Development of an ethanol/air reduced mechanism and its

advertisement

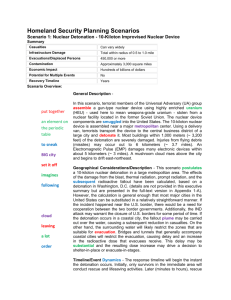

Development of an ethanol/air reduced mechanism and its application to two-phase detonation T. Shimada1, M. Koshi2, Y. Tatsumi1, A. K. Hayashi1, E. Yamada1 and N. Tsuboi3 Abstract/ The ethanol-air reduced mechanism is developed from its detailed mechanism and studied its properties such as flame speed and ignition delay time behind a reflected shock wave for the simulation of application. These calculated properties agree with the experiments and simulations of other mechanisms. Then liquid ethanol-air two-phase detonation is simulated using two-phase compressible Euler equations with a one-step overall ethanol-air reaction mechanism to study its detonation characteristics. At this time the developed ethanol-air mechanism was too large to simulate detonation. The ethanol-air detonation structure with an evaporation of the initial mixture is simulated to see the liquid phase effects on its structure. 1. Introduction In order to overcome the global warming by CO2, environmental pollution by NOx, and energy problem by draining of oil, methane, ethane, dimethyl ether as gaseous fuels and methanol, ethanol produced from biomass as liquid fuels are studied extensively recently. Especially ethanol as one of bio fuels is used for a long time for an automobile and aerospace fuel by being mixed in gasoline. This mixture is an alternative fuel which minimizes CO2 and nitrogen oxides emissions at the exhaust period. Ethanol is expected in the future as various thermal engine fuels. However although ethanol combustion study has been conducted for a long time such as an ignition delay time experiments by shock tubes, a premixed and non-premixed flame velocity by burners, these physical data in high pressure are not obtained enough for studies under high pressure conditions such as detonation. In order to apply ethanol combustion to high pressure and high temperature aerospace problems, ethanol-air two-phase detonation engine is picked up for the study. To this end, the mixture of ethanol-air is used to calculate liquid-gas two-phase detonation properties using two-phase compressible Euler equations. This paper deals with an investigation of a property of a developed reaction model for ethanol combustion in high pressure and high temperature phenomena such as detonation. Then ethanol-air two-phase detonation is simulated first using a simple ethanol one-step reaction mechanism to study properties and structure of liquid-gas 1 (ethanol-air) two-phase detonation. In this case the developed ethanol-air reaction mechanism is still large to provide a costly calculation, then a simple one-step model is used presently. 2. Numerical system First of all, in order to study the combustion mechanism of ethanol-air, a detailed, but reduced ethanol-air reaction mechanism is investigated comparing with other reaction mechanisms. The calculation is performed using a commercial code of CHEMKIN-PRO [1] for flame speed and ignition delay time as representative reaction properties. The detonation property such as C-J detonation velocity is calculated using a STANJAN code developed by Reynolds [2]. The Koshi model developed by Koshi is reduced from the ethanol oxidation model developed by Ogra et al. [3]. Table.1 Recation step and species in various reaction model compared in the present study. reaction step Pressure species dependent or not Pressure Temperature resion resion Koshi 295 50 Yes - - Marinov [4] 378 56 Yes 1-3.4 1300-1700 Leplat et al. [5] 252 38 Yes - - 142 32 No 1 1300-1700 1 5 No - - Norton and Dryer [6] Westbrook and Dryer [7] 2.1 Property of Koshi model The properties of Koshi model are studied in terms of flame speed and ignition delay time by comparing with other models such as Marinov model [4], Leplat et al. model [5], Norton and Dryer model [6], and Westbrook and Dryer model [7]. Figure 1 shows the comparison of flame speed between Koshi model and the experimental data of Gulder [8] and Egolfopoulos et al. [9], where Fig.1-a is at the atmospheric pressure and room temperature and Fig.1-b is at the pressure of 2 bar and room temperature. Both cases show a good agreement between the simulation and experimental data and especially the Koshi model well predicts the flame speed at the higher pressure case. 2 Exp(Gujder,300K,0.2MPa) Koshi model 50 45 40 35 30 25 20 15 10 0.4 0.6 0.8 1 1.2 1.4 1.6 Laminar flame speed [cm/s] Laminar flame speed [cm/s] Exp(Egolfopolous et al.,298K,1atm) Exp (Gujder,300K,0.1MPa) Koshi model Equivalence ratio 45 40 35 30 25 20 15 10 0.6 0.7 0.8 0.9 1 1.1 1.2 1.3 1.4 Equivalence ratio 50 45 40 35 30 25 20 15 10 (a) 1bar Exp(Egolfopolous et al.,298K,1.013bar) Exp (Gujder,300K,1bar) Koshi model 0.4 0.6 0.8 1 1.2 1.4 Equivalence ratio Exp(Gujder,300K,2bar) Laminar flame speed [cm/s] Laminar flame speed [cm/s] (b) 1bar 1.6 45 Koshi model 40 35 30 25 20 15 10 0.6 0.7 0.8 0.9 1 1.1 1.2 1.3 1.4 Equivalence ratio Fig.1 Ethanol flame velocity: the comparison between Koshi model analysis and the experimental data of Gulder and Egolfopoulos (a) at the atmospheric pressure and room temperature and (b) at the pressure of 2 bar and room temperature. Figure 2 shows the comparison of ignition delay time behind reflected shock wave between the analyses by Koshi, Marinov [5], Leplat et al. [6], Norton and Dryer [7] and Westbrook and Dryer’s one-step model [8] at the pressure of 10 bar and the equivalence ratio of unity of ethanol-air mixture and the experimental data by Cancino et al.[10]. Koshi model shows a better agreement at the higher temperature as Marinov model and Leplat et al. model, but a less agreement at the lower temperature since these three models do not have the low temperature reactions such as RO2 related reactions. 3 Three reaction models; Koshi, Marinov, and Leplat et al., are developed at high pressure and high temperature conditions, however Norton and Dryer model was developed at the condition of low pressure; atmospheric pressure, and relatively low temperature, then it has RO2 reactions. Cancino et al. also developed their detailed reaction model with 136 species and 1349 reactions and showed a good agreement with their experimental data [11]. The detonation calculation needs a cost performance for the detailed space precision, then at least a reduced reaction model such as Koshi model should be developed. But this time Koshi model is still large to spend a lot of computational time. 100000 Experiment results(Cancino et al.,10bar) Koshi model Marinov model Norton and Dryer model Leplat et al. model Westbrook and Dryer model Ignition delay time τ [μs] 10000 1000 100 10 0.8 0.9 1 1.1 1000/T [1/K] Fig. 2 Comparison of ignition delay time for the ethanol-air mixture of Stoichiometric condition at the pressure of 10 bar and the room temperature. 3. Detonation application of liquid ethanol-air mixtures In order to apply ethanol fuel to aerospace propulsion, pulse or rotating detonation engine is one of such propulsion systems. Then a study of detonation in ethanol-air mixture will be presented numerically. 3.1 C-J detonation velocity Ethanol has a similar property as C2 hydrocarbons, but has a weak bond-strength of OH radical like alcohol, then it is easy to proceed thermal decomposition reaction and radical exchange reaction. Due to this weak OH radical bond, its heat of reaction is 4 also low among C2 hydrocarbons. First of all the CJ detonation velocity of ethanol-air mixture is calculated using a STANJAN code to compare with that of other hydrocarbon fuels and of hydrogen. The calculation is performed with the initial condition of the pressure of 1.013 bar and the temperature of 300 K for the mixture at the equivalence of unity. This calculation is the equilibrium calculation; i.e., the reaction mechanism free calculation, but Fig. 3 shows such comparison that hydrogen-air mixture provides the similar C-J detonation velocity curve except hydrogen-air mixture. This result expects that ethanol detonation engine can provide the similar thrust as other fuels. 2200 Detonation Velocity [m/s] 2100 2000 1900 1800 1700 H2-Air C3H8-Air JP10-Air CH4-Air Ethanol-Air 1600 1500 1400 1300 0.4 0.6 0.8 1.0 1.2 1.4 Equivalence Ratio 1.6 1.8 2.0 Fig.3 Comparison of C-J detonation velocity in various fuels. 3.2 Ethanol-air two-phase detonation structure Ethanol-air two-phase detonation is simulated using a liquid-gas compressible Euler equation system with a one-step overall reaction mechanism developed by Westbrook and Dryer [7]. Liquid ethanol evaporates quickly depending on the d2-law of evaporation and reacts with oxygen based on the one-step reaction model. The two-phase Euler equations has a structure of liquid-phase and gas-phase mass, momentum, and energy conservations. Figure 4 shows the case of liquid ethanol – air detonation propagation. The size of ethanol droplets is 3 μm in diameter and the pre-evaporation is 30 % of liquid ethanol. The figure shows the pressure profiles at the different periods and shows the incident shock wave (IS), reflected shock wave (RS), transverse shock wave (TW), and transverse detonation wave (TD) (Fig.4-a). As the detonation head propagates forward (toward right hand side of the figure), TD moves upward together with bifurcating since non-reacted ethanol flows down. This type of 5 burning occurs often for the liquid fuel detonation case while the gaseous detonation barely happens except for the limit situation. The one-step reaction model is used in the present simulation, then the results may show the faster reaction than that using the detailed mechanisms. TW RS a d IS TD b e c f Fig.4 Pressure distributions at droplet diameter of 3μm and of the initial evaporation ratio of 30% 4. Conclusions Ethanol-air reduced reaction mechanism is developed and is investigated whether it is relevant for simulation use or not. Then the Koshi mechanism is compared in terms of the flame speed and ignition delay time behind reflected shock wave with that of other reaction mechanisms. Since it does not have low temperature mechanism of RO2, it does not predict well at the low temperature region of ignition delay time. Liquid ethanol-air two-phase detonation was simulated using one-step reaction mechanism. The typical liquid-gas detonation propagation structure was obtained using such simple mechanism. The results show the importance of pre-evaporation condition for detonation propagation. Acknowledgments This research was supported by KAKENHI (21360420) and collaborated with the JSS Systems in JAXA supercomputer system. References [1] CHEMKIN-PRO. Reaction Design, Inc.: San Diego, CA, 2008 [2] Reynolds, W. C., Technical Rept. A-3991, Dept. of Mechanical Engineering, Stanford Univ., Stanford, CA, Jan. (1986) [3] Ogura, T. Sakai, Y, Miyoshi, A. Koshi, M. and Dagaut, P. Energy and fuels 21, 3233-3239 6 (2007) [4] Marinov, N.M. International jornal of chemical kinetics 31, 183-220 (1999) [5] Leplat, N., Dagaut, C, Togbe, P., Vandooren J., Combustion and Flame 158,705-725 (2011); [6] Norton, T.S., Dryer, F.L. International Journal of Chemical 24, 319-344 (1992) [7] Westbrook, C.K., Dryer, F.L. Combustion Science and Technology,27, 31-43 (1981) [8] Gulder, O. L. Proc. Combust. Inst. 19, 275-281 (1982),. [9] Egolfopolous, F. N., Du, D. X., Law, C. K., Proc. Combust. Inst. 24, 833–841 (1992), [10] Cancino, L. R., Fikri, M, Oliveira, A. A. M. and Schulz, C. Energy and fuels 24, 2830-2840 (2010) その他 Li, J., Kazakov, A., Chaos, M. and Dryer, F.L. 5th US Combustion Meeting;2007 C26 Saxena, P., Williams, F.A. Proceedings of the Combustion Institute; 2007 1149-1156 Dunphy,M.P.,Patterson,P.M.,Simmie,J.M. Int. J. Chem. Soc., Faraday Trans. 87:2549-2559 (1991); Dunphy,M.P.,Simmie,J.M. Int. J. Chem. Soc., Faraday Trans. 87:1691-1696(1991) 7