ATA_England

advertisement

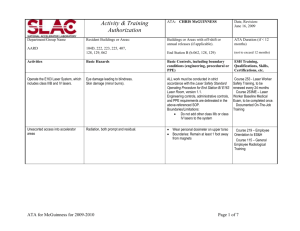

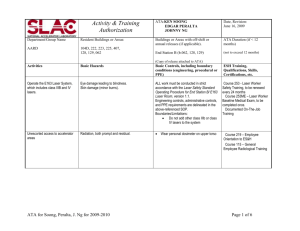

Activity & Training Authorization Department/Group Name Resident Buildings or Areas: AARD 104D, 222, 223, 225, 407, 128, 129, 062 Activities Operate the NLC Test Accelerator as an operator Work on medium- and highpower RF power sources Operate the E163 Laser System, which includes class IIIB and IV lasers. Basic Hazards Radiological Non-ionizing radiation Laser radiation Electrical Burns to skin Damage to eyes Eye damage leading to blindness. Skin damage (minor burns). ATA for England for 4/13/2011-4/12/2012 ATA: R. JOEL ENGLAND Date, Revision: April 12, 2011 Buildings or Areas with off-shift or annual releases (if applicable). ATA Duration (if < 12 months) End Station B (b.062, 128, 129) (not to exceed 12 months) Basic Controls, including boundary conditions (engineering, procedural or PPE) Engineering controls: NLCTA PPS, BCS, and MPS systems Administrative Controls: procedures defined in the NLCTA Directives PPE: none relevant. Boundaries: Operations to be approved at 9:30am Ops meeting CoHe required for some N-type connectors and all waveguide connections that must be breached. Observe signage. ESH Training, Qualifications, Skills, Certifications, etc. ALL work must be conducted in strict accordance with the Laser Safety Standard Operating Procedure for End Station B/ E163 Laser Room, version 1.1. Engineering controls, administrative controls, and PPE requirements are delineated in the above-referenced SOP. Boundaries/Limitations: Do not add other class IIIb or class IV lasers to the system Course 253 - Laser Worker Safety Training, to be renewed every 24 months Course 253ME – Laser Worker Baseline Medical Exam, to be completed once. Documented On-The-Job Training NLCTA Operator Training – as specified in 020401 Operator Safety Training Requirements Electrical Safety—RF Sources (Course 413) LOTO (Course 157+157R) required. Page 1 of 8 ATA TITLE: England 2011-2012 ATA# Unescorted access into accelerator areas Work in a PPA laboratory environment. Electrical – use DVMs and oscilloscopes to test electronic instruments Chemical – use small quantities of solvents to clean vacuum parts and optical components Vacuum – be present during system venting and pump down ODH – be present during system venting Radiation, both prompt and residual. Startle hazard from electrical hazards below 50 V, 10 A, 10J stored energy Chemical burns and blindness resulting from chemical exposure Cuts and lacerations resulting from implosion of a vacuum window Asphyxiation resulting from oxygen displacement by nitrogen boiloff Wear personal dosimeter on upper torso Boundaries: Remain at least 1 foot away from magnets Course 219 – Employee Orientation to ES&H Course 115 – General Employee Radiological Training Electrical Hazards Engineering controls: Equipment covers. Administrative controls: signage. PPE: none. Boundaries: Do not operate electronic equipment with the protective covers removed. Chemical Hazards Engineering controls: Equipment covers. Administrative controls: signage. PPE: nitrile or latex gloves and goggles or face shield Boundaries: Use restricted to Isopropanol, Methanol, Ethanol, and Acetone in 1 Liter point-ofuse bottles only. Vacuum Hazards Engineering controls: Experimental chamber cannot be pressurized Administrative controls: Avoid contact with all glass vacuum windows. PPE: none required Boundaries: do not pressurize any vacuum system under any circumstance. Oxygen Deficiency Hazards Engineering controls: ODM and shut-off valve in LN line Administrative controls: Personal Course 110 – Lab Safety for Particle Experimentalists =OR= Course 239 – General Electrical Safety =AND= Course 251 – Electrical and General Safety for R & D” =AND= Course 170 – Cryogen and ODH Safety 2 of 8 ATA TITLE: England 2011-2012 ATA# Work near NLCTA or E163 Experimental Hall magnets Electrocution, burns Use of hand tools (non-powered) such as wrenches, hammers, saws, screw drivers. o o o o cut hands/knuckles Stab wound Eye injury Smash hand or fingers o o o o o o ODM placed near point of most probable ODH PPE: none. Boundaries: Use only the plumbed-in LN system. Do not bring dewars into the accelerator housings. Engineering Controls: Lockout in accordance with the “NLCTA Electromagnet Equipment Lockout Procedure” is required. Administrative Controls: Signage describing voltage and current Boundaries: Absolutely no hot work is permitted. Course 157 – Control of Hazardous Energy Course 157PRA – Control of Hazardous Energy Practical Course 138 – CPR =AND= Course 110 -- Lab Safety for Particle Experimentalists =OR= Course 251 -- Electrical and General Safety for R & D) Course 255 – Personal Wear gloves when practical Protective Equipment is highly Use liquid wench or similar material to recommended. pre-loosen tight bolts. Apply force away from your body when prying with hand-tools. Wear safety glasses if something may fly into your eye. Keep tools sharp Use the right tool for the job 3 of 8 ATA TITLE: England 2011-2012 Operate machine shop type stationary power tools eye injury from flying chips, cutting fluids, or parts coming loose from machine Includes only the specific equipment located in building 104D listed below: /fingers/hands/jewelry/clothing/hair can get caught in rotating parts grinders back injury manipulating heavy or awkward parts band saw (vertical) drill press Sander exposure to high noise levels crushing of feet or hands while handling materials or parts falling out of machine chips/coolant/flying parts can hit operator or bystander o o o o o cuts Coolant on floor around machine can cause slip hazard o Parts can become hot and burn skin o o o o ATA# Only operate equipment that you are trained and qualified to operate. Follow all manufactures safety requirements. Limit distractions Wear safety glasses with side shields Where ear protection if exposed to prolonged high noise levels, or when posted as mandatory. Shirts and shop coats should be short sleeved. If long sleeved garments are worn, they must be tight fitting around the wrists and forearms. Keep long hair tied back. Keep necklaces and badges tucked away. Use break away badge necklaces. Wear safety shoes when handling/moving heavy equipment or materials. Always wear closed-toed shoes. Use machine guards and keep them properly adjusted. Do not wear gloves when operating equipment with rotating parts. Use proper clamping and tooling. Do not exceed the capacity of the machine. Training required: Personal Protection Equipment (PPE) (Course 255) Qualifications required: Successful completion of formal college or vocational machine shop program Or For each type of machine checked in row two, a documented evaluation that the employee has the skill and knowledge to safety operate the machine. 4 of 8 ATA TITLE: England 2011-2012 ATA# Double check machine tooling and make sure chuck key is removed before power is applied. o Use barriers to screen / partition off machine to help contain flying chips/coolant o Use hooks/pliers or other tools to remove chips from around rotating parts or when handling hot parts. o Be aware of the floor surfaces in your work area. Use absorbent to control fluids around machines. Control spills (absorbent, barriers/tape, etc) and clean up promptly. Report unsafe conditions that you cannot correct yourself. Boundaries: Excludes working with: Lead Beryllium Radioactive materials Soldering o o Burns Inhalation of fumes o Use protective holder to store heated iron. o Properly dispose of solder dross o Use in well ventilated areas None. 5 of 8 ATA TITLE: England 2011-2012 ATA# Climb ladders. Climbing on machines and equipment. o o o Falling Head injury People run into ladder o o o o o o o o o Stack or handle lead o Limits working with lead to 30 minutes/day o Excludes cutting, drilling, or machining lead, grinding. o Exposure to hazardous materials (lungs, skin, eyes) o Contamination of equipment and environment Don’t stand on steps not designed for standing (usually the top step and top of ladder) Inspect ladders before use. Do not use damaged ladders. Zone off area if there is a potential of falling objects to personnel below. Require use of hardhats if your work may potentially drop something below on workers. Have someone hold ladder if it will provide more support Use barricades or signs to warn of presence of ladder Do not position ladder in front of closed door that can open into the ladder. Use the right ladder for the job. For example, do not use an “A” frame ladder to lean against a building…use an extension ladder. Store ladders so they will not block exits in the event of an earthquake. Boundaries: Elevated surface work (unguarded elevated surfaces 4 feet or more above the surroundings) is not allowed. o Limit daily activity to 30 minutes o Wear gloves. Store gloves in marked zip lock baggie for future use or dispose of as “lead contaminated debris” o Containerize (sealed bag) all waste, properly label, and request disposal(example below) Course 293 – Stairway and Ladder Safety is highly recommended. Stack or handle lead o Limits working with lead to 30 minutes/day o Excludes cutting, drilling, or machining lead, grinding. 6 of 8 ATA TITLE: England 2011-2012 ATA# The words “hazardous wasteLead contaminated debris” The word “poison” Date Name and phone extension/pager number Training o Hazardous Waste Management (Course 105) required if you will generate hazardous waste Working in tight spaces o o o Bumping into things with body or head Trip hazards Getting in each others’ way o avoid rushing o wear hard hat/ wear bump hat o practice good housekeeping o be aware of your surroundings Boundaries: Entry into Confined Spaces is not allowed. None. 7 of 8 ATA TITLE: England 2011-2012 ATA# I will maintain compliance with my STA training requirements, including staying current with recertifications. I understand the type of activities, including boundary conditions, which I am authorized to perform, and the hazards and controls associated with such activities. Worker Name (please print) Signature Date R. Joel England I have reviewed the basic steps, hazards, controls & boundary conditions described in this ATA with all workers listed above. Workers listed above possess the skills, knowledge, training & qualifications to perform work as described in this ATA and are therefore authorized to carry out such work. Workers are also released to carry out such work in their resident work area, as defined in this ATA. Eric R. Colby Supervisor Name Signature Date I acknowledge the extension of the Resident Work Area to include End Station B and adjoining buildings. All yellow work in ESB must be released at the 9:30am daily operations meeting. Carsten Hast Test Facilities Head Signature Date 8 of 8