Template for Electronic Submission to ACS Journals

advertisement

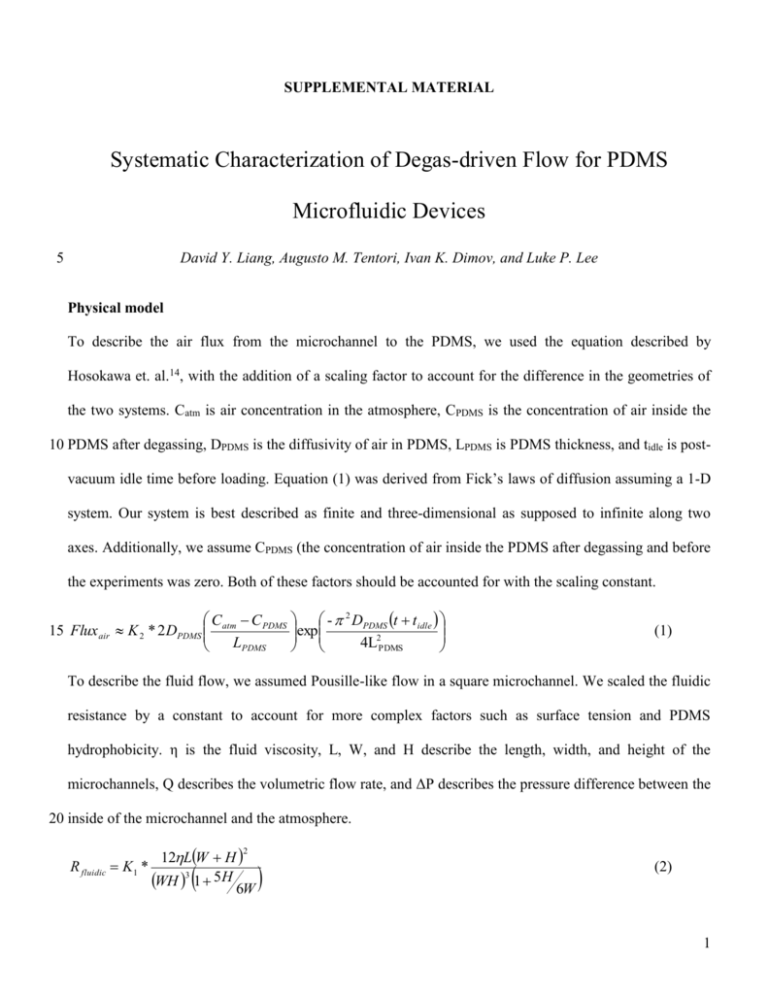

SUPPLEMENTAL MATERIAL Systematic Characterization of Degas-driven Flow for PDMS Microfluidic Devices 5 David Y. Liang, Augusto M. Tentori, Ivan K. Dimov, and Luke P. Lee Physical model To describe the air flux from the microchannel to the PDMS, we used the equation described by Hosokawa et. al.14, with the addition of a scaling factor to account for the difference in the geometries of the two systems. Catm is air concentration in the atmosphere, CPDMS is the concentration of air inside the 10 PDMS after degassing, DPDMS is the diffusivity of air in PDMS, LPDMS is PDMS thickness, and tidle is postvacuum idle time before loading. Equation (1) was derived from Fick’s laws of diffusion assuming a 1-D system. Our system is best described as finite and three-dimensional as supposed to infinite along two axes. Additionally, we assume CPDMS (the concentration of air inside the PDMS after degassing and before the experiments was zero. Both of these factors should be accounted for with the scaling constant. C C PDMS - 2 DPDMS t t idle exp 15 Flux air K 2 * 2 DPDMS atm LPDMS 4L2PDMS (1) To describe the fluid flow, we assumed Pousille-like flow in a square microchannel. We scaled the fluidic resistance by a constant to account for more complex factors such as surface tension and PDMS hydrophobicity. η is the fluid viscosity, L, W, and H describe the length, width, and height of the microchannels, Q describes the volumetric flow rate, and ΔP describes the pressure difference between the 20 inside of the microchannel and the atmosphere. 12LW H WH 3 1 5H 6W 2 R fluidic K1 * (2) 1 Q P R fluidic (3) To relate the phenomena, we used the following relations: P Patm nchannel RT V free (4) Assuming ideal gas behavior, we can relate the pressure difference to the amount of air inside the 5 microchannel (nchannel) and the fluid-free, gas-filled volume inside the microchannel (Vfree). Patm is the atmospheric pressure, R is gas constant, and T is temperature. Nchannel is related to the flux of air using the following relations: t nchannel ninitial Fluxair A free dt (5) 0 Ninitial is the amount of air inside the microchannel when the sample is loaded. Afree is the surface area of 10 the microchannel that has not been covered with fluid and is exposed to air. The surface area exposed to air and air volume in the microchannel are related to the volumetric flow rate through the following geometrical relations: t V free WHL Qdt (6) 0 A free 2 L(W H ) WH 2W H t Qdt WH 0 (7) 15 Combining equations (2), (3), and (4) and combining (1) and (5), we get the following relations: WH 3 1 5H 6W Patm nchannel RT Q K1 2 V free 12LW H nchannel t C C PDMS P WHL atm K 2 2 DPDMS atm 0 RT LPDMS (8) - 2 DPDMS t t idle A free dt exp 2 4L PDMS (9) To solve the system of equations (6) (7) (8) (9), we took time derivatives and used the ordinary differential equations system solver, ode15s, in MATLAB 9. 20 The four equations and initial conditions were the following: 2 dA free dt A free0 dV free dt 2W H Q WH 2 L(W H ) Aend Q V free0 WHL C C PDMS dnchannel K 2 2 DPDMS atm dt LPDMS PatmWHL RT WH 3 1 5 H dQ 6W K 1 dt 12LW H 2 WH 3 1 5 H dQ 6W K 1 dt 12LW H 2 Q0 0 - 2 DPDMS t t idle A free exp 4L2PDMS nchannel0 RT RT 1 dnchannel n dV free 2 V dt V free dt free 1 n K 2 2 DPDMS C atm C PDMS 2 Q LPDMS V free V free - 2 DPDMS t t idle A free exp 2 4L PDMS (10) To solve this system, we used the ode15s solver with 0.001 sec and 0.001 meters for the time and spatial steps respectively. The parameters used were chosen to match experimental conditions or obtained from literature18: 8.9 10 4 Pa s 2 D PDMS 3.4 10 9 m 5 s Patm 10 Pa 5 R 8.31472 J molK T 298 K C atm Patm RT H 50 10 m 6 3 FIG S1. Schematic showing experimental procedure for characterization of degas-driven flow. After pressing the PDMS device and the glass slide together to form reversible seals, the PDMS device is placed into a vacuum chamber and degassed for a determined time. To characterize degas time, 10 min, 45 min, 2 5 hr, and 24 hr were used. After degassing, the PDMS device is removed and placed under a microscope objective. The sample is added to the inlets, and the idle time is recorded. To characterize idle time, 2 min, 4 min, 7 min, and 10 min were used. The data from the last 10.7 mm of the straight microfluidic channels is recorded, and the number of pixels for each frame is converted to a fluid volume. 10 4 FIG S2. Mask layout of the microfluidic devices used to fabricate the PDMS devices, organized by design parameter. From left to right: S-curve channels (used for the mathematical model) of varying lengths: 10, 20, 35, 50, and 65 mm, channels of varying surface areas: 8.40, 8.85, 10.02, 12.01, and 16.00 mm2, and 5 channels of varying widths: 50, 100, 200, 350, and 500 µm. All S-curve and surface area channels are 50 µm wide, and the single straight channels in both the surface and width devices are 35 mm long. All channels are drawn to scale. 5 6 FIG S3. Comparison of physical model predictions and experimental data. Data was collected for two idle times, (A) 2 min and (B) 10 min, from a microfluidic device of S-curves with a channel height of 50 µm, width of 100 µm, and varying channel lengths ranging from 25 to 65 mm, as indicated by the legend. (C) 5 shows data collected from a microfluidic device with channel height of 50 µm, PDMS thickness of 2.2 mm, degas time of 24 hr, idle time of 2 min, and varying cross-sectional areas ranging from 0.0025 mm2 to 0.025 mm2, as indicated by the legend. Error bars represent ±1.96σ of the reproducibility measurements. 7 FIG S4. Time-lapse images of channels of varying surface areas being filled by vacuum-driven flow. A parabolic loading behavior was observed in the fork-like dead-end structures, with the channels on the edges traveling faster than those in the center. We hypothesize that this is due to a larger amount of bulk 5 PDMS surrounding the outside channels, which causes increased gas diffusion and thus faster flow velocities. 8 FIG S5. Fluid volume profile during channel filling for the 0.9 mm thick device. Data was obtained from the device used in Fig. 2A, with a degas time of 2 hr and idle time of 2 min. The 16.00 mm 2 channel exhibited slow degas-driven flow, but the 8.85 to 12.01 mm2 exhibited no degas-driven flow. Error bars 5 represent ±1.96σ of the reproducibility measurements. 9 FIG S6. Fluid volume profile during channel filling for the 2.2 mm thick device. Data was obtained from the device used in Fig. 3A, with a degas time of 24 hr and idle time of 10 min. Although the channels with widths 100 and 50 µm filled completely in less than 30 min, the channels with widths 500, 350, and 200 5 µm did not fill completely before the flow velocity reached zero. Error bars represent ±1.96σ of the reproducibility measurements. 10