Name - Futuronix

advertisement

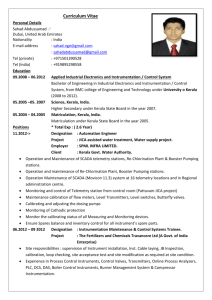

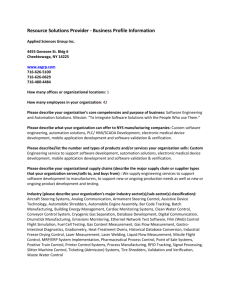

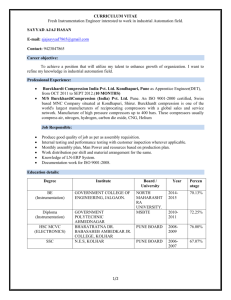

Sub: CAREER ORIENTED INDUSTRIAL AUTOMATION TRAINING. COURSE with 100% PLACEMENT The world of automation is constantly developing from Last few decades it have been observed that the gap between the skills required for industries and skills possessed by engineers / engineering professionals has created a peculiar situation where in even though in abundance, industry is short of trained professionals. There are complex Industrial Automation control systems installed / being installed across industries. There is a need to understand and acquire knowledge of these systems to keep the productivity and profitability high, reduce downtime of machines and troubleshoot the systems faster. Thus I take this privilege to introduce the Futuronix Automation Private Limited The “Only registered Member of ISTE” as an institution providing Industrial Automation Training. We deliver solid, proven automation technologies - the latest technologies that adapt quickly to your changing business. We adopted the corporate motto “WE WORK FOR A BETTER LIFE, A BETTER WORLD FOR ALL”. We customize each solution to meet your specific needs ensuring a sound technology migration path. we are always in a position to best serve our clients in fulfilling their needs .In this respect, our training title “INVESTING IN FUTURE” is a key message. Our experienced instructors our a combination of proven teaching techniques and hand-on real world application exercise to deliver focused information during the course. We have state of art lab with practical facilities where self- support based training is providing on the following systems: Course Brand Programmable Logic Controllers (PLC) Allen Bradley/Siemens/Schneider/Mitsubishi/ Fuji/Omron/LG. Allen Bradley / Schneider / Siemens/Control Technique/Yasakawa/Fuji Wonderware, Rsview, Astra,WINCC Schneider XBT, XBTR, XBTG Displays Process variable measurement and concept how to control in Industry using the PLC system, concept and benefits of PLC Networking in Industry Drives SCADA software HMI Field Instrumentation, Trouble shooting & calibration of Equipments, Process instrumentation, Panel Designing, PLC Networking Placement We have dedicated placement wing to route our trained engineers to untapped and infinite opportunities across various industries / Automation companies in project, maintenance, design, application engineering departments etc. We have 100% placement for IAE (module 1) participants. Proposal Fresh engineers can go for 3 months Module 1: IAE (Industrial Automation Engineer), which has 100% placement. Working Professionals can choose Module 2 to Module 10. Engineering Students desirous of undergoing summer training can choose Module 11. We will be happy to provide any other information, which might be required and assure you of our total cooperation. We assure you that the engineers who undergo training in our labs, we will meet the need of skilled technical manpower for automation and allied application .Kindly contact us for any other detail, which might be required Thanking you. Hoping for a prompt and favorable response. Sangita Chauhan Futuronix Automation Pvt. Ltd. 2nd floor ,14 Tilak Nagar Industrial Area Near Subhas Nagar Metro Station New Delhi-110018 Ph.no.-011-32595564,9818681326 E-mail- sangita@futuronix.in training@futuronix.in www.futuronix.in SELECT WHAT YOU WANT Only registered Member of ISTE” Automation Training Company Module M-7 SC M-7 RS M-7 VJ M-5 AB M-5 SCM M-5 SCT M-5 SCZ Course Contents SCADA Wonderware InTouch SCADA RS VIEW SCADA Vijolook SCHNEIDER Make Allen Bradley (Micrologix 1000/1200) SCHNEIDER(Modicon) MICRO SCHNEIDER (Modicon)TWIDO SCHNEIDER (Modicon)Zelio Duration hours 32 Hrs 32 Hrs 32 Hrs 32 Hrs 32 Hrs 32 Hrs 32 Hrs SIEMENS S7-200 32 Hrs M-5 SE M-5 FU FUJI SPB 32 Hrs M-5 MI MITSUBISHI 32 Hrs M-5 LG LG 32 Hrs M-8 DC AC DRIVE SCHNEIDER MAKE 32 Hrs M-8 DF AC DRIVE FUJI MAKE 32 Hrs M-8 DS AC DRIVE SIEMENS MAKE 32 Hrs M-8 DL AC DRIVE LG MAKE 32 Hrs M-8 DC AC DRIVE CONTROL TECHNIQUE MAKE Panel Desining 32 Hrs Basic industrial Instrumentation Training Troublshooting,Calibration of Process Equipments 16 Hrs M-9 M-2 M-3 16 Hrs 16 Hrs M-4 CPP CAP PSD ST IAE With 100% placeme nt PROCESS Instrumentation` 16 Hrs Certified PLC programmer AB, Siemens,Schneider,FUJI Wonderware, Rs view Any 4 PLC and 2 SCADA PLC/SCADA/DRIVE SUMMER TRAINING Industrial Automation Engineer 64 Hrs 1. Basic industrial instrumentation training 2. Troubleshooting, calibration of process equipments. 3. Process instrumentation 4. 7 Leading Brands of PLC (Programmable logic controllers ) 5. HMI (Human Machine Interface) 6. 4 Leading Brands of SCADA 7. PLC networking 8. 5 Leading Brands of Variable frequency drive 9. Panel designing 10. Auto CAD 11. On site exposure 12. DCS (Distributed Control System) 13. Project Courses Module’s Module-1 (IAE) Basic industrial instrumentation training Troubleshooting, calibration of process equipments. Process instrumentation Programmable logic controllers (PLC) HMI (Human Machine Interface) SCADA PLC networking Variable frequency drive 64 Hrs 80 Hrs 1 MONTH 3 MONTH Panel designing On site exposure Module-2: Basic industrial automation training Basic block of instrumentation system types of transducers (active and passive) Temperature measurement, working principle, types, and selection guidelines. Pressure measurement, working principle, types, and selection guidelines. Flow measurement, working principle, types, and selection guidelines. Level measurement, working principle, types, and selection guidelines. Displacement measurement, working principle, types, and selection guidelines. Angular displacement and speed measurement, working principle, types, and selection guidelines. Current to pressure converter and Control valves Module-3: Troubleshooting, calibration of process equipments. Testing of RTD and thermocouple. Testing of pressure measurement device. Testing of scales for displacement measurement. Testing of encoders. Calibration of process indicators. Module-4: Process instrumentation Process control basic Closed loop and open loop system Control algorithms (P, PI, PD, PID) Process control schemes. Module-5: Programmable logic controllers Introduction to PLC, PLC family, application of PLC in industry, benefits of PLC in industry. Introduction to PLC hardware Source and sink wiring concept Transistor and relay output concept Introduction to PLC programming software Addressing concept Introduction to ladder logic Basic programming instructions Advance programming instructions. Implementation of instruction and advanced Instruction’s for logic development as per industrial application. PID control using PLC Upload, download, monitoring of PLC Forcing of I/O’s Introduction of analog input and output Fault finding/troubleshooting Communication with HMI & SCADA Hands on experience on real time application Drive control using PLC. Module-6: HMI (Human Machine Interface) Introduction about HMI, Use and benefits of HMI Introduction about HMI programming software Creating applications Creating alarms and events Downloading/uploading program Communication with PLC Fault finding Module-7: SCADA Introduction about SCADA Introduction about SCADA software Creating graphic’s Attaching control to graphic objects Alarm and event management Real time and historical trends Communication with PLC Control loop interface with SCADA Recipe Management Fault finding/troubleshooting Module-8: Ac motor basics Introduction to AC drive and applications Breaking in drives Benefits of ac drive over conventional starters (DOL & Star/delta) Criteria for drive selections Parameter programming Energy saving concept Live Demonstration of effect of each programmed parameter on Drive. Designing of drive control panel Communication of drive with PLC,HMI & SCADA Fault finding/troubleshooting Soft starter and their advantage over conventional starters. Programming of drives using PC (Power Suit) Module-9: Variable frequency drives Panel designing Introduction about electrical symbols of accessories used in panel building Industrial standard color codes Introduction to switchgears and accessories Basics of control and power wiring Sizing of panel Preparation of general arrangement drawings Preparation of control and power circuits General wiring guidelines/practice Maintenance and troubleshooting of control circuit in live panels. Module-10: PLC Networking Module-11: Project, Summer Training Module-12 Distributed Control System Introduction to Control system Application of DCS systems Hardware architecture of DCS Comparison between PLC & DCS Latest trends in DCS Architectural evolution for DCS Processor, power supply, I/O modules Communication bus , redundancy Operator and Engineering station. Designing control systems solution using DCS Practical exposure on leading DCS system Technical evolution / Comparison between leading DCS system Consultancy for engineering students for there industrial projects. List of some selected projects successfully completed S. No. 1. 2. 3. Company/Industry Project successfully completed Cheema Paper Mills Kashipur, Uttaranchal Jazeera Tube Sohar Industrial Estate Sultanate of Omen Polymers Process Ltd. Badli Industrial Area, Delhi Basic Automation (three element Drum Level Control) Automation of Galvanization Plant PLC based Automation of Polymer Extrusion Line 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. Kushal Foods Ltd. Rania Road Kanpur, Uttar Pradesh Mawana Sugar Mawana, Uttar Pradesh Harinagar Sugar Mills Ltd. Champaran , Bihar Talbros India Ltd. Udyog Village Gurgaon NHK Spring IMT Manesar, Gurgaon Sathe Synthetic Kaviangar Industrial Area Ghaziabad, Uttar Pradesh Meghna Cement Bangladesh Filatex India Ltd. Dadre (Vapi), Gujrat Roop Polymer Ltd. Sohna Industrial Area Sohna, Gurgaon Mark Auto Ltd. Udyog Vihar Gurgaon (Ancilary Maruti Udyog) Garden Silk Karodara Road, Surat Gujrat Sequencing and Operation Control of Flour Mill i) Filtrate Clarification System (FCS) ii) Syrup Clarification System (SCS) Turbine Synchronisation Testing Equipments PLC based Water Pressure Management System PLC based Colour Dosing System Sequencing and Operation Control of Cement Plant Sequencing and Operation Control of Torey Winder Plant PLC based Hot Molding Power Precise PLC based leakage Tester for Fuel Tanks Temperature Control Generator List of some of our Original Equipments Manufacturers clients S. No. Company/Industry 1. 2. 3. 4. 5. Narendra Press Tech Anand Parbat, New Delhi Standard Hydraullics Manesar, Gurgaon EMCO Press Masters Ballabhgarh DIFTECH Technologies Pvt. Ltd. Green Park, N.Delhi Auto Test Mechanism Pvt. Ltd. Nangloi, N. Delhi and Noida, Uttar Pradesh Manufacturer Automated Power Press PLC based Hydraulics Power Press Automated Power Press FCS and SCS for Sugar Industries Special Purpose Machine for Automobile Industry 6. 7. 8. 9. 10. 11. 12. ASOMECH Machinary Ghaziabad, Uttar Pradesh Creative Concept India Pvt. Ltd. Noida, Sector-63 Technofeb Industries Faridabad, Uttar Pradesh Gapson Engineering and Cosultatnts, Lajpat Nagar, N. Delhi Mill India Ltd. Noida Hindfeb Faridabad Mellcon Engineers and Consultants Okhla Placement Clients ABB Samtel Rockwell Schneider Fuji Siemens Bajaj Hidustan Dabur Balco Indorama LML Ltd Flex And many more Wire Drawing Machine Specialized Ozone Plant Packing Machinery for Food Industry Galvanization plants for steel industry Complete Soap Plant Wire Drawing Machine Chiller Plants