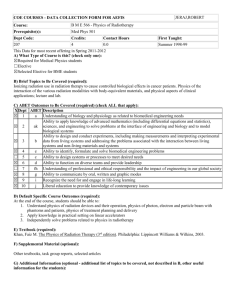

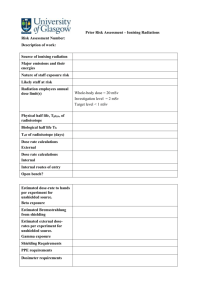

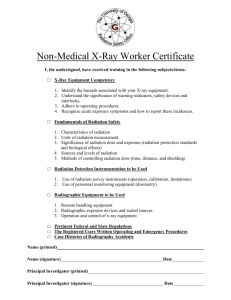

radiation safety officer (rso) responsibilities

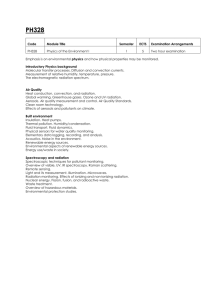

advertisement