restrictive rules. The main objective of framing is rational use of surface material. After framing are obtained some indicators that give us information about the material recovery efficiency, and thereby cause some changes in the constructive design of product. To the achievement of framing should be considered the restrictive conditions which are imposed, mainly by specific nature and material, required features by the model and by technological operations to be used in the cutting operation [ST-HZ]. Keywords: patterns, employment, product reference, restrictive conditions, material recovery. B.1.8. Increasing production efficiency of garments industry using new automated systems Doble L.; Bohm G. ; Cicarac (Muresan) D. A. Abstract Robotics have changed the financial circumstances increasing the volume of industrial fixed assets, improving production conditions, which will increase the reliability of operational, executive and management systems. With the introduction of new robotic technologies, organizational training activities are activities with the highest importance. The advances achieved in information technology, expansion of electronic computers, office computers and personal information enhances the statement of the importance of economic growth and development resource, a consumer good and with social value. Until recently it was thought that automating processes of production was profitable only to achieve high range products. Today, this have broad applicability and implementation by products of small series or for achieving of so-called "on order" production. Advances in microelectronics and information processing have resulted in new models of sewing machines and microprocessors. It is distinguished by: specific features of graphics memory variants sewing, sewing variants change, adaptation from sewing to the next version, automation of fixing, sewing operations, unloading / loading parts, production and display of shutdowns. 7 Keywords: Robotics, microelectronics, manufacturing system, control system, database. B.1.9. Robust Distributed Fuzzy Tracking For Swarm Based UAV Missions Under Unknown Environmental Conditions Georgios P. Kladis Hellenic Army, Nikolaou Floutzi Str., 12461, Chaidari, Athens, Hellas E-mail: klamouf@gmail.com, gk110@leicester.ac.uk Abstract This paper focuses on a systematic analysis for the tracking problem in swarm-based missions for Unmanned Aerial Vehicles (UAVs) with linear and angular velocity constraints flying under unknown wind information. A distributed Takagi-Sugeno (TS) framework design is adopted for the representation of the nonlinear model of the dynamics for the swarm of UAVs. The distributed control law introduced is composed of both node and network level information. Firstly feedback gains are synthesised, using a Parallel Distributed Compensation (PDC) control law structure, for the isolated UAVs while ignoring communications among the swarm. The resulting common Lyapunov matrix is utilised at network level, to incorporate into the control law the relative differences in the states of the agents, to induce cooperative behaviour. Eventually stability is guaranteed for the entire swarm. The control synthesis is all performed using tools from linear control theory where criteria are posed as Linear Matrix Inequalities (LMIs). An illustrative example based on a UAV tracking scenario is included to outline the potential of the analysis. Keywords: Graph theory, Multi-agent systems, Consensus, Parallel Distributed Compensation, Takagi-Sugeno fuzzy model, Linear Matrix Inequalities, Robust control. B.1.10. A Graphical User Interface for Unmanned Aerial Vehicle Missions For Navigation Purposes Georgios P. Kladis Control Group, Department of Engineering University of Leicester, University Road, Leicester, LE1 7RH, United Kingdom E-mail: klamouf@gmail.com, gk110@leicester.ac.uk Abstract The aim of this report is the development of a Graphical User Interface (GUI) platform to be used for general case fixed wing Unmanned Aerial Vehicle (UAV) missions. This is capable to aid the operator for navigation purposes for the UAV mission under nominal conditions and in case there is loss or failure of the Global Positioning System (GPS). The common practice for navigation purposes is the use of GPS or onboard sensors in the UAV, or other hybrid approaches which have their limitations and drawbacks. Thus the demand is towards an approach that can be fully autonomous, immune to exogenous disturbances, is decoupled from information broadcasted to the Aerial Vehicle (AV), can perform real-time while in flight, and 8 rely on robust and efficient sensors that are embedded in the payload of the vehicle. In the literature, such an efficient approach utilises the information content of the terrain in order to estimate the position of the UAV. This is termed Terrain Aided Navigation (TAN) and a statistical approach (Particle Filters-PFs) is adopted for the sollution of the localisation of the UAV in this report. The platform developed, includes tools to assist the operator for the UAV mission such as the mission planification, the motion planning, the tracking module, and the estimation of position in the event of GPS loss etc. Thus a more complete, user friendly, and close to reality platform is outlined. The potential of the analysis is illustrated through a mission scenario where the UAV is deployed over the region of Arcadia. Keywords: Terrain Based Navigation, Particle filters, Graphical user interface, Control, Takagi Sugeno fuzzy model, Linear matrix inequalities, Graph theory. 9