Advanced Calculations of Magnetic Leakage Fields in Transformers

advertisement

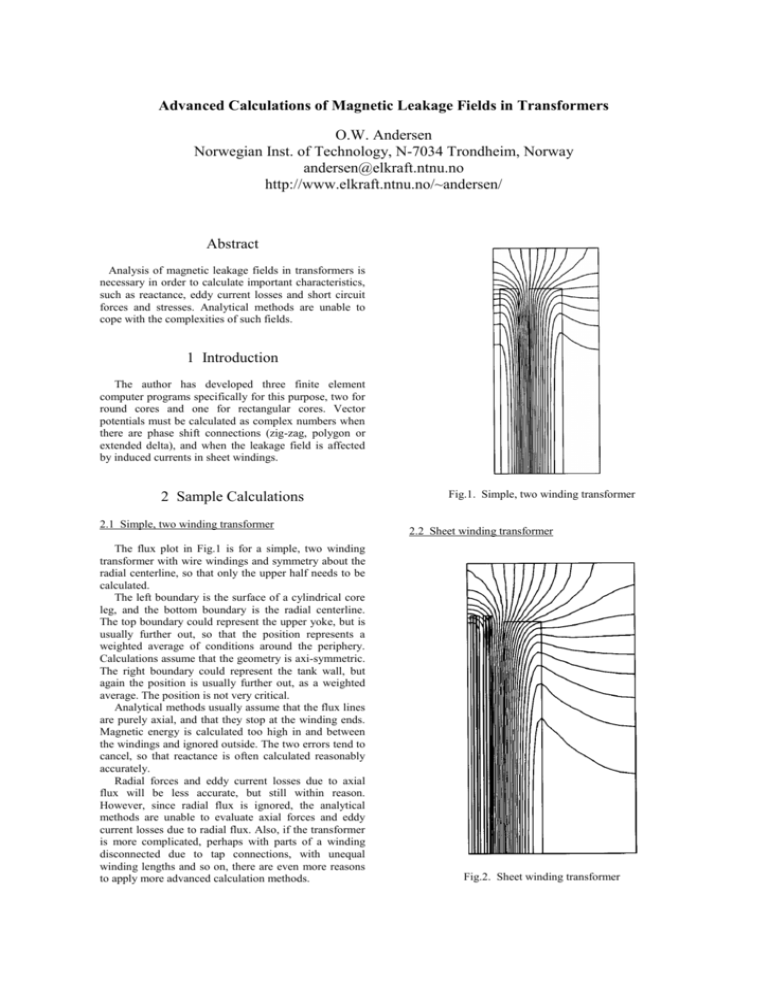

Advanced Calculations of Magnetic Leakage Fields in Transformers O.W. Andersen Norwegian Inst. of Technology, N-7034 Trondheim, Norway andersen@elkraft.ntnu.no http://www.elkraft.ntnu.no/~andersen/ Abstract Analysis of magnetic leakage fields in transformers is necessary in order to calculate important characteristics, such as reactance, eddy current losses and short circuit forces and stresses. Analytical methods are unable to cope with the complexities of such fields. 1 Introduction The author has developed three finite element computer programs specifically for this purpose, two for round cores and one for rectangular cores. Vector potentials must be calculated as complex numbers when there are phase shift connections (zig-zag, polygon or extended delta), and when the leakage field is affected by induced currents in sheet windings. 2 Sample Calculations 2.1 Simple, two winding transformer The flux plot in Fig.1 is for a simple, two winding transformer with wire windings and symmetry about the radial centerline, so that only the upper half needs to be calculated. The left boundary is the surface of a cylindrical core leg, and the bottom boundary is the radial centerline. The top boundary could represent the upper yoke, but is usually further out, so that the position represents a weighted average of conditions around the periphery. Calculations assume that the geometry is axi-symmetric. The right boundary could represent the tank wall, but again the position is usually further out, as a weighted average. The position is not very critical. Analytical methods usually assume that the flux lines are purely axial, and that they stop at the winding ends. Magnetic energy is calculated too high in and between the windings and ignored outside. The two errors tend to cancel, so that reactance is often calculated reasonably accurately. Radial forces and eddy current losses due to axial flux will be less accurate, but still within reason. However, since radial flux is ignored, the analytical methods are unable to evaluate axial forces and eddy current losses due to radial flux. Also, if the transformer is more complicated, perhaps with parts of a winding disconnected due to tap connections, with unequal winding lengths and so on, there are even more reasons to apply more advanced calculation methods. Fig.1. Simple, two winding transformer 2.2 Sheet winding transformer Fig.2. Sheet winding transformer When radial flux tries to penetrate a sheet winding, induced eddy currents will be set up to prevent it, according to Lenz's law. As a result, flux lines will be straightened out through the winding and will be almost purely axial, except at the very ends. This is shown in Fig.2 in a sheet winding with six turns. Induced currents are phase shifted with respect to the main current in the winding, so that vector potentials must be calculated as complex numbers. Current densities will usually be very high at the winding ends, often several times the average. However, this is concentrated in a small volume, and losses and temperature rise are usually tolerable. Current density distribution can be improved by making the low voltage sheet winding slightly longer than the high voltage wire winding in a transformer such as the one in Fig.2. Current density distribution is calculated in each turn. The distribution is shown in Fig.3 for the inner turn of the sheet winding in Fig.2 from the radial centerline to the end of the winding. Each vertical bar represents the current density calculated in a finite element mesh. The horizontal dashed line represents the current density for a uniform distribution. this, and now often require documentation from manufacturers that their transformers are designed to withstand short circuits, based on computer programs that they both are familiar with and have confidence in. Radial forces are dominant and due to axial flux. They usually produce tensile stress in the outer winding and compressive stress in the inner winding. Compressive stress can cause buckling, and the winding must be properly supported by axial spacer bars. Axial forces due to radial flux are usually compressive. Accumulated forces acting on the spacer blocks between disks are usually maximum near the radial centerline, whereas forces per unit volume are usually highest at the winding ends. In disk and helical windings they tend to bend disks between spacers. 5 Eddy Current Losses In wire windings, eddy currents are usually confined within such small conductors that their influence on the magnetic leakage field is negligible. Losses are proportional to (fdB)2 times volume, where f is frequency and d is the conductor dimension perpendicular to either axial or radial flux density B. If parallel strands are not properly transposed, circulating current losses will also be present. Eddy current losses in wire windings are inversely proportional to resistivity and will decrease as the winding temperature increases. In sheet windings, induced currents counteract radial flux, as mentioned earlier. Current density distribution is strongly influenced by the length and thickness of the winding and varies from turn to turn. Eddy current losses are nearly constant as a function of resistivity, and therefore also of temperature. The losses often become excessively high when the winding is thicker than 50-60 mm, which makes it impractical to use sheet windings in large transformers. The calculation of the losses is impossible by analytical methods. Fig.3. Current density distribution, inner turn 6 Crossover Points 3 Reactance Short circuit reactance is calculated from magnetic energy, which can be found by integrating either ½HB or ½JA times volume. In the calculation based on current density J times vector potential A, the integration must only be performed in winding regions. The integration of field strength H times flux density B times volume must be performed in the whole region of the field, but the added time this takes is insignificant. Both methods give the same magnetic energy. For the transformer in Fig.1, in seven digit numbers the first six digits were identical. 4 Forces and Stresses Forces at short circuit are calculated as flux density times current times length. The windings must be designed to withstand such forces, but this is usually not validated by tests, and accurate calculations are essential. Utilities are becoming increasingly concerned with Disk and helical windings often have a large number n parallel conductors. For them to share the current equally, they must change positions at n-1 transposition or crossover points. These points have often been equally spaced in the past, but their spacing should really be inversely proportional to average axial flux density times turns/mm axially. Placing them in proper positions as given by the computer output involves no extra cost and can save significant losses due to circulating currents. 7 Parallel Circuits Windings often have parallel connected circuits, where current distribution and circulating currents are not known in advance, when magnetic leakage fields are to be calculated. A three winding rectifier transformer is used as an example, as shown in Fig.4. It has a primary high voltage winding consisting of two parallel connected parts H1 and H2. There are two secondary windings above each other, one wye connected and one delta connected. Both are designed for the same rated MVA and kV. LY H1 8 Phase Shift Connections In windings with phase shift connections, currents are displaced 60 degrees between the two winding parts on one core leg if the connection is zig-zag or polygon, 30 degrees if it is extended delta (Ref.3). An accurate calculation of the magnetic leakage field is only possible if the phase shift is properly accounted for, with vector potentials calculated as complex numbers. 9 Rectangular Cores LD H2 Fig.4. Three winding rectifier transformer One problem here is to calculate short circuit reactance and forces for a short circuit in one of the secondary windings, such as LY, not knowing ahead of time what the current distribution is between H1 and H2. The MVA is zero for LD and 100% for LY, but it is uncertain initially what the MVAs should be for H1 and H2, except that the sum should be the same as the MVA for LY. Two methods for finding the current distribution between H1 and H2 will now be explained. Sufficient accuracy can be obtained with calculations in two dimensions. If the core is round, the field is axisymmetric. With rectangular cores, the field is assumed to be flat along the straight parts of the coils, axisymmetric around the corners. Reactance and eddy current losses are calculated from weighted averages. Large shell type transformers can be analyzed with the program made for rectangular cores. 10 Program Input Fig.5 shows a transformer without symmetry about the radial centerline, so that the full height must be calculated. It has three layers (or windings) belonging to two terminals (high and low voltage). The layers are divided up into segments, since they are not uniform axially in this case. 7.1 Minimizing magnetic energy Current distributions and circulating currents always adjust themselves to give minimum magnetic energy. This is often the easiest way of finding the correct currents. 100% MVA can be specified initially for H1, zero for H2. Then gradually MVA is decreased for H1 and increased for H2 until minimum calculated magnetic energy is reached within a certain tolerance. The current distribution will then be correct. 7.2 Equalizing flux linkages Since H1 and H2 are in parallel, for the correct current distribution they should have the same flux linkages. Flux linkages are linear functions of currents. Again, 100% MVA can be specified initially for H1, zero for H2. The difference in flux linkages is recorded. Then current distribution can be changed by say 1%, to 99% in H1, 1% in H2. That will probably make the difference in flux linkages closer to, but not quite zero. Linear extrapolation down to zero establishes the correct current distribution for a third calculation, where flux linkages will be equal. If desired, the result can be checked by observing how the calculated magnetic energy is changed with small deviations from the calculated currents. The changes should always be positive. Fig.5. Transformer without axial symmetry The programs can handle up to 30 layers, 6 terminals and 200 segments, which is intended to cover all practical cases. The finite element grid is generated automatically, and only the most essential information needs to be specified about the geometry, connections and current distribution. An input file must be made up containing this information, and there are different ways of doing this. Numbers can be changed and inserted directly in an input file, using a text editor, based on information in the user's manual of what the numbers mean. Headings can be brought in first, using a simple command. Then the numbers can be changed and inserted, using a text editor. Finally, the headings must be removed, again using a simple command. An input subprogram can be run, which creates new input, based on earlier input. Detailed explanations are given when the program asks for the input items, one at a time. When an item is the same as in the earlier input, the user simply strikes ENTER. The new input file is created in the right format automatically. A design program can create the input file for the finite element leakage field calculation completely automatically. Such a program has also been made by the author, and is described in Ref. 4. 11 Demo Program A demo program can be downloaded from the author's web page (address in heading). It contains information about input and output and allows a user to analyze a simple two winding transformer of his own, like the one in Fig.1. Most of the information in this paper is also contained in the demo. Like the main programs, the demo runs under MS-DOS, which is an option under all the versions of Windows, currently used. 12 Conclusions The calculation of magnetic leakage fields in transformers by finite elements is rapidly becoming not only a desirable option, but a necessity for transformer manufacturers who want to stay in business. In the absence of tests, customers more and more demand that the ability of transformers to withstand short circuits is documented this way. Also, reactance and eddy current losses can be predicted much more accurately than previously possible, using analytical methods. References [1] O.W. Andersen, "Transformer Leakage Flux Program Based on the Finite Element Method", IEEE Transactions on Power Apparatus and Systems, Vol. PAS-92, 1973, pp. 682-689. [2] O.W. Andersen, "Magnetic Leakage Fields in Rectifier Transformers", Conference Proceedings ICEM, Paris September 1994, pp. 738-740. [3] O.W. Andersen, "Large Transformers for Power Electronic Loads", IEEE Transactions on Power Delivery 1997, October 1997, pp. 1532-1537. [4] O.W. Andersen, "Optimized Design of Electric Power Equipment", IEEE Computer Applications in Power, April 1992, pp. 34-38.