null measure

advertisement

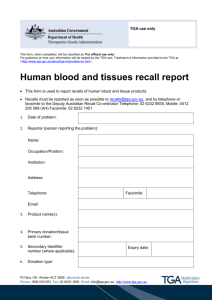

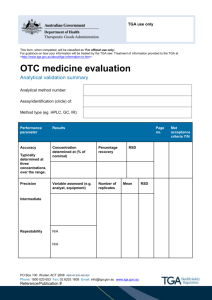

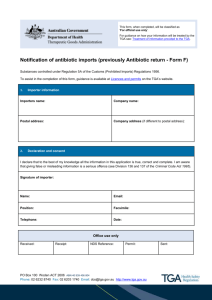

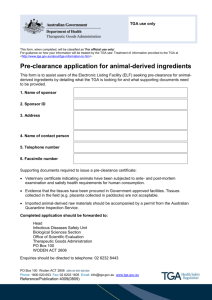

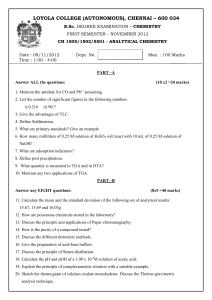

Thermogravimetric Analysis of Highway, Offroad and Racing Tire Composition 1. Purpose The purpose of this lab is to use thermogravimetric analysis (TGA) to compare the composition of three types of tire tread used in various conditions: cement (car tire), soft soil (ATV/tractor) and asphalt (racing tire). 2. Theory Thermogravimetric analysis uses heat to induce chemical and physical changes in materials and performs a corresponding measurement of mass change as a function of temperature or time. Thermogravimetry is performed on a wide range of materials including polymers, composites, laminates, adhesives, food, coatings, pharmaceuticals, organic materials, rubber, petroleum, chemicals, explosives and biological samples. While some TGA analyses are intended to measure transitions associated with weight gain (e.g. oxidative stability and absorption properties), most TGA experiments focus on weight loss measurements. Weight loss can occur through various processes—decomposition, evaporation of water or volatiles, desorption, chemical reduction, etc. In some advanced instruments residual gases released from materials can be analyzed using TGA-tandem instruments, such as TGA-FTIR or TGA-Mass Spectrometry, to determine the identity of the released gas and give insight into the weight loss mechanism. Also, while not the focus of this lab, kinetic models can be extrapolated from TGA weight loss data, which in turn can be used to predict product lifetime at given temperatures and decomposition rates under various conditions. The most common form of temperature-induced weight loss in materials investigated by TGA is decomposition—the breaking apart of chemical bonds to release small, gaseous molecules (carbon dioxide, carbon monoxide, water vapor, NOx’s, etc.). Thermal stability is widely dependant on the type of material being investigated, and major decomposition mechanisms for different materials can occur over wide temperature ranges. This is advantageous in composition analysis of multicomponent materials as each component can be individually decomposed in a stepwise fashion to quantitatively determine the amount of each component in the material (Figure 1). Figure 1. TGA plots of various multicomponent materials. Instrument Overview The TGA thermogravimetric is a analyzer, research whose grade leading performance arises from a responsive low-mass furnace; sensitive thermobalance, and efficient horizontal purge gas system with flow rate control (Figure 2). Its convenience, expandability and powerful, results-oriented software make it perfect for the multi-user laboratory where a wide variety of TGA applications are conducted. Figure 2. A Q50 TGA from TA Instruments. The sample rests on a small platinum or ceramic pan, which hangs from a small hook connected to the balance. The weight of the sample pan and sample is measured using a photodiode balance. The balance operates on a null-balance principle. At the zero mark, or “null” position, equal amounts of light shines on the 2 photodiodes. If the balance moves out of the null position an unequal amount of light shines on the 2 photodiodes, at which point a current is applied to the meter movement to return the balance to the null position. The amount of current applied is proportional to the weight loss or gain. A furnace is raised around the pan to apply heat to the sample. This furnace is linked to computer software that controls the temperature rate and cycle. A detailed schematic of the TGA is shown in Figure 3 below. Figure 3. Q50 TGA instrument schematic. While the furnace is running, there are two different atmospheric environments in which the sample can be exposed—nitrogen or air. Depending on the type of decomposition and the information desired, a specific type of purge gas is desired. In Figure 4, a schematic representing the flow of purge gases is shown. The balance (flowing at 40 ml/min in Figure 4) is always kept under nitrogen gas to protect Figure 4. Q50 TGA furnace. the instrument coating from oxidative degradation, but the sample purge gas (60 ml/min) can be varied. Also, the two sample purge gases can be used interchangeably during an experiment, which is helpful, for example, in determining filler content of composites whose matrix and reinforcement have different thermal stabilities in different environments. Experimental Procedure Pre-lab 1. Open gas valve on the nitrogen (N2) and air cylinders along the north wall of the lab. Never adjust regulator valve. The pressure should read 35 psi for N2 and 40 psi for air. 2. Your instructor or lab assistant will log on to the computer and have the instrument initiated when you arrive to the lab. (Follow lab SOP if this is not the case) 3. Using the Pyris software, select which TGA instrument to bring online (#1 or #2) by clicking on the appropriate button in the drop-down bar at the top of the screen. 4. In the “Methods Editor” window enter the sample name, operator and any identifying comments. Save your data to the class folder: c\program files\pyris\data\MatE 453 Fall 2014, by clicking on the file name box then clicking on the “Browse” button. 5. In the “initial state” tab, “set the initial value” temperature to 50°C. 6. Use the “method editor” to “add a step” to your procedure. a. Set the purge gas to N2 using the instructions in the next section. b. Heat the sample from 50°C to 650°C at a rate of 25°C/min. c. Switch the purge gas to air. d. Heat the sample from 650°C to 850°C at a rate of 25°C/min. e. Cool to 50°C at 50°C/min. 7. Cut a sample of each tire type: road, off road and racing, weighing approximately 10mg. Remember to use weigh paper when measuring the mass of your samples on the micron sensitive scale. Label each sample with the tire type and mass. Lab procedures 1. Make sure that the software and instrument are connected, designated by button on the right hand side panel of the software window. 2. On the gas control station, push the following sequence to assure purge gas in flowing: RUN-MANUAL-N2 (or air)-START. (See images in lab TGA SOP) 3. Check that the sample pan is clean, and carefully use tweezers to place the empty pan into the stirrup. Manually raise the sample platform, making sure the pan is correctly oriented with the balance wire. Slowly lower the platform so that he empty pan is suspended by the balance hook, and rotate it to the side of the instrument. (DO NOT TOUCH THE WIRE WITH YOUR HANDS!) 4. To tare the empty pan, raise the furnace by pushing the button with the blue arrow pointing up, on the left hand panel. Alignment of the furnace tube may require manual assistance. 5. Once the pan mass has equilibrated, press the “zero weight” button on the right hand panel. (Empty scales) The instrument will take a few moments to tare, and the weight, on the top panel, will read a mass very close to zero (Ex: 1.234x10-4). 6. Lower the furnace using the “lower furnace” button on the right side panel, with the blue arrow down. Manually raise the platform and gently remove the empty pan from the hook. 7. Take the small piece of natural rubber sample and place it into the center of the pan. Raise the platform gently and place on the hook. Raise the furnace using the blue arrow up button. Lower the safety shield in front of the furnace. 8. Measure the sample mass using the “sample weight” button on the right panel, scales with yellow load. The sample should be approximately 10 mg. This automatically enters the sample mass weight into the “sample info” tab. 9. Equilibrate the furnace at the starting temperature by clicking on the button, “go to temp” located on the right side panel with the thermometer and opposite pointing blue arrows. Once the initial temperature has equilibrated, start the run using the “start/stop” button at the top of the column on the right. Clicking on the “instrument viewer” allows you to see the measurements as they progress. 10. Once the experiment is finished, the instrument will automatically lower the furnace. When the furnace temperature is near room temperature, use the platform to gently remover the pan from the hook. Clean the pan and repeat the procedure using the SBS and tire rubber samples. **If there is still residue on the sample pan, carefully hold the pan with tweezers, and clean the pan by applying acetone. Acid can be used to remove sticky residue.** 11. When all runs have been completed, turn off the gas flow by pushing the following buttons on the gas control station: STOP-BACK-BACK. 12. Collect a text file of your data for analysis using MS Excel. 13. Close the Pyris software by selecting “close all” from the “start pyris” drop down bar at the top of the screen. 14. Turn off the Nitrogen gas valve and TGA release valve before leaving the lab. Assignments 1. What is the weight percent of rubber and carbon black filler, respectively, in each of the tire tread samples? 2. Why is the nitrogen gas first used as an atmospheric environment, and why is it switched to air during the experiment? What is the decomposition temperature of each tire tread rubber under nitrogen gas? 3. What is the weight percent of inorganic filler in each tire tread? Carry out a brief literature search to identify potential fillers of each tire. 4. SBS rubber and natural rubber are both common constituents of rubber formulas in tires, based on the TGA data provided and that which you collected, make a conjecture on the type of rubber used for your samples? Comment on the comparison of rubber volume content of the three samples. 5. Explain how sample mass, sample shape, and position of the sample on the sample pan can affect data in a TGA experiment.