Advanced Manufacturing Technology Curriculum - e

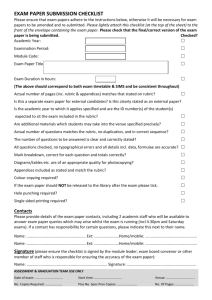

advertisement