TND00022301000000000000DAE01101

advertisement

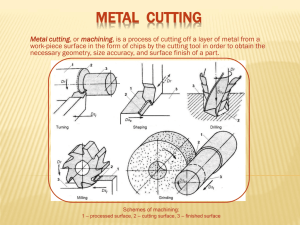

ANNEXURE – 1 TO TENDER ENQUIRY NO.: DPS/AMPU/CAP/497 Technical Specifications of the items CLOSED CHAMBER ABRASIVE CUT-OFF MACHINE FOR PETROLOGY LABROATORY The closed chamber abrasive cut-off machine useful for cutting of geological rock samples for petro-mineralogical studies. The specifications of the machine should conform to the following: 1. Cutting capacity : Up to 80 mm solid bar stock 2. Cutting wheel : 300 mm diameter and 2 mm thick Al2O3 cutting wheel 3. Heavy duty motor :10 HP 3 phase,440 volts 4. Cutting motion : Swinging type arm and with two links & lever mechanism for the effortless cutting with lever outside the chamber 5. Vice dimensions : 150(W),47(H), 110(opening ) in mm 6. X-Y sliding plate : Made out of m.s plate with heat treated and chrome plated components . The vice to be a integral part of the X-Y plate sliding motion 100 mm in X-Y direction achieved with the help of wheels provided outside the machine . Dim: 350 mm(W)x300mm(D)x215(H). 7. Coolant throw system: Cast Aluminium wheel guard having focused veins wiper fitted on window for clearing the mist deposited side port provided for insertion of extra large components 8. Operation Panel: Consists of on/ off switch with key. Emegency stop , indication lampsfor machine start , door open , line on and limit switch for door . 9. Heavy duty stand : The stand should comprise of various storing racks for consumable, tool kit , cut jobs, cutting wheels with provision for incorporation of coolant pump/slump arrangement mounted on castors(for easy cleaning access). SEMI AUTOMATIC POLISHING/GRINDING MACHINE FOR MICROSCOPIC STUDIES ON GEOLOGICAL SAMPLES Semi automatic polishing/grinding machine for lapping work of geological samples for microscopic studies. 1 Disc : Aluminium disc, well dynamically balanced ,dia-200 mm 2. Pneumatic loaded semi automatic polishing machine for low work volume laboratories 3. Specimen holding capacity , 6Nos 4. Motor : 1 HP 5. 6. Grinding polishing disc- 200 mm Machine Top- Sturdy top, anticorrosive F.R.P moulded with built-n-sink, with water faucet &quick drain outlet for wet polishing . The suppliers should enclose brochure of the product offered. The quote should also include the list of laboratories, preferably government institutions (CSIR, DAE, Defence, IIT, Universities etc.) to whom similar units were supplied in the last five years along with the date of supply and copy of the Purchase Order. They should also enclose performance certificate , if any, from the clients already using the machines. All the brought out items viz. motor, electronic/electrical components should be of reputed make with certificates attached (Kirloskar/Bajaj/Crompton etc., Anchor, Havells or any ISI certified Vendors). construction, gauge etc.). The supplier should clearly give the technical specifications of the grinding wheel (Material of construction, gauge etc.). Vendors with good quality control profile are preferred.