Supplemental Info revised

advertisement

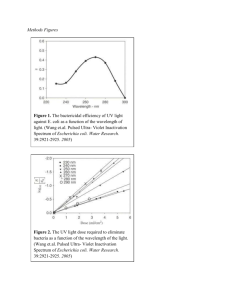

Supplementary Information Periodic Arrays of Gold Nanodisks Coupled with Evanescent Spectroscopy Hao Jiang1, Touraj Manifar1,2, Aref Bakhtazad1, HosseinHojjati1,2, Jayshri Sabarinathan1 and Silvia Mittler2 1 Department of Electrical and Computer Engineering, The University of Western Ontario (Western University), London, ON N6A5B9, Canada. 2 Department of Physics and Astronomy, The University of Western Ontario (Western University), London, ON N6A3K7, Canada I. SAMPLE FABRICATION A. Fabrication and characterization of channel waveguides Channel waveguides were fabricated using ion-exchange on metal-masked Schott BK7 glass slides (Hellma Optics, Germany). The fabrication procedure is shown in FIG. S1. Prior to ion-exchange, first titanium fiducial marks were fabricated on top of the BK7 glass using photolithography, metal deposition and lift-off. In later processing steps, the waveguide channels and the gold nano-disk arrays will both be aligned relative to these fiducial marks. The glass was first thoroughly cleaned using nanostrip solution (Cyantek Inc., USA) and coated with 5 nm of chromium and 100 nm of gold by evaporation deposition (Hoser, USA). Then the samples were coated with a positive photoresist (S1805, Shipley, USA) and exposed photolithographically through a hard mask at a wavelength of 405 nm in a mask aligner (Karl Süss MA6, Germany) to form the desired waveguide structures in photoresist. Prior to the exposure the waveguide channels were aligned to the fiducial marks. After development, the photoresist became a pattern with waveguide openings. Wet chemical etching was used to etch the gold and chromium layers sequentially, which transferred the pattern from the photoresist into the metal film. Gold was etched by a gold etchant (TFA, Transene Company Inc., USA) for 60 seconds. Chromium was etched by a chromium etchant (Cr etchant 1020, Transene Company Inc., USA) for 30 seconds. Then the photoresist was removed by N-methyl-2-pyrrolidone (MicroChem Corp., USA) and the samples were thoroughly cleaned using nanostrip. The samples with the patterned metal masks were now ready for ion-exchange. The samples were immersed into molten salt, a mixture of NaNO3 and AgNO3 (molar ratio 9:1). The temperature was controlled to be 360 oC. The Ag+ - ions in the molten salt were allowed to exchanges with the Na+- ions in the top surface layer of the glass for about 45 min. Since Ag+ - ions have a larger polarizability than Na+ - ions, the refractive 1 index of the glass material with exchanged ions increases. Since the ion-exchange took place only within a few micrometers from the surface of the substrate, and only through the openings in the metal mask, a high refractive index region was formed and surrounded by low refractive index, yielding optical channel waveguides. After the ionexchange step, the metal mask was removed using the gold and chromium etchants. In the following, the end-surfaces of the sample were polished using diamond lapping paper (Buehler, Canada). FIG. S1: Scheme of the fabrication procedures of the channel waveguides using ion-exchange technique. The waveguide pattern was designed into a double-S bend configuration. The bends implemented here were able to remove higher order waveguide modes and substrate modes. In the region where nano-disk arrays were to be fabricated, the waveguides were tapered to 100 µm width and can be approximated as a slab waveguide. In order to characterize the channel waveguides, a slab waveguide was fabricated under identical conditions and characterized by m-line spectroscopy using a 632.8 nm HeNe laser (Newport, USA) [1]. FIG. S2 shows the refractive index diffusion profile calculated using the WKB method [2]. 2 FIG. S2: Refractive index profile of a BK7 glass ion-exchanged slab waveguide (after 45 min. of ion-exchange), characterized by prism coupled m-line spectroscopy (WKB method). B. Fabrication of gold nano-disk arrays The 2D Au nano-disk arrays in square lattice were fabricated on top of the ion-exchanged waveguides by electron beam lithography (EBL). The fabrication process is schematically outlined in FIG. S3. After the waveguide substrate was thoroughly cleaned by nanostrip, a 300 nm thick photoresist (ZEP520A, ZEON Corp., USA) layer was first spin-coated on top. A 20 nm thick sacrificial chromium layer was sputtered on top of the photoresist to make the substrate conductive. Before EBL exposure, the alignment program was implemented to align the pattern relative to the fiducial marks, so that the AuNPs pattern can be written on top of the waveguide with sufficient accuracy in positioning. Patterns of nano-disk arrays, precisely controlled by the EBL system, were then exposed on the photoresist. After EBL, first the chromium layer was removed by the chromium etchant followed by developing the photoresist in amyl acetate (Sigma-Aldrich, Canada) for 180 seconds. After developing the photoresist, 2 nm chromium and 50 nm gold were sequentially deposited onto the patterned photoresist by electron beam evaporation deposition. Finally, a lift-off process of the sample immersed into N-methyl2-pyrrolidone removed the photoresist and the metal on top, leaving the periodic array of gold nano-disks on top of the waveguide channels. 3 FIG. S3: Scheme of the fabrication of periodic arrays of elliptical Au nano-disks on channel waveguides. FIG. S4 show the fabrication results. As seen in the optical microscope image in FIG. S4(a), a Au nano-disk array was located on top of the waveguide. FIG. S4(b)-(d) show the atomic force microscopy (AFM) images of some fabricated nano-disk arrays. The lattice constants of the fabricated arrays were 500 nm, 550 nm and 600 nm, respectively and the fabricated nano-disks were about 50 nm in height and in slightly elliptical in shape with average diameters of 190 nm and 215 nm in the X and Y directions, respectively. FIG. S4: Images of fabricated samples. (a) Dark-field optical microscope image of a fabricated sample, waveguide and fiducial marks. The red dotted lines serve as guide for eyes to find the boundaries of the tapered waveguide. AFM images of fabricated Au nano-disk arrays with lattice constants of (b) 500 nm, (c) 550 nm and (d) 600 nm. 4 II. WAVEGUIDE TRANSMISSION MEASUREMENT The extinction spectra of the fabricated devices were measured by a waveguide transmission setup. The scheme of the setup is shown in FIG. S5. Broad-band light (360 nm – 2000 nm) from a light source (HL-2000, Ocean Optics, USA) was coupled into an optical fiber (Ocean Optics, USA) and collimated into a parallel beam. The beam was then focused by an objective lens (40×) into a spot of around 40 µm diameter onto the polished end fire of the waveguide. The transmitted light was collected by another objective lens (10×) and coupled into a spectrometer (HR2000, Ocean Optics, USA) measuring an intensity spectrum. Alignment stages were implemented for finely adjusting the positions of the focused beam to optimize the coupling efficiency of the light into the waveguide. A polarizer selected the excitation of the TE or TM waveguide mode. To measure the extinction spectrum of a sensor channel, a reference intensity spectrum Iref(λ) was first measured from an ‘empty’ waveguide channel (no AuNPs) and then the intensity spectrum from a waveguide channel with AuNPs on top Idev(λ) was measured under the same condition. The extinction spectrum for the corresponding device is given by Ext (λ) = - log10 (Idev(λ)/ Iref(λ)) (1) A fluidic chamber was built on top of the waveguides using a silicone isolator and a piece of microscope glass slide (Sigma-Aldrich, Canada). Water was introduced into the chamber so that each nano-disk array was measured under water. The TE and TM modes correspond to different polarization directions relative to the geometry of the Au nanodisks. For the TE mode polarization, the electric field is oscillating along the longer axis of the ellipse, while for the TM mode polarization, the electric field is oscillating along the shorter axis and the vertical axis of the ellipse. The double-S bends were implemented into the waveguide pattern design so that higher order waveguide modes could be effectively filtered out. Therefore, the waveguide modes interacting with the Au nano-disks were predominantly TE0 and TM0 modes. The measured extinction spectra for the TE0 and TM0 modes are presented in FIG. S6. The TE0 and TM0 mode excites distinctively different LSPR resonances. A single resonance peak appears for the TE mode and red-shifts with increasing lattice constants. For the TM mode, there are multiple resonance peaks, corresponding to the two electric field polarization directions. Due to the undesirable formation of silver colloids during the ion-exchange process, the optical losses of the waveguides were too high and lead to a low signal-to-noise ratio. The measured extinction spectra were thus quite noisy. We have attempted to change the refractive index of the dielectric environment surrounding the AuNPs and measured the extinction spectra, but the peak-shifts were found to be very difficult to accurately quantify due to the high noise level. Sensing applications using this waveguide structure require improvement on the waveguide quality. 5 FIG. S5: Scheme of the waveguide transmission setup FIG. S6: Measured extinction spectra for structures of different lattice constants interrogated with (a) TE0 mode and (b) TM0 mode of the waveguide. III. REFERENCES: [1] T.-M. Lee, S. Mittler-Neher, D. Neher, G. Stegeman, C. Roux, M. Leclerc, J. Martin, and S. Najafi, “Side-chain dilution effects on the optical properties of poly[3alkylthiophene]s,” Optical Materials, vol. 1, no. 2, pp. 65 - 70, 1992. [2] S. I. Najafi, Introduction to glass integrated optics, Artech House, Boston, MA, 1992. 6