Intramuscular Injections

advertisement

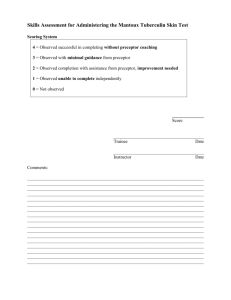

Name ___________________ Period _________ Proper Injections Lab Procedure: 1. Divide into your assigned group 2. Group A will begin at station 1 and each person will demonstrate mastery in giving shots. Group B begins at station 2, etc. 3. Each group will get a chance to practice using a syringe and needle 4. If your group is not with the teacher doing the practice, you are to be reading and working on your packet (attached). It is due at the end of class. Supplies Needed: 4 Oranges 4 medicine containers filled with water 4 Syringes with needles Procedure for IM injections: 1. Prepare the syringe and needle making sure the needle is clean as well as straight. By placing an already-used needle into a medication, you run the risk of contaminating the medicine and weakening or destroying its ability to fight pathogens. Using the same needle on more than one animal may spread diseases Bent needles tend to break off easily and can break off when giving the shot. The needles can stay in the meat the rest of the animal’s life causing infections. Needles have even ended up on consumer’s dinner plates. 2. Shake the vaccine, medicine, etc jar to make it one consistent product. 3. Tip the medicine up side down using one hand 4. Place the syringe in the center hole (the rubber part) with the other hand 5. Slowly fill the syringe to desired quantity by pulling out on the plunger making sure to avoid any air bubbles in the syringe. If air bubbles do occur, push the plunger in squirting liquid back into the jar until the air bubbles disappear. Air bubbles in IV and IP injections can cause death to the animal. 6. Tip the jar right side up and pull the syringe out 7. Find the location in which you want to insert the needle, touch the animal with your hand in that location, slowly remove hand and carefully insert the needle. Be sure to hold the syringe securely because animals will jump or jerk when poked with the needle. 8. When the needle is in all the way, depress the syringe lever so that all the liquid is dispensed. Not giving the animal a full dose can cause more sickness by allowing the bacteria to become resistant to the medicine or vaccine 9. Pull the needle out and replace needle. Needles should be disposed of in a plastic container that is clearly marked “NEEDLES” so that nobody mistakes them for garbage and cuts themselves. Giving Proper Injections Medications are commonly given to cattle as part of regular husbandry practices to improve health, control disease or increase productivity. Medications may be given by injection, by mouth (orally) or through the skin as a pour-on (topically). Injections are commonly given into the muscle (intramuscularly, or IM), under the skin (subcutaneously, or SC) or into the bloodstream (intravenously, or IV). Medications are administered to cattle by injection for a variety of reasons. For example, vaccines (biologicals) are injected to prevent disease, and antibiotics or anthelmintics may be injected to treat bacterial or parasitic infections, respectively. Other medications may be given by injection for supportive medical care, to relieve pain or to enhance production. Injection may be the best, or the only, route of administration for a particular medication. When there is a choice to inject or use another route of administration, the decision to use injectables may be based on cost, ease of administration, effectiveness, accuracy and reliability or other considerations related to the activity of the product. Risks Related to Injecting Medicines Decisions to use injectable medications in cattle should be made after giving careful consideration to the benefits and the risks of the activity. The process of injecting cattle with medications carries certain risks to the animal, the operator and the consumer, thus it is best to seek the advice of a veterinarian. Injecting medication presents several risks to the animal. Injections with multiple-use needles can spread some diseases. Anaplasmosis and bovine leukosis are two notable diseases of cattle that are spread through the use of common needles. Dirty, bent, broken or dull needles may lead to injuries or infection at the site of injection. Adequate restraint of cattle prior to injection is necessary to decrease the risk of injury to both the animal and humans. You as the operator also assume certain risks while administering injectable medications. There is risk of injury to yourself while handling and restraining the animal. You may be injured by the animal, the equipment or by the interface of the two. Operators must be aware of the risk of injury due to accidental self-injection of the medication. Financial loss related to carcass damage following an injection, or due to losses related to medication withholding times and lost opportunities for sales are additional risks. The risks to the consumer following cattle injections come in the form of injection site blemishes and the possibility that residues of the medication will remain in the final meat product. All intramuscular injections reduce tenderness at the injection site and sometimes the blemish is even less appealing. The risks associated with giving injections cannot be completely eliminated. However, the risks can be reduced by controlling certain factors (control points) related to the injection process. The operator can both minimize the risks and maximize the benefits of injectable cattle medications by understanding the control points in the injection process. Where to give injections The route that injectable medications are given influences how well the product works and the fate of the product in the animal's system. The label on injectable products describes the appropriate routes of administration. Do not deviate from the label recommendations without the advice of a veterinarian. It is unlawful to administer any injectable product in any dosage or by any means other than that stated on the label unless directed to do so by a veterinarian. Penalties for breaking this law can spend time in jail and will pay huge fines. The Injection Site. All over-the-counter (OTC) or veterinary prescribed (Rx) injectable medications carry a label or prescription indicating the tissue location that the drug should be deposited into. For producer administered products this will practically always be either intramuscular (IM) meaning in the muscle or subcutaneous (SQ) meaning under the skin. For an injectable drug to perform as intended, it must be placed in the prescribed tissue location. The preferred site to administer IM injections in small pigs and large hogs is in the neck muscle at a point just behind and below the ear. Large hogs may need to be restrained with a snout cable or in a stall but small pigs may simply be held. The skin at the site should be pulled slightly to one side and the needle placed through the skin and into the muscle. Once the proper dose is placed in the muscle, the needle is extracted and the skin is released to the original position. This helps to prevent back-flow of the medication from the injection site. Although it may be tempting to use the large muscles of the ham area for IM injections, this is not advisable. Physical damage or iron staining of the ham may cause trim losses or blemishes in this high value pork cut. Some injectable products are labeled for intramuscular (IM) or subcutaneous (SC) use. Use the subcutaneous route of injection whenever that option is available to reduce the risk of injection site lesions within the carcass. Intramuscular injections should given in the muscles of the neck to avoid blemishes in more valuable carcass cuts, regardless of the age of the animal. Do not give intramuscular injections in the rear leg or over the rump. Subcutaneous injections should be administered in front of the shoulder. Figure 2 shows appropriate injection sites for cattle of all ages. How to give injections Proper injection methods require that the animal be appropriately restrained to avoid injury to either the animal or the operator. What defines appropriate restraint may depend on the size of the animal, the disposition of the animal and the type of injection. Appropriate restraint means that the animal is held well enough that the operator is able to safely approach and administer the medication, and Figure 2. that the animal is not injured by Proper injection sites for subcutaneous or intramuscular injections in cattle of all ages. the restraint or the injection. Anticipate how the animal could respond to an injection and assure yourself that the animal's reaction to the injection will not lead to injury to yourself or to others. Do not place yourself at needless risk of injury for the sake of an injection. If you cannot give the medication safely, don't give it. The volume of drug administered at an injection site depends not only on the dosage of the medication but also on the route of administration and the maximum volume recommended per site. Always follow the label recommendations for dosage and volume per injection site unless directed to do otherwise by your veterinarian. Do not exceed 10 cc (cubic centimeter or milliliters) at any intramuscular injection site. Needle Selection. Needle selection criteria center primarily on the appropriate diameter and length of hypodermic needle needed for each injection situation. Needle diameter is measured using a standard "gauge" scale. Lower gauge numbers refer to larger needle diameters. For example, a 14-gauge needle is considerably larger in diameter than a 20-gauge needle. Generally, it is recommended that the smallest needle diameter be used that will effectively discharge the drug to be administered. Thicker, more viscous medications will require a larger diameter needle than thinner, free flowing solutions. Also, the size and age of the pigs being injected will influence the gauge of needle needed, with younger smaller pigs requiring smaller needles than older, larger animals. The needle length selected should be just long enough to reach the intended drug deposition site when the needle is fully inserted. Using needles that are longer than necessary increases the chance of injury to the pig and increases the possibility of bending or breaking the needle. Needles used for subcutaneous injection should be 1 inch or less in length for any age animal. The following Table lists National Pork Producer Council guidelines on the recommended needle gauge and length for giving IM and SQ injections to pigs of various sizes. Recommended Needle Sizes and Lengths for Swine* Intramuscular (IM) Type of Pig Subcutaneous (SQ) Needle Gauge Needle Length Needle Gauge Needle Length Baby pigs 18 or 20 5/8" or 1/2" -- -- Nursery pigs 16 or 18 3/4" or 5/8" 16 or 18 1/2" Finishing pigs 16 1" 16 3/4" Breeding stock 14 or 16 1" or 1 1/2" 14 or 16 1" *Source: NPPC Pork Quality Assurance Guidelines Avoiding Use of Damaged Needles. High quality disposable needles are the products of choice for routine on-farm injections. These are readily available from veterinary or livestock supply companies. Disposable needles can be used with inexpensive disposable syringes or sophisticated repeating syringes. Under all circumstances any needle used should be "razor" sharp and free of any physical damage. Sharp needles are easier to insert, minimize pain experienced by the pig and produce little or no tissue damage. Needles that have become dull due to extended use or physical damage should be replaced with a fresh, sharp needle. As with dull needles, any needle with a bent or broken shaft should be removed from the syringe, discarded and replaced with a fresh needle. Under no circumstance should a needle that has become bent be re-straightened and used. Needles that have been bent and restraightened have a weakened point along the shaft and are likely to break. This creates the risk of the needle shaft breaking off and remaining in the pig's tissue at the injection site. Although the occurrence of this is rare, it does happen. As a result, there have been reports of retail consumers of pork products that have found or even bitten into broken needles when eating pork. Again, the occurrence of this is very rare, but when it happens, it causes a safety hazard for the consumer. Furthermore, such an occurrence is extremely detrimental to the public perception of pork as a healthy, quality assured product. Use only needles with aluminum hubs because they are less likely to break during injections. Do not use needles with plastic hubs. Needles that break off and remain in the animal must be removed; surgery is often required. Contact your veterinarian if assistance is needed to remove a broken needle. Do not let an animal with a broken needle enter the food chain. To prevent needle breakage use proper animal restraint and do not try to straighten or reuse bent needles. When administering an injection, clean, sharp needles should be rapidly placed into the site, the dose administered, and the needle quickly removed. Some medications must not be placed directly into the bloodstream, and it may be necessary to draw back on the syringe and observe for blood before beginning an intramuscular injection. Subcutaneous injections should be given at the base of a "tented" fold of loose skin lifted away from the animal with your free hand. This "tenting method" minimizes the risk of injecting into muscle. Preventing Abscesses at Injection Sites. Abscesses are localized sites of infection in the tissues of pigs. They may be located near the surface of the body or in tissues deep within the body. Abscesses near the surface may be seen as an extended or swollen mass of tissue. When palpated, an accumulation of fluid within the cavity of the abscess may be detected. This accumulated fluid, commonly referred to as "pus", results from an immune reaction in response to foreign matter or infectious bacteria within the abscess site. In addition to being a direct health risk to the pig, abscesses have a direct negative impact on pork quality assurance. At pork processing plants, abscesses must be completely trimmed from the hog carcass and discarded as trim loss before the carcass can pass inspection and be further processed. If abscesses are extensive, significant portions of the carcass must be trimmed and discarded or perhaps the entire carcass may be condemned. The most common way that injection practices can contribute to the occurrence of abscesses is through the use of dirty needles and other unsanitary injection practices. Only clean needles should be used for injection purposes. Between injections, the syringe and needle should not be placed on dirty surfaces. Instead, a clean pan or tray lined with fresh paper towels should be prepared for syringe and needle storage during injection procedure. The protective plastic shield that covers all new disposable needles may also be replaced over the needle when not in use. When in doubt about the cleanliness of a needle, it may be swiped with alcohol using absorbent paper or cotton. However, alcohol should not be drawn into the interior of the injection needle as it may affect the potency of vaccines or antibiotic drugs. The injection site should be inspected before inserting the needle. If the site is dirty or damp, it should be swiped clean and dry before injection. When the site is dirty, the injection needle may carry contaminants and bacteria from the skin into the tissue, increasing the risk of abscess formation. Steps should also be taken to avoid contamination of medication vials. When reloading a syringe from a multi-dose vial, a separate needle should be used to pass into the rubber vial stopper than the one used to inject the pigs. The number of pigs treated before changing to a fresh needle is a judgement call for producers and herdsmen. If the needle and injection sites are clean, multiple sets of pigs may be treated with the same needle. However, under dirty conditions, frequent changes to a fresh, sterile needle is advisable. When processing baby pigs, a good practice is to change needles between each litter. With cattle, Needles are often used in more than one animal to save time and money. This practice is most common when multiple dose syringes are used. When needles are used in more than one animal the risk of injection site blemishes increases, as does the risk of transmitting diseases. When more than one animal will receive an injection from the same needle, the decision to change needles should be based on needle contamination, damage or dullness. No more than 10 animals should be injected with the same needle. When multiple animals are being processed it may be useful to keep syringes with "backup" doses drawn up to avoid the temptation to use a contaminated, bent or dull needle. This gives the operator time to change needles or redraw an automatic syringe. Meeting Withdrawal Times. Many injectable medications, especially those containing an antibiotic as the active ingredient, have a required pre-slaughter clearance time requirement. These pre-slaughter withdrawal periods are specific for each product and are established to insure that all potential drug residues are cleared from the pig before it is slaughtered and processed into pork. For example, pigs treated with an injection of tylosin antibiotic must not be shipped for slaughter within 14 days of the last injection. Accurate records of the type of medications used, when they are administered and identification of the pigs treated are essential to assure that pre-slaughter withdrawal times are met on hog farms. Sanitation and product quality The risk of infected injection sites can be reduced by maintaining clean working conditions and equipment. The surfaces of tables and restraint equipment should be kept free of dust, moisture and manure. After use, syringes can be disinfected by disassembling and washing with hot soapy water, rinsing with alcohol and drying before reassembly. Soaps, alcohol and other disinfectants will cause live or modified-live vaccines to become inactive. Syringes used for live or modified-live vaccines should be sterilized using either moist or dry heat. If it is necessary to rinse out a syringe during use, then draw sterile saline or sterile water into and out of the syringe several times. The effectiveness of the injectable product depends on how carefully the product is handled after purchase. When medication is not being used it should be stored in a clean, closed location at an appropriate storage temperature. Keep medications labeled and discard out-ofdate items. Contamination can be avoided during use if the rubber bottle stopper is wiped clean before inserting the needle. Special care is required to avoid contamination of the product in multiple dose vials; insert a new clean needle into the rubber stopper and use that as a transfer needle to fill syringes rather than repeatedly inserting needles that have been injected into the animal. Assure that the product remains at the appropriate temperature during use. Protect modified-live vaccines from ultraviolet light (including direct sunlight), heat and freezing. Keep vaccines on ice packs within coolers until used. Protect all products from extreme heat or freezing. A light bulb or other heat source can be wired into a cooler to provide a warm chute-side container for medication during cold weather. Conclusion The decision to administer injectable medications should be made after comparing the benefits and the risks of doing so. Your veterinarian is the best source of advice on maximizing the benefits of treatment and reducing the risk of problems. Remember: All intramuscular injections reduce meat tenderness at the injection site; Give intramuscular injections only in the neck muscles. Never give an intramuscular injection in the rear leg or rump regardless of the animal's age or use; Use only injectable products that meet Beef Quality Assurance guidelines; Use subcutaneous products whenever possible and avoid injectable medications that are irritating to tissues. When used correctly, medications improve animal health and well-being, increase profitability and provide the consumer with a higher quality food product. Directions: After reading the handout, answer the following questions. Some of the answers you will not find in the reading and must use judgment from what you learned in the reading to apply to other real-life situations. 1. List two (2) reasons why medications are given to animals. 2. List three (3) ways to medicate cattle. 3. What is the purpose of giving a vaccine? 4. Explain the risks to humans when injecting medication. 5. Explain the risks to animals when injecting medication. 6. What is the problem of using the same needle to medicate two dogs? 7. As a consumer of meat, what are two (2) concerns you should have about the meat you eat in relation to medicating animals? 8. How are needles measured (give the name of measurement i.e. inches, feet, etc.)? 9. What two (2) things determine the size of needle you need to use? 10. List some (at least 2) ways that you can keep medicine fresh and effective for the next use. Using the following information, Answer questions 11-16: Scenario: Your animal is very sick and the label directions on the medicine tells you the maximum amount to give is 15cc. Your friend told you he administered 20cc and the animal was cured twice as fast. The medication states that you must administer it by means of IM. 11. How many cc’s of medicine will you give your animal? 12. Could anything happen if you give your animal more than 15ccs? 13. Where on the animal will you give the medication? 14. How will you administer the medication to the animal? 15. How many total ‘shots’ will you give the animal to complete the full dose of medicine if you will give it the full dose of 15cc? Explain why. 16. If your animal is a lamb, what area of the body will you avoid giving the shot? Why? Using the following information, Answer questions 17-22: Scenario: You manage a dog kennel where you must give many animals vaccines on a regular basis. The dogs must be completely off of medication before they can be sent home with an owner. All dogs are Labrador retrievers (average 50 lbs) that you will be medicating/vaccinating. 17. How will you know if a dog is ok to be sent home? 18. What kind of system will you have in place to track animals that have been medicated? 19. Explain how you will medicate all the different dogs (explain how many times you will use a needle and how will you draw medicine from the jar) 20. What size of needle will you use on the Labrador dogs? 21. Dogs in kennels often get a respiratory infection called Kennel Cough and must be treated with a series of medication that takes several days. If one of your lab dogs gets kennel cough and a person wants to take the dog home that same day what will you do? 22. In the kennel area you have a container with this symbol on it. What is the purpose of it and what material is the container most likely made of?