Hazard Communication Standard

advertisement

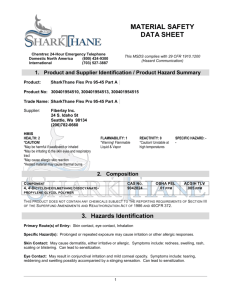

HAZARD COMMUNICATION Hazard Communication Standard The right-to know movement was precipitated by OSHA in the 1983 with the promulgation of the Hazard Communication Standard (HCS) 29.CFR1910.1200. The basic principle of HCS is that informed workers are less likely to be injured by chemical and chemical processes than the uninformed workers. The purpose of the HCS is to ensure that the information of hazard associated with handling, transport and storage of chemicals, are evaluated and transmitted to relevant individuals or parties; chemical manufacturers, transporters and users1. Through the Hazard Communication Standard, OSHA requires chemical manufacturer or importer to2: 1. Analyze and assess all hazards of the chemicals produced or imported. 2. Document associated hazards and develop written warning labels/information and material safety data sheet (MSDS). 3. Address the hazard information to the individuals working with the chemicals. 4. Label, tag and attach warning documentation of chemicals leaving the workplace. A required component in the program is a list of hazardous chemicals known to be present in the workplace. MSDS of the chemicals should also be available to employee. If the substance was purchased before the right to know era and no MSDS is on hand, the employer is required to obtain or generate one. Some good sources for MSDS information are current manufacturer /distributor of the chemicals or state consultant agency. 1 Thomas, C.E, Process Technology Safety, Health, and Environment Second Edition, Thomson Delmar Learning, 2005. 2 Asfahl, C.R, Industrial Safety and Health Management Fifth Edition, Prentice Hall 2003. Ways of addressing the hazards and means of protection from the hazards are to be accomplished by comprehensive hazard communication programs such as written forms of warnings and training. Written hazard communication program for the workplace is developed through lists of hazardous chemicals present, labeling of containers of chemicals in the workplace, as well as of containers of chemicals being shipped to other workplaces, preparation and distribution of material safety data sheets to employees and downstream employers. OSHA also place responsibility of hazard communication to employers and requires employers to address the following: 1. Preparing a written Hazard Communication program. 2. Organizing hazardous chemical inventory list. 3. Designing MSDSs. The written hazard communication program should be designed so every new employees are informed upon initial assignment and existing employees maintain high alert of the hazards. The content of the written program should also be site-specific, readily accessible by plant personnel, and being updated accordingly. Training on hazard communication program should be provided as well to inform the physical and chemical hazards due to the chemicals substances to the workers, to guide workers on how to detect release of hazardous chemicals, how to read an MSDS, how to select and use PPE and how to understand the standard labeling systems, Department of Transportation (DOT), National Fire Protection Association (NFPA) and Hazardous Materials Identification System (HMIS). In addition, the regulation also requires distributors to transfer the required information to employers. Employers who do not produce or import chemicals need only focus on those parts of this rule that deal with establishing a workplace program and communicating information to their workers. Appendix E of the regulation is a general guide for such employers to help them determine their compliance obligations under the rule. In the workplace the employer shall maintain copies of the required material safety data sheets for each hazardous chemical, and shall ensure that they are readily accessible during each work shift to employees when they are in their work area. Electronic access, microfiche, and other alternatives to maintaining paper copies of the material safety data sheets are permitted as long as no barriers to immediate employee access in each workplace are created by such options.3 The Hazard Communication program built by the safety division should set up information system that trace the identity, location of use, and time of use for hazardous substances along with each employee exposure for a retention period of at least 30 years. Employee medical record must be preserved and maintained for the duration of employment plus 30 years. The reason of very long retention period is to permit tracing the cause of illnesses that may have extreme long latency periods after exposure to hazardous substances. The Hazard Communication program also concerns on the record retention of hazardous chemicals. Sale of the business does not relieve the employer to the record-retention responsibility because upon sale the successor of the company is required to receive and maintain the record. If the business is closed permanently, the employer may be required to transfer the record to NIOSH, depending on the specific standards pertaining to the hazardous substance. Sources of reference in implementation of hazard communication standard can be accessed in many ways. Protocol guides such as AIHA protocol guide on hazard communication established in 1995 is readily available and can be used as reference. Chemical and Physical Properties of Product Comprehensive information on all the chemicals involved in the process starting from raw materials, intermediates and final products, is necessary in order to prepare precaution of the hazards these chemicals imposed due to its properties. A list of some important physical and chemical properties of any chemical is given in Table X. These properties are very helpful in identifying certain protection measure against hazards that may be present during the handling of hazardous chemicals. 3 Idem as 2 Reactivity, instability and explosive properties and information on the physical and chemical properties of chemicals and on the associated hazards and the appropriate precautions cast in standard format is available in the form of MSDSs. Table X. Important physical and chemical properties of a chemical4 • Molecular structure • Freezing point, vapor pressure, boiling point • Critical pressure, temperature, volume • Vapor density, specific heat, viscosity, thermal conductivity • Liquid density, specific heat, viscosity, thermal conductivity • Latent heats of vaporization and fusion • Dielectric constant, electrical conductivity • Flammability limits • Flash point • Autoignition temperature • Minimum ignition energy • Maximum experimental safe gap • Self-heating • Corrosiveness to materials of construction • Incompatibility with particular materials Polymerization, • Polymerization characteristics Decomposition • Decomposition, hydrolysis characteristics Impurities • Impurities in: General properties Flammability Corrosion raw material plant material Reaction, 4 • Mutual solubility with water • Heats of formation, combustion, decomposition Lee’s Loss Prevention in The Process Industries Vol.1, Vol.2 and Vol.3 Hazard Identification, Assessment and Control. 3rd Edition. Elsevier. 2004. Explosion Toxicity Radioactivity • Energy hazard potential • Thermal stability • Impact sensitivity • Threshold limit values, emergency exposure limits • Lethal concentration LC50, lethal dose LD50 • Exposure effects (inhalation, ingestion, skin and eye contact) • Long-term low exposure effects • Warning levels (smell) • Radiation survey • α-particle, β- , γ- ray exposures Hazards and Exposure Limits The degree of hazard of a chemical is determined by its physical and chemical properties and the magnitude or dose of those properties. In some cases, even the least hazardous materials such as water may be toxic to human if consumed overdose. Exposure limits of chemicals substances are designed to allow process technician to work safely with a certain chemical over a period of time. The poison is in the dosage not the chemical The limits are represented by numerical values and available from four different exposure limits: a. Threshold Limit Values (TLV) TLV for a large number of chemical agents were established by the American Conference on Governmental Industrial Hygienists (ACGIH). Threshold dose is the lowest value on the response versus dose curve, where below this dose the body is able to detoxify and eliminate the agent without any detectable effects. The TLVs refer to airborne concentration corresponds to the condition under which no adverse effects are normally expected during a workers’ lifetime. There are three types of TLVs; time-weighted average (TLV-TWA), short-term exposure limit (TLV-STEL) and ceiling or maximum limit exposure (TLV-C). Assumptions used in the TLV method is that the exposure occurs only during normal working hours, eight hours per day and five days per week. TLV is also known as the Maximum Allowable Concentration (MAC). TLVs calculation uses part per million (ppm) by volume, milligrams of vapor per cubic meter of air (mg/m3) and specifically for dust, millions of particles per cubic foot of air (mppcf). b. Permissible Exposure Limits (PEL) – OSHA mandated regulatory limits Permissible exposure level (PEL) is OSHA defined threshold dose which also follows the TLV-TWA of ACGIH. However, the differences between PEL and TLV lie in the number of chemical covered and the frequency of update, whereas PEL has less number in both category, and that TLVs value are more conservative than PEL. c. Occupational Exposure Limits (OELs) OELs are developed by OSHA and industrial hygiene for chemical substance that does not have TLVs information. d. Suppliers recommended limits Another exposure limit that is important to know is the Immediately Dangerous to Life and Health (IDLH). IDLH is another quantity threshold frequently reported, where exposure to this quantity and above would cause severe damage to health and even death. Material Safety Data Sheet (MSDS) With regard to the right-to-know requirements, for any hazardous chemical that attracts the requirement for a Material Safety Data Sheet (MSDS) under the OSHA 1970, the facility has to submit either the data sheets or a list of the chemicals to the local emergency planning committee, the state Emergency Response Center and the responsible fire department. The facility must also submit to the same three bodies information on the hazardous inventory.5 The OSHA act also discuss about requirement to submit information on the ‘toxic chemical release emission inventory’, or Toxic Release Inventory (TRI), on the Toxic Chemical Release Form. 5 Idem as 4 The data required in this form are concerned primarily with passage of toxic chemicals into the environment. For each chemical, a mass balance and the quantity emitted annually is required. Safety data sheet compilations are prepared by various organizations and are available on the internet. An EC Directive (91/155/EEC) lays down the contents of a safety data sheet. In the United Kingdom, this is implemented by the Chemical Hazard Information and Packaging (CHIP) Regulations. HSE guidance: Safety Data Sheets for Substances and p reparations Dangerous for Supply (1993) has been amended on a regular basis since its inception and further guidance is available in The EC Safety Data Sheet Directive by CONCAWE (1992 92/55). Other sources include those by the NFPA (NFPA 704) and the NIOSH6. The directive requires that the contents of a safety data sheet cover: 1. Identification of the substance/preparation and company 2. Composition/information on ingredients 3. Hazards identification 4. First-aid measures 5. Firefighting measures 6. Accidental release measures 7. Handling and storage 8. Exposure controls/personal protection 9. Physical and chemical properties 10. Stability and reactivity 11. Toxicological information 12. Ecological information 13. Disposal considerations 14. Transport information 15. Regulatory information 16. Other information. Both the guides mentioned give detailed guidance on the material to be included under each of these heads. It is the responsibility of the supplier of a chemical to supply the safety data sheet. 6 Idem as 4 Sensitive issue on MSDS is trade secret which is addressed in details by OSHA standard. With proper justification, industries have the right to withhold specific chemical identities from MSDS. Nevertheless, if required the specific chemical identities should be disclosed in criteria specified in the standard. In non-emergency situation, the manufacturer or importer may ask for confidentiality agreement.7 In Figure X, MSDS of acetic acid is given as an example. Hazardous Materials Identification System - NFPA Rating System The widely used chemical labeling system was originally intended to provide basic information to fire fighting, emergency, and other personnel, enabling them to more easily decide whether to evacuate the area or to commence emergency control procedures. It was also intended to provide them with information to assist in selecting fire fighting tactics and emergency procedures.8 The National Fire Protection Association (NFPA) hazard rating system uses a diamond-shaped diagram symbols and numbers to indicate the degree of hazard associated with a particular chemical. The diamond symbol is placed on containers or MSDSs to identify the degree of hazards of the chemical. The diagram has three color-coded hazard categories, which are fire hazard, reactivity and health. Each category has rating numbers of hazardous level, which increases as the hazard level of the chemical increases. The last part of the diamond section is for other specific hazard associated with that particular chemical. 7 8 Idem as 2 http://safety.science.tamu.edu/nfpa.html Figure X. NFPA diamond symbol* The four categories of NFPA rating are explained in the following9: HEALTH The degree of health hazard of a chemical or material is based on the form or condition of the material, as well as its inherent properties. The degree of health hazard of a material should indicate the degree of personal protective equipment required for working safety with the material. 1 indicates slightly toxic material which requires only minimal protection (e.g. safety glasses and gloves). 2 indicates moderately toxic material which requires more rigorous PPE or protection system (e.g. chemical goggles, lab/work smock, local ventilation) in addition to that required for less toxic material. 3 or 4 indicate highly to extremely toxic or deadly materials such as carcinogen, mutagen, or teratogen materials. These materials will require specific PPE and equipment protection system (e.g. respirator or exhaust hood, full face shield, rubber apron, 9 http://www.sefsc.noaa.gov/HTMLdocs/nfpahazard.htm specialized glove, handling tongs, etc) beyond that required for moderately toxic material. The selection of specific PPE is determined using MSDS and/or other safety information. FLAMMABILITY/FIRE HAZARD The flammability or fire hazard is strongly related with the degree of ease of the material to ignite and burn. The physical state of the materials, as well as the properties, affects the extent of the hazard. Many hazardous materials such as acetone and gasoline have a flash point far below freezing and will readily ignite with a spark if the vapor concentration is sufficient. 1 indicates materials with a flash point > 200°F. 2 indicates materials with a flash point between 100°F- 200°F. 3 indicates materials with a flash point between 73°F-100°F. 4 indicates materials with a flash point < 73°F. REACTIVITY The reactivity hazards indicate the potential of energy release of a material or chemical. Some materials are capable of rapid energy release without any catalyst, while others can undergo violent eruptive or explosive reactions if they come in contact with water or other materials. The rating is used to indicate the potential to react if the material is heated, jarred, or shocked. 1 indicates a material that may be reactive if heated and one that reacts with water. 2 indicates a material that may react violently without detonation. 3 indicates a material that may detonate or explode if subjected to a strong initiating force or heating under confinement. 4 indicates a material that readily detonates or explodes. SPECIFIC HAZARD - This information may include the chemical or material's radioactivity, proper fire extinguishing agent, skin hazard, and its use in pressurized containers, protective equipment required, or unusual reactivity with water. Other hazardous properties which is OX or OXY indicates a material that is an oxidizer. W or W indicates a material that is water reactive. ALK indicates a material that is alkali. COR indicates a material that is corrosive. RAD indicates a material that is radioactive.