Cryogen Safety

advertisement

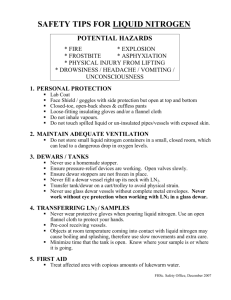

Cyogenic Material Safety: Liquid Nitrogen and Helium Areas of concern 1. 2. 3. 4. Freezing Oxygen enrichment Asphyxiation Pressure-related explosions 1. Freezing While the Lindenfrost effect offers, a measure of protection freeze damage from liquid nitrogen is still a major concern. Brief contact with Liquid Nitrogen, while to be avoided will not necessarily cause harm, as the evaporating gas causes a protective buffer. Harm usually occurs due to prolong contact, when the liquid Nitrogen soaks into clothing. Do Not wear clothing that can capture liquid nitrogen run-offs or spills, such as cuffed pants. Always wear protective gloves that can easily be removed in the event of a spill should be worn when handling liquid nitrogen. If the liquid Nitrogen soaks the gloves, they should be removed immediately. Always wear safety goggles—LN can boil up and into your face at any moment, quickly blinding you. Never pour LN above your head, and do not kneel next to someone pouring LN. Do Not hold containers of LN with one hand, or in any other precarious way. Have a clear exit path in case something goes wrong—if you drop a whole container of LN, you and everyone else around you needs to get away from it quickly. Some Do’s and Don’ts. Do wear goggles or a face shield. Do Not Wear clothes that can trap liquid Nitrogen- like canvas shoes. Do Not use unprotected hands to hold onto things that have been cooled by liquid Nitrogen. Version 1.0 Jan 2012 2. Oxygen enrichment Although not flammable, oxygen when present in higher concentrations can significantly increase the chance of fire or an explosion. The boiling point of oxygen is above those of nitrogen and helium. In closed systems (such as cold traps cooled with liquid nitrogen), these liquids can cause oxygen to condense on their surface (resulting in a bluish liquid on the surface). This can lead to the ignition of normally non-combustible materials, and the flammability limits of flammable gases and vapors are widened. Oil and grease may spontaneously ignite and as such should not be use where oxygen enrichment may occur. In the Sykes lab we should dispose of any standing liquid Nitrogen at the end of each work day or when it is no longer required. 3. Asphyxiation A small amount of liquid nitrogen turns into a large amount of nitrogen gas—LN expands by 700 times when it vaporizes. If you use a lot of LN in a closed space, it will displace the oxygen and suffocate you before you know what’s happening. This is the largest cause of death from LN. The danger is very, very real. You can’t tell that you are suffocating on nitrogen. The panicky feeling you get from choking or staying under the water too long doesn’t come from lack of oxygen— it comes from the buildup of CO2 in your blood. Your lungs can get rid of CO2 just fine in a pure nitrogen environment, so your body doesn’t send those helpful distress signals. Also, breathing pure nitrogen is much worse than just holding your breath. Breathing nitrogen actually sucks the existing oxygen out of your bloodstream. In a room with 10% Oxygen just two breaths will kill you. • Do Not use LN in an unventilated area. • Never go into an elevator with LN. If a dewar breaks in the elevator, you’re dead. • Never carry LN in a vehicle’s passenger compartment. You get into an accident, the LN spills and vaporizes, you suffocate instantly. • If you see someone passed out near an LN tank, do not try to help. Many people who die from nitrogen suffocation were trying to help co-workers. If the victim has passed out they are probably already dead. Call campus police x66911. 617 627 6911 In the Sykes lab the door to the quiet room should remain open whenever the room is occupied. 4. Pressure-related explosions Here are two examples of LN Dewar explosion. First is a blow-out of a pressure release plate of a properly maintained Dewar. Second is a major explosion of an incorrectly modified Dewar. This first Dewar is a similar design to that used in the Sykes lab. It was used by a restaurant that cooked food with LN. In their own words: Version 1.0 Jan 2012 While moving our 160 liter LN dewar from the 4th floor to the second floor of our building the dewar got knocked over—don’t ask how. One of our interns pulled a Hercules and righted the many-hundred pound monster single handedly. Seconds later, the dewar vented with a thundering ka-boom, blowing the cap off the top, and punching out a ceiling tile. The hallway filled with nitrogen. We were okay because we followed the rules. Everyone cleared the area. I opened the window and monitored oxygen levels on our oxygen meter. We put the dewar in the elevator without anyone in it (that is one of our standard safety rules), and took it down and outside where Pressure release plate, post release we chained it up. Imagine if we didn’t have the “no people riding in the elevator with the dewar” rule. If the dewar had vented 20 seconds later and it was in an elevator with people, they most likely would have been asphyxiated. Some of the safety rules we follow with liquid nitrogen seem to guard against far-fetched scenarios that will never happen. Ceiling tile hit by pressure release plate Looks like they can happen. tay safe. Second incident due to modifications of dewar safety systems Liquid nitrogen tanks are usually equipped with pressure relief fittings, since nitrogen does tend to want to be a gas, and gases do tend to want to expand quite a bit. This tank, though, which seems to have been kicking around since 1980, had been retrofitted by a real buckaroo. Both the pressure relief and rupture disks had failed for some reason in the past, so they'd been removed and sealed off with metal plugs. You may commence shivering now. Why it didn't blow long ago is a real stumper, but presumably people were taking nitrogen out of it quickly enough to keep things together. Not this time, though: at around 3 AM, things came to a head as the internal tank (the dewars are double-walled) expanded until it pressed against the outer one. That kept it from expanding anywhere else except on the ends, and as fate would have it, the bottom blew out first. The engineer's best guess is that this took place at around a 1200 psi load. I'll let the engineer's report Dewar compressed by force of striking the ceiling. The bottom of these Dewar failed first. Version 1.0 Jan 2012 take it from here: The cylinder had been standing at one end of a ~20' x 40' laboratory on the second floor of the chemistry building. It was on a tile covered 4-6" thick concrete floor, directly over a reinforced concrete beam. The explosion blew all of the tile off of the floor for a 5' radius around the tank turning the tile into quarter sized pieces of shrapnel that embedded themselves in the walls and doors of the lab. The blast cracked the floor but due to the presence of the supporting beam, which shattered, the floor held. Since the floor held the force of the explosion was directed upward and propelled the cylinder, sans bottom, through the concrete ceiling of the lab into the mechanical room above. It struck two 3 inch water mains and drove them and the electrical wiring above them into the concrete roof of the building, cracking it. The cylinder came to rest on the third floor leaving a neat 20" diameter hole in its wake. The entrance door and wall of the lab were blown out into the hallway, all of the remaining walls of the lab were blown 4-8" off of their foundations. All of the windows, save one that was open, were blown out into the courtyard. In the Sykes Lab we should be aware of the dangers inherent with both N2(L) and He(l) tanks, both of which are used in the lab. We should be aware of ice forming on any of the instruments causing a blockage, which could lead to an increase in pressure. The LT-STM dewars should not be allowed to run dry of cryogen, unless planned. He(g) should be used, when appropriate, to flush out the dewars before adding cryogen. Version 1.0 Jan 2012