Responsible Care ® Product Stewardship Chlorine Guideline

advertisement

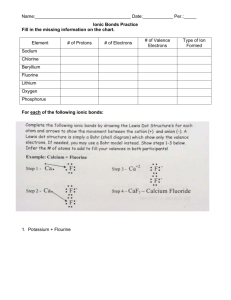

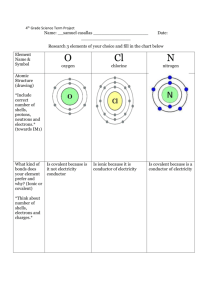

CHEMICAL AND ALLIED INDUSTRIES’ ASSOCIATION MANAGEMENT PRACTICE STANDARD SERIES FOR PRODUCT STEWARDSHIP: PART 2.4 GUIDANCE DOCUMENT FOR CHLORINE AUGUST 2011 1 TABLE OF CONTENTS 1. 2. 2.1 2.2 3. 3.1 3.2 4. 4.1 4.2 4.3 5. 5.1 5.2 5.2.1 5.2.2 5.2.3 5.2.4 5.2.5 5.2.6 6. 6.1 6.2 6.3 6.4 6.5 6.6 7. 8. 9. 10. 11. 11.1 11.2 11.3 12. 12.1 12.2 13. Glossary INTRODUCTION PROPERTIES OF CHLORINE Physical Properties Chemical Properties HAZARDS OF CHLORINE Health Hazards Environmental Hazards SAFE STORAGE OF CHLORINE Chlorine Storage Containers Safety Rules for Chlorine Cylinders and Containers Storage Storage Areas and Practices SAFE HANDLING OF CHLORINE Chlorine Handling Safety Requirements Chorine Safety Equipment Fire Fighting Equipment Personal Protective Equipment (PPE) Protective Breathing Equipment Chlorine Leak Detection Equipment and Repair Kits Emergency Equipment Medical Equipment EMERGENCY PROCEDURES Emergency Action Plans Procedures in the Case of the Inhalation of Chlorine Procedures in the Case of Eye or Skin Contact Chlorine Leaks and Spills The Buddy System Emergency Disposal of Chlorine Waste INCIDENT INVESTIGATION PERSONNEL TRAINING CHLORINE SIGNAGE TRANSPORTATION OF CHLORINE WORKPLACE SAFETY Risk Assessment Monitoring Exposure Medical Surveillance EXTENDING SAFETY TO THE CUSTOMER Customer Sites Customer Support REFERENCES 2 Page 3 4 5 5 6 7 7 8 9 10 10 10 12 12 13 13 14 15 17 18 18 18 19 19 20 21 22 22 23 23 24 26 27 27 28 29 29 29 31 31 GUIDANCE DOCUMENT FOR CHLORINE GLOSSARY Eco-toxicological: a combination of the methods of ecology and toxicology in studying the effects of toxic substances and especially pollutants on the environment. Incompatible materials: chemicals that should not be mixed or stored close together as this could result in an undesirable chemical reaction. SDS (Safety Data Sheet) also called MSDS (Material Safety Data Sheet): is a written document that outlines the information and procedures for handling and working with a specific chemical. The document contains information on the physical and chemical properties, potential hazards, emergency procedures as well as the manufacturer’s contact details. Occupational exposure limit – Recommended limit (OEL-RL): The concentration of an airborne substance, averaged over a reference period, at which according to current knowledge, there is no evidence of a risk to health if employees are exposed by inhalation day after day to that concentration. Biological monitoring: is the study of the presence and concentration of chemicals in humans usually by the measurement of blood, urine or breath (exhaled air). Properly conducted, these data provide a picture of the amount of a chemical or agent actually absorbed into the body for a specific period of time. Medical screening: The administration of a medical test to an individual for the purpose of detecting organ disfunction, before a disease becomes manifest leading the individual to seek medical cure. Medical surveillance: The systematic collection, analysis and evaluation of health data to identify problems or trends suggesting an adverse health effect or the need for further investigation or medical attention. It is a planned programme of periodic examination by an occupational health practitioner or by an occupational medical practitioner. The surveillance programme may include: clinical examinations medical tests / screening biological monitoring 3 PRODUCT STEWARDSHIP GUIDANCE DOCUMENT FOR CHLORINE 1. INTRODUCTION The element chlorine (Cl) is one of the 92 natural elements found on our planet. The diatomic molecule Cl2 is formed when two chlorine atoms combine chemically at room temperature (standard temperature and pressure). Chlorine gas consists of Cl2 molecules. The bonding between the two chlorine atoms in the Cl2 molecule is relatively weak which makes the molecule highly reactive. The gas has a greenish-yellow colour and has a characteristic pungent odour – the smell of bleach. The name chlorine is derived from “chloros”, meaning green, referring to the colour of the gas. Figure 1 illustrates the typical greenyellow colour of chlorine gas. FIGURE 1 Chlorine gas has a number of uses. It is used: as a powerful oxidant in bleaching and disinfectants as an essential reagent in the chemical sector in making plastics, solvents for dry cleaning and metal degreasing, textiles, agrochemicals and pharmaceuticals, insecticides, dyestuffs and household cleaning products Chlorine is used worldwide to purify water supplies and as defence against waterborne microbiological infection. Chlorine also plays a critical role in the 4 production of thousands of commercial products. Products containing chlorine include everyday household items such as household bleach and swimming pool disinfectants, computer hardware, silicon chips and automotive parts. In the upper atmosphere, chlorine-containing molecules such as chlorofluorocarbons have been implicated in the destruction of the ozone layer. Although chlorine is a toxic gas that irritates the respiratory system, it does not need to pose a serious risk if people working with the chemical are properly trained in its handling. This Guideline Document will supply information for the safe handling, storage and use of this chemical throughout its life cycle and will assist Responsible Care signatories to adopt chlorine safety and stewardship initiatives. Such initiatives will ensure continuous improvement to safety and contribute towards the protection of human health and the environment during the production, distribution and use of chlorine. 2. PROPERTIES OF CHLORINE It is important that the manufacturers and users of chlorine are aware of the properties and characteristics of this chemical. The physical and chemical properties of the chemical should be considered during risk assessment to assist with the identification and implementation of risk mitigation measures. It is advised that the Safety Data Sheet (SDS) be consulted for the full set of characteristics of this chemical including chlorine specific ecotoxicity data. The following characteristics of chlorine gas should be specifically noted: 2.1 Physical Properties: Under ambient conditions, chlorine is a non-flammable greenish-yellow gas and is about 2,5 times heavier than air. The gas will settle and accumulate in low-lying areas unless there is sufficient wind for dispersal. Chlorine has a vapour pressure of 4 800 mm Hg, freezes at - 102 ̊C and boils at - 34 ̊C. The gas is slightly soluble in water, soluble in alkalis, alcohols and chlorides. Liquid chlorine is amber in colour. 5 2.2 Chemical Properties: Chlorine gas is a stable but very reactive chemical and will react violently with many other chemicals creating heat due to the exothermic nature of the reactions. Care should be taken to avoid contact of the gas with (amongst others): Hydrogen Acetylene gas Organic solvents e.g. ether Ammonia Metals Sulphur dioxide Caution should be given where the gas comes into contact with water droplets as chlorine could create a highly corrosive and dangerous acid mist. In its liquid form it is a powerful oxidising agent. Although chlorine is a noncombustible gas, it will support combustion and the products of combustion are often toxic. Contact between chlorine and the following substances should also be avoided at all times: Arsenic Bismuth Boron Calcium Activated carbon Carbon disulphide Glycerol Hydrazine Iodine Methane Potassium Propylene Silicon Chorine is normally stored or transported in steel containers. At high enough temperatures the chlorine and iron will react vigorously. It is 6 recommended that steel chlorine vessels and piping not be exposed to temperatures above 120oC. The reaction is very exothermic and selfsustaining and usually can only be brought under control by removing one of the reagents (water deluge will not stop the fire). Care should be taken regarding location and routes of piping. Other heat sources such as veld fires should be taken account of. 3. HAZARDS OF CHLORINE Safety in the production, handling and storage of chlorine gas is of paramount importance. Despite its hazards, chlorine gas does not have to be a serious risk to those that handle the chemical or to the environment if appropriate safety practices are effectively implemented. 3.1 Health Hazards: It is important to note that exposure to chlorine gas can occur through inhalation, ingestion and eye or skin contact. Chlorine gas is toxic and an irritant to the skin, eyes, nose and mucous membranes. Inhalation of the gas or exposure to the chemical should be prevented at all times. The following hazards to human health should be noted: Liquid chlorine in contact with any part of the body will result in a freeze burn (blistering of the skin) of varying severity depending on the length of exposure. Inhaling the gas at almost any noticeable concentration effects both the upper and lower respiratory tract. Acute exposure to low levels of chlorine could result in: - burning of the eyes, nose and throat and excessive salivary and sputum formation sneezing, coughing, tears and a running nose redness in the face dizziness Higher chlorine concentrations could cause: - breathing difficulties 7 - violent coughing nausea vomiting choking laryngeal oedema and acute tracheobronchitis. These symptoms result from chlorine combining with moisture in the eyes, nose, throat, and lungs forming a weak acid. The effects of chlorine gas on human health depend on both the concentration and the length and frequency of the exposure. Exposure to a sufficiently high concentration of chlorine gas can result in difficulty in breathing and, if prolonged, death through suffocation. Chlorine gas’ strong pungent odour may result in detection at levels as low as 1,0 ppm and most people will detect it by the time the concentration reaches 3,5 ppm. Even concentrations below the threshold of smell can result in minor eye and throat irritation if the exposure is long enough. At high concentration the following effects could be observed: Tightness in the throat and chest Pulmonary oedema (build-up of fluid in the lungs). Note that 1 000 ppm is rapidly fatal. To receive a lethal exposure, a person would have to remain near a leak or source, within a chlorine cloud, and with no respiratory protection. As chlorine gas is particularly irritating to persons afflicted with asthma and certain types of chronic bronchitis, such persons should avoid exposure to chlorine at all times. 3.2 Environmental Hazards: Chlorine gas production facilities should be designed and operated so that the gas is prevented from being released to the environment. If accidental release should occur, the environmental effects, as well as all relevant reporting requirements, must be considered. Chlorine gas dissolves only slightly when mixed with water. It can also escape from water and enter air under certain conditions. Most direct releases of chlorine gas to the environment are to air and to surface water. 8 Once in air or in water, chlorine gas reacts with other chemicals. It combines with inorganic materials in water to form chloride salts, and with organic materials in water to form chlorinated organic chemicals. Because of its reactivity chlorine gas is not likely to move through the ground and enter the groundwater. Plants and animals will not store or bio-accumulate chlorine in the gas form. However, laboratory studies show that repeat exposure to chlorine gas in air can affect the immune system, the blood, the heart, and the respiratory system of animals and that it is especially harmful to organisms living in water and soil. When chlorine gas enters the air, wind disperses and dilutes the gas. Due to its reactivity, it does not remain as molecular chlorine, but breaks up into atomic chlorine. Some chlorine gas molecules react with water vapour, oxygen, or other substances in the five to seven kilometers near-earth atmosphere (troposphere). The products of these reactions have little, if any, environmental effect. Most of the remaining chlorine gas molecules are believed to react with hydrogen in the atmosphere to form hydrogen chloride gas which is either washed out by rainfall or combines with fine solid particles (e.g. dust or smoke particles) that fall to earth due to gravity. The hydrogen chloride gas makes a minor contribution to acid rain. 4. SAFE STORAGE OF CHLORINE Chlorine can be stored in different containers. The choice of the container used depends on the purpose that the gas will be used for. Chlorine is used in liquid form and as a compressed gas Liquid chlorine may be stored in a low-pressure vessel at low temperature or in a pressure storage vessel at ambient temperature. Pure dry (<20 ppm H2O) chlorine, both as a gas and as a liquid under pressure, reacts with only a few metals at ambient temperature. For this reason, chlorine may be safely stored in metal containers, usually steel. Moist chlorine corrodes most metals rapidly and therefore it is of utmost importance that all containers, pipes and equipment used to transport chlorine gas away from cylinders should be dry and clean. 9 4.1 Chlorine Storage Containers: Chlorine is supplied in any of the following containers: Steel tank trucks and semi tankers Steel cylinders containing 1 ton Standard steel cylinders containing approximately 45 kg to 70 kg at about 5 atmosphere pressure Smaller cylinders of steel or stainless steel, containing 5 kg to 9 kg of chlorine (not common in South Africa). 4.2 Safety Rules for Chlorine Cylinders and Containers Storage: Box 1 supplies basic rules applicable to cylinders and containers that must be adhered to: BOX 1 – RULES FOR CHLORINE CYLINDERS AND CONTAINERS Never expose cylinders to heat. Never tamper with a *fusible plug Always keep the valve protection cap in place, except when the cylinder is being used Never lift a cylinder by its valve protection cap Never drop or knock over a cylinder Cylinders must be kept upright at all times when moved or stored Use a specially designed and manufactured STORAGE clamp and lifting mechanism to lift cylinders Use a properly balanced hand trolley to move cylinders at floor level and ensure that the cylinders are attached to the trolley by a clamp or chain Hoist cylinders in a specially designed cage Secure chlorine containers with chains, chocks or appropriate equipment Note: *Fusible plugs are thermally operated non-reclosing pressure relief devices to function by the yielding or melting of the fusible alloys sintered in the plug body. 4.3 Storage Areas and Practices: All installations in which chlorine containers are stored should be specifically designed or adapted for this purpose. It is important that storage areas are well ventilated and that the air vents are at floor level. The special requirements applicable to chlorine container storage areas are indicated in Box 2: 10 BOX 2 – STORAGE AREA REQUIREMENTS Clearly identify chlorine storage areas and storage containers Storage areas must be under cover and weather protected – dry and wellventilated area Protect the containers from extreme temperature changes Store containers off the ground on rails or pallets to prevent corrosion Keep chlorine containers apart from other compressed gas containers or hydrocarbons Keep storage areas clean and practice good housekeeping principles Store empty containers separately from full containers Store full and empty containers in single rows with at least one meter gangways between rows of cylinders for access (full 50-70 kg cylinders are normally stored upright, 1 ton containers are stored horizontally) Check if the valves of all empty containers are properly closed and if protective devices are in place prior to storage Store containers away from heavily travelled areas and emergency exits Visually inspect storage areas on a routine basis, at least weekly Storage sites for chlorine should be secure against unauthorised access Display appropriate warning signs and placarding prominently in the area where the gas is stored Storage areas should not be in close proximity to emergency exits Figure 2.1 illustrates the correct storage of a chlorine cylinder and Figure 2.2 illustrates the correct movement of a chlorine cylinder: FIGURE 2.1 FIGURE 2.2 11 It is recommended that quantities of hazardous chemicals (including chlorine) stored on site be kept to a minimum and that the storage capacity is in line with the usage requirements and the shelf life of the chemical. Containers used for the storage of chlorine should be treated as full unless the container has been rendered free from the hazardous content. Care should be taken to ensure that all containers stored are labelled according to South African legal requirements to allow unmistakable identification of the container’s content. All labels should comply with the relevant regulations. 5. SAFE HANDLING OF CHLORINE The safe handling of chlorine includes a proper facilities design, an operation and maintenance programme, the appropriate safety equipment, and an emergency action plan. Chlorine equipment and handling systems should always be designed by engineers familiar with the properties of chlorine. Periodic inspection of such equipment should also be conducted by knowledgeable persons in order to ensure that the equipment is kept in a suitable operating condition. Statutory inspections will be required for certain applications. All chlorine installations should be subject to periodic preventative maintenance and safety inspections and special attention should be paid to the appropriateness of emergency plans and equipment as discussed in Sections 5.2.5 and 6. 5.1 Chlorine Handling Safety Requirements: To ensure that no serious risk is posed to people and the environment the following guidelines must be adhered to during the handling of chlorine: Proper instruction, training and supervision should be provided to the workers charged with the responsibility of the chlorine equipment Provide appropriate personal safety equipment to workers handling chlorine or its associated equipment Install safety showers and eye wash stations near the chlorine equipment If a leak occurs, allow two people to make the repairs – Buddy System 12 Keep all self-contained breathing apparatus that will be used for emergencies outside the chlorine storage area Workers handling and operating chlorine containers should receive special training in standard safety procedures for handling compressed corrosive gases All pipes and containment used for chlorine services should regularly be inspected and tested. The small amounts of impurities formed in industrial chlorine can deposit in flow meters and control valves – maintenance is therefore required on a regular basis 5.2 Chlorine Safety Equipment: In order to protect workers against chlorine exposure and to protect the environment from pollution and contamination, suitable safety equipment should be available on all sites that manufacture, store or use chlorine. Safety equipment should include: Fire fighting equipment Personal protective equipment Chlorine leak detection equipment and repair kits Emergency equipment – e.g. eye wash facilities 5.2.1 Fire Fighting Equipment: The “agent of choice” for fighting fires involving oxidisers is water. Manual fire fighting equipment in the form of portable water fire extinguishers or water hose reel stations should be provided at chlorine sites. It is important to note that the following portable fire extinguishers should not be used for chlorine related fires: Dry chemical extinguishers (Class A:B:C) – the reaction between chlorine and the ammonium salts in the fire extinguish agent may produce an explosive compound Halon extinguishers Carbon dioxide extinguishers 13 5.2.2 Personal Protective Equipment (PPE): PPE is not usually required if there is a closed chlorine handling system. If engineering controls and work practices are not effective in controlling exposure to chlorine, then wear suitable personal protective equipment including approved respiratory protection. Appropriate personal protective equipment must be available for use in the case of emergencies such as spills or fire. Workers should use appropriate personal protective clothing and equipment that should be carefully selected, used, and maintained to be effective in preventing skin contact with chlorine. The selection of the appropriate PPE should be based on the extent of the worker’s potential exposure to chlorine as determined via a risk assessment. PPE could include: Gloves Overalls Aprons Sleeves Encapsulating suits Splash-proof chemical safety goggles or face shields Safety boots The resistance of the materials to permeation by both chlorine liquid and chlorine gas should be considered when selecting the PPE. To evaluate the use of the PPE materials with chlorine, the best available performance data and manufacturer’s recommendations should be considered. Chemical resistant clothing that is used should be periodically evaluated to determine its effectiveness in preventing dermal contact. It is important that employers provide lockers or other closed areas to store work and personal clothing separately. Protective clothing should be kept free of oil and grease and should be inspected and maintained regularly to preserve its effectiveness. Note: Some operations may require the use of a chemical protective full-body encapsulating suit and respiratory protection as discussed in Section 5.2.3. 14 5.2.3 Protective Breathing Equipment: As the consequences of the inhalation of chlorine are immediate and could be extremely serious, particular attention should be given to protective breathing apparatus for personnel. Suitable respiratory protective equipment should be available for handling emergencies and should be located outside the probable location of any likely chlorine leak as well as carried on all vehicles, transporting the material. If respiratory protection is required, institute a complete respiratory protection program including: selection fit testing training maintenance and inspection. Gas masks should be located at readily accessible points away from the area likely to be contaminated. Prevailing wind direction should be accounted for when locating PPE so that is usually upwind of the likely leak area. All persons should be periodically instructed in the use and care of gas masks. It should be emphasised to all concerned that a faulty gas mask is worse than no mask. Depending on the risk, protective breathing equipment should be used: before appropriate engineering controls have been instituted during work operations such as maintenance or repair activities that involves unknown exposures during operations that require entry into tanks or closed vessels during emergencies It is recommended that the following respiratory protection guidelines that consider chlorine concentrations in air be considered for selecting protective breathing equipment: Chlorine concentration lower than 10 ppm (parts per million): - use a chemical cartridge respirator with appropriate cartridge that can protect against chlorine 15 Chlorine concentration higher than 10 ppm (parts per million): For chlorine concentrations higher than 10 ppm, the following options should be considered: - supplied air respirator operated in a continuous flow mode powered air-purifying respirator with cartridge(s) to protect against chlorine full-face piece chemical cartridge respirator with cartridge(s) to protect against chlorine gas mask with canister to protect against chlorine full-face piece self-contained breathing apparatus full-face piece supplied air respirator. Emergency situations concentrations: or planned entry in unknown chlorine For unknown chlorine concentrations the following options should be considered: - Positive pressure, full-face piece self-contained breathing apparatus positive pressure, full-face piece supplied air respirator with an auxiliary positive pressure self-contained breathing apparatus. Escape situations: For escape situations, a gas mask with canister to protect against chlorine, or an escape-type self-contained breathing apparatus is recommended. Note: The Immediately Dangerous to Life or Health (IDLH) concentration of chlorine is 10 ppm. Box 3 contains an important warning relating to the storage of respiratory equipment: BOX 3: STORAGE WARNING WARNING: DO NOT LOCK CABINETS OR CLOSETS IN WHICH RESPIRATORY EQUIPMENT IS STORED, AS THE EQUIPMENT MUST BE READILY AVAILABLE. 16 5.2.4 Chlorine Leak Detection Equipment and Repair Kits: It is recommended that chlorine leak detection and monitoring systems (with sound and visual warnings) be installed to warn personnel about a possible chlorine leakage in production, storage or loading/unloading areas in order to enable them to take appropriate action. Alarms should be loud enough for all personnel working in noisy areas to hear. A monitoring system can also be used for the automatic closing of valves to isolate chlorine-containing equipment in the case of a release or leak. This unit should be calibrated and tested at regular intervals and documented. Most leaks will occur in piping, valves, connections, and the pressurized portions of chlorine equipment. These leaks will usually be eliminated by tightening packing, replacing gaskets, or repairing the equipment. Replace flexible connections annually or sooner if there is evidence of deterioration. Box 4 contains a warning regarding the handling of chlorine leaks: BOX 4: CHLORINE LEAK WARNING WARNING: WARNING: NEVER UNDER ANY CIRCUMSTANCE SPRAY WATER ON A CHLORINE LEAK. THIS WILL ONLY MAKE THE CONSEQUENCES WORSE. Chlorine leaks are best located using a plastic squeeze bottle containing aqueous ammonia (commercial 26° Baume aqueous ammonia as household ammonia is not strong enough). If such a wash bottle is used, the dip tube should be cut off so that squeezing the bottle directs vapour, not liquid out of the nozzle. A white cloud of ammonium chloride will be formed at the site of any leak. Liquid ammonia solution should not sprayed on the leak area as it may increase corrosion and worsen the leak It is recommended that tank and line repair kits be available throughout the worksite. 17 5.2.5 Emergency Equipment: To cater for emergencies that result from chlorine releases due to equipment failure or leaks, the following emergency equipment should be available at all facilities that handle or store chlorine: Coloured vests Flash lights Life lines Safety helmets It may be useful to have the relevant Chlorine Institute kit A or B on site or at the Hazmat/fire fighting station (the relevant training for appropriate use of the kits would have to be done). 5.2.6 Medical Equipment: The medical equipment recommended below is intended to provide a medical back up for persons who will be involved in the work for stopping leaks or transferring the chlorine during emergency situations: 6. Blankets First Aid kit Eye wash bottles Oral resuscitation equipment (for use by a competent person) Spray with corticosteroid (treatment for the control of inflammatory responses - to be use by a competent person), and Oxygen bottles EMERGENCY PROCEDURES Through its odour and irritant effects chlorine can easily be detected. It is treated as a chemical with good warning properties when emergencies arise. The measures in the event of chorine emergencies or accidents should be carefully prepared and should be regularly tested and updated. All workers should be familiar with emergency procedures, the location and proper use of emergency equipment and the various methods of protecting themselves during rescue operations. 18 It is important that a list of all relevant emergency contact phone numbers be available at a number of locations in the plant or office. The list should include the Local fire department Police department Local Department of Health Local police and fire departments should be informed of the possible hazards associated with chlorine stored or handled on a facility so that they can be prepared in the case of an emergency. 6.1 Emergency Action Plans: It is important to ensure that fire fighting, first aid and Haz Mat personnel are trained in chlorine emergency procedures. A written emergency control plan should be developed and unscheduled drills of emergency situations where the plan is executed should be conducted at least annually. The plan should include: Escape/evacuation plans from areas where chlorine leaks could occur Allocation of responsibilities during emergency incidents An alarm plan for events without off-site consequences An alert plan for incidents with potential off-site consequences outside of the plants limits. This plan has to be developed in co-operation with the local authorities, fire and other emergency services 6.2 Procedures in the Case of the Inhalation of Chlorine: The accidental inhalation of chlorine should be prevented at all times. If the gas is inhaled, the victim should immediately be removed to fresh air and should be given immediate medical attention. The inhalation of chlorine in the workplace can be prevented by: Wearing the appropriate PPE Ensuring that hazard and warning information is posted in the work area. Should there be a release of chlorine gas, inhalation can be prevented by immediately leaving the area where the gas was released. If outdoors, employees should move upwind from the smell and the highest ground 19 should be found as the gas is heavier than air and will sink to lower levels. If indoors, the building should be evacuated immediately. Care should be taken during evacuation in multiple story buildings as chlorine gas could accumulate in lower levels. 6.3 Procedures in the Case of Eye or Skin Contact: Eye and skin contact with chlorine should be prevented at all times. If liquid chlorine or high concentrations of chlorine gas get on the skin, the contaminated skin must immediately be flushed with water. If liquid chlorine or high concentrations of chlorine gas penetrate through clothing, the clothing must be removed and the skin must immediately be flushed with water and thereafter washed with soap and water. No attempt should be made to neutralise the chlorine with other chemicals, nor should any ointments be applied for 24 hours. In the case of eye contact, it is recommended that the eyelids be parted and that the eye be washed with copious amounts of water for 15 minutes. Immediate medical attention should be sought. NOTE: The SDS for chlorine gas should be available at the clinic/hospital to aid with appropriate treatment of patients. Box 5 supplies information on what to do in case of a chlorine emergency: BOX 5: IN CASE OF AN ACCIDENT USE SAFETY EQUIPMENT TO PROTECT THE RESCUER AND MOVE THE VICTIM TO A SAFE AREA. IF REATHING HAS STOPPED, START ARTIFICIAL RESPIRATION IMMEDIATELY. IF HEART HAS STOPPED, START CPR (CARDIOPULMONARY RESUSCITATION) IMMEDIATELY. IN ALL CASES, OBTAIN MEDICAL ATTENTION AS SOON AS POSSIBLE. 20 6.4 Chlorine Leaks and Spills: When a chlorine leak occurs, authorised, trained personnel equipped with respiratory and appropriate other PPE should investigate and take the necessary action. Persons not wearing protective equipment and fullyencapsulating, vapour-protective clothing should be restricted from the contaminated areas until clean-up has been completed. Other personnel should be kept away and the hazardous areas should be isolated. People potentially affected by a chlorine release should be evacuated or sheltered in places as circumstances warrant and should be moved to a point upwind of the release. Higher elevations are preferred due to chlorine being heavier than air. When sheltering inside a building is preferred, close all windows, doors and openings and turn off any air conditioners or air intake systems. People should move to the side of the building furthest from the release. If a fire is present or imminent, chlorine containers and equipment should be moved to a safe location if possible. Non-leaking containers or equipment that cannot be moved should be kept cool by the application of water. This should continue until well after the fire has been extinguished and the containers are cooled. Water should not be used directly on a chlorine leak as chlorine and water reacts and forms strong acids that could have negative environmental effects. Where vapours are reduced with a water spray, all run-off water contaminated with chlorine should be handled as potential hazardous waste. If a leak occurs in equipment of piping, the supply should be discontinued and the material under pressure at the leak should be disposed of. Box 6 supplies information on common causes of chlorine piping leaks. BOX 6: COMMON CAUSES OF CHLORINE PIPING LEAKS Re-use of gaskets. This should never be done. Always have an adequate supply on hand and always use new gaskets of the correct material and size as identified on the equipment parts drawing. Improperly made-up threaded pipe joints. 21 Chlorine container leaks: In the case of a container leak (other than a valve leak), the following steps should be considered: 1. 2. 3. 4. 5. 6. Notify safety personnel. Remove all sources of heat or ignition. Keep all combustibles (wood, paper, oil, etc.) away from the leak. Ventilate potential explosive atmospheres. Evacuate the spill area for at least 20 meters. Find and stop the leak if this can be done without risk – if not, move the leaking container to an isolated area until the gas has dispersed. 7. If possible, turn the container so that the gas instead of the liquid escapes (the volume of gas that will escape is 1/15 the volume that escapes from a liquid leak). 8. If available, apply an appropriate emergency kit device. 9. If possible, reduce the pressure in the container by removing the gas to a suitable disposal system (e.g. absorb in an alkaline solution). The tank and other equipment provided for an absorption system must be fabricated of materials suitable for the chemicals involved. Provision must be made for dissolving the chlorine in the alkaline solution in such a way that the solution cannot be sucked back into the container. NOTE: use water spray to reduce vapours but do not put water directly on the leak or spill area. 6.5 The Buddy System: It is recommended that a second person be available in the plant when handling chlorine. If one person becomes incapacitated, the other can call for help should an emergency arise. 6.6 Emergency Disposal of Chlorine Waste: Provision should be made for the emergency disposal of chlorine from leaking containers in storage areas. The gas may be absorbed in solutions of caustic soda or soda ash. 22 7. INCIDENT INVESTIGATION All chlorine related incidents and near misses that resulted or could have resulted in an uncontrolled chlorine release should be thoroughly investigated. Investigations should be initiated as promptly as possible. An investigation team should be established and a report should be prepared. The report should include as a minimum: A description of the incident The root cause of the incident Factors contributing to the incident The preventative and corrective actions to be taken and relevant follow-ups to the changes should be done. (A documented change management process should be followed) The report should be reviewed by the management responsible for the safety standards in the facility. 8. PERSONNEL TRAINING The safe handling of hazardous chemicals like chlorine depends upon the effectiveness of employee education, proper safety instructions, good supervision and the effective use of safety equipment. Training of new employees should take place to ensure the required knowledge, skills and abilities are obtained before the employee is involved in the operating process. Refresher training of current employees should take place periodically (e.g. every two/three years) in order to maintain a high degree of safety in chlorine handling procedures. Employees should also be informed of the hazards that result from the improper handling of chlorine. They should be cautioned to prevent leaks and thoroughly instructed regarding the proper action to take in case leaks do occur. Each employee should know what to do in case of an emergency and should be fully informed as to the appropriate first aid measures. Box 7 indicates what the employee training should encompass. 23 BOX 7: EMPLOYEE TRAINING COMPONENTS The potential risk to health caused by exposure The necessity of personal air sampling and medical surveillance Safe work procedures regarding the use, handling, storage and labelling of chlorine Safe handling of chlorine containers Location of emergency and fire fighting equipment Procedures to be followed in case of a spill, leak or accident Alarms (emergency/evacuation) Emergency shut-down equipment Location, proper use and care of PPE (including respiratory first aid equipment) Operating procedures Changes in process technology or facilities Safety showers, eye baths and the closest source of emergency water Avoiding the inhalation of chlorine vapours and direct contact with the liquid Reporting of incidents involving leaks and equipment failures to management and the authorities The importance of good housekeeping and personal hygiene Local legal requirements pertaining to hazardous substances How to access the SDS Main findings of risk assessments Possible incompatibility of chlorine and other chemicals that may be present on site Any training should be documented and training records should be kept indefinitely. Drivers that transport bulk or packaged chlorine must be specifically selected, trained and authorised to drive vehicles transporting chlorine. They must be trained in the: 9. appropriate driving standards for dangerous goods properties of chlorine emergency procedures should an incident occur on the road national road safety requirements. CHLORINE SIGNAGE All access doors to chlorine gas storage areas should be properly labelled with appropriate warning signs. It is also recommended that emergency 24 posters be displayed to inform employees of the handling and working precautions necessary to be effective and safe. Figures 2.1, 2.2 and 2.3 illustrate chlorine warning signs that can be used in on-site storage and handling areas: FIGURE 2.1 FIGURE 2.2 FIGURE 2.3 25 10. TRANSPORTATION OF CHLORINE The road, rail and marine transport of chlorine is permitted for the bulk and packed product. Road transport is used exclusively in South Africa and chlorine in both bulk and packed form is carried. Road tankers carry relatively small amounts of chlorine, typically between 10 to 17 ton per load. Packed chlorine is transported in 70kg vertical cylinders as well as the 900 to 1 000kg horizontal tanks. These cylinders and tanks may be transported on the same vehicle provided the mass is within the legal carrying capacity of the vehicle and that the containers are adequately secured to the vehicle to prevent shifting in transit and in the event of an accident. It is not recommended that a vehicle of less than 3 500kg, gross vehicle mass (GVM) draw any trailer or semi-trailer while transporting chlorine. For road transport, appropriate route risk assessment should be conducted and the route taken by vehicles specified. Routes should be selected considering: Density of the population along the route Road conditions The availability of emergency services along the route Security of the cargo The speed in South Africa of heavy goods vehicles, exceeding 9 000kg GVM is limited to 80 kilometres per hour. For smaller vehicles the applicable national speed limit will apply. It is important that drivers remain with their vehicles at all times as is required by dangerous goods legislation therefore ensuring that the product is continually supervised throughout the journey. Road transportation of chlorine is regulated by the National Road Traffic Act 93 of 1996, specifically Chapter VIII – Transportation of Dangerous Goods and substances by road together with applicable national SANS Standards. Such standards include: SANS 10231 – Transport of Dangerous Goods. Operational requirements for road vehicles. SANS 10232 – Transport of Dangerous Goods. Emergency Information Systems. Part 1: Emergency information systems for road transport. 26 SANS 1518 – Transport of Dangerous Goods. Design, construction, testing, approval and maintenance of road vehicles and portable tanks. If a chlorine leak develops in transit through a populated area, it is recommended that the vehicle keep on moving until an area is reached where it will not pose a risk to the local residents. Appropriate emergency measures should then be taken as quickly as possible. Contact the specialist telephone number on the dangerous goods placards displayed on transport vehicles and refer to the 1st Responders Emergency Response Guide as held by the Emergency Services personnel. If a motor vehicle transporting chlorine containers is damaged, any leaking containers should, if possible, be positioned so that only gas escapes, and if necessary, moved to an isolated area before attempts are made to stop the leaks. If there is any possibility of fire, the containers should be removed from the vehicle. Suitable respiratory protective equipment should be available for handling emergencies and should be carried on all transport vehicles. 11. WORKPLACE SAFETY 11.1 Risk Assessment: A risk assessment must be conducted to determine the potential exposure of employees to chlorine gas. The risk assessment will assist in determining the control measures (monitoring and health surveillance) that need to be implemented. The following aspects must be considered when doing the risk assessment for chlorine: how exposure could happen what is the chance of the exposure occurring who would be exposed the degree of exposure frequency of exposure (daily, all day or infrequently) 27 the extent of the exposure that includes employees directly exposed and employees indirectly exposed precautions or controls required that includes prioritisation of the hierarchy of controls, justification for each level of control and specifications for the correct PPE air monitoring requirements that includes occupational exposure limits and measurements that need to be undertaken health surveillance requirements for chlorine storage requirements for the chemical as specified by the SDS physical handling of the containers emergency leak and disposal requirements including controls that are suitable for the management of leaks/releases and controls required for the prevention of environmental contamination PPE to be worn during leaks/releases Additional Risk assessments will be required should: new scientific information be obtained on the properties and hazards of chlorine the results of monitoring or health surveillance show that it is necessary to do so information received (via audits / inspections) indicates defects in the control measures. 11.2 Monitoring Exposure: Where an employee could inhale chlorine, an air monitoring measurement programme of the airborne concentrations of chlorine, which the employee may be exposed to, must be developed by the Departmental Manager in conjunction with the local safety personnel. The measurements must be conducted: after the Health and Safety Committee has been informed of the measurement by an Approved Inspection Authority (AIA) or 28 by a person whose ability to do the measurements has been verified by an AIA Chlorine is a hazardous chemical with a Time Weighted Average Occupational Exposure Limit - Recommended Limit that may not be exceeded (in South Africa = 0.5 parts per million or 0.5 mg/m3). Measurements have to be repeated every 24 months. 11.3 Medical Surveillance: If the risk assessment indicates that health surveillance is required, the Occupational Health Medical Practitioner on site (where these services are available on site) together with the site management must set up a surveillance programme. The purpose of the programme must be to check for any changes in the health of those shown at risk in the risk assessment. Medical surveillance could include biological monitoring to measure the extent of the absorption of chlorine by the employee or medical screening to detect any adverse effects resulting from the exposure to chlorine. 12. EXTENDING SAFETY TO THE CUSTOMER The chemical industry under Responsible Care is committed to promoting safety at all stages of chlorine’s life cycle, from production to end-use and disposal. This includes helping to educate customers and end-users on safe handling practices and so preventing chlorine related incidents. 12.1 Customer Sites Customers using chlorine must continually strive to reduce chlorine incidents in their operations with the ultimate goal of eliminating all such incidents. Only through continuous improvement in chlorine safety performance and prudent attention to security can the industry and all participating in it hope to achieve long-term success. It is therefore important that prior to the installation of bulk chlorine storage and handling facilities on customer sites, the capability of the customer to handle such facilities first be evaluated and assessed. If deficiencies are found, the customer should be advised on how to correct the deficiencies so that safety, health and environmental protection can be enhanced. The evaluation should assess the following: 29 Personal safety of employees and training Emergency response Security of facilities Bulk containers securement Bulk containers unloading system procedures Process piping (liquid and gaseous services) Process equipment – vapourisation system, storage system, process area considerations and scrubber equipment Packaging/processing Warehousing/storage areas Delivery vehicle access Useful Checklists that can be used for customer sites are available from The Chlorine Institute’s website: http://www.chlorineinstitute.org/files/PDFs/ChlorineCustomersGenericChecklis t-Edition2-Final.pdf http://www.chlorineinstitute.org/files/PDFs/ChlorineCylinderandTonContainerC hecklistFinal_Interactive_Form%2020090514.pdf Responsible Care signatories that supply chlorine are encouraged to use these checklists, or a company specific custom made checklist to conduct an assessment on new customers and those existing customers who may benefit from the assessment. Each company should determine the frequency that it is best to survey its customers using the checklist. If a customer demonstrates compliance with the checklist and has an incident, the supplier of chlorine should decide if a revalidation of the customer’s systems and processes are required. The circumstances of the incident should be considered during this decision. The chlorine supplier must decide if they want to physically visit the customer’s site or if the checklist should be completed by either representative(s) of the chlorine customer facility or by representative(s) of the chlorine supplier or jointly. Both the customer and the supplier should agree in advance who will complete the checklist, how this task will be accomplished, and how the results will be used. The completed checklist should be kept confidential between the parties unless it is mutually agreed to release it to 30 other parties. The chlorine supplier should have a record retention policy for this checklist and should advise the customer what that their policy is. 12 .2 Customer Support The customer should be supported in all possible applications of chlorine. It is recommended that the following be considered: Correct product use; Provision of chlorine’s SDS; Specify that appropriate precautions and procedures are in place; Provide detailed codes of practise regarding the handling and transportation requirements in specific packaging and under specific mode Where the customer is to purchase reasonable quantities of chlorine over time, the supplier shall provide training to the customer’s employees Customers should be reminded at annual intervals of the dangers of the chemical or product, e.g. by letter or circular In any case if the supplier is not satisfied that appropriate arrangements are in place, withhold supply and advise the customer in writing with the reasons for withholding supply Suppliers may consider alternative hazard communication activities such as laminated information cards for individuals or information sheets or posters available in the areas of use, exposure, and substitute formulations 13. REFERENCES a) Euro Chlor (2002) Guidelines for the Safe Handling and Use of Chlorine, Euro Chlor Publication, Brussels, Gest 92/169, 2nd Edition, September 2002, b) Euro-Chlor (2001) Safe Transport of Chlorine, Stephen Heyworth, Euro Chlor Fifth Technical Seminar, TSEM 01/275, A Sustainable Future for Chlorine: Improving Health, Safety and Environmental Performance, 8-9 February 2001 c) Euro-Chlor (2004) Chlorine Emergency Equipment, GEST 92/176, EuroChlor, 2nd Edition , June 2004 d) SABS 0265 for explanation of the above safety phrase for chlorine 31 e) NCP Chlorchem: Training Manual - The Use and Handling of Chlorine f) NCP Chlorchem: Threshold Checklist for Prospective Transporters of Packed Chlorine. 14. OTHER RESOURCES: A Safety Data Sheet for chlorine is available from the following source: Sigma Aldrich: http://www.sigmaaldrich.com/safety-center.html (product number: 22752) 32