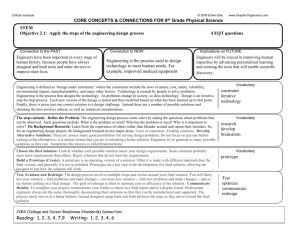

display

advertisement

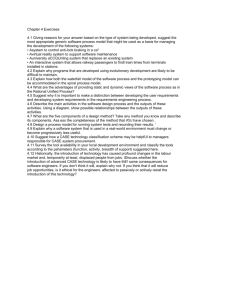

Effect Cause Foot failing in down position User would trip and fall Sensor unable to detect terrain or send faulty readings 1 Actuator malfunction 2 Structural failure, orthotic unable to support equipment Spring Yielding/Buckling Power supply 3 4 Importance Risk Item Severity ID Likelihood MSD Project Risk Assessment: P13002 2 3 6 1 2 2 1 3 3 1 2 2 1 2 6 2 2 4 1 2 2 2 2 4 2 3 6 2 2 4 1 3 3 5 Scheduled deadlines not met Timeline falls behind, other deadlines change Material acquisition delay Prototype cannot be built and tested 6 Personal conflicts: time management, overloads schedule, illness Long lead times, parts not ordered on time 7 Incorrect material handling Overload system capabilities Misuse of supplies Project failure, unhappy customer Weight of device too heavy 8 9 Unable to meet customer specifications 10 11 Device contains sharp edges, harms the users Action to Minimize Risk Software fail safe, if no data is sensed will fail in natural position Owner Engineering Lead System free to move if actuator breaks Large enough factor of safety Engineering Lead Structural modification, mechanical prevented action Before system runs out of power, lock in normal state. Warning signal included Communication among members to know each other’s schedules, understand critical path, seek help when needed Contact with vendors, determine parts with long lead times, order by week 7 Responsible team members in charge of their components. Understand system capabilities and specifications Be cautious of component weights when creating detailed design Avoid using heavy metals, use composites and plastics when possible Ensure all points of contact will not harm user, no pressure points Engineering Lead Engineering Lead Electrical Engineers Team Manager Team Manager Engineering Lead Engineering Lead ME- Pattie Mechanical Engineers Memory overflow Device would go into an error state 12 Friction between sliding components Back mechanism breaking Small objects get stuck in locking system Jamming or blocking the system from moving Mechanism firing at incorrect time 13 14 Incorrect power to solenoid 15 Not enough memory on the micro controller and associated memory systems Friction effects on system larger than tolerances assumed User kicks up small objects; finger placed between components Mechanism misinterprets terrain Attachment to orthotic 16 Unable to read terrains Device will not move in proper position 17 Wiring come unconnected Electrical components become unattached 18 19 Sensors reading surfaces such as grass, snow,glass Someone or something pulling wiring out of place Unaxial bending force applied Fluid leaking out of valve 20 Fluid leaking out of piston 21 Fluid leaking out of storage tank or connection tubing 2 2 4 2 3 6 1 2 2 1 3 3 1 3 3 1 3 3 2 2 4 1 2 2 1 2 2 1 2 2 1 2 2 1 3 3 1 3 3 1 2 2 22 Cylinder over pressurizing Hydraulic system would burst Too much pressure applied to cylinder Hydraulic system would burst Hydraulic fluid freezing in system too much heat applied to system System too cold for operating range 23 Fluid combustion 24 Fluid freezing 25 Ensure enough memory is available on micro controller Large factor of safety implemented when determining the friction force applied to the system Design system to avoid large gaps between orthotic and system components Fail safe design with isolated power supply Computer Engineers Mechanical Engineers Mechanical Engineers EE- Rob ME- Pattie Test the sensors on the surfaces to determine all common surfaces that a user will interact Ensure that the wiring is protected from foreign objects when system is wired together EE- Dana Electrical Engineers ME- Shane Take in account the sealing methods Take in account the sealing methods Take in account the sealing methods between the main piston and the storage tank and ensure the tubing is properly fitted Understand the operating pressure and determine the full operating range of cylinder All parameters will function in the safe range of -20⁰-120⁰F All parameters will function in the safe range of -30⁰-150⁰F Mechanical Engineers Mechanical Engineers Mechanical Engineers Mechanical Engineers Mechanical Engineers Mechanical Engineers 26 27 28 Likelihood scale 1 - This cause is unlikely to happen 2 - This cause could conceivably happen 3 - This cause is very likely to happen Severity scale 1 - The impact on the project is very minor. We will still meet deliverables on time and within budget, but it will cause extra work 2 - The impact on the project is noticeable. We will deliver reduced functionality, go over budget, or fail to meet some of our Engineering Specifications. 3 - The impact on the project is severe. We will not be able to deliver, or what we deliver will not meet the customer's needs. “Importance Score” (Likelihood x Severity) – use this to guide your preference for a risk management strategy Prevent Action will be taken to prevent the cause(s) from occurring in the first place. Reduce Action will be taken to reduce the likelihood of the cause and/or the severity of the effect on the project, should the cause occur Transfer Action will be taken to transfer the risk to something else. Insurance is an example of this. You purchase an insurance policy that contractually binds an insurance company to pay for your loss in the event of accident. This transfers the financial consequences of the accident to someone else. Your car is still a wreck, of course. Accept Low importance risks may not justify any action at all. If they happen, you simply accept the consequences.