Sanitization of Purified Water Generation (Ultra Filtration)

advertisement

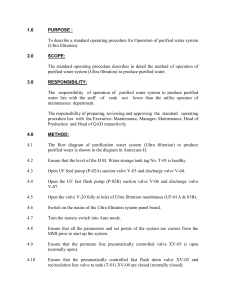

1.0 PURPOSE: To describe a standard operating procedure for sanitization of purified water distribution loop system. 2.0 SCOPE: The standard operating procedure describes in detail the method of sanitization of purified water generation (Ultra filtration system) including DM water storage tank, purified water storage tank and purified water distribution loop system to reduce the growth of microbes to its pertaining alert/action limits. 3.0 RESPONSIBILITY: The responsibility of sanitization of purified water generation and distribution loop system as per the SOP lies with the staff of rank not lower than the utility operator of maintenance department. The responsibility of preparation, review and approval of the standard operating procedure lies with the Executive – Maintenance, Manager- Maintenance, Head of Production and Head of QAD respectively. 4.0 METHOD: 4.1 Sanitization of Purified Water Generation (Ultra Filtration) System: 4.1.1 Sanitization of purified water generation (Ultra filtration) system shall be carried out with hot water at the temperature 80-85°C. 4.1.2 Fill the DM water upto High-level in the DM water storage Tank (T-01). 4.1.3 Put the selector switch of the control panel in Auto mode and select the sanitation operation. 4.1.4 The pneumatically controlled steam valve (XV-01) of DM water storage tank jacket opens automatically. 4.1.5 Open the UF feed pump suction valve (V-03) and discharge valve (V-04) and also open the UF fast flush pump suction (V-06) and discharge valve (V-07). 4.1.6 Ensure that the pneumatically controlled permeate water valves (XV-03) is closed and recirculation valve (XV-04) is open. 4.1.7 The UF feed pump (P-02A) starts automatically, water circulates through Ultra filtration membranes (UF-01A & 01B) and return back to the DM water storage tank (T-01). 4.1.8 Switch on the sequence of PLC on the panel board. 4.1.9 The water in the DM water storage tank (T-01) gradually heats up using steam in the jacket and when it reaches 80°C the pneumatically controlled steam valve (XV-01) closes / opens automatically and maintains the hot water at 80 - 85°C through out sanitation period by PLC. 4.1.10 After 4 hours stop the total system and drain the DM water from storage tank and all drain points. 4.1.11 Record the sanitization data in Annexure-I. 4.2 Sanitation of purified water distribution loop system: 4.2.1 Sanitization of purified water distribution loop system shall be carried out with hot water at the temperature 80-85°C. 4.2.2 Fill the purified water storage tank (T-02) upto 80% level. 4.2.3 Put the selector switch of the control panel in auto mode and select the sanitation operation. 4.2.4 The steam valve (XV-05) of purified water storage tank jacket opens automatically. 4.2.5 Open the suction valve V-14, discharge valve V-15 and UV by pass valve V-18. 4.2.6 Ensure that the valves XV-06 opened and XV-07 closed. 4.2.7 Ensure that all the user points in production blocks are closed. 4.2.8 Switch on the sequence of the PLC on the panel board. 4.2.9 The water in the purified water tank gradually heats up using steam in the jacket and when it reaches 80°C the steam valve (XV-05) closes / opens automatically and maintains the hot water at 80 - 85°C through out sanitation period by PLC. 4.2.10 After 4 hours stop the total system and drain the purified water from all the user points and purified water storage tank (T-02). 4.2.11 Record the sanitization data in Annexure-I. 4.3 After completion of hot water sanitization system shall be kept in normal operation. 4.4 Frequency: Frequency of sanitization shall be fixed based on the validation data of water system by Quality control department. 5.0 RECORDING: The responsibility of recording the details of sanitization of purified water generation and distribution loop system lies with the staff of rank not lower than the utility operator of maintenance department as shown in Annexure-I.