CAFO Fact Sheet #11 - Heartland Regional Water Coordination

advertisement

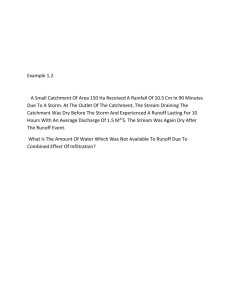

CAFO Fact Sheet series Fact Sheet #11: CAFO Requirements for Dairy Barnyards By Peter Wright, Cornell University Introduction Disclaimer This fact sheet reflects the best professional judgment of the contributing author and is based on information available as of the publication date. Also, your state may have additional, more stringent requirements than EPA's requirements. Contact your permitting authority for complete information on the regulations that apply to you. Copyright © 2003. MidWest Plan Service, Iowa State University, Ames, Iowa 50011-3080. Copyright Permission For copyright permission, call MidWest Plan Service (MWPS) at 515294-4337. Organizations may reproduce this fact sheet for noncommercial use, provided they acknowledge MWPS as the copyright owner and include the following required credit statement: In December 2002, EPA released new rules revising and clarifying the Concentrated Animal Feeding Operation (CAFO) regulations. They also notified states that these rules need to be implemented. Producers who in the past may not have known about or responded to CAFO requirements will now need to meet them. This fact sheet focuses specifically on the barnyard. Production areas, which include barnyards on dairy farms, were regulated by the previous CAFO regulations and continue to be regulated. The “production area” includes the animal confinement areas (including barnyards), the manure storage area, the raw materials storage area, and the waste containment area. The new rules require farm operators, even those who had assumed they had no discharge from their barnyard, to file with the regulating agency. Farms that fall under the CAFO rules (see CAFO Fact Sheet #2: Do I Need an NPDES Permit for My Livestock or Poultry Operation?) need to apply for a permit and implement a Nutrient Management Plan (NMP) controlling the runoff from their barnyard and treating it appropriately. This fact sheet will provide information about the best way to do this. Requirements for Dairy Operations The Effluent Limitations Guidelines (ELG) for dairy CAFOs apply only to those operations that have a onetime capacity of 700 mature dairy cows (milked or dry). More information on the applicability of the new CAFO regulations can be found in CAFO Fact Sheet #2 of this series. There must be no discharge of manure, litter, or process from the production area unless certain requirements are met: Rainfall causes the discharge AND Reprinted from Livestock and Poultry Environmental Stewardship curriculum, fact sheet authored by Peter Wright, Cornell University, courtesy of MidWest Plan Service, Iowa State University, Ames, Iowa, 50011-3080 and your land-grant universities, Copyright © 2003. 1 October 2003 Requirements for Dairy Operations (continued) Pasture vs. Barnyard The production area is designed, operated, and maintained to contain all of the manure, litter, and process wastewater, including storm water plus runoff from the 25-year, 24-hour rainfall event AND The CAFO is otherwise complying with the inspection, monitoring, recordkeeping, and mortality disposal provisions in the rule. Producer Checklist 1. Determine if you are a CAFO (see CAFO Fact Sheet #2). 2. Determine if you have a barnyard (see the following section titled Pasture vs. Barnyard). 3. Determine if you would have a discharge during a 25-year, 24-hour storm. 4. Can the barnyard be: a. Eliminated? b. Reduced? c. Moved? 5. Control outside clean water. a. From roof areas b. Surface flow c. Subsurface flow d. Overflowing waterers 6. Catch the runoff. 7. Treat the stored runoff appropriately. Pastures are not regulated by CAFO rules because by definition a pasture is not a CAFO, since the animals are not stabled or confined and there is vegetation and forage growth in the pasture. However, winter grazing areas where the animals are kept for more than 45 days and have removed the vegetation may be considered a CAFO. Denuded areas in a pasture where animals congregate such as around feeders and waterers may be considered production areas. Laneways that are bare but are only used to move the animals to and from pastures are not considered production areas. Supplying food and water to a pasture does not make it a CAFO. Commonsense and sound judgment should be used to distinguish between a pasture and an abused area that needs to have the runoff controlled under the CAFO rules. Sufficient Design Capacity Under the new regulations, manure and process wastewater discharges from large dairy CAFOs are prohibited except when rainfall causes an overflow from a facility that is designed, maintained, and operated to contain all manure and process wastewater including storm water plus runoff from the 25year, 24-hour rainfall event. It may be obvious to you that your barnyard [without best management practices (BMPs) to catch and store the runoff] will have a discharge that flows to surface waters during the 25-year, 24-hour storm event (see Figure 1). If it is not obvious to you, a hydrologist or Figure 1. Rainfall from a 25-year, 24-hour storm, in inches. This is a theoretical event that could occur on average once in a 25-year period and may include an intense short-duration storm for a period less than 24 hours. 2 October 2003 engineer can help you determine what will happen during this large rainfall event. Discharges from dairy barnyards during storms larger than the 25-year, 24hour storm are allowed to run off but only the portion that exceeds the 25-year, 24-hour storm. You will need to install BMPs to control the runoff. Eliminate the Barnyard Before the negative environmental consequences resulting from having a barnyard were well understood, there were a number of good reasons for barnyards to be installed or allowed on dairy farms. However, now that the environmental impacts are more defined and the regulations for CAFO permits require control of this runoff, it may make more sense for the farm operator to eliminate the barnyard and house the dairy animals either in a barn or on a pasture system without allowing them to use a barnyard. Past uses for a barnyard included as a holding area while the barn was being cleaned or before the cows were milked. These areas were generally small and could be roofed. Some farms used outside lots to provide supplemental feed to the animals. However, using total mixed rations reduces the need for barnyards to be used as feeding areas. The feed preserves its nutrition and energy levels best when kept under a roof to avoid being overheated by the sun or soaked by the rain. Restricting access to the feed to when the cows are outside can also lower dry matter intake. Using outside barnyards as resting areas for the cows is an indication that cow comfort in the barn stalls is not adequate for maximum production. Cows do not benefit from exercise in the barnyard; studies examining exercise impacts on cows generally start at 2 miles per day. barnyard before spending money on controlling the runoff from it. Reduce or Move the Barnyard Planning the location and size of barnyards can reduce the pollution potential. Furthermore, lowering the pollution potential to desired levels costs less in properly located and sized barnyards. Many of the problems of diverting or controlling outside surface water and catching and treating dirty barnyard runoff can be reduced or eliminated by locating the barnyard in the right place. Moving existing barnyards to higher ground, away from a stream, or away from the drip edge of a roof can help prevent pollution while avoiding the increased costs that outside water control systems would require. The size of existing and proposed barnyards should be evaluated to eliminate the cost of extra concrete placement and the environmental effect of too large of an abuse area. Table 1 shows the recommended size for barnyards. Smaller sizes will stress the animals. Table 1. Barnyard sizes, in square feet Feeder Cattle or Heifers Using an outside area for heat detection is not needed if the cows have access to each other in a freestall and have traction to exhibit mounting behavior. Even without freestalls, secondary signs of heat detection such as milk reduction, discharges, and behavior changes can be used to identify cows to breed. Synchronized ovulation can be used at a cost of about $8/cow. Every effort should be made to eliminate the 3 Finishing Cows 400-800 lbs 800-1,200 lbs 1,300 lbs 150-300 250-500 300-500 20-25 30-35 40-45 200-600 400-800 500-800 40-50 50-60 60-75 Lot Space Unpaved lot with mound (includes mound space) Mound Space Providing outside access to overcome poor barn ventilation might be better dealt with by improving barn ventilation. Hoof health concerns raised when cows are always on concrete can also be dealt with by improving the surfaces that they walk on in the barn. Hoof problems and mastitis are some of the health risks associated with dirty barnyards. Calves Unpaved Lot without Mound Paved Lot From Beef Housing and Equipment Handbook. Keeping the Clean Water Clean Extra water from barn roofs, overflowing waterers, and/or uphill overland flow can increase the potential of pollutant runoff. Barnyards that are adjacent to or even include a stream or a depression can create significant environmental problems. Barnyards over sized for the number of cattle they contain add to the runoff problems without improving the operation. Barnyards that are not cleaned or can only be poorly cleaned leave contaminants exposed on the surface that will wash away later. October 2003 Keeping the clean water clean is vital to good barnyard management. A continuously leaking waterer will carry pollutants to a filter area and then ruin the sod's ability to filter the pollutants by constantly wetting the vegetation. Grass will not remain healthy if it is constantly exposed to dirty water without a rest period. Maintaining waterers so that they do not overflow is part of good barnyard management. Roof water can be controlled by using rain gutters or drip trenches. Because barn roofs are much larger than most roofs, the rain gutters and downspouts need to be designed to carry the amount of water these large areas can provide. The size of the gutters, their slope, and the placement and size of the downspouts all depend on the amount of rain water to be carried. The 10-year, 5-minute storm is a common design storm for rain gutters. The gutters also need to be protected against snow and ice damage. Hanging them lower than the projected roofline prevents snow and ice from sliding off barn roofs and knocking the gutters down. Extra hangers for the gutters, as closely spaced as 16 inches, or ice-breaking obstacles on the roof that stop sliding snow are often required to protect the gutters and keep them working properly. Drip trenches that collect falling roof water and direct it to a ditch or tile to be carried away from the barnyard are often longer lasting and cheaper than roof gutters. A gravel trench with a tile line is placed under the drip line of the roof. To avoid contaminating the clean water with manure, the drip trench needs to be fenced out of the barnyard. Diversions, berms, or land grading can prevent uphill surface flow from running through the barnyard. Tile inlets with small storage structures can be used when the surface water cannot be easily moved around the barnyard. Subsurface drainage should be used to prevent ground water from surfacing in the barnyard, adding to the contaminated runoff water. These structures should be designed according to Natural Resource Conservation Service (NRCS) standards by a competent conservation contractor, a Soil and Water Conservation District (SWCD) or NRCS employee, or an agricultural engineer. Catch the Runoff Barnyard paving should be planned to control the runoff and urine flow. To facilitate scraping, curbs are needed around all concrete areas. A corner of the barnyard with higher curbs should be graded lower, making the liquids flow to it. This shallow storage area can contain urine and low flows until the barnyard is cleaned. Mixing the rest of the manure with this liquid should enable it to be picked up and 4 spread, limiting runoff to large storm events. The runoff from large events may be directed to properly designed filter areas, constructed wetland systems, or storage systems for later land application. These runoff collection systems need to be designed to handle the manure solids that accompany the runoff water. Small holes in the curbs or more sophisticated solid retention systems should be used to keep most of the solids on the paved pad for future cleaning and spreading. Picket dams of treated two by sixes set upright three fourths of an inch apart can help to retain the solids. These picket dams can be followed by a one-half-inch and then a quarter-inch screen in series to sort out finer and finer solids. Although these screens will require cleaning after each runoff event, they provide a positive solid trap that reduces the loading on downstream collection or treatment systems. Storage ponds need to be big enough to collect the runoff flowing from all areas of the barnyard for events up to a 25-year, 24-hour storm. If clean water diversion systems are not installed or do not catch the 25-year, 24-hour storm, that water needs to be included. The storage areas need to be sized to include the manure washed off the barnyard, solids that were not removed, and any past runoff that was not treated or land applied before the next storm event. The soils at the storage site need to be evaluated and/or modified to prevent polluted water from moving into the ground. On some sites, these storage areas may need to be lined. Inspections Manure storage sites need to be maintained and monitored. The operators of large CAFOs (with more than 700 cows or 1,000 heifers) are required to perform weekly inspections of all storm water diversion devices, runoff collection structures, waste storage structures, and manure or runoff transporting systems. To prevent inadvertent overflows onto barnyards or into storage areas, water lines need to be inspected daily. Depth markers or staff gauges need to be installed (see CAFO Fact Sheet #15: Liquid Level Markers for . . .) in the storage areas to determine the amount of storage volume remaining, ensuring that a 25-year, 24-hour storm will not over-top the structure and that there is adequate freeboard. Any deficiencies or discharges need to be recorded and then addressed as soon as possible. In addition, mortalities must be kept from the wastewater system. The dairy farm operator must keep a complete copy of these records for the last five years (see CAFO Fact Sheet #6: What CAFO Reports Must I Submit?). October 2003 Treat the Runoff Appropriately Manure and wastewater caught from a barnyard need to be either treated or applied at agronomic rates to cropland. CAFO Fact Sheet #20: What is Required in a Nutrient Management Plan? describes this process. The nutrient contents of barnyard runoff may vary considerably so multiple samples may be needed to determine the appropriate loading rates. Wastewater can be treated in vegetated filter areas, constructed wetlands, or other treatment systems. These systems must be designed to prevent the varying concentrations and volumes of barnyard runoff from causing pollution. Is Cost Sharing Available? Through government programs, USDA-NRCS has allocated some money that may be used to cost share the BMPs needed to correctly handle barnyard runoff. Check with your local NRCS, SWCD, or Environmental agency to see what funds are available and if you qualify. CAFO Fact Sheet #40: Financial and Technical Assistance Available to CAFO Owners/Operators will help you identify cost share programs for which you may be eligible. farm operators must consider when dealing with their barnyard discharges. Definition of Terms Barnyard–Areas where cattle are confined for more than 45 days during the year without vegetated cover. Part of the “production area” covered under the CAFO regulations. BMPs–Best Management Practices. Practices that help prevent pollution. Often have standards developed by the Natural Resources Conservation Service. CAFO–Concentrated Animal Feeding Operation. Farms that by definition are point sources and need regulating according to the Federal Government. Drip trench–A system of channels and berms that collects roof water at the base of the roof, preventing clean water from entering a barnyard and polluted water from the barnyard from mixing with the clean roof runoff. Laneways–Non-vegetated areas in a pasture system that are used only for cattle movement to pastures. Time Line for Compliance with Production Area Provisions of the New CAFO Rule The time line for compliance with the new rules is fairly complex. Some provisions took effect upon adoption of the rule in December 2002; others do not take effect until the year 2006. CAFO Fact Sheet #3: How Soon Must I Apply for an NPDES Permit? details these compliance deadlines and provides a means for you to determine what deadlines your CAFO faces. Supporting Sections 40 CFR Part 412.30-47 Effluent Limitations Guidelines–Concentrated Animal Feeding Operations (CAFO) Point Source Category. Subpart C: Dairy Cows and Cattle Other Than Veal Calves Summary Barnyards on dairy farms have previously been regulated by federal CAFO regulations and continue to be regulated by a small number of changes adopted in April 2003. Existing dairy farm CAFO operators who fall under the CAFO rules (see CAFO Fact Sheet #2) need to apply for a permit and implement an NMP by December 31, 2006, controlling the runoff from their barnyard and treating it appropriately. States may have additional, more stringent requirements. This fact sheet provided an outline of issues that dairy 5 NMP–Nutrient Management Plan. A plan that considers the source and fate of nutrients on the farm and is designed to minimize nutrient losses to the environment. Pasture–An area where vegetation exists for cattle feed. It is not generally considered part of a CAFO. Vegetated filter area–A system designed to prevent pollution by treating diluted wastewater through flow into a vegetated area. Author Peter Wright, a Manure Management Specialist at Cornell University, can be reached at pew2@cornell.edu. Reviewers The author wishes to thank Dana Chapman, Agricultural Consulting Service, and Lee Telega, PRO-DAIRY, for their review of this fact sheet. October 2003 For More Information State Contacts EPA CAFO Phone Line Nebraska Iowa Missouri National and Regional 202-564-0766 202-564-0766 202-564-0766 202-564-0766 http://www.oznet.ksu.edu/ kcare/ http://extension.agron.iastate .edu/immag/ http://outreach.missouri.edu/mo mmag/ http://www.epa.gov/npdes /caforule/–To obtain copy of regulations Gary Buttermore John Harsch Gene Tinker Randy Kixmiller Ralph Summers (402)-471-4255 (785) 296-0075 (515) 281-3103 (573) 751-6568 (913) 551-7418 gary.Buttermore@ndeq.state.ne.us jharsch@kdhe.state.ks.us gene.tinker@dnr.state.ia.us nrkixmr@dnr.state.mo.us summers.ralph@epa.gov Rick Koelsch Joel DeRouchey John Lawrence John Lory State Cooperative Extension contacts 402-472-4051 (785) 532-2280 (515) 294-6290 (573) 884-7815 rkoelsch1@unl.edu jderouch@oznet.ksu.edu jdlaw@iastate.edu LoryJ@missouri.edu Mike Kucera Lyle Frees Chris Murray Troy Chockley (402) 471-4102 (785) 823-4553 (515) 284-4370 573-876-9394 Michael.Kucera@ne.usda.gov lyle.frees@ks.usda.gov chris.murray@ia.usda.gov troy.chockley@mo.usda.gov Educational Resources http://www.lpes/ http://www.lpes/ http://www.lpes/ http://www.lpes/ http://www.lpes/ USDA Farm Bill Resources http://farmbill.unl.edu/ See national site See national site See national site http://www.nrcs.usda.gov/ programs/farmbill/2002/ Environmental Regulations Related Resources State Environmental Regulatory Agency State Cooperative Extension State Natural Resources Conservation Service (NRCS) 202-564-0766 Kansas http://manure.edu.edu http://cnmp.unl.edu The LPES educational materials were developed with support from the USDA-CSREES, the U.S. EPA’s National Agriculture Compliance Assistance Center, and the University of Nebraska Cooperative Extension at Lincoln, under Cooperative Agreement Number 97-EXCA-3-0642. 6 http://www.reeusda.gov/1 700/statepartners/usa.htm/ MWPS (MidWest Plan Service), headquartered at Iowa State University, is the primary distributor of LPES curriculum materials. To order the materials on-line, access their website at http://www.mwpshq.org and visit the catalog section. Discounts are offered on LPES materials. October 2003