2-109

TECHNOLOGY FOR PROCESSING AMMONIUM RHODANIDE

OF COKING PLANTS INTO HIGH-PURITY

AMMONIUM THIOCYANATE AND THIOUREA

F. Kh. Urakaev, V. S. Shevchenko

Institute of Geology and Mineralogy SB RAS, Novosibirsk, Russia

The regularities of the reversible reaction of isomerization of ammonium thiocyanate

NH

4

NCS into thiourea (NH

2

)

2

CS and back were analyzed on the basis of the available literature data and our own results. Based on the known volatilities of

NH

4

NCS and (NH

2

)

2

CS we have developed an ecologically clean and highly efficient method for extraction, purification, separation and production of the isomers from the coal byproduct ammonium thiocyanate.

1. INTODUCTION

The coal byproduct ammonium thiocyanate (rhodanide), NH

4

NCS, is the product of the recovery of hydrogen cyanide (HCN) by ammonium polysulfides from coke-oven gas in byproduct coke ovens [1]. The content of the end product in technical-grade ammonium thiocyanate ranges from 60 to 95%, depending on the recovery methods used. Ammonium thiocyanate belongs to the class of pseudohalides [2], has a melting point of 150°C and exhibits a unique ability to be converted to its organic isomer - thiourea, (NH

2

)

2

CS, a molecular crystal with a melting point of 180°C, which may be used for the industrial production of thiourea [3].

The reversible isomerization NH

4

NCS ↔ (NH

2

)

2

CS has been studied since 1869 [4]. It is known [3] that this reaction proceeds in the solid phase, melt and solutions at 140−180°C at an appreciable rate as a first-order kinetically reversible reaction; the rate constants of the forward and reverse reactions have been determined. It has been shown that the forward and reverse reactions lead to the formation of an equilibrium mixture, which contains about

75% ammonium thiocyanate and about 25% thiourea; the equilibrium mixture has an eutectic melting point of about 104°C. Attempts have been made

(including mechanochemical [5]) to shift the equilibrium to either side, but no positive results have been obtained. The thermodynamic parameters of the isomers and isomerization reaction have been determin ed; no significant side reactions and formation of other products have been observed in the temperature range indicated (at higher temperatures there are formed thermal decomposition products [6, 7]).

Thiourea and ammonium thiocyanate are widely used in preparative, analytical and applied chemistry, organic synthesis (derivatives, medicinal preparations, toxic substances), nonferrous metallurgy (extraction of noble, heavy and radioactive metals), agriculture (fungicides), wood chemistry, textile and industrial rubber industries, polymer production, etc. The production of thiourea in world practice is based on the utilization of two types of raw material: calcium cyanamide (CaCN

2

, which is traditionally produced with large energy consumption by the action of nitrogen on calcium carbide at 1100−1250°C) and ammonium thiocyanate. The first method is based on the following reaction: CaCN

2

+ CaS +

4H

2

O = (NH

2

)

2

CS + 2Ca(OH)

2

. Both methods have been protected by numerous

2-109

patents. The first method has not been realized in Russia because of the shortage of calcium cyanamide. Due to the unlimited possibilities of byproduct coke plants the second method has been used in attempts to develop solution technologies for the production of thiourea, which have however failed because of the complexities encountered in the purification and fractional crystallization of the solutions.

Based on the known volatility of NH

4

NCS in the temperature range of

29−53°C [8], we have developed a "dry" method of purification of technical grade ammonium thiocyanate. The same method based on the volatility of

(NH

2

)

2

CS experimentally estimated by us (no information is available in the literature on the vapor pressure of thiourea) served as the basis for an ecologically clean and highly efficient method of purification, separation and production of the pure isomers from the coal byproduct ammonium thiocyanate after preliminary processes of its purification and isomerization.

2. EXPERIMENT

In order to evaluate the vapor pressure of the isomers at elevated temperatures and to accomplish the processes of purification, separation and production of high-purity ammonium thiocyanate and thiourea from the coal byproduct ammonium thiocyanate, we designed, constructed and assembled a universal setup based on glass (see Fig. 1).

Fig. 1 . Block diagram of a universal device made of glass for measuring the vapor pressure, extraction,

Fig. 2 . Schematic description of the vapor deposition methods for producing high-purity purification, separation and preparation of ammonium thiocyanate and thiourea ( see the text ). ammonium thiocyanate and thiourea from the equilibrium mixture of isomers.

The setup consists of a two-necked one-liter round-bottom flask 1, temperature-controlled corner tube 2 and desublimation cells 3–6 with internalwall tubes 210 mm long and with an internal diameter of 14 mm, pressuremeasuring devices 7 (a standard vacuum gage, a mercury pressure gage and thermal transformers), a liquid-nitrogen trap 8, a forepump 9 and various valves

(¤). The parts 1-6 were made on the basis of ground-glass joints no. 29. In order to rule out the application of vacuum grease to ground -glass joints, shells

0.2 mm thick were made from a fluoroplastic bar. The temperature of the internal walls of glass parts 1–6 was maintained by thermostats 10–14 (water thermostats 10 and 11, up to 100°C, and thermostats based on silicone oil 12–

14, up to 230°C) to within ±0.5°C. The second sprout of flask 1 serves for

2-110

purging and filling of the system with an inert gas (argon or nitrogen cylinder 15 ) during the preparation of an equilibrium mixture (melt) or for introducing measured-out amounts of technical-grade (crude) ammonium thiocyanate upon its purification and of the melt upon its separation into its isomers and also for evaluation of the vapor pressure of the high-purity end products obtained by the method proposed at elevated temperatures.

The kinetics of the conversion and the purity of the separated isomers were traced by measuring the conductance of aqueous solutions of samples of the products obtained (the ammonium thiocyanate solution is an ordinary electrolyte, whereas thiourea dissolves in molecular form and its solutions do not exhibit conductance). This method was approved for the separate determination of both products when they are jointly present in solutions [5, 9].

The device for conductance measurements was designed by us on the basis of an impedance meter (Impedance Meter BM507, Tesla, Brno) and a Pt-electrode

(Conductometric Bell Electrode, Type OK-9023, Radelkis Electrochemical

Instrument, Budapest). We also used X-ray phase, calorimetric, spectroscopic, crystallooptical and chemical methods of qualitative and quantitative determinations of small contents of isomers in samples.

3. EVALUATION OF THE VAPOR PRESSURE OF AMMONIUM

THIOCYANATE AND THIOUREA

In order to choose the most efficient conditions for the separation of isomers, it is necessary to know the vapor pressures of the individual components of the equilibrium melt. As pointed out above, there is only one work [ 8] devoted to the indirect measurement of the vapor pressure of ammonium thiocyanate by means of the effusion and torsional-effusion methods. The methods employed by De Kruif are dynamic, which is why the data obtained cannot correspond to equilibrium values of the vapor pressure and sublimation heat of ammonium thiocyanate. The vapor pressure of ammonium thiocyanate measured in [8] is ~2×10

−3

mm Hg or torr at ~40°C and does not lie within the region of the expected working temperatures of the process of purification and separation of isomers (120−230°C).

In order to estimate the vapor pressure of ammonium thiocyanate and thiourea in the high-temperature region, we chose the boiling-point method as the simplest in practical realization. The method consists in the following: at a given temperature during the decrease in the pressure in the system the liquid substance boils, i.e., its vapor pressure becomes equal to the pressure in the system, which is easily determined visually or from a change in the liquid temperature. There are two ways for the realization of the method: isothermal or isobaric. The advantage of the method under consideration is the possibility of measuring the vapor pressure upon decomposition of the substance since the boiling process corresponds to the content of the main substance present in the quasiclosed volume of the flask 1 (see Fig. 1) if the pressure in the system is reduced rather rapidly. The accuracy of pressure determination by the method is

±0.5 torr. The shortcomings of the method (the measurement accuracy is not high and it is not possible to establish the vapor composition) are compensated for by the rapidness and the relative reliability of the results.

In connection with the isomerization process NH

4

NCS ↔ (NH

2

)

2

CS, the relatively correct and comparative measurements of the pressure of the isomers

2-111

became possible only at the melting point of thiourea (~180°C). Measurements were carried out according to a simplified scheme without using desublimators

(see Fig. 1). Finely ground and very pure ammonium thiocyanate or thiourea was poured into the flask in an amount of 10 g; the system was evacuated and filled with argon to the atmospheric pressure; the flask was lowered to the edges of the polished sections into thermostat 14. Upon completion of the melting of the sample the needle valve set up between the pressure gages and the liquidnitrogen trap was used to fix the speed of evacuation of the system, which makes it possible to measure the vapor pressure within 1 min, as a rule. The boiling point was fixed visually or by means of a thermocouple inserted through the second neck of flask 1 and compared at this moment with the pressure of the complex 7. The average data on the vapor pressure at 180°C were 3−4 torr for thiourea and about 35 torr for ammonium thiocyanate.

Based on [10], it is not difficult to conclude that such high values of vapor pressure for both products and the substantial difference between them under isothermal conditions can be used for the development of new vacuum-gas-phase methods of their purification and separation and for the production of high -purity ammonium thiocyanate and thiourea from technical-grade (crude) ammonium thiocyanate.

4. PURIFICATION OF THE COAL BYPRODUCT AMMONIUM

THIOCYANATE

The crude ammonium thiocyanate with a melting point of up to 130 °C was received from Donetsk and Kemerovo byproduct coke plants. The first three columns of Table 1 give their average technical characteristics, which are compared with those of pure ammonium thiocyanate ( AT ).

Table 1 . Refinement of ammonium thiocyanate ( AT , NH

4

CNS)

* Impurities in AT, no more than

Purity of AT, wt.%

(* - indication of this column)

AT from Donetsk /

Kemerovo

GOST 3768-64 for pure

AT

1. NH

4

CNS

2. Nonvolatile substances

3. Water-insoluble substances

4. Sulfates

5. Heavy metals

6. Chlorides

7. Iron

8. Substances oxidized by iodine

9. Thiourea

92.5 / 80−90

0.13 / −

0.6 / −

0.7 / −

− / −

0.9 / −

0.9 / −

− / −

− / −

99

0.01

0.005

0.0025

0.0003

0.002

0.001

0.002

−

2-112

9

2

3

4

5

6

7

8

Table 1 (continued).

Refinement Temperature (°C) of cells 1-2, yield # of AT parameters (%) from theoretical value and impurity contents in cells 3–6

*

1

Temperature (°C) of cells 3–6 & and purity of NH

4

CNS, in %

130 150 170 190 210 230

99.8

# 99.5

# 99.5

# 99 # no

- no no

- no no

- no no

- no

94 # no

-

89 # no

-

90 70 50 20

99.9 99.6 99.0 97-

98 no

- no no no no more 10 -5 % no more 10 -3 % no more 10 -5 % no more 10 -3 % no

- no no

- no no

- no no no traces 1 % 4 % 8 % traces no no no

The method of purification of crude ammonium thiocyanate consists of its gas-phase recrystallization and dehydration and sublimation-desublimation process at given temperatures of sublimation (1, 2) and desublimation (3-6) substrates at low pressures (10

-1 −10 -3

torr) (see Fig. 1). The feed substance is pulverized and introduced into flask 1 in an amount of 20 g. Drying is made under vacuum at flask 1 wall temperatures of 20−80°C. The most volatile impurities are captured by the nitrogen trap 8.

When the drying is complete, with the forepump 9 being operated the flask is withdrawn from thermostat 14, the temperature of which is then brought to the value required for the purification process (130−230°C; see columns

#

). Simultaneously, there are also established the temperatures of desublimation substrates 3–6 (see columns

&

) provided by thermostats 10–13. The flask 1 is again introduced into thermostat 14. The particles of crude ammonium thiocyanate adjacent to the flask wall undergo melting; the resulting melt boils up and is converted to the gas phase. The steady state of melting and vaporization of ammonium thiocyanate is established very rapidly. The vapor desublimates on substrates 3–6. The columns

#

of Table 1 presents some of their characteristics. The end of the process is easily determined from the disappearance of the boiling melt.

The nonvolatile impurities are left in the flask.

A specific feature of the method is that upon heating of the fee d substance in vacuum only that part of the substance is evaporated which comes into contact with the heated wall of the flask. The temperature of the remaining part is < 130°C because of the low heat transfer of the powder and it sublimates to a lesser extent.

Thus, despite the relatively high temperatures in the still, their absolute value does not affect the quality of the purified ammonium thiocyanate, the characteristics of which in some desublimators 3-5 exceed the characteristics of pure ammonium thiocyanate (see Table 1, columns

&

). The chosen temperature range in the still part has an optimum at 150−180°C. Below 150°C the sublimation rate decreases and above 180°C the degree of decomposition of ammonium thiocyanate increases (the main decomposition products are elemental sulfur and guanidines

[6, 7]). The pressure in the system begins to exert a substantial effect on the purification process only if its value exceeds 0.5 torr. Thus, from cells 3-5 there was obtained about 4 kg of "the gas-phase purification product" containing about 99.5% ammonium thiocyanate, which is used for the production of an

2-113

equilibrium melt and for the development of the method of separation of the isomers.

5. PRODUCTION OF AN EQUILIBRIUM MELT AND ITS SEPARATION

The equilibrium mixture of isomers (melt) was also produced by a simplified scheme with account taken of the well-known kinetics of the isomerization process [3]. Purified ammonium thiocyanate was charged in an amount of 300 g into flask (Fig. 1). The system was purged and filled with an inert gas (mostly, with argon). The flask 1 was lowered into thermostat 14 heated up to >150°C and kept in it for a given time. The resulting melt was then poured out from the flask into a vessel with liquid nitrogen. The resulting porous bar was pulverized to a powder. As a result of the analysis of the composition of powders, there were established the optimal temperatures for the preparation of a melt (155−170°C) and the corresponding exposure times for the complete melting of ammonium thiocyanate in the flask (from 3hrs to

1 hr).

The melts formed at >170°C had a yellowish-green color due to the decomposition products of the isomers and the preparation of a melt at temperatures of < 155°C required a prolonged exposure time (for example, at

140°C almost a week is required: 24 hours for the melting of ammonium thiocyanate and several days in order to obtain an equilibrium composition). This did not improve its quality either. The colorless melts obtained contained 20−30% of thiourea, 70−80% of ammonium thiocyanate and <1% of the decomposition products of the isomers. The total amount of the powder obtained in 10 experiments was about 2.8 kg (i.e., the total loss was about 7%) and it contained

26.8% of thiourea and 72.6% of ammonium thiocyanate.

In order to separate ammonium thiocyanate and thiourea, the resulting powder of the equilibrium mixture of isomers was charged into flask 1 in an amount of up to 10 g; the system was evacuated and the required parameters of the separation of the isomers were specified. After preliminary experiments we established an optimal amount of the substance being charged: about 1 g. The purity of the products was very high. Evacuating and filling the system with an inert gas, we could consume up to 20 g of the powder within a single experiment. We used 5 g (Table 2). Table 2 gives the results of 10 experiments for the separation of the isomers, which do not require special explanations. It should only be noted that ammonium thiocyanate cannot sublimate onto substrates with a temperature of >120°C and the substrate temperature 150°C is rather high for preparing pure thiourea because of its isomerization to ammonium thiocyanate. The most optimal conditions for the sublimation of thiourea can be provided at substrate temperatures of 120 −140°C; for ammonium thiocyanate the temperature is below 100°C. The substrate 4 performs the function of spatial separation of the isomers and is a necessary attribute of the method described. The material from the substrate may be used for further "conversion" by the same method since it contains both products.

2-114

Table 2 . Separation of ammonium thiocyanate and thiourea ( TU ) by a gas-phase method.

Run no.

1

6

7

8

9

10

2

3

4

5

1-2

150

160

170

180

180

180

180

180

190

200

Temperature of cells, °C

3 4 5

145

130

140

130

100

130

90

110

70

80

70

80

6

20

20

20

150 110 80 20

20

3

19

26

20

135 110 50 20 26

5

130 130 80 20 26

21

Yield of products by cells, %

4

19

5

20

4

4

2

5

50

63

45

130 110 80 20 23 11 68

130 110 80 20 26 7 63

6

6

3

2

2

2

68 0.6

22 68

120 110 80 20 20 10 68

70

62

2

2

0.3

8

Total

94.0

Parameters Content of basic substance by cells, % Melting point $ of Pressure in

Run TU mixture TU/AT AT isomers, °C the system,

97.0

97.0

98.0

98.0

98.6

97.0

97.0

96.6

93.0 no.

1

2

3

4

5

6

7 c. 3

99.1

99.7

99.5

99.8

99.7

99.6

- cell 4

17.2 / 82.4

-

16.8 / 83.0

-

-

-

18.7 / 80.7 c. 5

98.4

99.5

99.5

99.5

99.5

91.6

99.5

TU

180

182

181

182

182

182

172

TA

148

149

149

149

149

142

149

8

9

99.8

99.7

-

-

99.5

99.5

182

182

149

149

10 98.0 - 99.2 178 147

&) Note: procedure for determining the melting points of samples had an error of

1°C. torr

5×10 -3

5×10 -3

5×10 -2

5×10 -2

5×10 -3

5×10 -3

5×10 -3

5×10 -1

5×10 -1

5×10 -3

Optical investigations have shown that crystals of ammonium thiocyanate and thiourea obtained by well-known methods have a large number of defects

(including three-dimensional voids – vacuoles filled with a crystallization medium); the phase composition of inclusions includes a gas and an aqueous solution of thiourea or ammonium thiocyanate. No gas-liquid inclusions were detected in crystals of ammonium thiocyanate (fine acicular form) and thiourea

(fine lamellar form) produced by the vacuum gas-phase method, see Fig. 2.

Physically, the methods of purification of crude ammonium thiocyanate and of the isomers separation from the melt are absolutely identical. The only differences are those in the parameters of the corresponding processes. Both methods yield the end products corresponding to the qualification of ultra-pure chemical reagents.

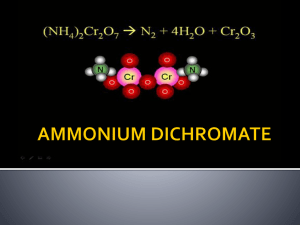

CONCLUSION

The principles described enable one to simplify the technology of purification and separation of isomers and to increase the purity of the end products , see

Fig. 3 . The purification and separation of isomers by vacuum distillation are carried out in a single stage without considerable power consumption, do not require other chemical reagents and are ecologically clean processes with a small content of by-products that can easily be trapped.

This work was supported by the Integration grant of the SB RAS # 11.

2-115

Fig. 3 . Original hardware registration for continuous-periodic technology of isomers production: 1 - pumping-out; 2 – isomerization chamber (melt); 3 - self-acting batcher by 3-way ball valve (T = 160°C);

4 - vaporizer (T = 200°C); 5 - hot chamber; 6 - desublimation column; 7 - self-moving inert ferromagnetic balls (desublimators) at T = 130°C; 8 - magnetic seal; 9 - electromagnetic ball mill; 10 - mill chamber for separating off thiourea from balls surface; 11 - thiourea outlet; 12 - magnetic pump; 13 - lifting column;

14 - all-welded device from stainless steel (T = 130°C); 15 - desublimation chamber for ammonium thiocyanate (T = 70°C); 16 - ammonium thiocyanate outlet.

REFERENCES

1. A.G. Starovoit, I.I. Pidgursky, E.I. Toryanik, I.V. Shulga, Yu.B. Dolzhanskaya, and

Yu.V. Teleshev. Coke and Chemistry. 2000. No. 6. P. 43-54.

2. Chemie der Pseudohalogenide, eds. A.M. Golub, H. Kohler and V.V. Skopenko,

VEB Deutschher Verlag der Wissenschaften, Berlin, 1979.

3. Yu.Ya. Kharitonov. Russian Journal of Physical Chemistry. 2000. Vol. 74. No. 6.

P. 924-933.

4. J.E. Reinolds and E.A. Werner. J. Chem. Soc. Transactions. 1903. Vol. 83. P. 1-8.

5. F.Kh. Urakaev and L.Sh. Bazarov. Coke and Chemistry. 1999. No. 8. P. 40-42.

6. S.K. Adhya, P.C. Srivastava, and B.K. Banerjee. Fert. Technol. 1981. Vol. 18.

No. 1-2. P. 81-90.

7. P.E. Adams, J.T. Person, and J.A. Wood. Anal. Proc. 1985. Vol. 22. No. 2. P. 38-

39.

8. C.G. De Kruif. J. Chem. Phys. 1982. Vol. 77. No. 12. P. 6247-6250.

9. F.Kh. Urakaev and L.Sh. Bazarov. Russian Journal of Inorganic Chemistry. 2001.

Vol. 46. No. 1. P. 47-48.

10. M.M. Factor, Growth of crystal from the vapor, Chapman & Hall Lim., London,

1974.

2-116