4. drainage design considerations

advertisement

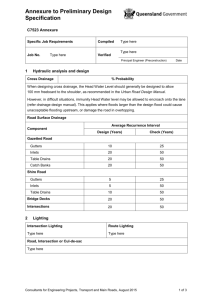

4. DRAINAGE DESIGN CONSIDERATIONS 4. DRAINAGE DESIGN CONSIDERATIONS Introduction Drainage of pavement structures has long been recognized as an important factor influencing the performance of concrete pavements. Early road-building practices emphasized the need to remove excess water from beneath the pavement, and recent years have seen a renewed interest in providing positive drainage to pavement structures. Critical concrete pavement distresses related to and accelerated by excess moisture and poor drainage conditions include pumping, faulting, and corner breaks (caused by erosion and loss of support beneath the corners and/or edges of concrete pavement slabs). Other concrete pavement distresses, such as transverse cracking, punchouts, D-cracking, and alkali-silica reactivity, are also greatly influenced by the presence of excess moisture within the pavement system. Types of Subsurface Drainage A variety of subsurface drainage designs have been tried over the years with varying success, and these are briefly described in the following sections. Although there are other conditions that may require special drainage designs (such as the presence of a high water table), only the subsurface drainage of surface infiltrated water (i.e., water that enters a pavement structure through cracks or joints in a pavement surface) is considered here. Daylighted Bases “Daylighting” of a base beneath a pavement structure refers to the lateral extension of aggregate base courses beyond the edge of the pavement and all the way to the ditchline. The expectation is that the granular nature of the base will allow some lateral drainage of moisture from beneath the pavement. Experience on the effectiveness of daylighted bases (either dense- or open graded) has been mixed. For example, the rigid pavement sections at the AASHO Road Test, which consisted of daylighted dense-graded granular bases with a maximum 8 percent of nonplastic fines, were noted for their poor drainage conditions and extensive pumping (HRB 1962). Similarly, the results of a recent concrete pavement performance study suggested that daylighted dense-graded bases become clogged with fines and are no longer able to drain (Yu et. al. 1998). However, it was also shown that pavements with daylighted dense-graded bases perform better than pavements with non-daylighted aggregate bases (Yu et al. 1998). Nevertheless, because of their potential for contamination and inability to be maintained, daylighted dense-graded bases as a drainage system by themselves are generally not recommended (FHWA 1992). On the other hand, preliminary results from NCHRP study 1-34 appear to indicate that the performance of pavements constructed with daylighted open-graded bases is similar to that of pavements constructed with permeable bases with edge drains. However, this finding is preliminary and needs further verification under a wider range of conditions. Concrete Pavement Design Details and Construction Practices 23 4. DRAINAGE DESIGN CONSIDERATIONS Longitudinal Edge Drain System Longitudinal edge drain systems consist of longitudinal pipes placed at the outer edge of the pavement structure containing a dense-graded base course material. Historically, these have been the most common subsurface drainage system used in highway pavement construction. However, their effectiveness has been limited by the inability of surface infiltration water to migrate through the dense base to the longitudinal edge drain. Furthermore, the use of a granular material susceptible to saturation may have compromised the performance of many of these designs. More recently there has been interest in the use of longitudinal edge drains in conjunction with a nonerodible base course. For example, California has adopted a drainage design that incorporates longitudinal edge drains with a lean concrete base (LCB) or an asphalt concrete base (ACB), as shown in figure 4 (Caltrans 1995). These bases resist the erosive action of water, prevent moisture from infiltrating the granular materials below, and provide a drainage path to the longitudinal edge drains. The longitudinal edge drains are placed in a treated permeable material (TPM) in the shoulder to facilitate migration of the water to the edge drains (see figure 4). A granular subbase is also placed beneath the structures if they are constructed on a weak subgrade or will be exposed to heavy traffic loadings (Caltrans 1995). Drainage designs similar to that used by Caltrans and using an LCB have been constructed in some European countries for several years (FHWA 1993). Inner Shoulder Traveled Way Slope Slope PCC Outer Shoulder PCCP Slope PCCP PCC TPM Tie Bars Filter Fabric, High Side of Tangents and Superelevations Tie Bars Base (LCB, ACB) Plastic Pipe (Slotted), Low Side of Tangents and Superelevations Filter Fabric Figure 4. California drainage design with nonerodible base course (Caltrans 1995). Drainable Pavement System The use of drainable pavement systems, which feature a permeable base course, has greatly increased in the last 10 years. With the inclusion of the permeable base course, these designs are intended to provide a positive means through which surface infiltration water can be removed from beneath the pavement structure and outletted to the ditches. According to a recent survey, 27 of 39 responding highway agencies had used permeable bases beneath concrete 24 Concrete Pavement Design Details and Construction Practices 4. DRAINAGE DESIGN CONSIDERATIONS pavements (Christopher and McGuffey 1997). However, there have been some reported difficulties in the construction and performance of these systems. For example, the California Department of Transportation found that many asphalt-treated permeable bases (ATPB) under their JPCP designs were experiencing severe stripping after only a few years of service that was detracting from the performance of the pavement (Wells 1993). Because of some reported performance problems, many agencies are now approaching the use of drainable pavement systems more cautiously. These systems are very sensitive to design, construction, and maintenance practices, and local experience and performance should be considered when contemplating the use of drainable pavement systems. A drainable pavement system consists of the following elements: Permeable Base. Permeable bases are constructed with very few fines such that they have a very high level of permeability that allows the passage of water through the base course so that it may then be collected by the edge drains and removed away from the pavement structure. The permeability of these bases is generally greater than 300 m/day (1,000 ft/day) and often exceeds 3,000 m/day (10,000 ft/day). However, the required permeability for a given pavement structure will depend on many factors, including cross slope, longitudinal gradient, and drainage layer thickness and width (Crovetti and Dempsey 1993). Consequently, depending on the conditions, bases with higher permeability levels may not necessarily provide any drainage or performance advantages. A minimum value of 300 m/day (1,000 ft/day) is generally recommended for most permeable bases (FHWA 1992; Christopher and McGuffey 1997). Lower base permeabilities have been used by agencies when the subgrade is permeable and is expected to provide a certain amount of “vertical drainage” (Yu et al. 1998). A computer program called DRIP (Drainage Requirements In Pavements) has recently been developed by the FHWA that can be used to design a permeable base and other drainage features (Wyatt et al. 1998). Permeable bases may be either treated or untreated, with the treated materials having the ability to withstand construction traffic better than untreated materials. Both asphalt (asphalt contents of 2 to 3 percent by weight) and cement (two to three bags of portland cement per cubic yard) are used to modify the granular base material. Permeable bases are generally placed between 100 and 150 mm (4 and 6 in) thick. Common permeable base installations are illustrated in figure 5 (FHWA 1992). Detailed information on the design and construction of permeable bases is found in reports by the FHWA (1992), Baumgardner (1993), and Yu et al. (1998). Separator Layer. A separator layer is generally required between the underlying subgrade and the permeable base in order to prevent the upward migration of fines into the permeable base. This intrusion of fines could clog the permeable base course, thereby rendering it ineffective in allowing the passage of excess moisture. Concrete Pavement Design Details and Construction Practices 25 4. DRAINAGE DESIGN CONSIDERATIONS Pre-Pave Installation Permeable Base Geotextile Aggregate Separator Layer Concrete Pavement With Asphalt Shoulder Geotextile Optional Post-Pave Installation Geotextile Pre-Pave Installation Permeable Base Geotextile Aggregate Separator Layer Optional Post-Pave Installation Geotextile Geotextile Concrete Pavement With Concrete Shoulder Figure 5. Typical permeable base cross sections (FHWA 1992). Separator layers are either a dense-graded aggregate layer or a geotextile material, although some treated base course materials have been used as well. Aggregate separator layers must be sufficiently thick (up to 300 mm [12 in] for some soft soils) to effectively prevent contamination, and must also be carefully designed to meet established filtration criteria (Yu et al. 1998). The apparent opening size (AOS) of geotextile materials also must be carefully designed to ensure adequate protection of the base. FHWA (1992) provides detailed guidelines for the design of both aggregate and geotextile separator layers; Holtz, Christopher, and Berg (1995) also provide a comprehensive treatment on the design and use of geotextile separator layers. 26 Concrete Pavement Design Details and Construction Practices 4. DRAINAGE DESIGN CONSIDERATIONS Generally, aggregate separator layers are preferred due to their added strength they provide to the pavement structure (Baumgardner 1993). However, a recent laboratory evaluation of aggregate and geotextile separator layers revealed that while both techniques were effective in preventing pumping and subgrade infiltration for subgrade soils with a CBR above 4, the geotextile material was more effective in preventing intrusion of fines than the aggregate separator layer for subgrade soils with a CBR below 4 (Signore and Dempsey 1998). In addition, it was noted that aggregate separator layers were effective in preventing intrusion of fines when the separator material was dry and did not approach saturation; when the separator material was saturated, the strength of the material was diminished and significant intermixing of the dense- and open-graded layers occurred, resulting in poor performance (Signore and Dempsey 1998). Longitudinal Collector Pipes. These pipes are placed at the edge of the permeable base to collect the surface infiltration water in the permeable base. The longitudinal drains carry the water and either outlet it to the ditches via outlet pipes at regular intervals or deposit it into storm water collection systems. Most longitudinal edge drains are either flexible, corrugated polyethylene (CPE) pipe or rigid, polyvinyl chloride (PVC) pipe. The pipe size is controlled by the spacing of the outlets and the longitudinal grade (minimum 1 percent recommended), but generally a minimum 100-mm (4-in) pipe is recommended (FHWA 1992). A geotextile should be placed around the trench containing the edge drain, and the trench should be backfilled with permeable material. Special design considerations (for instance, shorter outlet spacing) are needed if the minimum longitudinal grade of 1 percent cannot be achieved. Outlets for the collector pipes are generally rigid pipes and are placed at 76 to 152-m (250 to 500-ft) intervals (closer in very flat areas) (FHWA 1992). Headwalls and rodent screens are recommended at the outlet faces to protect the pipes from damage. Figure 6 illustrates a recommended headwall design (FHWA 1992). In the design of a drainage system for a project, special design considerations should be given to sag vertical curves, crest vertical curves, superelevation transitions, and cut-to-fill transitions in order to maintain the ability of the pavement structure to drain water (Yu et al. 1998). Design and Analysis of Drainage Systems The design and analysis of pavement subsurface drainage systems consists of many different components. Basic information required for any drainage design and analysis includes the following (Moulton 1980): Properties of the paving materials (e.g., gradation, permeability, porosity). Geometrics of the roadway and pavement structure (e.g., transverse and longitudinal slopes, cross section information). Climatic data for the geographic area (e.g., precipitation, depth of frost penetration). Concrete Pavement Design Details and Construction Practices 27 4. DRAINAGE DESIGN CONSIDERATIONS Precast Concrete Headwall In Slope Slotted Headwall Detail 2" 3" Side View 3" 5" 12" Top View 3/4" 4" 3" 45 Deg. 36" 3" 5" 3" Rodent Shield Front View 8" 6" 12" 1" 6" 12" 1 in = 25.4 mm Front View Openings: 1/4" - 3/8" square Figure 6. Recommended headwall design (FHWA 1992). Once this information has been collected, the anticipated water inflow into the pavement structure—which represents the quantity of water that must be removed by the subsurface drainage system—can be determined. This information is then used to perform drainage designs for new pavements or to assess the suitability of existing systems. Manual procedures for determining water inflow and designing subsurface drainage systems are found in reports by Moulton (1980) and by the FHWA (1992). However, the use of these manual procedures tends to be rather laborious as they involve the use of many charts, graphs, and tables. As mentioned previously, a computer program called DRIP is now available that greatly facilitates the conduct of detailed drainage designs and analysis (Wyatt et al. 1998). The program not only determines pavement drainage times using the given material property, geometric, and climatic data, but also performs permeable base, separator layer, and edge drain designs based on the drainage requirements of the pavement system (Wyatt et al. 1998). Consideration of Drainage in Slab Thickness Design The 1986/1993 AASHTO rigid pavement design procedure includes a drainage coefficient (Cd) intended to account for the effects of drainage on pavement performance (AASHTO 1993). This coefficient, which is determined from table 5, considers the overall drainability of the pavement and the percent time that the pavement is exposed to saturated conditions. The selection of lower 28 Concrete Pavement Design Details and Construction Practices 4. DRAINAGE DESIGN CONSIDERATIONS Cd values serves to increase slab thickness, whereas the selection of higher Cd values serves to decrease slab thickness. Thus, although this approach represents an attempt to consider drainage directly in slab thickness design, it is questionable whether adjustments to slab thicknesses is the appropriate way to account for prevailing drainage conditions. Table 5. Recommended Cd values for 1986/1993 AASHTO rigid pavement design (AASHTO 1993). Quality of Drainage Percent of Time Pavement Structure is Exposed to Moisture Levels Approaching Saturation Less Than 1% 1 – 5% 5 – 25% Greater than 25% Excellent 1.25 – 1.20 1.20 – 1.15 1.15 – 1.10 1.10 Good 1.20 – 1.15 1.15 – 1.10 1.10 – 1.00 1.00 Fair 1.15 – 1.10 1.10 – 1.00 1.00 – 0.90 0.90 Poor 1.10 – 1.00 1.00 – 0.90 0.90 – 0.80 0.80 Very Poor 1.00 – 0.90 0.90 – 0.80 0.80 – 0.70 0.70 Quality of Drainage: Excellent Good Fair Poor V. Poor = = = = = Water Removed Within 2 Hours Water Removed Within 1 Day Water Removed Within 1 Week Water Removed Within 1 Month Water Will Not Drain The 1998 AASHTO Supplement does not directly consider drainage in the slab thickness design procedure. However, it does require a modified AASHTO drainage coefficient when conducting the joint faulting check (AASHTO 1998). Another way that drainage may be partially accounted for in these procedures is by reducing the properties (elastic modulus or k-value) of the underlying base and subgrade materials to reflect saturated conditions. Again, however, this leads to increases in slab thickness, a result that does not address the drainage problem and may not provide the desired level of performance. Determining Need for Subsurface Drainage Although drainage is recognized as important to concrete pavement performance, determining the need for subsurface drainage is a difficult problem. The need for drainage is based on a variety of factors, but perhaps of particular importance is the availability of free moisture. The availability of free moisture is generally characterized by the Thornthwaite Moisture Index (TMI), an agricultural index that accounts for annual precipitation levels and evapo-transpiration rates to assess the presence of free moisture throughout the year (on average). If the TMI > 0, then excess moisture is available through the year, suggesting the need for positive drainage. However, other factors should also be considered when evaluating the need for drainage, including traffic levels, subgrade drainability, and proposed cross-sectional design and materials properties. A detailed drainage analysis of a pavement system, such as that performed by the DRIP computer program, can provide considerable insight into the need for pavement drainage. Concrete Pavement Design Details and Construction Practices 29 4. DRAINAGE DESIGN CONSIDERATIONS The pavement design catalog recently completed under NCHRP project 1-32 provides guidance on determining the need for pavement subsurface drainage (Darter et al. 1997). Table 2, presented earlier in chapter 2, was developed from the design catalog recommendations and indicates the need for pavement drainage based on traffic level, climatic region, subgrade strength, and pavement type. That table suggests the use of different levels of pavement drainage depending on those input factors. The levels of drainage are (Darter et al. 1997): Level 1, sealed joints and cracks and appropriate geometric design. This approach attempts to minimize the amount of water entering the structural section by keeping joints and cracks sealed, and providing side ditches on both sides of the pavement section with flowlines well below the lowest structural layer of the pavement. This approach is recommended for low traffic roadways only (less than 3 million ESAL applications). Level 2, erosion-resistant, moisture-insensitive materials. This approach includes Level 1 recommendations in conjunction with the use of materials that are not moisture sensitive and will not erode or disintegrate in the presence of excess moisture, given the level of heavy traffic loads over the design period. Higher traffic levels and more severe climates require more erosion-resistant materials. PIARC’s recommendations for classifying materials according to erodibility are summarized below (Ray and Christory 1989): – Class A, extremely erosion resistant. Examples: dense-graded or permeable lean concrete with 7 to 8 percent cement, dense-graded or permeable bituminous concrete with 6 percent bitumen and stripping-resistant aggregate. – Class B, erosion resistant. Example: plant-mixed cement-treated granular material with 5 percent cement, bituminous concrete with 4 percent bitumen and stripping-resistant aggregate. – Class C, erosion resistant under certain conditions. Examples: plant-mixed cement-treated granular material with 3.5 percent cement, bitumen-treated granular material with 3 percent bitumen. – Class D, fairly erodible. Examples: granular material treated on site with 2.5 percent cement, fine soils treated on site, untreated granular materials. – Class E, very erodible. Examples: untreated granular material contaminated by fines, untreated fine soils. Level 2 is recommended for most moderately trafficked roadways (3 to 6 million ESAL applications). 30 Level 3, edge drains and erosion-resistant, moisture-insensitive materials. This approach uses both Level 1 and Level 2 recommendations (including full consideration of base material moisture sensitivity and erodibility) plus removal of excess moisture that enters the pavement section and seeps to the longitudinal edge drain. Daylighted granular base or subbase layers may facilitate the removal of water from the pavement structure. This Concrete Pavement Design Details and Construction Practices 4. DRAINAGE DESIGN CONSIDERATIONS drainage level is recommended for most moderate to high trafficked roadways (6 to 18 million ESAL applications). Level 4, full subdrainage system with permeable base. This approach includes both Level 1 and Level 2 recommendations (including full consideration of base material moisture sensitivity and erodibility) plus a subdrainage system that will rapidly remove excess water that enters the pavement section. For rigid pavements, this includes a permeable drainage layer beneath the concrete slab, a granular separation layer between the permeable layer and the subgrade, a geotextile fabric between the permeable layer and the granular separation layer, longitudinal permeable trenches with edge drains, and outlets. This drainage level is recommended as one drainage alternative for most high-trafficked roadways (> 18 million ESAL applications). In light of this information, the following general recommendations on the use of subsurface drainage are offered: Concrete pavements designed for traffic levels less than 6 million ESALs generally do not require positive drainage features, except for undoweled JPCP constructed on weak subgrades in wet areas. Concrete pavements designed for traffic levels greater than 6 million ESALs require a positive subsurface drainage system. This may be either a drainable pavement system or a moisture-insensitive base and longitudinal edge drain system. For traffic levels between 6 and 18 million ESALs, the permeable base system is considered an option only for those concrete pavements constructed on medium/weak subgrades, whereas it is an option for every climatic region and subgrade type for design ESALs greater than 18 million. Local experience with the design, construction, and performance of each subsurface drainage system should be relied upon in the ultimate selection of the appropriate drainage system for inclusion on a new concrete pavement design. In addition, where an existing subgrade has some degree of permeability, the vertical drainage provided by the subgrade should be exploited by not placing a dense-graded material directly above the subgrade (Yu et al. 1998). Maintenance of Drainage Installations Many drainage systems have been limited in their success in removing moisture from the pavement structure because of lack of maintenance. A recent study of pavement edge drain systems showed a significant build-up of debris, vegetation, and rodent nests in both outlet pipes and mainline collector pipes (Daleiden 1998). In addition, some construction damage of the drainage pipes (e.g., crushed pipes preventing water flow) were noted during these inspections (Daleiden 1998). These observations highlight the need for both careful installation practices and regular maintenance and flushing activities. A guide specification has been prepared to assist agencies in the video inspection of drainage systems (for both new construction acceptance and for maintenance evaluations) (Daleiden 1998). Drainage systems should be inspected at least once a year, and may include the following key drainage maintenance activities (FHWA 1992; Christopher and McGuffey 1997; Daleiden 1998): Concrete Pavement Design Details and Construction Practices 31 4. DRAINAGE DESIGN CONSIDERATIONS Installing and maintaining reference markers at outlet locations. Clearing of debris and vegetation at outlets. Inspection of the pipe using optic video equipment (as needed). Flushing and rodding of the edge drain system using high pressure equipment (as needed). Cleaning of ditches and re-establishment of depths and grades (as needed). For drainable pavement systems in particular, if the highway agency is not willing to make a commitment to maintaining the system, permeable bases should not be used because of the potential for increased pavement damage due to the pavement system becoming permanently saturated (FHWA 1992; Christopher and McGuffey 1997). Surface Drainage Considerations To reduce the potential for hydroplaning and to help ensure the effectiveness of the subsurface drainage system within a pavement structure, certain pavement cross section characteristics and surface drainage factors are required. These include items such as cross slopes, depth of ditches, and longitudinal grade of ditches. Table 6 summarizes recommendations for these critical items (Yu et al. 1998). Table 6. Cross section and surface drainage recommendations (Yu et al. 1998). Cross Section Feature Recommendation Pavement Surface Cross Slope Shoulder Cross Slope Width of Ditches Depth of Ditches Minimum 2 percent Minimum 3 percent 0.9 to 1.2 m (3 to 4 ft) Minimum 1.2 m (4 ft) beneath mainline pavement edge (deeper if greater flows anticipated) Longitudinal Grade of Ditchline Minimum 1 percent 1 ft = 0.305 m The importance of surface drainage was recently studied under an NCHRP research project (Anderson et al. 1998). That study evaluated the significance of the thickness of water film accumulating on the pavement surface and its effect on hydroplaning and on tire splash and spray. An interactive computer program (PAVDRN) for predicting the depth of water flow on pavement surfaces and a set of design guidelines (PTI 1998) were the major products of the research. In the development of the design guidelines, a variety of cross slopes, longitudinal grades, and traveling speeds were considered (PTI 1998). Preliminary indications from the study are that greater minimum cross slopes (perhaps even 2.5 percent) are needed on higher speed roadways to prevent hydroplaning (by minimizing the water film thickness on highways); alternatively, some other measures are needed to reduce the length of the surface drainage flow path (such as 32 Concrete Pavement Design Details and Construction Practices 4. DRAINAGE DESIGN CONSIDERATIONS crowned sections or the grooving of the pavement surface) (PTI 1998). However, it is noted that the surface drainage recommendations first require field validation before they are implemented. References for Drainage Design Considerations American Association of State Highway and Transportation Officials (AASHTO). 1993. Guide for Design of Pavement Structures. American Association of State Highway and Transportation Officials, Washington, DC. American Association of State Highway and Transportation Officials (AASHTO). 1998. Supplement to the Guide for Design of Pavement Structures. American Association of State Highway and Transportation Officials, Washington, DC. Anderson, D. A., R. S. Huebner, J. R. Reed, J. C. Warner, and J. J. Henry. 1998. Improved Surface Drainage of Pavements. Final Report, NCHRP Project 1-29. NCHRP Web Document 16. Transportation Research Board, Washington, DC. Baumgardner, R. H. 1993. “Overview of Pavement Drainage Systems.” Western States Drainage PCC Pavement Workshop—Summary Report. FHWA–SA-94-045. Federal Highway Administration, San Francisco, CA. California Department of Transportation (Caltrans). 1995. Highway Design Manual. Fifth Edition. California Department of Transportation, Sacramento, CA. [Also available on the Internet: http://www.dot.ca.gov/hq/oppd/hdm/hdmtoc.htm]. Christopher, B. R. and V. C. McGuffey. 1997. Pavement Subsurface Drainage Systems. NCHRP Synthesis of Highway Practice 239. Transportation Research Board, Washington, DC. Crovetti, J. A. and B. J. Dempsey. 1993. “Hydraulic Requirements of Permeable Bases.” Transportation Research Record 1425. Transportation Research Board, Washington, DC. Daleiden, J. F. 1998. Video Inspection of Highway Edgedrain Systems. FHWA-SA-98-044. Federal Highway Administration, Washington, DC. Darter, M. I., H. Von Quintus, Y. J. Jiang, E. B. Owusu-Antwi, and B. M. Killingsworth. 1997. Catalog of Recommended Pavement Design Features. Final Report, NCHRP Project 1-32. Transportation Research Board, Washington, DC. Federal Highway Administration (FHWA). 1992. Drainable Pavement Systems. FHWA-SA92-008. Federal Highway Administration, Washington, DC. Federal Highway Administration (FHWA). 1993. Report on the 1992 U.S. Tour of European Concrete Highways. FHWA-SA-93-012. Federal Highway Administration, Washington, DC. Highway Research Board (HRB). 1962. The AASHO Road Test, Report 5—Pavement Research. Special Report 61E. Highway Research Board, Washington, DC. Concrete Pavement Design Details and Construction Practices 33 4. DRAINAGE DESIGN CONSIDERATIONS Holtz, R. D., B. R. Christopher, and R. R. Berg. 1995. Geosynthetic Design and Construction Guidelines. FHWA-HI-95-038. Federal Highway Administration/National Highway Institute, Washington, DC. Khazanovich, L., M. I. Darter, R. Bartlett, and T. McPeak. 1998. Common Characteristics of Good and Poorly Performing PCC Pavements. FHWA-RD-97-131. Federal Highway Administration, Washington, DC. Moulton, L. K. 1980. Highway Subdrainage Design. FHWA-TS-80-224. Federal Highway Administration, Washington, DC. Pennsylvania Transportation Institute (PTI). 1998. Proposed Design Guidelines for Improving Pavement Surface Drainage. NCHRP Project 1-29. Transportation Research Board, Washington, DC. Ray, M. and J. P. Christory. 1989. “Combatting Concrete Pavement Slab Pumping State of the Art and Recommendations.” Proceedings, Fourth International Conference on Concrete Pavement Design and Rehabilitation. Purdue University, West Lafayette, IN. Signore, J. M. and B. J. Dempsey. 1998. Accelerated Testing of Separation Layers for OpenGraded Drainage Layers. Final Report, Project C960014. Illinois Department of Transportation, Springfield, IL. Wells, G. K. Evaluate Stripping of Asphalt Treated Permeable Base. Minor Research Report 65332-638047-39303. California Department of Transportation, Sacramento, CA. Wyatt, T., W. Barker, and J. Hall. 1998. Drainage Requirements in Pavements, User’s Manual for Microcomputer Program. FHWA-SA-96-070. Federal Highway Administration, Washington, DC. Yu, H. T., K. D. Smith, M. I. Darter, J. Jiang, and L. Khazanovich. 1998. Performance of Concrete Pavements, Volume III—Improving Concrete Pavement Performance. FHWA-RD-95111. Federal Highway Administration, Washington, DC. 34 Concrete Pavement Design Details and Construction Practices