Minimum Standards for Production of Frozen Semen April` 2005

advertisement

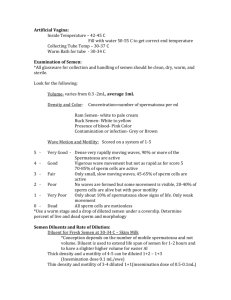

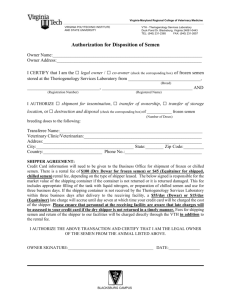

Minimum Standards for Production of Frozen Semen April' 2005 CENTRAL MONITORING UNIT Department of Animal Husbandry & Dairying Ministry of Agriculture, Government of India CONTENTS Particulars 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 10 (A). 10(B). 10 (C). 10(D). 10(E). 10(F). 10(G). 10(H). 10(1). 10(J). 10(K). 11. 12. 13. 14. Standards for Genetic Merit of Breeding Bulls Physical Examination Quarantine Testing of Bulls Vaccination Schedule Culling of Bulls and Semen Doses due to Specific Diseases Housing Management of Bulls Semen Collection Handling of Semen, Processing & Freezing Premises Equipment Personnel Hygiene Diluents Evaluation & Processing Colour Specifications Printing of Straws Post-thaw Motility Quality Checks for Frozen Semen Information System Semen Storage Cleaning and Sterilisation of Laboratory Equipment Summary of Sterilisation Quality Control of Consumables Manpower Requirement for Semen Production Page 1 2 2 3 3 3 4 4 5 6 6 8 9 9 9 10 11 11 11 12 12 13 15 15 16 Annex. _ 0 % " I. II. III. IV. V. VI. VII. VIII. IX. X. XI. Drawing Tuberculosis Management Jhone's Disease (JD) Management Brucellosis Management Infectious Bovine Rhinotracheitis (IBR) Management Bovine Genital Campylobacteriosis Management Bovine Trichomoniasis Management Foot and Mouth Disease Management Feeding Growing and Mature Bulls List of Laboratory Equipment for Frozen Semen Stations Qualifications Recommended for Semen Station Personnel Job responsibilities of the QCO Plan of a Model Semen Station 18 19 20 21 22 23 24 25 27 29 30 32-33 MINIMUM STANDARDS FOR PRODUCTION OF FROZEN SEMEN Artificial Insemination with frozen semen has been proved to be the best tool world wide for genetic improvement through dissemination of superior germplasm. This objective can be achieved only if the frozen semen used in Al programme conforms to the quality standards. For production and distribution of quality semen, it is most important that the bulls used in Al programme satisfy pedigree norms, bulls are disease free and semen is harvested and processed in accordance with the standard protocols. The least protocols required for production of quality semen are covered in this manual. Failure to observe these guidelines could lead to production of poor quality semen making it unfit for distribution to AI centres. The minimum pedigree standards for bulls in the Al programme are given in the following table. 1. Standards for Genetic Merit of Breeding Bulls Breed Pure HF Pure Jersey Sahiwal Red Sindhi Gir Kankrej Tharparker Hariyana Rathi Ongole Deoni Khillar Dangi Amritmahal HFCross-F2 Jersey CB- F2 Sunandini Murrah Mehsana Nil! Rav! Jaffrabadi Surti Dam's Lactation yield (K Imported Farm bom (minimum) First Best 4500 3000 2400 2000 2400 2000 2000 1600 1600 1100 300 380 400 400 4000 2800 2600 2400 2400 2400 2800 1600 5600 3750 3000 2500 3000 2500 2500 2000 2000 1600 1000 500 530 500 5000 3500 3000 3000 3000 3000 3500 2000 9000 6000 — — — _ — — . — — — — — — ~ — — — — —r -------- gs) Fat % 3.5 5 4 4.5 4.5 4.5 4 4 4 4 4 4 4 4 4 4.5 3.5 7 7 7 8 7 Sire's daughters' averages of the bulls Min number Average First Reliability (%) Lactn yield of records (Kgs.) 30 30 20 20 20 20 15 15 20 _ _ _ — _ 30 30 30 30 30 30 30 30 4000 2500 1500 1500 1500 1400 1400 1400 1500 — . — — — — 2500 2000 3500 1800 1800 1800 2000 1600 85 85 80 80 80 80 75 75 80 _ — — — — 85 85 85 85 85 85 85 85 Dam's milk yield for F1 crosses will be as that of the indigenous dam's i.e. Gir, Sahiwal, Kankrej, Red Sindhi, etc. Minimum Standards Average lactation yield (305 days) of HF and Jersey for the year 2002 for th e following countries available from ICAR booklet are as below: Breeds New Zealand HF Jersey 3361 NA Australia 6027 4381 Canada 8534 6048 US 9447 4619 France Israel 6608 NA 10463 NA The above information would be updated every year for information of all concerned so that this data can be used during import of bulls. 2. Physical Examination Before inducting new bulls in the semen station, a thorough physical examination shall be conducted by an accredited Official / Veterinarian to ensure that the bulls do not display clinical symptom(s) of any infection or any contagious diseases. Prior to introduction of new bulls to the sperm station, breeding soundness examination shall also be carried out. Standards for scrotal circumference and weight gain index for various breeds shall be fixed by initiating age wise (monthly) recording of scrotal circumference and body weight, by the semen stations. Before introducing to semen station, all bulls shall be karyotyped to rule out any chromosomal defects. Specific tests may also be conducted for genetically transmitted diseases like Bovine Leukocyte Adhesion Deficiency (BLAD), Cttrullinemia and Deficiency of Uridine Monophosphate Synthase (DUMPS) for HF and HF crosses. 3. Quarantine A minimum quarantine period of 60 days is compulsory before bringing new bulls in a semen station (incase of bulls are brought from known sources, 30 days quarantine is sufficient). This period shall be divided in two periods of 30 days during which a series of compulsory examinations and tests are carried out. Only after favorable results from the health control point, the bull shall be admitted to the semen station. a). In the quarantine station new bull/s shall be housed for minimum of 60 days in a place which is effectively separated from (preferably at a distance of 5 km) the facilities occupied by resident bulls and all equipment used in handling, feeding, watering and cleaning the new bulls shall not be shared with the resident herd(s). b). Each new bull in quarantine station will be tested against major contagious diseases before its entry to resident herd e.g. TB, JD, Brucellosis, Infectious Bovine Rhinotracheitis (IBR/IPV), Campylobacteriosis and Trichomoniasis. All tests shall be done by an accredited agency or disease diagnostic laboratory. c) If any bull is found positive for TB, JD and Brucellosis, the positive bull shall be removed immediately without retesting. The remaining bulls shall be further tested twice for that particular disease at an interval of 60 days. If any bull is found positive, all animals in that batch shall be culled. As regards animals positive for IBR, culling shall be made based on isolation of virus for IBR-IPV. Minimum Standards d) During quarantine period, the bulls shall be vaccinated against FMD, HS, BQ, Theileriosis and Anthrax. However, vaccinations against bacterial diseases shall be done only if there is an outbreak or prevalence of a particular disease. Once the quarantine period is over, all bulls shall be introduced to the resident herd. The resident herd would also go through periodical testing and vaccinations as per the schedule listed in the manual. 4. Testing of Bulls Testing protocols for bulls against Tuberculosis, Johne's disease, Brucellosis, IBR, Campylobacteriosis and Trichomoniasis are given in Annex I to VI. As per OIE guidelines, the breeding bulls should be free from above mentioned diseases. Though Johne's disease is not a sexually transmitted disease but from the herd health point of view, bulls found positive should be removed and therefore it has been included in the MSP. 5. Vaccination Schedule The bulls shall be vaccinated against FMD, HS, BQ and Anthrax. However, vaccinations against bacterial diseases shall be done only if there is an outbreak or prevalence of a particular disease. Theileriosis - to be vaccinated once in lifetime in exotic and crossbred bulls. To reduce lay off time, the bulls shall be vaccinated on the rest day or the day after completing semen collection. Sexual rest may not be required unless otherwise febrile condition is noticed. The semen station shall arrange for carrying out ring vaccinations for all animals against FMD, HS and BQ within a radius of 10 km around the semen station. Vaccinations against HS and BQ shall be carried out in the areas having incidence of these diseases. 6. Culling of Bulls and Semen Doses due to Specific Diseases Bulls Diseases FMD Retain Brucellosis TB JD IBR/IPV Castrate & remove Remove Remove Remove based on specific symptoms Treat and retain Treat and retain Campylobacteriosis Trichomoniasis Minimum Standards Semen doses Last one month doses to be discarded, refer Annex- VII To be discarded since the last negative test To be discarded since the last negative test To be discarded since the last negative test To be discarded since the last negative test To be discarded since the last negative test To be discarded since the last negative test The semen station must remove bulls (within 48 hours) which are positive for above diseases, poor libido, poor semen quality, incurable lameness, etc. Besides, the semen station shall also cull those bulls which have completed six years of productive period or 2 lakh semen doses, whichever is achieved earlier. 7. Housing Bull sheds shall have spacious individual pens with adequate loafing area, manger and water trough with access to drink water all time. Provision for adequate shade around the bull shed shall be given priority. The roof shall be made of asbestos or suitable materials. During summer cooling system with sprinklers and fan is required particularly for the buffaloes and exotic bulls. Disinfectants like formalin or phenyl based compounds shall not be used in the bull sheds. Alternatively compounds containing Gluteraldehyde shall be used. Weekly spraying of Sodium Bicarbonate (4%) solution shall also be practiced. The floor should be sterilized at least once a year by a blowlamp or by burning straws. At one comer of the farm there shall be isolation shed for separating ailing / sick bull for treatment. Bulls once diagnosed suffering from infected disease, shall be removed immediately from semen station for safety of other bulls. 8. Management of Bulls The objective of daily care of bulls is to ensure a satisfactory state of cleanliness. For proper management of bulls the following points shall be considered: a) The bulls shall be kept under hygienic conditions at all times. b) The coat of the bulls shall be kept clean and generally short. The hooves shall be regularly trimmed. c) The length of the tuft of hairs at the preputial orifice, which is invariably soiled, shall be cut to about 2 cm. The hair would not be removed altogether, because of its protective role. If cut too short, it may cause irritation of the preputial mucosa. d) Bulls shall be brushed and groomed regularly, and where necessary special attention shall be given to the underside of the abdomen, a day prior to semen collection. Also, prepuce shall be washed with sterile normal saline solution. e) In the event of obvious soiling, careful cleaning of the preputial orifice and the adjoining areas with soap or a detergent is recommended; followed by thorough rinsing and drying. f) Scientific feeding schedule shall be followed for the bulls. A general guideline is attached as Annexure - VIII. Semen station shall carryout routine quality analysis of feed and fodder for arriving at a balanced ration. Minimum Standards 9. Semen Collection a) Ideally, the floor of the collection yard shall be made of concrete layer at a depth of one foot from the ground level. Mixture of sand and limestone shall be used to fill up to ground level and pressed firmly. If it is not possible to renovate the entire collection arena, at least the mounting area shall have sand and limestone mixture for proper footing of bulls. Alternatively, good quality rubber mat (with interlocking arrangement) or coir mat shall be put into concrete groove of the mounting area for adequate cushioning effect. After collection, the area must be thoroughly cleaned and odorless disinfectant solution (Colloidal iodine) be sprayed. A dusty floor shall be avoided to prevent dust falling on the AV / semen samples. b) On the day of collection, before taking semen collection, the bulls shall be properly washed and cleaned. After the bulls are brought to collection arena, before taking collection, the prepuce shall be cleaned externally with a sterilized napkin soaked in normal saline to remove any sand or dust particles. For each bull a separate napkin shall be used. c) The person responsible to carry out preputial wash must use disposable gloves and separate sterilized nozzle for each bull to avoid transmission of IBR infection from one bull to another. d) The bulls shall be sexually prepared by giving two / three false mounts followed by two minutes restraint and the total time limit should be not more than 12 minutes. The duration of each false mount shall be for 1 to 2 minutes. e) Sterilized bull aprons shall be used to avoid penis touching hindquarter of the dummy. f) Preferably veterinarians shall take semen collection. If semen is collected by staff, a veterinarian shall remain present to supervise the collection process. While taking collection it shall be ensured that AV is not thrusted on penis of bull, instead penis should be guided to AV. g) Before every collection, the semen collector shall either wash his hands with 0.1% Savlon solution or use disposable gloves or do both. The semen collector shall not touch the penis. h) Immediately after collection, the AVs shall be thoroughly cleaned by nonspermicidal neutral detergent. Separate AVs shall be used for each mounting. The AV shall be changed even if the bull has inserted its penis without successful ejaculation. The same AV shall not be used twice. The AVs shall always be kept inverted and the collection tube shall be covered with felt / water jacket (plastic bottle filled with warm water at 34° C) to avoid cold shock. The open end of sterilized AVs shall be covered with aluminum foil, which would be removed at the time when bulls are ready for giving semen. i) Preferably 10° size AVs shall be used for cattle and 8 to 9" size for buffaloes to ensure semen is ejaculated in cone. For buffaloes goat AVs can also be used. The cone shall be of top quality Neoprene rubber. Minimum Standards j) Use of lubricant shall be avoided. If it is extremely essential to use lubricant, separate sterilized glass rods shall be used for smearing K-Y Jelly on each AV. k) The AV shall not to be shaken after ejaculation; otherwise lubricant and debris may mix with the semen samples. I) The entry of visitors/ staff / labourers shall be strictly prohibited in the collection arena at the time of semen collection and inside the semen laboratory. m) Protective clothing (barn coat) and gumboots shall be used by the Veterinarians and personnel while taking semen collection. Gumboots and bam coat should be washed daily immediately after completion of semen collection work. n) Semen must be obtained from a bull having normal libido. While taking two ejaculations the semen station shall keep a gap of 10 to 12 minutes between two ejaculates, depending upon the refractory period of the bull. (To harvest more quantity of semen, interval between two ejaculates shall be kept for 40 to 45 minutes. After taking first ejaculate, the bull shall be taken back to the shed for feeding and watering and again brought back for taking second ejaculate. However, care shall be taken to use a fresh & sterilised apron during second ejaculate) o) Semen stations must follow the norm of two ejaculates per collection and two collections per bull per week for taking annually at least 90 collections and 180 ejaculates from each adult bull. 10. Handling of semen, processing & freezing 10 (A) Premises a) Sufficient trees shall be planted and lawns prepared around the semen station to reduce dust. b) The ceiling and walls of the laboratory shall be made up of non-porous materials. All cracks and crevices shall be sealed to control pests and insects. c) Entry of persons to the laboratory other than laboratory personnel shall be strictly restricted. Airlock system or anti-room shall be provided to avoid direct entry to the semen-processing lab. d) Lab windows shall be made of single sheet glass with fixed aluminium frame. The glass panes shall be plastered with sun control films to avoid direct sunlight. The doors shall be kept closed, especially during dilutor preparation and semen processing. e) Intake areas of the air conditioners shall be -disinfected weekly and if possible, split type air conditioners with remote temperature control mechanism should be installed to maintain the room temperature at Minimum Standards 20°C. The number of ACs to be fixed to sustain this temperature shall depend on the size of the processing room. Maintaining this temperature is most important to achieve the best results when single step dilution method is followed for freezing semen. Alternatively, HEPA filters shall be installed near intake area of air conditioners. The flow of air from AC must not be towards the front side of the Laminar Air Flow Unit. Adequate number of dial thermometers shall be kept in a few places in the laboratory to check the room temperature. f) Sink drains shall be decontaminated routinely with a disinfectant. Preferably, the sink shall not be placed in the semen processing room. g) The floors shall be preferably made up of vitrified tiles. Floors and horizontal surfaces shall be cleaned and mopped with a disinfectant solution, as dirt and dust, which settle on these surfaces, are the main sources of contamination. h) Unwanted furniture, equipment and materials shall not be kept in the laboratory as they only provide additional area for dust and spores to collect. i) Appropriate no. of germicidal UV lights (2470 A) in respect of area of laboratory, laminar airflow unit, apron and laboratory footwear cabinet shall be fixed with a common operating switch outside the laboratory. These lights shall be kept 'on' at least for 8 hours prior to commencement of work in the laboratory and shall be switched off before beginning work The date of installation of the UV lights shall be noted to facilitate replacement as the life of UV tube is of 2000 hours. A logbook should be maintained for timely replacement of UV lights. j) Laboratory shall be fumigated weekly for 2 hours with 12 ml of 37% formaldehyde solution in 100 ml water per cubic meter at weekends, using humidifier. After fumigation, switch on the exhaust fans for clearing formalin fumes. However, this should be supported by monitoring of lab environment by bacterial load test. The bacterial ioad shall be measured every week to monitor pollution of the laboratory atmosphere. k) (Mixing formalin and water with potassium permanganate crystals*. *WARNING: the correct relative concentration of these two components is essential to avoid a violent reaction. It is therefore recommended that this method is NOT used. (Reference; Bid-safety Unit, Health and Safety Department, University of Edinburgh, August 2003) I) The work platform, the parts of equipment and other items to be handled during processing of semen, shall be cleaned with 70% alcohol or Glutaril (Qualigen). It is advisable to repeat cleaning schedule after completing processing of semen. m) Clean laboratory footwear, apron, hand gloves, mask and caps shall be compulsorily put on while working in the laboratory. n) Eating, drinking, smoking, etc. shall be prohibited in the laboratory and unnecessary conversation should be discouraged. Besides, entry of persons shall be strictly restricted. Minimum Standards o) Long exposure of semen to ultraviolet rays, visible light in direct sunlight and white florescent light causes chromosomal damage and hence direct exposure to such sources of light shall be avoided. Hence, there shall be provision for indirect or diffused lighting inside the semen processing room. Care shall also be taken not to switch on tube lights in CH cabinet and laminar airflow unit. 10(B) Equipment a) The exteriors of all equipment and furniture shall be cleaned weekly. The equipment shall be kept covered by plastic covers when not in use. b) The pre-filter of Laminar Airflow unit shall be cleaned weekly. Routine servicing and OOP testing twice a year will ensure efficiency of HEPA filters. Alternatively culture plate test shall be carried out at frequent interval to assess bacterial load of the air passing through the filters. c) Digital photometer / Computer aided Spectrophotometer shall be validated with Haemocytometer readings for sperm concentration twice a year separately for cattle and buffalo (10 samples each). d) The automatic semen straw filling and sealing machine shall be thoroughly cleaned, immediately after use. e) The microscope lens shall be gently cleaned daily with a piece of cotton soaked in a mixture of ethyl and methyl alcohol (1:1). f) The bio-freezer shall be defrosted and thoroughly cleaned and dried, immediately after use. g) Incubators to maintain artificial vagina shall be cleaned and disinfected daily with 70% alcohol. h) Single distilled water shall be used in autoclave and thermocontrolled water bath. The water bath shall be cleaned and filled with single distilled water on a regular basis. i) The thermometer kept immersed in water bath shall be cleaned daily to have precise temperature reading. j) The Liquid Nitrogen containers returning / received from foreign countries and contagious disease prone areas shall be disinfected thoroughly with 4% soda solution and finally with 1 to 4% formaldehyde. Excess liquid nitrogen available as a result of filling the containers with canisters and goblets, shall never be brought inside the semen processing room. k) The refrigerator meant for storing eggs, antibiotics and buffer shall not be used for storing vaccines and other materials. All such materials shall be stored at a place away from semen lab. The refrigerator used for storing eggs, etc. shall be sterilized every week using alcohol swab. Minimum Standards 8 10 (C) Personnel Hygiene Clothing, skin and hair of laboratory personnel are the sources of the contamination. Hence all should wear laboratory aprons and footwear all the time while they are in the laboratory. Hands shall be washed with soap and water and rinsed with 70% alcohol, before commencing work in the laboratory. The bull attendants must undergo test for TB every year. Restricted entry inside the semen processing room and freezing room shall be strictly adhered to. 10 (D) Diluents a) All disposable and reusable supplies coming in contact with the semen and dilutor must be sterile and devoid of toxins and pyrogens. b) Prolonged storage of purified water is not recommended because water purity deteriorates progressively over a period of time as heavy metals leach from some glass and plastic storage vials / containers. c) Glass wares, collection tubes, etc. shall not be handled from their rim / mouth. d) Pipetting shall be done away with, instead adjustable micropipettes and disposable tips shall be used. e) After adding all the components of buffer viz. TRIS, Citric Acid, Glycerol and Fructose in double, preferably triple distilled water, it should be again sterilized. If buffer is prepared on the previous day and stored in the refrigerator then antibiotics are to be added on the next day morning after warming it at 34°C. f) Antibiotics in diluents: Combination of antibiotics, in diluents, which can control Mycoplasma like Tylosin, Lincospectin and Gentamycin may be used. Alternatively, a combination of Penicillin and Streptomycin shall be used. g) The eggs used for making dilutor must be fresh. The eggs shall be stored in refrigerator after wiping with dry cotton. Just before preparation of dilutor, eggs shall be wiped with 70% alcohol. To avoid Mycoplasma infection, eggs shall be purchased from known sources. h) The required quantity of yolk shall be separated from albumin on sterile (autoclaved) standard filter papers (Whatman No. 1/ Borosil) and yolk membrane shall be punctured using sterile glass rod or Pasteur pipette or sterile straws under the Laminar Flow Unit. Only fresh semen extender/dilutor shall be used because changes in the pH of stored extender are considered to be responsible for the deterioration of some nutrient components. Day old extender shall not be used. 10 (E) Evaluation & Processing a) As soon as the neat semen is received, it shall be kept in a thermo-controlled water bath at 34° C under Laminar Unit, after recording the volume of semen. Minimum Standards b) The tube containing the freshly collected semen should be capped with aluminum foil as soon as it is placed in the pass box before transferring to the laboratory. The collection tube shall be kept capped until processed. c) After examination of sperm concentration and initial motility, semen samples shall be primarily diluted with dilutor maintained at 34° C. In the case of buffalo semen, examination of mass activity is mandatory because semen samples with zero mass activity may not give better result and usually discarded after freezing. Alternatively, a small drop of fresh semen shall be examined under a cover slip to check motility and to assess the semen samples. d) Sperm concentration shall be checked preferably by a digital photometer with auto dilutor, manufactured by a reputed company. The photometer shall be calibrated separately taking 10 readings each for cattle and buffalo semen, at least once in six months, with haemocytometer readings. Semen samples showing less than 500 million / ml sperm concentration shall be discarded. e) Semen samples selected for freezing should have minimum 70% initial motility. Final dilution of semen keeping a minimum of 20 million spermatozoa per dose shall be done in appropriate flasks with the dilutor maintained at 34° C. f) Filling and sealing of semen shall be done under Laminar Flow Unit using sterile straws, filling nozzles and fresh rubber tubings. Rubber tubings shall be used once only. Reuse of rubber tubes is not recommended. Considering the advantages the French Mini Straws has over French Medium straws, the semen stations shall use French Mini straws. g) Unused straws shall be repacked (air-tight) under Laminar Unit before storage. h) Immediately after use, all the glass wares, rubber wares, plastic tips and other reusables shall be immersed in neutral detergent solution (to be kept in a plastic tub near the Laminar Unit). 10(F) Colour Specifications : All semen stations shall follow the following colour codes : 1. 2. 3. 4. 5. 6. 7. If any Jersey Yellow Holstein Pink Indigenous Orange HF Crossbred Pistachio Green (light green) Jersey Crossbred Salmon Sunandini Blue Buffalo Grey of above colour is not available then transparent colour is used. Minimum Standards 10 10 (G) Printing of Straws Information regarding bull number, breed, name of the organization, year, batch no. (as per the day of the year), etc. shall be printed on straws preferably after their filling and sealing. After printing the ink gets instantly dried. If filled straws are printed and racked, the actual number of straws can be easily counted. While printing and racking, the room temperature shall be maintained at 20 ° C. AH semen stations shaii foiiow the following printing abbreviations: Jersey Holstein HF Cross Jersey Cross Sunandini Sahiwal RedSindhi Kankrej Gir Tharparker Rathi Haryana Murrah Buffalo Surti Buffalo Jaffrabadi Buffalo Mehsana ^- JY HF CBHF CBJY SUN SAH RS KANK GIR THAR RATHI HAR MBF SBF JBF MSNB Farm No. / Name Breed Name of Institute Batch No. / Date of Prodn. 10 (H) Post thaw motility After freezing, the semen straws shall be stored in a separate container. Postthaw motility of semen should be examined at 24 hours. Differences in observations shall be updated and recorded for the purpose of accepting a particular batch of semen doses. Whenever there is any doubt, post-thaw motility shall be examined by two experienced persons. Preferably, the person involved in evaluation of neat semen, shall not check the post thaw motility. For a minimum concentration of 20 million per dose, minimum acceptable post thaw motility shall be 50%. Semen doses below 50% progressive motility shall be discarded. 10 (I) Quality Checks for frozen semen This includes (i) Quarterly testing of random samples from each batch for bacterial load using standard plate count (The standards for acceptable colony forming unit in processed semen is 5000 CFU per ml as per OIE norm. If the bacterial load exceeds the OIE limit, the semen doses are to be discarded.) (ii) Hypo osmotic swelling test (HOST) - every day four to six samples (iii) Incubation test - everyday four to six samples (iv) Acrosome integrity test by Giemsa staining - for all bulls at least once in a quarter shall be mandatory. Alternatively wet smear of semen shall be examined using DIC microscope (v) Percent Intact Acrosome - all bulls to be covered once a quarter (vii) Sperm Concentration randomly two samples per week each for cattle and buffalo Minimum Standards 11 Validation of photometer shall be done once in 6 months, at least 10 samples each for cattle and buffalo. Neat semen shall be examined at an interval of every six months for morphological abnormalities particularly for crossbred bulls. Morphological examination of sperm of young bulls must be carried out (at least six samples at weekly intervals) before introducing them in the herd. Semen should not be used if the sample contains a total abnormality of more than 20% and head and mid-piece abnormality ( alone) of 7%. 10 (J) Information System a) The semen stations shall use a suitable software to record data pertaining to various activities and also should have online facility for the same. The semen stations producing more than one million doses may introduce software that can identify and trace the bulls and their ejaculates, production, storage and dispatch of semen (barcode system). b) Volume of semen, density, motility, sperm concentration, dilution rate, total extended volume, post-thaw motility (24 hrs), total number of doses produced, etc. shall be maintained. Pre-freeze and post-thaw motility shall be checked for new and problematic bulls. c) Miscellaneous information regarding actual reason(s) for not donating semen, undesired percentage of gross morphological defects, semen pH, presence of dirt, dust, blood, pus, etc. in semen samples. d) Details of semen supplied to various agencies including post-thaw motility at the time of dispatch. e) Fertility data of bulls, conception rate, records of the progeny associated with any genetic defect, percent male / female born, etc. f) Report on microbiological examination of semen samples. g) Records of all quality tests for neat and frozen semen samples. 10 (K) Semen Storage To avoid accidental spread of diseases, the semen station shall follow the procedure of preserving semen doses for at least 30 days after production. Semen doses produced before 30 days from the date of dispatch shall only be supplied for field use. After checking post-thaw motility, if found acceptable, frozen semen doses would be kept in temporary storage for 7 days. After the temporary storage the semen goblets shall be transferred to the bulk storage containers with proper recording of position in the canisters. After each dispatch, records redefining the position of remaining doses shall be updated. Liquid Nitrogen shall be replenished at regular intervals depending on the liquid nitrogen evaporation rate of the container. Minimum Standards 12 11 Cleaning and Sterilisation All the items to be washed shall be initially cleaned with running tap water and soaked in warm neutral detergent for at least 30 minutes. These items will then be thoroughly cleaned under running tap water using a brush. Filling nozzles shall be cleaned with pressure using 20 ml syringe. These materials shall be rinsed thoroughly with de-ionized water (5 to 7 changes) to completely remove detergent residues and other impurities. Appropriate procedure for sterilization of different materials, used in the semen station, is given below: 1. Laboratory and other areas a. Materials 1. 2. 3. 4. Fumigator: Aerosol formation disinfector Formaldehyde Solution 37 % w/v Lab dimensions Lab area in cubic meters b. Procedure 1 . Review of the microbial count indicates the necessity of fumigation 2. Calculate the area in cubic meter, which is to be fumigated 3. Calculate the formaldehyde solution using dosage 12 ml of 37% w/v of the formaldehyde solution in 100 ml water per M3 4. Decide the no. of fumigators to be used (based on area) 5. Put total quantity of formaldehyde solution in all the fumigators 6. See the doors and windows are sealed properly 7. Switch off the exhausting fans and other fans and switch all the fumigators from outside switch 8. Evaporate full formaldehyde solution and switch off fumigators after completing fumigation (about 2 hrs.) 9. Ensure that all the dampers of exhaust area, ducts are shut off during fumigation 10. Switch on the exhaust fans / air handling systems after 2 hours of fumigation 11. Inspect the room for the absences of formalin fumes before the personal entry 12. Expose the settle plates and record the microbial count 1 3. Review the microbial count so as to establish the effectiveness of fumigation c. Maintain a register to record observations on microbiological load in semen processing lab. 2. Artificial Vagina (AV) a) Cone from the AV and water from AV jacket shall be removed before washing. b) Cones and AVs shall be cleaned thoroughly with a soft sponge brush under running tap water and then soaked in warm neutral cleaner for about 30 minutes, followed by proper rinsing in warm and clean water and lastly rinsed three times with double distilled water. Minimum Standards 13 c) For sterilization, fully assembled AVs shall be autoclaved at 5 p.s.i. pressure for 20 minutes. During sterilization the AV - valve shall be kept open. Alternatively, use AV sterilizer (using double distilled water in the sterilizer) for proper sterilization of AVs. d) Finally the AVs shall be stored overnight in an incubator at 45° C. e) To achieve best cleaning effect, AVs shall be cleaned immediately after use, preferably by non-spermicidal neutral detergent. 3. Glasswares a) The glasswares shall be washed thoroughly with running tap water and soaked in warm, non-spermicidal neutral detergent solution for about 30 minutes. b) Using appropriate nylon brush, the glasswares shall be cleaned and rinsed with running tap water. The collection tubes shall be brushed at least 3 times and thoroughly cleaned and rinsed with distilled water. c) Finally the glasswares shall be rinsed three times with double distilled water and allowed to dry by keeping them inverted on a blotting paper. d) The open end/s of the dried glasswares shall be covered with aluminium foil and sterilized in hot air oven at 160° C for 1 hour or at 180° C for 30 minutes. 4. Rubber wares The washing and cleaning procedure of rubber wares is similar to that of glasswares. Care shall be taken to clean the rubber wares with sponge brush instead of nylon brush. Plastic tips shall be cleaned by water jet with force using a syringe. Sterilization technique, however, differs owing to the thermo-sensitivity of the rubber items. Thermo-sensitive rubber wares shall be packed and sealed in specific polythene bags and sterilized in Ethylene Oxide gas sterilizer. Thermoresistant rubber wares shall be sterilized by autoclaving at 3 - 4 p.s.i. for 10 minutes. (The rubber tubing for semen filling shall not be reused). 5. Distilled Water Triple glass distilled water or Milli-Q purified water shall be autoclaved at 15 p.s.i. fop 45 ^minutes and used for preparation of the dilutor. The Triple glass distilled water or Milli-Q purified water stored for more than 5 days shall not be used for buffer preparation. 6. Buffer Buffer shall be sterilized by autoclaving at 5 p.s.i. pressure for 20 minutes. After autoclaving buffer shall be cooled and stored in refrigerator. 7. Bacteriological Media It is to be autoclaved at 15 p.s.i. pressure for 15 minutes. Minimum Standards 14 8. Filter Papers A bunch of clean filter papers of standard brand like Whatman No 1 (thrashed to remove dirt, if any) shall be wrapped in thick cotton cloth for sterilization in an autoclave at 5 p.s.i. pressure for 20 minutes. 12 Summary of Sterilization a) Autoclave Sr.No. 1. 2. 3. 4. 5. 6. 7. 8. 9. Item Pressure Time (p.s.i.) (Min.) Artificial Vagina 5 20 Buffer 5 15/20 Plastic Tips 5 20 Filter Papers 5 20 Bull Apron 5 20 Thermo-resistant Rubber wares 3-4 10 Bacteriological Media 15 15 Distilled Water 15 15 Surgical Equipment 10 10 (The rubberwares can withstand above pressure and duration provided the quality is good) b) Hot Air Oven Sr.No. Item 1. 2. Time (min.) 60/30 60/30 Temperature Glass wares Filling Nozzles c) AV Steriliser 160°C/180°C 160° C/ 180° C Wherever Autoclave is not used, AVs and rubber cones shall be sterilised using AV sterilizer. After sterlizer starts boiling, 30 minutes vapour sterilisation shall be done. d) Ethylene Oxide Gas Steriliser The exposure time for gas sterilization is inversely proportional to the gas concentration under which the equipment is exposed in the sterilizer. Commonly used concentration of ethylene oxide is 900 mg per litre of cubic space for a period of six hours. All items sterilized with gas must be aired adequately before use. A minimum exposure of 72 hours at room temperature with adequate ventilation is recommended. 13 Quality Control of Consumables Chemicals The chemicals of only highest purity of either, Analytical Reagent (AR) or Graded Reagent (GR), from reputed manufacturing companies shall be used. Whenever a new chemical is to be introduced in the routine process, it is recommended to Minimum Standards 15 examine the post-thaw revival rates after conducting few spilt ejaculate trials (maintaining a control) with the new chemical. Assay of chemicals shall be >99%, having less impurities. Straws 1. Straws manufactured by reputed companies are safer to use for production of quality semen. While buying straws package volume and microbial load in straws shall be checked randomly from the consignment. In addition, some empty straws should be placed in auto filling & sealing machine and run the machine for sealing the straws. In case any foul smell, it should be presumed that the straws are manufactured from poor plastic which could be toxic to the spermatozoa and can even result in reduced motility on long storage. 2. The factory plug should not be loose. The factory seal should be impenetrable and the seal formed should be homogeneous and compact. 3. The straws should be intact (without cracks / dents etc.) during and after freezing /thawing. 4. The movement of straws along the printing machine should be free and print should be clear and sharp. Print should not fade as a result of freezing and subsequent thawing. 5. The use of dark coloured straws should be avoided, as they are not transparent enough. Not only is filling / racking inconvenient, it is also difficult to distinguish between filled / semi-filled straws. 6. Movement of the factory plug should be free. 7. Straws should be routinely checked for microbial load. Note: The semen stations should avoid purchase of consumables on lowest quotation basis. To produce top quality semen, it is better to use AR / GR consumables manufactured by reputed companies whose products are reliable. 14 Manpower Requirement for semen production Designation QIC vo QCO Lab Technician Lab Attendant Office Assistant Bull Attendant Minimum Standards Up to 5 lakh doses 1 1 1 .— 2 — 5-10 lakh doses 1 10-25 lakh doses 1 2 1 2 3 1 2 1 3-4 3-5 1 1 person per 7- 8 bulls 16 Above 25 lakh doses 1 3 1 4-5 4-6 1 The manpower structure suggested above, is meant only for semen production. For dispatch of semen, facility should be created preferably away from semen station and operated by other person/s not responsible for semen production. The GOI / Department of AH / Livestock Boards / NGO / Private agencies / Union and Federation shall review the requirement of manpower position for each semen station and finalise the staff structure for recruiting additional manpower. After recruitment, all new persons shall be trained at any of the recognized institutes. Once trained, they shall continue to work in the semen station at least for five years. Refresher training / visit to other semen lab technical exposure of semen station personnel working in the semen lab must be arranged compulsorily once in two to three years at reputed institutions like SAG-Bidaj, CFSP&TI-Hessarghatta, KLDBMatupatty, etc. As semen production activity is an extremely technical work, frequent transfer of personnel could be detrimental in maintaining the quality of semen. Therefore, before considering transfer, in the interest carrying out good work it is essential that proper replacement is identified at least six months in advance and is trained in semen production technology. Minimum Standards 17 Annex-1 Tuberculosis Management Screening Test details Name Delayed Hypersensitvity Single Intradermal test Reagent Reagents from Testing at Jovine tuberculin PPD VRI, Izatnagar Where animals are housed by RDDL/CDDL/NDDB As per OIE norms Negative : Increase in skin thickness less than 2 mm & without clinical signs viz. exudation, necrosis, pain, inflammation of the lymphatic duct of that region or the ymph node, 72 hours postinoculation. Inconclusive : Increase in skin thickness more than 2mm & less than 4mm, absence of above clinical signs, 72 hours post-inoculation. Positive : Increase in skin thickness 4 mm or more, or presence of dinical signs viz. exudation, necrosis, pain, inflammation of the lymphatic duct of that region or the lymph node, 72 hours post-inoculation. Positive result criteria Eligible animals Frequency of testing Action on finding a positive bull Positive herd Negative herd Annual test is minimum. Six months (± 1 week) after last whole herd negative testing, desirable. Animal Immediate isolation and elimination Semen Destroy semen doses since last negative test Herd found negative on two consecutive tuberculin tests at an interval of 6 months, the first being performed 6 months after the slaughter of last affected animal Tuberculosis free herd (OIE) Quarantine All animals above 6 months of age, have shown a negative result to at least two tuberculin test carried out at an interval of 6 months Minimum 60 days after culling of last positive animal Duration of quarantine Test schedule Minimum Standards Minimum 90 days Two tuberculin tests, minimum interval of 60 days between tests. 18 Annex - II Johne's Disease (JD) Management Screening test Details Name Delayed Hypersensitivity test (Skin test) Reagent Reagents from Testing at Johnin PPD IVRI, Izatnagar Where animals are housed by RDDUCDDL/NDDB Increase in skin thickness of over 4mm (discrete circumscribed swelling), 72 hours post-inoculation Positive result criteria Eligible animals Frequency of testing Action on finding a positive bull Quarantine Positive herd All animals above 6 months Minimum 60 days after culling of last positive animal Negative herd Annual test is minimum. Six months (± 1 week) after last whole herd negative testing, desirable. Animal Semen Immediate isolation and elimination Destroy semen doses since last negative test Duration of quarantine Minimum 90 days Test schedule Two Johnin tests, minimum interval of 60 days between tests. Minimum Standards 19 Annex- III Brucellosis Management Screening Test Name ELISA, RBPT+CFT Details Sample Reagents from Testing at Serum CDDL / RDDL • Ail above one year • In females 14 days after calving or abortion Eligible animals Frequency of testing Action on finding a positive bull Positive herd 30 to 60 days after culling of last positive animal Negative herd Exactly one year (± 1 week) after last whole herd negative testing Negative herd (optional) Where the disease has been maintaining a very low profile (less thanl % positive) quarterly or six monthly sample could be collected to minimize losses Animal Immediate isolation and elimination after castration Destroy semen doses since last negative test Semen Brucellosis free herd (OIE) Quarantine CDDL/ RDDL/NDDB Herd found negative on two consecutive annual tests Duration of quarantine Test schedule Additional testing at sexual maturity Minimum Standards Minimum 30 days Two tests, Serum ELISA, interval of 30 days between tests. Only negative animals to be allowed to mix with the rest of the herd. Serum ELISA before bulls are used for semen collection and distribution forAI 20 Annex- IV Infectious Bovine Rhinotracheitis (IBR) Management Screening test details Eligible animals Frequency of testing Name Sample Testing at ELISA /SNT Serum CDDL / RDDUNDDB All animals Positive Herd Whole herd test, 30 to 60 days after culling of positive animals. Six monthly, after the herd become negative. Exactly one year (± 1 week) after last whole herd testing Where the disease has been maintaining a low profile (less than 5 % positive) quarterly or six monthly sample could be collected to minimize losses Immediate isolation and elimination after castration Negative herd Action on finding a positive bull Animal Semen Destroy semen doses since last negative test IBR free herd (OIE) ^ Quarantine Duration of quarantine Testing Whole herd tested negative on two consecutive occasions at an interval of 2 to 12 months between tests Minimum 30 days Additional testing at sexual maturity Minimum Standards Two tests, Serum ELISA/ SNT, interval of 21 days between tests Serum ELISA/SNT before bulls are used for semen distribution in field Al programmes 21 Annex- V Bovine Genital Campylobacteriosis Management Screening test details Name Bacterial isolation & identification Sample Testing at Eligible animals Preputial washing, semen RDDL/CDDUNDDB All male animals Prevention Annual sheath lavage Frequency of testing Positive herd 30 days after culling of positive animal. Negative herd Exactly one year (± 1 week) after last whole herd negative testing Action on finding a positive bull Animal Treat the animals Semen Destroy semen doses since last negative test Quarantine Duration of quarantine Test schedule Minimum 30 days One test if age is less than 6 months, else 3 consecutive tests at weekly intervals. Minimum Standards 22 Annex - VI Bovine Trichomoniasis Management Screening test details Name Agent isolation & identification Sample Testing at Preputial washing RDDL/CDDUNDDB All male animals Annual sheath lavage Annual Action on finding a positive animal Animal Treat the animals Semen Destroy the semen doses since last negative test Quarantine Duration of quarantine Test schedule Minimum 30 days One test, if age is less than 6 months, else 3 consecutive tests at weekly intervals. Eligible animals Prevention Frequency of testing Additional testing at sexual maturity Protozoa isolation before bulls are used for semen distribution forAI Minimum Standards 23 Annex-_V!l Foot and Mouth Disease Management Action during FMD outbreak Animal solate diseased animals till recovery, do not cull. Semen Semen from FMD infected bulls : Destroy semen collected during one month before onset of outbreak. Do not collect semen from bulls during the outbreak and three months after the last case of FMD recovered in the farm. Infected animals must be given 90 days rest Semen from healthy bulls maintained in FMD infected farm: Destroy semen collected during one month before onset of outbreak. Do not collect semen from bulls during the outbreak and one months after the last case of FMD recovered in the farm. Semen could be used other than the above mentioned periods, if there is no new case of FMD develops during three months period after last FMD case recovered in the farm. Semen for export Vaccination - as per manufacturer's recommendations. Quarantine Vaccination Test each batch by virus isolation and PCR Oil vaccine Minimum Standards As per manufacturer's recommendations in farm and 10 km around the farm Test for seroconversion, by collecting serum on the day of vaccination and 21 days later. 24 Annex-VIII Feeding Growing and Mature Bulls Daily nutrient requirements of growing and mature bulls Body wt (kg) Growing bulls 100 150 200 250 300 350 400 450 500 550 600 gain/day DM/da c.P.(g) TON (kg) Ca(g) (g) y (kg) 750 750 750 750 750 750 700 600 400 250 100 2.8 4.3 5.7 7 8.2 9.3 10.2 10.4 10 10 9.8 390 460 530 610 680 760 820 875 885 845 800 Maintenance of mature breeding bulls 8.3 640 500 600 700 - 9.6 10.9 735 830 VitA P(g) (1000 IU) 1.9 2.7 3.4 4 4.6 5.2 5.7 5.8 5.6 5.6 5.5 11 15 18 21 23 24 25 26 26 25 24 8 11 14 16 17 18 19 20 20 19 18 4 6 8 10 13 15 17 19 21 23 26 4.6 5.4 6.1 20 22 25 15 17 19 21 26 30 Daily ration for Bulls Growing bulls 100 150 200 300 400 a) 500 600 b) a) b) a) b) 2 - b) Body wt. (kg) (kg) - 2.5 3 3 - 2.5 - 2 . C.F................B.P.F. ....... .. (kg) Minimum Standards 2 2 2 2 2.5 2.5 - • - Mature breeding bulls 500 a) 600 Calf starter ?nn - (kg) . .. .. HO _ ._ 0.5 0 0.5 1 3 3 2-4 2-4 2-4 2-4 adljb_. ad }ib. ad lib. ad lib. ad lib. id Kb, ad lib. 2-4 2-4 ad lib. ad Kb, ______ Hay Green Fodder . ............ rin .............................. - ,- - ... (kg) (kg) 25 6-8 8-10 15 Note : 1) Mineral mixture should be supplemented as follows : 50 g mineral mixture for bulls up to 200 kg body weight 70 g mineral mixture for bulls between 200 to 350 kg body weight. 100 g mineral mixture for bulls above 350 kg body weight 2) Fresh water should be made available 24 hrs. Green fodder requirement of 10 mature bulls would be approx. 125 MT per year, which can be grown in 1 hectare of land by intensive farming. * Source: Ranjhan, S.K (1980). Animal nutrition & feeding practices in India, ' ______ 2nd Ed., p196-212 ____________ ___ _________ Nutrients available in feed & fodder Calf starter DM% CP% TDN% C.F. B.P.F. 90 90 90 22-23 18-19 62-64 22-23 65-68 70 Minimum Standards Green fodder 20-25 Hay 5-6 90 5-6 55-60 55 26 Annex - IX List of laboratory equipment for Frozen semen stations (A). Processing Lab Sr. No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 Items Phase contrast microscope with Biotherm (Nikon/ Olympus) DIC Microscope with bio-therm lide warmer ^to / Eppendorf Pipette Waterbath (IMV) aminar Air Flow Unit CCTV MV make Photometer PH Meter Auto filling-sealing machine (Mini) Straw Printing Machine et Printer Cold Handling Cabinet- Split Biological freezer Freezing Racks (Mini) Distribution Ramp (Mini) ncubator Autoclave Hot Air Oven Double glass distillation plant Mlipore water purifying equipment ETO Steriliser Magnetic Stirrer Electronic Weighing balance WM bulk FS storage Container with freezing Grill Bulk FS Storage Container Geyser Vacuum Cleaner Voltage Stabiliser (Central) FS storage Cont (12000 Mini st) LN Storage Cont. (50 Lt. Cap) PC (to connect with Microscope), Printer & UPS Fumigator/Humidifier Thawing Unit (IMV) LN Pump/Transfer device (IMV) SS Forceps -18" Refrigerator Minimum Standards < 5 lakh 5 to 10 lakh 10 to 20 lakh > 25 lakh 1 Nil 1 3 1 1 Nil 1 1 1 1 Nil 1 1 30 1 1 Nil 1 3 2 2 1 2 2 2 2 Nil 1 1 1 2 1 2 1 1 2 1 60 1 2 2 2 2 1 1 1 1 2 1 1 5 2 2 1 2 1 2 Nil 2 2 2 80 1 3 2 2 2 1 1 1 1 2 1 1 6 2 3 1 2 2 2 Nil 2 4 2 100 1 3 2 4 2 1 1 2 1 2 1 2 1 2 2 2 1 2 3 2 1 2 5 2 1 As per req. 5 10 1 As per req. 10 15 1 As per req. 12 20 1 As per req. 15 20 2 1 2 2 6 1 1 2 2 2 2 2 6 2 2 2 2 6 2 27 6 2 (B). Miscellaneous Equipment Items Sr. No. 1 AV Stand 2 Test Tube Stand 3 Auto Pipette Stand 4 Plastic Tips Holder 5 Spirit Lamp 6 Timer/ stop watch 7 Scissors Straight- 6° 8 Hot Air Blower/ Hair Dryer 9 Trolley for Movement of LNC 10 Anaesthetic Trolley 11 PC with Printer + Software (SSMS) 12 Glass wares 13 Air-conditioner with Hepa filter < 5 lakh 5 5 2 2 2 2 2 1 5 1 1 5 to 10 lakh 5 5 3 3 2 2 4 2 5 1 1 10 to 20 lakh 5 5 5 5 2 2 4 2 10 1 2 >25 lakh 5 5 5 5 2 2 4 2 10 2 2 In sufficient quantity 1 ton for 100cft area with remote (C). Semen despatch section 1 2 3 4 Phase Contrast Microscope with biotherm IMV Waterbath Thermocol box Long Forceps 1 1 1 1 1 2 1 2 8 1 2 8 1 3 8 8 (D). Quality Control Laboratory Phase Contrast Microscope IMV Water bath Laminar Airflow Unit Autoclave Hot Air Oven Incubator with digital Temp Haemocytometer Refrigerator Gas connection Water bath Glass ware/Media/ chemicals Table.Chair, Almirah Misc. Items Minimum Standards 28 1 2 3 4 5 6 7 8 9 10 11 12 13 1 1 1 1 1 1 2 1 1 1 Adequate 11 11 Annex - X Qualifications recommended for Semen Station personnel 1. Officer-in-charge MVSc. in Animal Reproduction / Livestock Production & Management, trained in semen production. 2. Senior Veterinary Officer MVSc. in Animal Reproduction / Livestock Production & Management, trained in semen production. 3. Veterinary Officer MVSc. in Animal Reproduction / Livestock Production, trained in semen production/ Livestock management. 4. Quality control Officer MVSc. in Animal Reproduction / Vety. Microbiology, trained in carrying out all tests to determine quality of semen samples as per MSP. 5. Lab Technician Bachelor degree in Science / Microbiology / Bio-chemistry, in semen production and quality control. Persons having post-graduation degree are preferable. 6. Semen Collector Diploma in livestock management or stockman training course with two years experience in livestock farm / semen laboratory. 7. Lab Attendant/ Bull Handler High school / 8th standard, should be able to read and write and with two years working experience in semen station/ bull station/livestock farm. For semen & LN Distribution 1. Stockman (Semen & LN Distributor) Stockman with two years experience, trained in transfer of straws & distribution 2. Stockman (Semen Despatch} Stockman with two years experience, trained in examination of semen under microscope. Minimum Standards 29 Annex - XI Job responsibility of the The QCO shall be responsible for the quality control work pertaining to semen production and any other related work as may be required from time to time. He shall be responsible to carryout the following: a). Bacteriological tests: Neat semen Frozen semen Lab environment AV washing - Randomly two samples daily Randomly eight samples daily, all bulls to be covered once in a quarter Plates shall be placed daily at different location in the processing room, AV room, washing room, pass box, Incubator, Laminar airflow unit ,etc. to check bacterial load Randomly two AVs once a week. b). Morphological abnormalities : For adult bulls as and when there is report about poor semen quality, particularly of crossbred bulls - Young bulls four to six times before putting for regular collection. Thereafter, based on the report of poor quality of semen Depending on the report of poor quality of semen or certain abnormalities, such bulls shall be kept under observation and semen samples examined twice a week for 4 to 6 weeks. Semen from such bulls shall not be frozen until cleared by the QCO. Morphological abnormalities c). Acrosome integrity test: Frozen semen samples of all adult & young bulls in each quarter d). Validation of photometer Sperm concentration of neat semen shall be measured by Haemocytometer separately for cattle & buffalo bulls for validation of IMV photometer (as per MSP) - twice a year e). Sperm concentration of frozen semen sample : - Randomly two samples per week each of cattle and buffalo. Minimum Standards 30 f). pH measurement: - washing of sterilized glassware / rubberware shall be checked for pH once a week g). HOST - everyday four samples after 24 hrs. PTM h). Incubation Test - every day 4 to 6 samples j). Percent intact acrosome - all bulls to be covered once a quarter Semen samples frozen routinely shall not be checked by those who are involved for semen processing. Semen samples shall be checked by the QCO for PTM after 24 hours of freezing. The QCO will be the final authority to accept or reject semen samples. In addition, he will be testing the quality of straws or any other consumable materials used in semen station. NB. Depending on the work load, the QCO should be assisted by a Lab technician and Lab attendant. arb:C/alldoc/Min Stn/Min. Sid. for Govt.doc (April1 2005) Minimum Standards 31 N.D.D.B. SEMEN BANK DRAWING NO. ANAND 388001 TOP PLAN LAB 01.A4 SEMEN BANK-LAB.01A4 2 8 -1 1 - 0 2 N.D.D.B. ANAND 388001 BULL SHED GROUND FLOOR PLAN - SECTION DRAWING NO. AR-02-05.A4 BULL SHED-05.A4 - S3 - 28-11-02 'i^jii*^ ^'.'^'.^^-»>,-,